System for producing acetylene gas by using recycled calcium carbide dust

An acetylene gas and dust technology, which is applied in the field of acetylene gas production systems, can solve the problems of small evaporation, large rainwater, and high water content in sediments, and achieve the effects of eliminating potential safety hazards, ensuring safe production, and improving utilization rates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

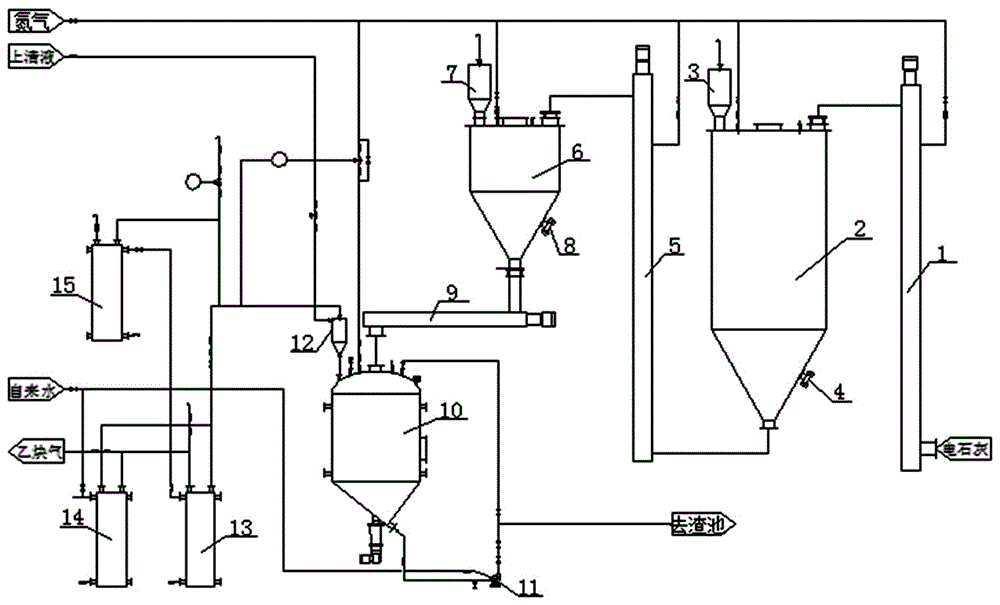

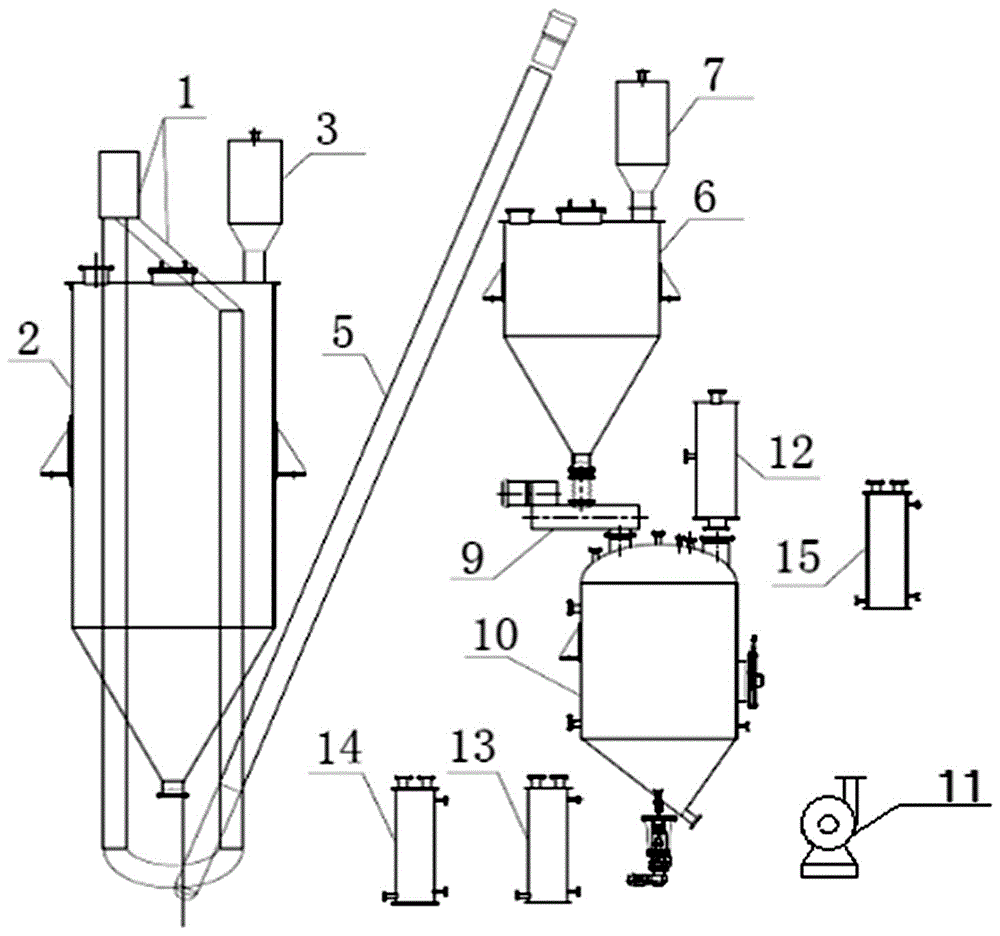

[0024] like figure 1 or figure 2 As shown, the system for producing acetylene gas by recycling calcium carbide dust in this embodiment includes a primary loader 1, an ash storage bin 2, a silo dust collector 3, a secondary feeder 5, an upper hopper 6, and an upper hopper dust collector 7. Feeding auger 9, acetylene generator 10, scrubber 12, positive water seal 13, safety water seal 15, reverse water seal 14, slurry pump 11;

[0025] Its connection mode: the acetylene generator 10 is connected to the slurry buffer tank through the calcium carbide slag conveyor, the primary feeder 1 is connected to the ash storage bin 2 through a pipeline, the dust collector 3 of the silo is connected to the top of the ash storage bin 2, and the ash storage The bottom of warehouse 2 is connected to the secondary feeder 5 through the pipeline, the secondary feeder 5 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com