Preparation technique and device for ultra-pure hydrogen phosphide

A hydrogen peroxide, ultra-high technology, applied in peroxide/peroxyhydrate/peroxyacid/superoxide/ozone, inorganic chemistry, chemical instruments and methods, etc., can solve high-purity hydrogen peroxide The product index is low, the impurity content is low, and the quality cannot meet the use requirements, etc., to achieve the effect of small footprint, easy automatic operation, and content reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A process for the continuous production of ultra-high-purity hydrogen peroxide, first mixing industrial-grade hydrogen peroxide raw materials with modified activated carbon with a weight of 0.5% to 2% of hydrogen peroxide raw materials, and then operating under the operating pressure of 0.1 to 0.2MPa The filtrate is pumped into the multi-tower series rectification tower, and the metal ion complexing agent is added to the first-stage tower, and the semi-finished product out of the tower runs at 1.0-1.4MPa Reverse osmosis is carried out under pressure. After the reverse osmosis is completed, the ultra-high-purity hydrogen peroxide product is obtained by nanofiltration membrane filtration at an operating pressure of 0.5-0.8 MPa. In this embodiment, the amount of modified activated carbon is peroxide The weight of hydrogen raw material is 0.5%, 1% or 2%; the pressure selection for microfiltration membrane filtration or ultrafiltration membrane filtration is: 0.1, 0.15 or 0.2...

Embodiment 2

[0030] 35% (weight) in raw material tank 1, the technical grade hydrogen peroxide that contains impurity more is passed in the gac premixer 2, and the gac of modification adds by 1% of hydrogen peroxide treatment capacity, removes organic carbon here . The hydrogen peroxide with reduced organic carbon content is passed through the pipeline through the microfiltration ultrafiltration filter 3 (the pore size of the microfiltration membrane is 0.2-0.8 μm, the operating pressure is 0.1-0.2 MPa, the temperature is controlled at 20-25 ° C, the ultrafiltration membrane The pore size is 0.01-0.05μm, the operating pressure is 0.1-0.2MPa, and the temperature is controlled at 20-25°C), where macromolecular organic matter and small particle impurities are removed. The treated hydrogen peroxide is then input into the multi-tower series rectification column 4 with polymer metal ion complexing agent through the pump 8 made of oxidation-resistant and corrosion-resistant materials, where most ...

Embodiment 3

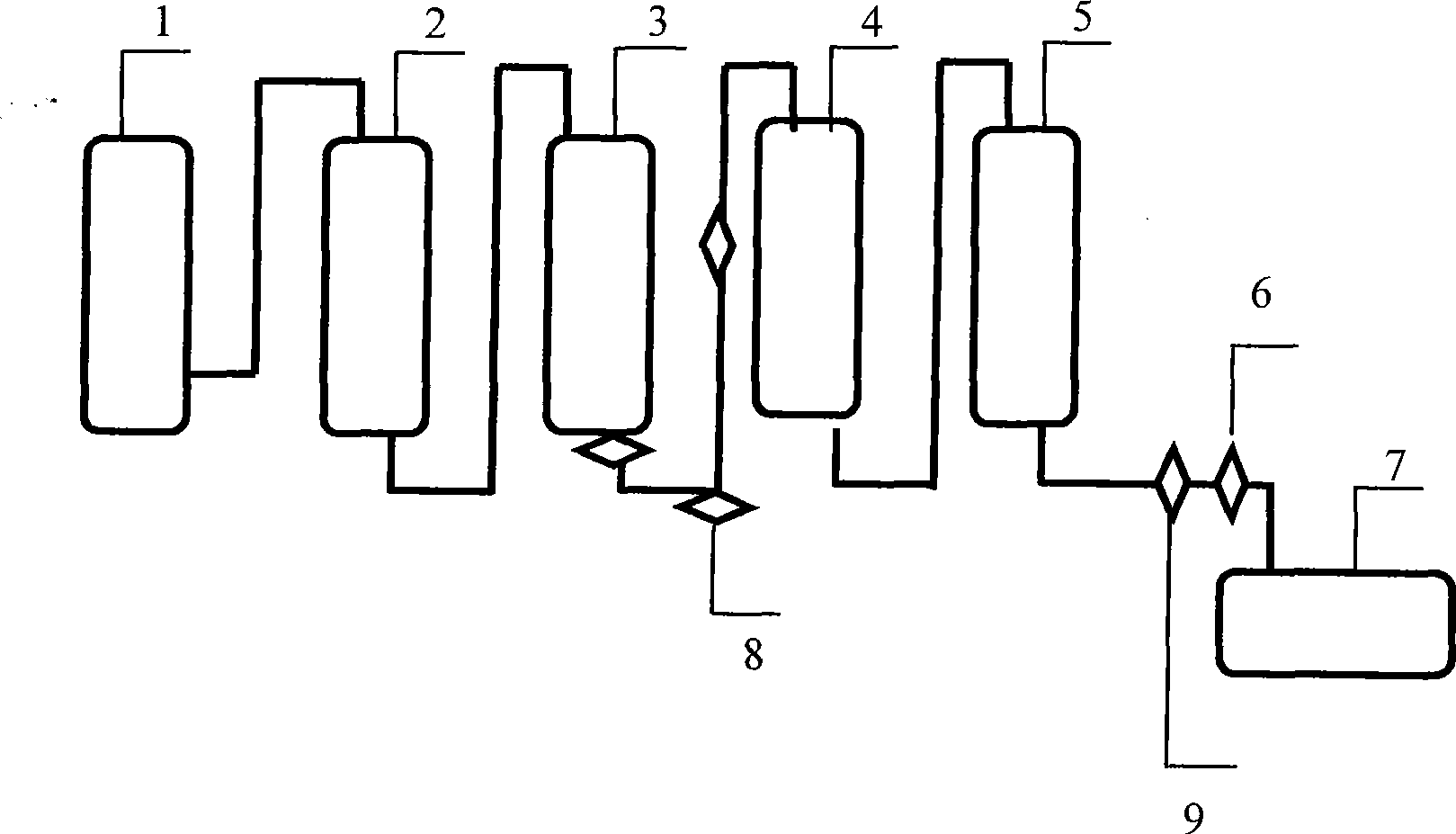

[0032] A device for implementing the above-mentioned continuous production of ultra-high-purity hydrogen peroxide, comprising a raw material tank 1, an activated carbon premixer 2, a microfiltration ultrafiltration filter 3, a multi-tower series rectification tower 4, and a reverse osmosis device 5 , nanofilter 6, finished product receiver 7, pump 8 and valve 9, the outlet of raw material tank 1 is connected with the inlet of activated carbon premixer 2, the outlet of activated carbon premixer 2 is connected with the inlet of microfiltration ultrafiltration filter 3, and the outlet of microfiltration ultrafiltration Filter 3 outlet and pump 8

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com