Calcium carbide preparing and feeding automatic control method of acetylene generator

An acetylene generator and generator technology, applied to acetylene generators, parts of acetylene gas generators, electrical program control, etc., can solve the problems of poor continuity of calcium carbide preparation and feeding of acetylene generators, and reduce the failure rate and staff The effect of reducing labor intensity, simplifying operating procedures, and improving the level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

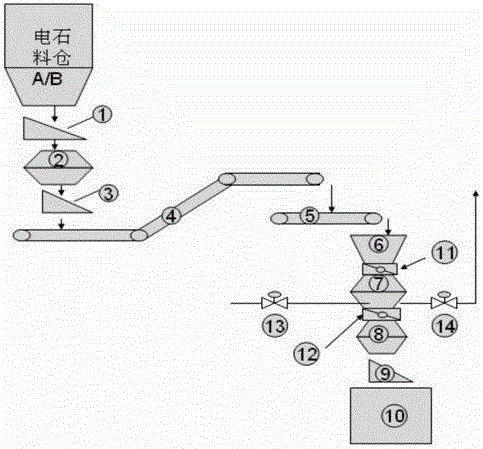

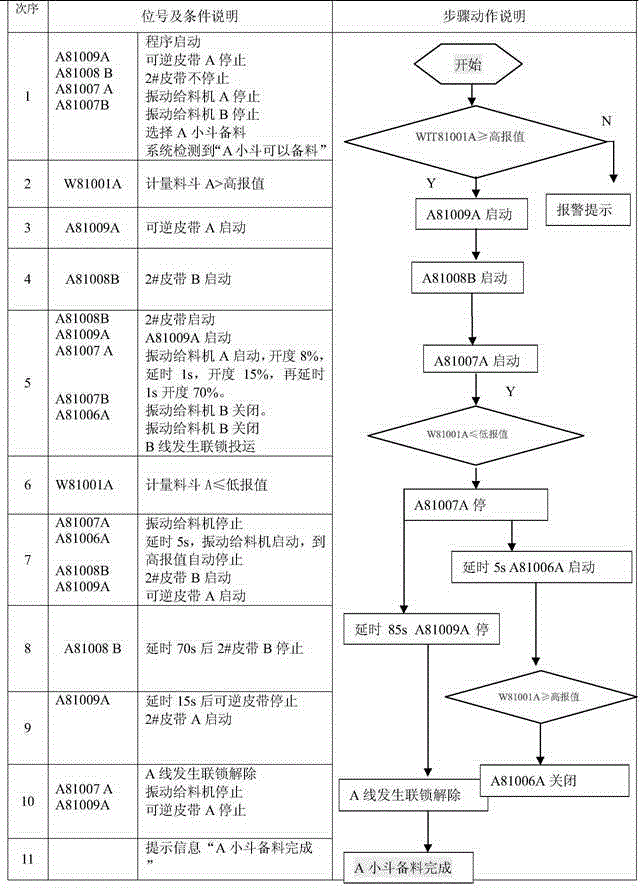

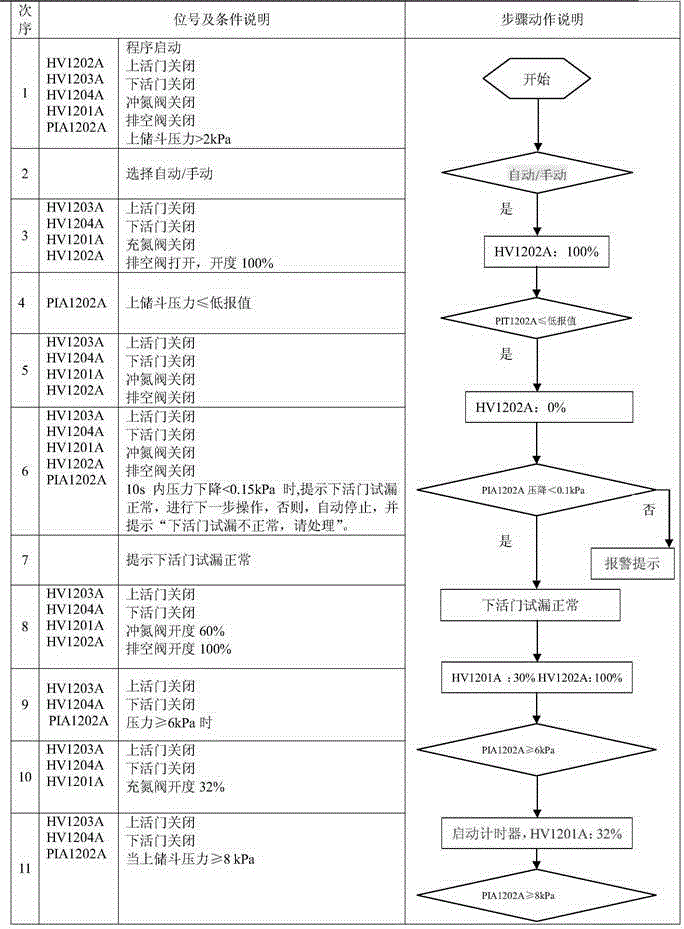

[0021] Please refer to figure 1 , 2 , 3, 4, the automatic control system of calcium carbide preparation and feeding of acetylene generator is carried out according to the following process:

[0022] 1. Generator small storage hopper for material preparation

[0023] When selecting the generator and metering hopper that need to prepare materials, the program will start the reversible belt (A81009A / B), 2# belt conveyor A81008A / B, vibrating feeder A81007A / B / C / D in sequence according to the set program, The opening of the vibrating feeder changes from 0 to 8% after a delay of 1s, then to 15% after a delay of 1s, and then to 15% after a delay of 2s. At the same time, "A / B line interlock" is automatically put into use. When the weight of the weighing hopper W81001A / B / C / D is low, the vibrating feeder A81007A / B / C / D will stop and delay Finally, the reversible belt (A81009A / B) stops, the "interlock of A / B line" is automatically released, and it prompts "the preparation of the small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com