System and method for treating high boiling residuary solution in chloroethylene produced by adopting calcium carbide method

A processing system, vinyl chloride technology, applied in chemical instruments and methods, parts of acetylene gas generator, petroleum industry, etc., can solve problems such as difficult to handle, rectification high boiling residual liquid polluting the environment, etc., to increase the service life , Realize resource reuse and reduce the effect of oxychlorination unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention provides many applicable inventive concepts that can be embodied in numerous specific contexts. The specific examples described in the following embodiments of the present invention are only used as illustrations of specific embodiments of the present invention, and are not intended to limit the scope of the present invention.

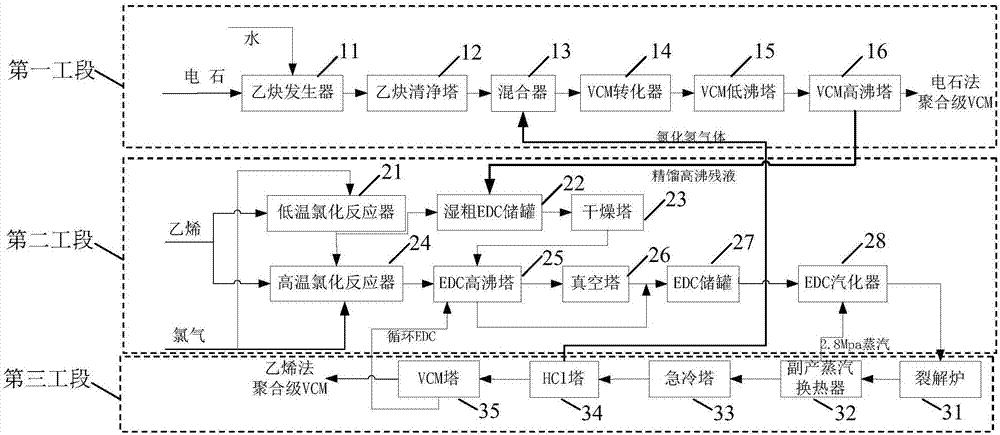

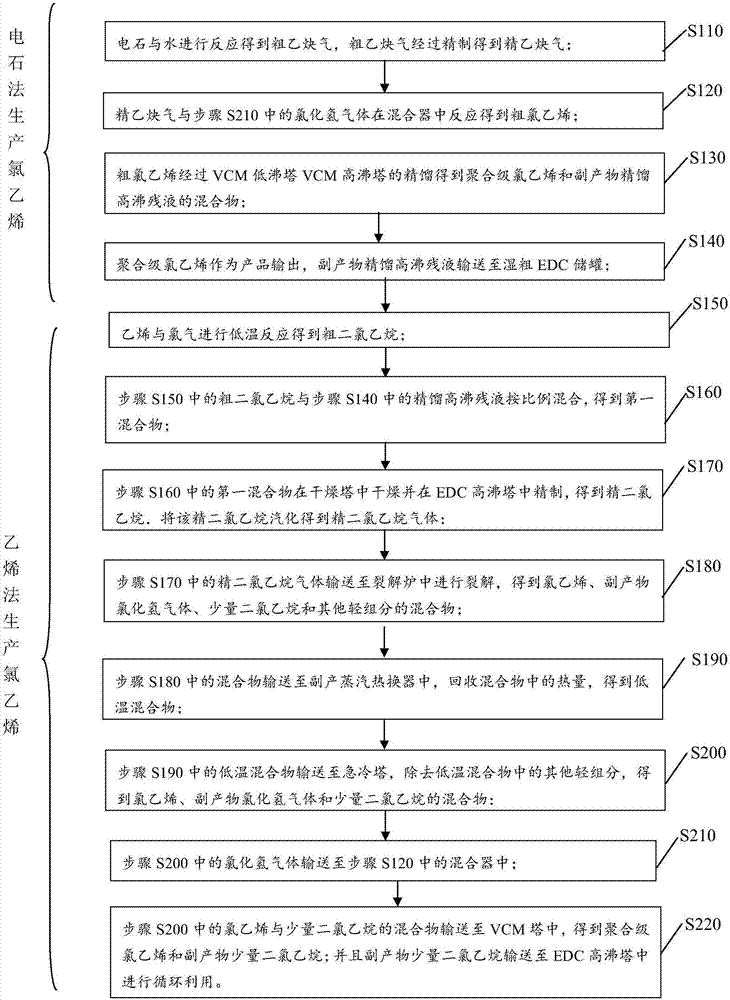

[0021] figure 1 It is a vinyl chloride production system, which includes the first section for producing vinyl chloride by the calcium carbide method, the second section for producing ethylene dichloride by chlorination of ethylene, and the third section for producing vinyl chloride by cracking ethylene dichloride in the second section, The by-product high boiling raffinate produced in the first section is processed through the second section and the third section, wherein, the first section (calcium carbide method produces vinyl chloride), which includes an acetylene generator 11 connected in sequence, an acetylene cleanin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com