Method for decomposing hydrogen phosphide cumene to prepare phynol and acetone

A technology of cumene hydroperoxide and phenol, which is applied in chemical instruments and methods, preparation of organic compounds, catalysts for physical/chemical processes, etc. It can solve problems such as large heat release, no reports of industrialization, decomposition explosion, etc. , to achieve the effects of less by-products, easy control of the reaction progress, and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0027] Preparation of solid acid catalyst: prepare 500g 1mol / L NH 4 NO 3 solution and 500g 3mol / L NH 4 NO 3 solution; add 50g bentonite (Heishan Town, Liaoning) into a 1000mL three-neck flask, then add 500g 1mol / L NH 4 NO 3 Solution; mechanically stirred, heated to 100°C under condensing and reflux conditions, exchanged for 8h; static overnight. Suction filtration the next day; then pour the filter cake back into the flask, and then add 500g 3mol / L NH 4 NO 3 Solution; mechanically stirred, heated to 100°C under condensing and reflux conditions, exchanged for 8h; static overnight. Then repeatedly wash with water and filter with suction. The filter cake was dried at 120°C for 4h, then calcined at 400°C for 4h, and ground to obtain 1 # catalyst.

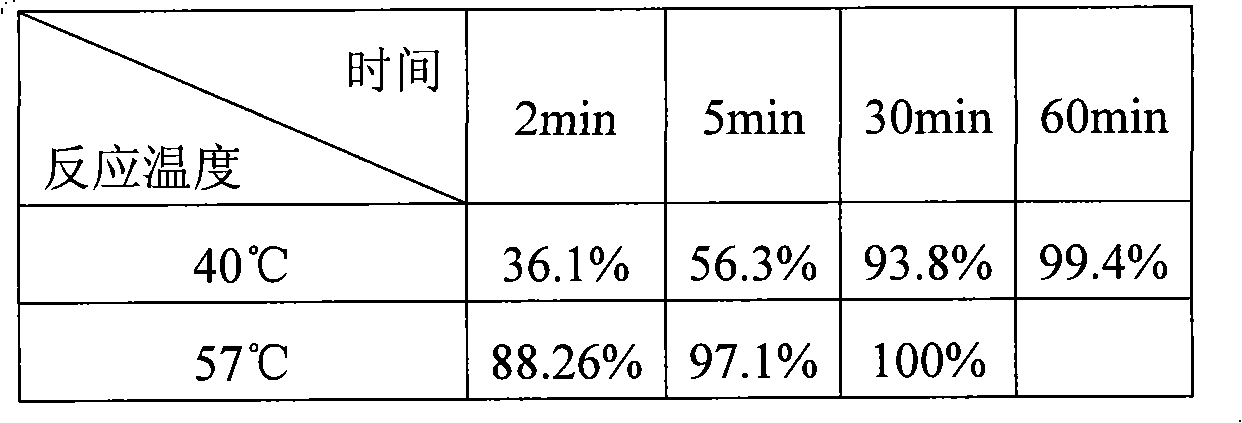

[0028]Preparation of phenol acetone: put a 250mL three-necked flask with a condenser in a magnetically stirred water bath; add 50g of acetone (which acts as a solvent) and 1g of catalyst powder, and raise the temperature to 40 ...

example 2 and 3

[0033] Preparation of solid acid catalyst: prepare 500g 1mol / LNH 4 NO 3 solution and 500g 2mol / LNH 4 NO 3 solution; in a 1000mL three-necked flask, add 50g bentonite (Shanghai Shisi Hewei Chemical Co., Ltd.), then add 500g 1mol / LNH 4 NO 3 Solution; mechanically stirred, heated to 100°C under condensing and reflux conditions, exchanged for 8h; static overnight. The next day, it was suction filtered, and a part was taken out and dried at 120°C for 4 hours, then roasted at 400°C for 4 hours, and ground to obtain 2 # catalyst.

[0034] Pour the other part of the filter cake back into the flask, and then add 500g 2mol / L NH 4 NO 3 Solution; mechanically stirred, heated to 100°C under condensing and reflux conditions, exchanged for 8h; static overnight. Then repeatedly wash with water and filter with suction. The filter cake was dried at 120°C for 4h, then calcined at 400°C for 4h, and ground to obtain 3 # catalyst.

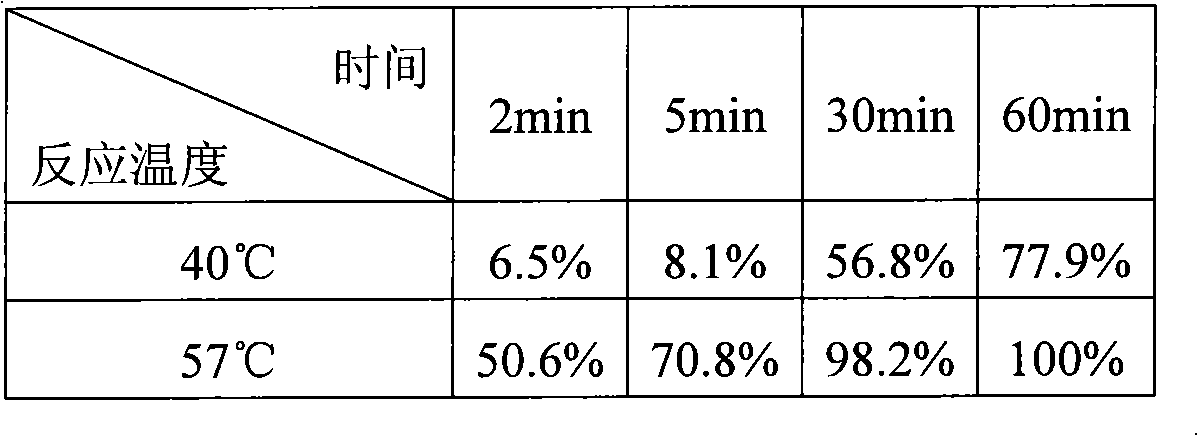

[0035] Preparation of phenol acetone: According to meth...

example 4、5、6、7 and 8

[0040] Preparation of solid acid catalyst: prepare 500g 1mol / LNH 4 NO 3 solution and 500g 2mol / LNH 4 NO 3 solution; in a 1000mL three-necked flask, add 50g bentonite (Shanghai Shisi Hewei Chemical Co., Ltd.), then add 500g 1mol / LNH 4 NO 3 Solution; mechanically stirred, heated to 100°C under condensing and reflux conditions, exchanged for 8h; static overnight. Suction filtration the next day, pour the filter cake back into the flask, and then add 500g 2mol / LNH 4 NO 3 Solution; mechanically stirred, heated to 100°C under condensing and reflux conditions, exchanged for 8h; static overnight. Then repeatedly wash with water and filter with suction. The filter cake was dried at 120°C for 4 hours, divided into five equal parts; then roasted at 250°C, 300°C, 350°C, 500°C and 600°C for 4 hours, and ground to obtain 4 # 、5 # 、6 # 、7 # and 8 # catalyst.

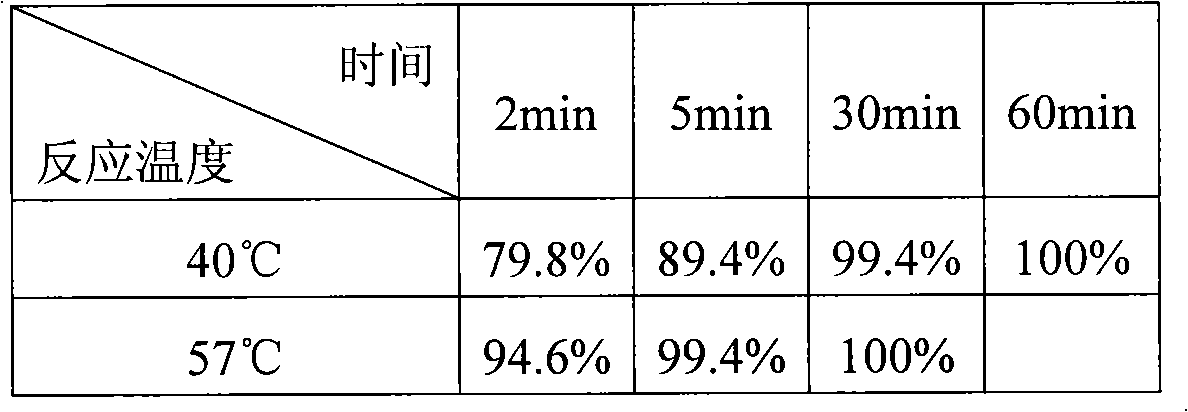

[0041] Preparation of phenol acetone: According to method I. 4 # The CHP conversion rate of the catalyst is shown in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com