Preparation method of Cu3P nanowire negative electrode, Cu3P nanowire negative electrode prepared by method and application of Cu3P nanowire negative electrode

A nanowire and negative electrode technology, applied in the field of energy devices, can solve the problem of insufficient sodium-ion batteries, and achieve the effects of good electron/ion fast transport channels, good structural integrity, excellent rate performance and cycle stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

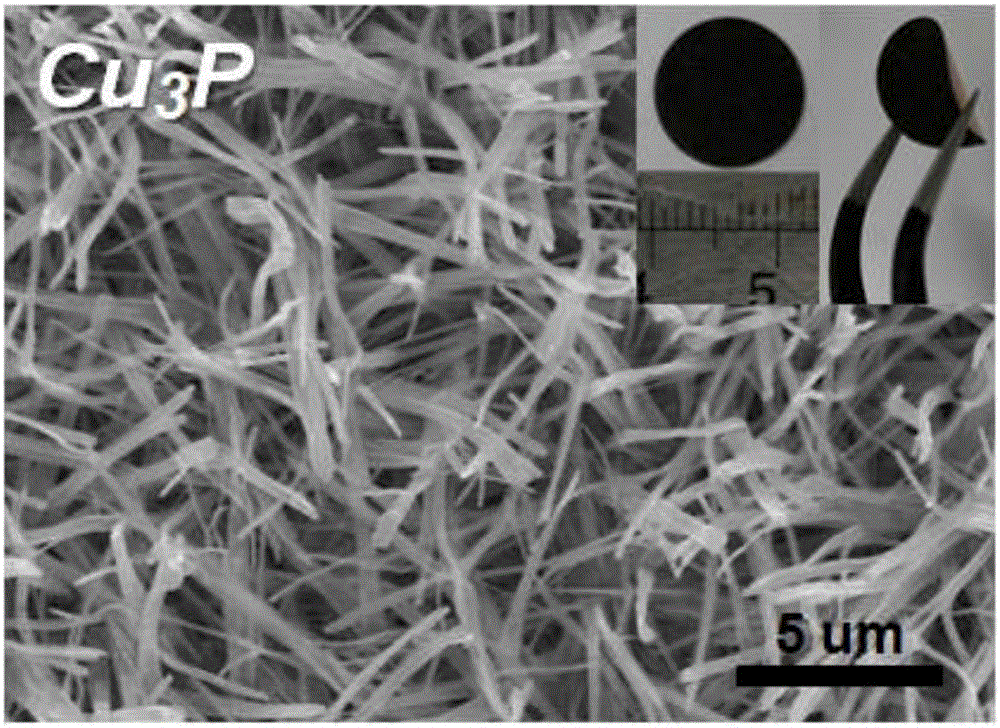

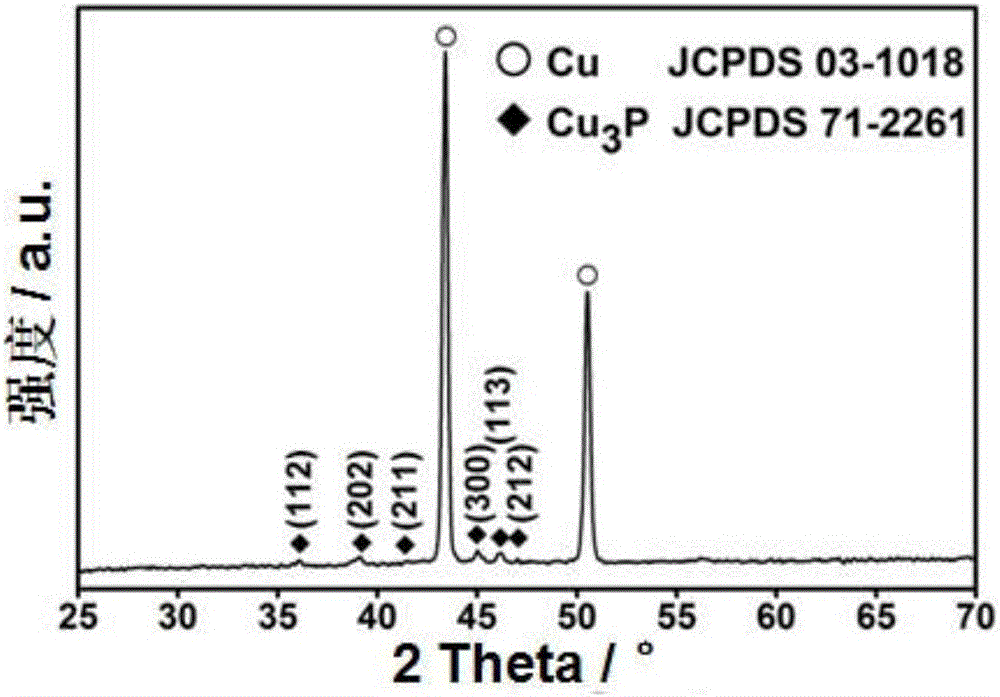

[0050] This embodiment provides a Cu 3 The preparation method of P nanowire negative electrode material, it comprises the following steps:

[0051] (a) Copper foil (1 cm 2 ) to remove impurities on the surface (washed several times with hydrochloric acid and deionized water successively), and then immerse one side of it in a mixed aqueous solution (45ml) of ammonium persulfate (5mmol) and sodium hydroxide (0.1mol) at room temperature for 10min , taken out from the solution, washed with deionized water several times (3-5 times) and dried in a blast drying oven at 60°C to obtain copper hydroxide nanowires grown on one side of the copper foil substrate;

[0052] (b) Place excess sodium hypophosphite in the middle of the tube furnace, pass argon gas into the tube furnace for 15 minutes, and then heat the middle of the tube furnace to 350°C, and at the same time form copper hydroxide on the surface of one side The copper foil of the nanowire is placed downstream of the sodium hyp...

Embodiment 2

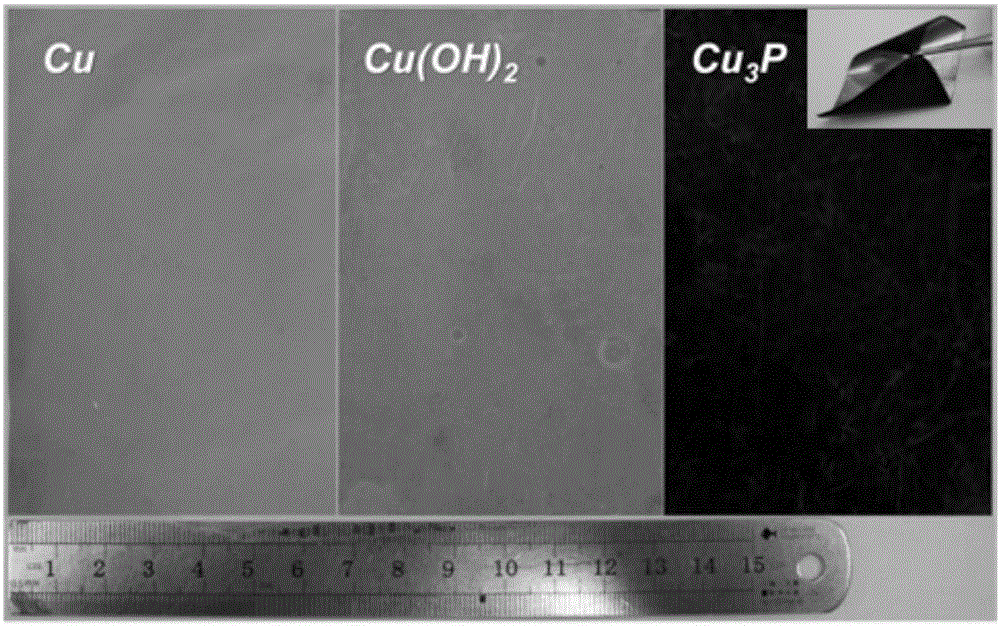

[0054] This embodiment provides a Cu 3 The preparation method of the P nanowire negative electrode material is basically the same as that in Example 1, except that the size of the copper foil is 6.5×10.5 cm 2 , image 3 For the prepared Cu 3 Comparison of optical pictures of P nanowire anode material (abbreviated as C-2) before and after reaction.

Embodiment 3

[0056] This embodiment provides a Cu 3 The preparation method of the P nanowire negative electrode material is basically the same as that in Example 1, except that the reaction time of the copper foil in the mixed aqueous solution is 30 minutes and 50 minutes respectively. Figure 4 and Figure 5 respectively prepared Cu 3 FESEM images of P nanowire anode materials (abbreviated as C-3 and C-4, respectively). Depend on Figure 4 It can be seen that the average width of C-3 is about 300-500 nm, and the average length is about 12 μm. Figure 5 It can be seen that the average length of C-4 is about 20 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com