A kind of preparation method of low-cost cadmium phosphide quantum dot material

A quantum dot material, cadmium phosphide technology, which is applied in the field of preparation of low-cost cadmium phosphide quantum dot materials, can solve the problems of transportation and storage conditions, no industrialization prospects, difficulty in scaling up synthesis experiments, etc., and achieve easy separation , production cost reduction, and the effect of easy experimental dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

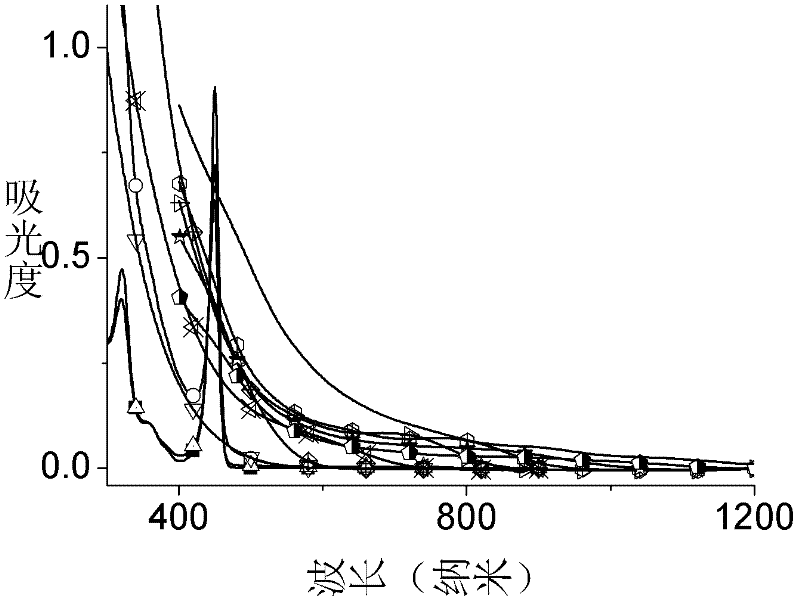

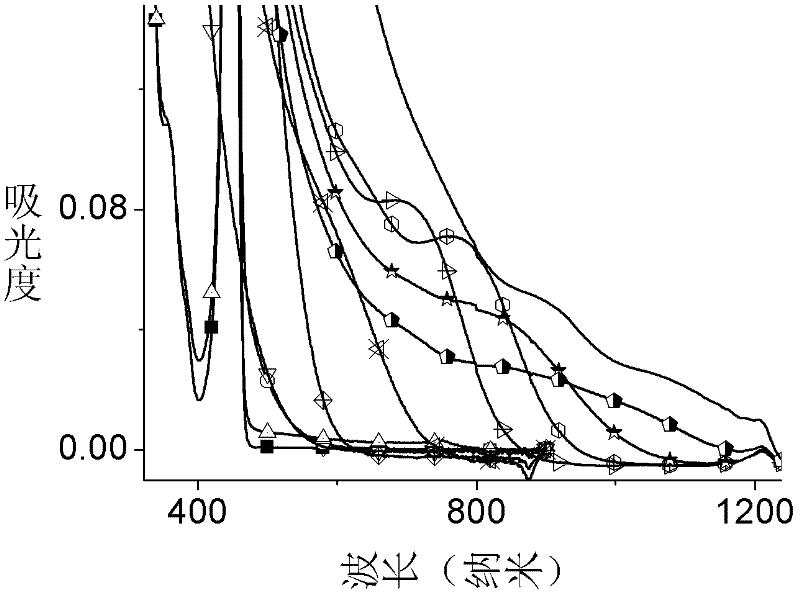

Embodiment 1

[0050] The preparation method of low-cost cadmium phosphide quantum dot material in the present embodiment is to operate according to the following steps:

[0051] a, Preparation of cadmium precursor

[0052] Put 0.258g of cadmium oxide and 1.3mL of oleic acid in a 25mL three-necked flask, add 15mL of octadecene, vacuumize (0.5-0.05mbar) at room temperature for 30 minutes, then heat to 270°C in a nitrogen atmosphere, and keep warm for 20 minutes to obtain Cadmium oleate solution;

[0053] b. Preparation of cadmium phosphide quantum dots

[0054] The temperature of the obtained cadmium oleate solution is controlled at 60°C, and with the assistance of nitrogen gas flow, the pH 3 gas, pH 3 Flow rate is 2mL / min, carrier gas N 2 The flow rate is 30mL / min, N 2 with PH 3 The flow rate ratio is 15:1, and the insulation reaction is 180min to obtain an octadecene solution of cadmium phosphide quantum dots, with a yield of 97.5%;

[0055] c. Separation and purification

[0056] A...

Embodiment 2

[0058] The preparation method of low-cost cadmium phosphide quantum dot material in the present embodiment is to operate according to the following steps:

[0059] a, Preparation of cadmium precursor

[0060] Put 0.258g of cadmium oxide and 0.8g of lauric acid in a 25mL three-necked flask, add 15mL of octadecene, vacuumize (0.5-0.05mbar) at room temperature for 30 minutes, then heat to 250°C in a nitrogen atmosphere, and keep the temperature for 20 minutes to obtain Cadmium laurate solution;

[0061] b. Preparation of cadmium phosphide quantum dots

[0062] The temperature of the obtained cadmium laurate solution is controlled at 120°C, and with the assistance of nitrogen gas flow, the pH 3 gas, pH 3 Flow rate is 2mL / min, carrier gas N 2 The flow rate is 2mL / min, N 2 with PH 3 The flow rate ratio is 1:1, and the insulation reaction is 120min to obtain an octadecene solution of cadmium phosphide quantum dots, with a yield of 97.0%;

[0063] c, the method for separation a...

Embodiment 3

[0065] The preparation method of low-cost cadmium phosphide quantum dot material in the present embodiment is to operate according to the following steps:

[0066] a, Preparation of cadmium precursor

[0067] Put 0.258g of cadmium oxide and 1.05g of palmitic acid in a 25mL three-necked flask, add 15mL of octadecene, vacuumize (0.5-0.05mbar) at room temperature for 30 minutes, then heat to 260°C in a nitrogen atmosphere, and keep the temperature for 20 minutes to obtain Cadmium palmitate solution;

[0068] b. Preparation of cadmium phosphide quantum dots

[0069] The temperature of the resulting cadmium palmitate solution is controlled at 180°C, and with the assistance of nitrogen gas flow, the pH 3 gas, pH 3 Flow rate is 2mL / min, carrier gas N 2 The flow rate is 20mL / min, N 2 with PH 3 The flow rate ratio is 10:1, and the heat preservation reaction is 30min to obtain an octadecene solution of cadmium phosphide quantum dots, with a yield of 97.3%;

[0070] c, the method ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com