Method for measuring hydrogen phosphide content in gas to be measured

A technology for gas to be measured, phosphine, applied in the field of analysis and detection, to achieve the effect of improving accuracy and precision, and good absorption and enrichment effect

Inactive Publication Date: 2016-11-02

云南冶金云芯硅材股份有限公司

View PDF6 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, no method has been found to detect phosphine in the hydrogen produced in the polysilicon production process.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0068] Instruments and equipment: TH-600 intelligent flue gas sampler, gas pressure buffer, iCAP6000 ICP-AES instrument.

[0069] The working parameters of the ICP-AES instrument are: RF power 1150W, atomizer flow rate 0.7L min -1 , auxiliary gas flow 0.5L min -1 , peristaltic pump pump speed 70r min -1 , integration time short wave 15s, long wave 10s, washing time 25s.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Login to View More

Abstract

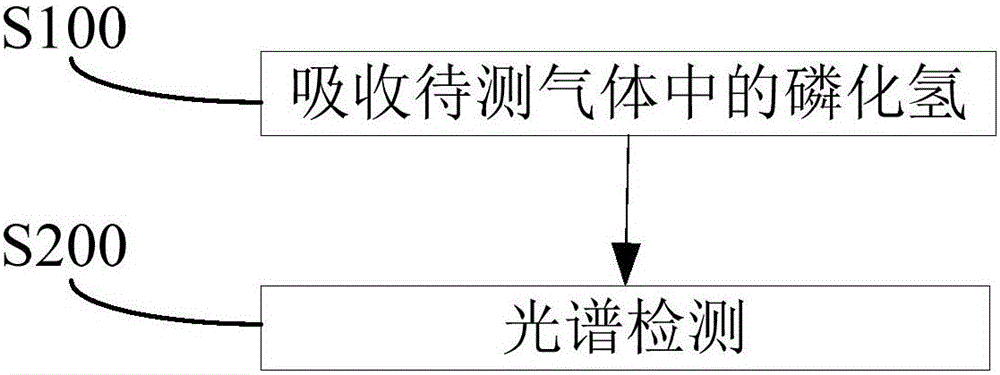

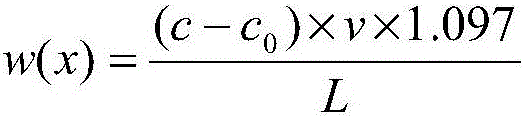

The invention discloses a method for measuring the hydrogen phosphide content in gas to be measured. The method comprises: collecting gas to be measured in a predetermined volume, and absorbing hydrogen phosphine in the gas to be measured to obtain absorbed liquid; and conducting spectral detection on the absorbed liquid by using an ICP-AES detector; and based on the spectrum detection results, determining the content of hydrogen phosphine in the gas. The method uses hydrogen phosphide absorption liquid for absorption and enrichment of hydrogen phosphide in the gas to be tested, then uses high-precision ICP-AES detector for enrichment of concentration of phosphorus elemtn in the phosphine absorbed solution, so as to obtain the content of hydrogen phosphide in the gas to be measured. Compared with the method for direct detection of hydrogen phosphide in the gas to be tested by analysis instrument without enrichment in the prior art, the method has significantly improved the accuracy and precision, and can be used for the detection of phosphorus content in the gas containing low-concentration hydrogen phosphide.

Description

technical field [0001] The invention relates to the field of analysis and detection, in particular to a method for measuring the content of phosphine in the gas to be tested. Background technique [0002] In the process of producing polysilicon by the improved Siemens method, the hydrogen in the reduction tail gas and hydrogenation tail gas is recovered and recycled through the dry tail gas recovery process, and the phosphine in the hydrogen is slowly enriched in the circulation system of the entire polysilicon production process. Phosphorus is the main impurity element in polysilicon, and its content has a significant impact on the quality of polysilicon products. The analysis, detection and monitoring of the phosphine content in the hydrogen produced in the polysilicon production process is of great significance to the quality of polysilicon products. [0003] Phosphine has special physical and chemical properties: boiling point -87.7°C, relative density 1.17, slightly so...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N21/71

CPCG01N21/71

Inventor 毛智慧张云晖亢若谷金波钱津旺李晓华韩小叶郭秀红卢华曾娟

Owner 云南冶金云芯硅材股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com