Method for preparing adsorbent capable of simultaneously removing hydrogen sulfide, hydrogen phosphide and arsenic hydride

A hydrogen sulfide and phosphine technology, which is applied in the preparation of arsine hydrogen sorbent, phosphine, and hydrogen sulfide removal at the same time, can solve the problems that the preparation method of mesoporous silicon-based adsorbent has not been reported, and achieve high selectivity Excellent adsorption performance, good removal effect, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

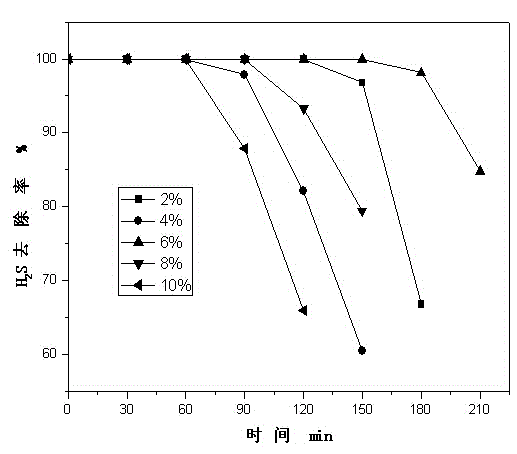

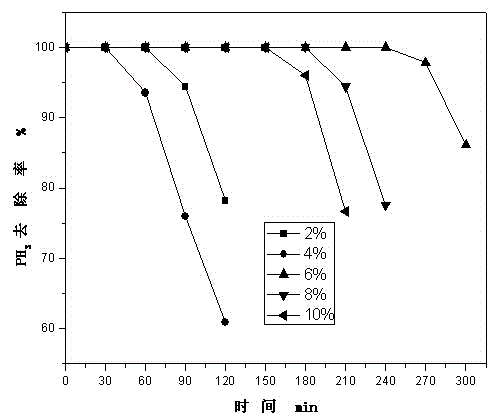

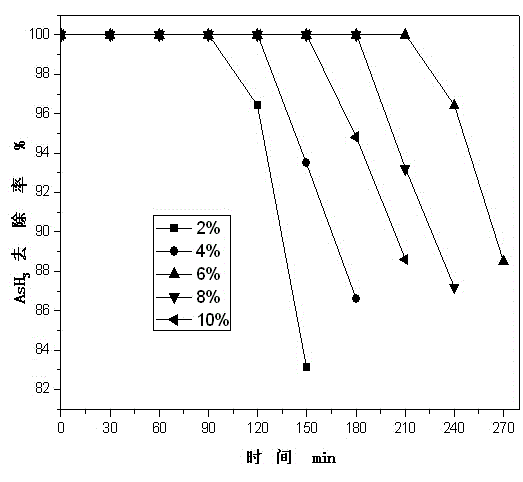

[0024]Grind and sieve diatomite into 40-60 meshes, then wash 4-6 times with water until the supernatant is suspended without turbidity, and dry in a blast drying oven at 100°C for 5 hours; Stir and impregnate in a 1mol / L HCl solution for 30 minutes for 0.5 hours, then wash with distilled water until the pH is constant, filter and dry in a blast drying oven for 5 hours at 100°C; add the dried diatomaceous earth to the metal Saline solution (composed of 2% ferric nitrate by diatomite mass, 1% copper nitrate by diatomite mass, and 2% cobalt nitrate by diatomite mass) was ultrasonically immersed for 40 minutes, and then the impregnated diatomite was placed in Dry in a blast drying oven at 100°C for 5 hours, and then bake at 500°C for 3 hours; put the calcined diatomite into a 5% HCl solution and ultrasonically impregnate it for 0.5 hours (the temperature of immersion is 50 °C), and then the impregnated diatomite was dried in a blast drying oven at 100 °C for 5 hours to obtain a me...

Embodiment 2

[0026] Grind and sieve diatomite into 40-60 meshes, then wash 4-6 times with water until the supernatant is suspended without turbidity, and dry in a blast drying oven at 110°C for 6 hours; Stir and impregnate in a 2mol / L HCl solution for 40 minutes for 0.6 hours, then wash with distilled water until the pH is constant, filter and dry in a blast drying oven for 6 hours at 110°C; add the dried diatomaceous earth to the metal Saline solution (composed of 4% ferric nitrate by diatomite mass, 2% copper nitrate by diatomite mass, and 4% cobalt nitrate by diatomite mass) was ultrasonically immersed for 50 minutes, and then the impregnated diatomite was placed in Dry in a blast drying oven at 110°C for 6 hours, then bake at 600°C for 4 hours; put the calcined diatomite into 15% HNO 3 Ultrasonic immersion in the solution for 0.6 hours (the immersion temperature is 45°C), and then the impregnated diatomite was dried in a blast drying oven at 110°C for 6 hours to prepare the mesoporous ...

Embodiment 3

[0028] Grind and sieve diatomaceous earth into 40~60 meshes, then wash 4~6 times with water until the supernatant is suspended without turbidity, and dry in a blast drying oven at 120°C for 7 hours; Stir and impregnate in a 3mol / L HCl solution for 50 minutes for 0.7 hours, then wash with distilled water until the pH is constant, filter and dry in a blast drying oven at 120°C for 7 hours; add the dried diatomaceous earth to the metal Saline solution (composed of 6% ferric nitrate by diatomite mass, 3% copper nitrate by diatomite mass, and 6% cobalt nitrate by diatomite mass) was ultrasonically immersed for 60 minutes, and then the impregnated diatomite was placed in Dry in an air blast oven at 120°C for 7 hours, then bake at 450°C for 4.5 hours; put the calcined diatomite into 20% H 2 SO 4 Ultrasonic immersion in the solution for 0.7 hours (the immersion temperature is 40°C), and then the impregnated diatomaceous earth was dried in a blast drying oven at 120°C for 7 hours to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com