Patents

Literature

49 results about "Cells/well" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

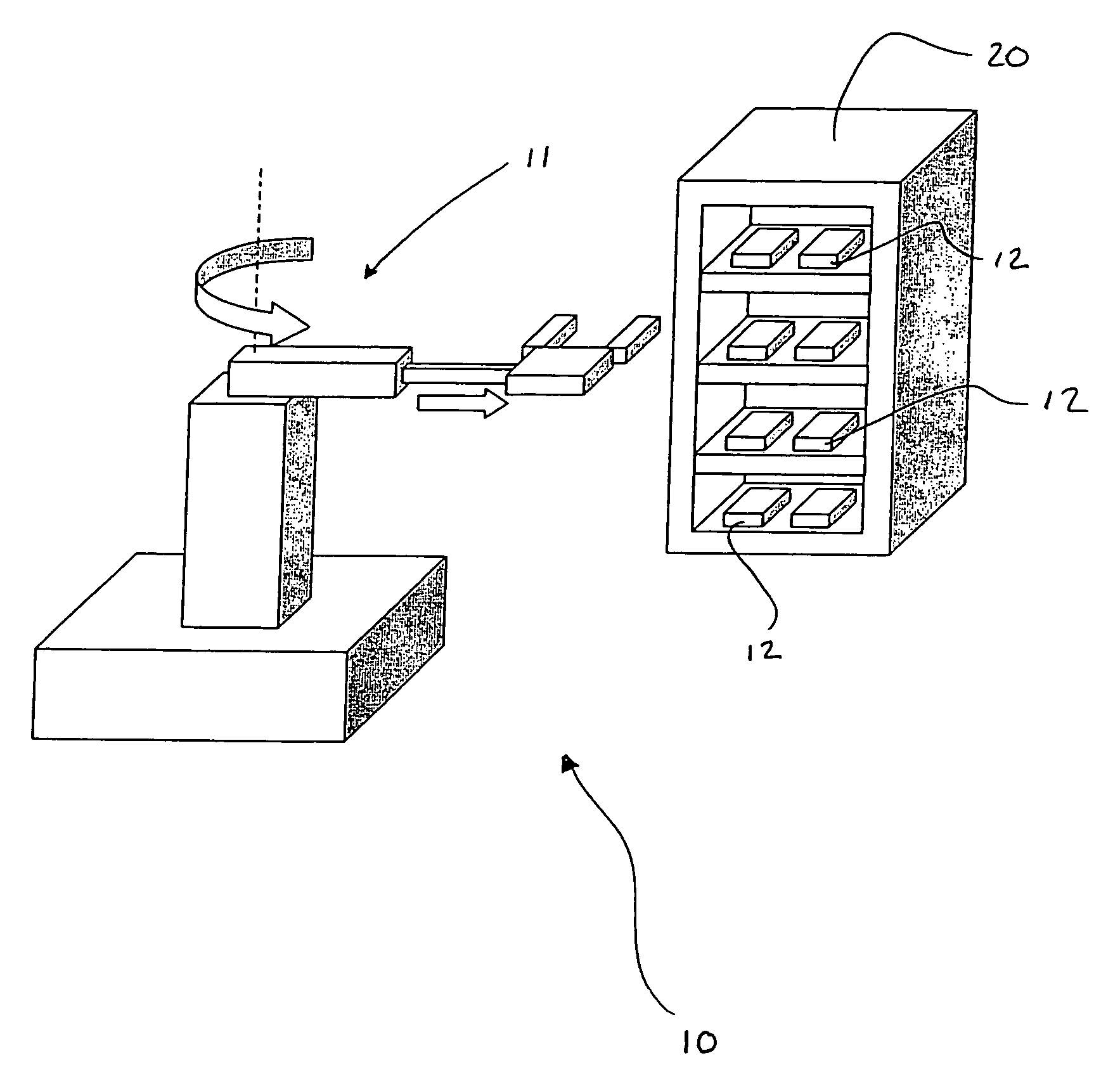

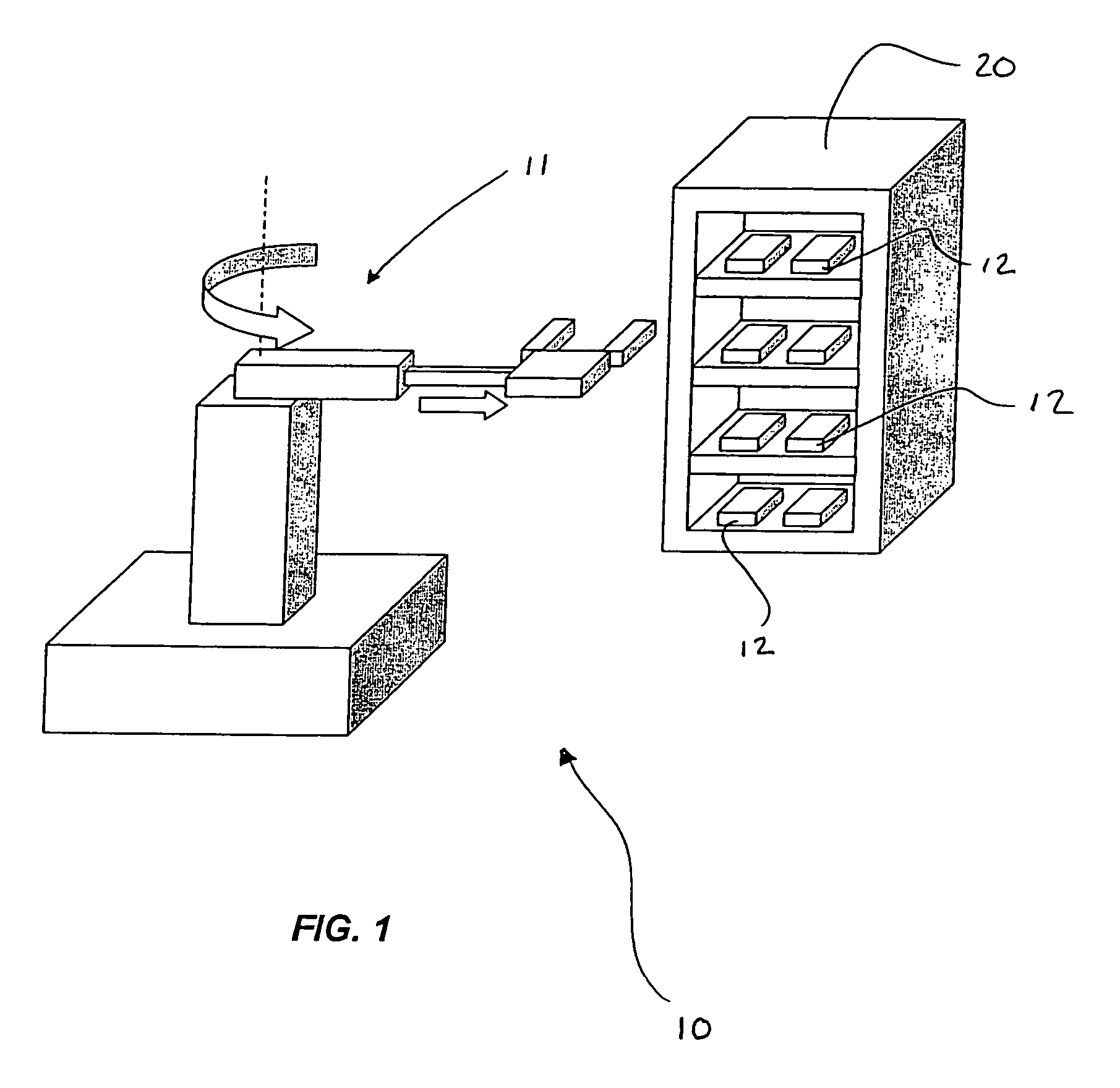

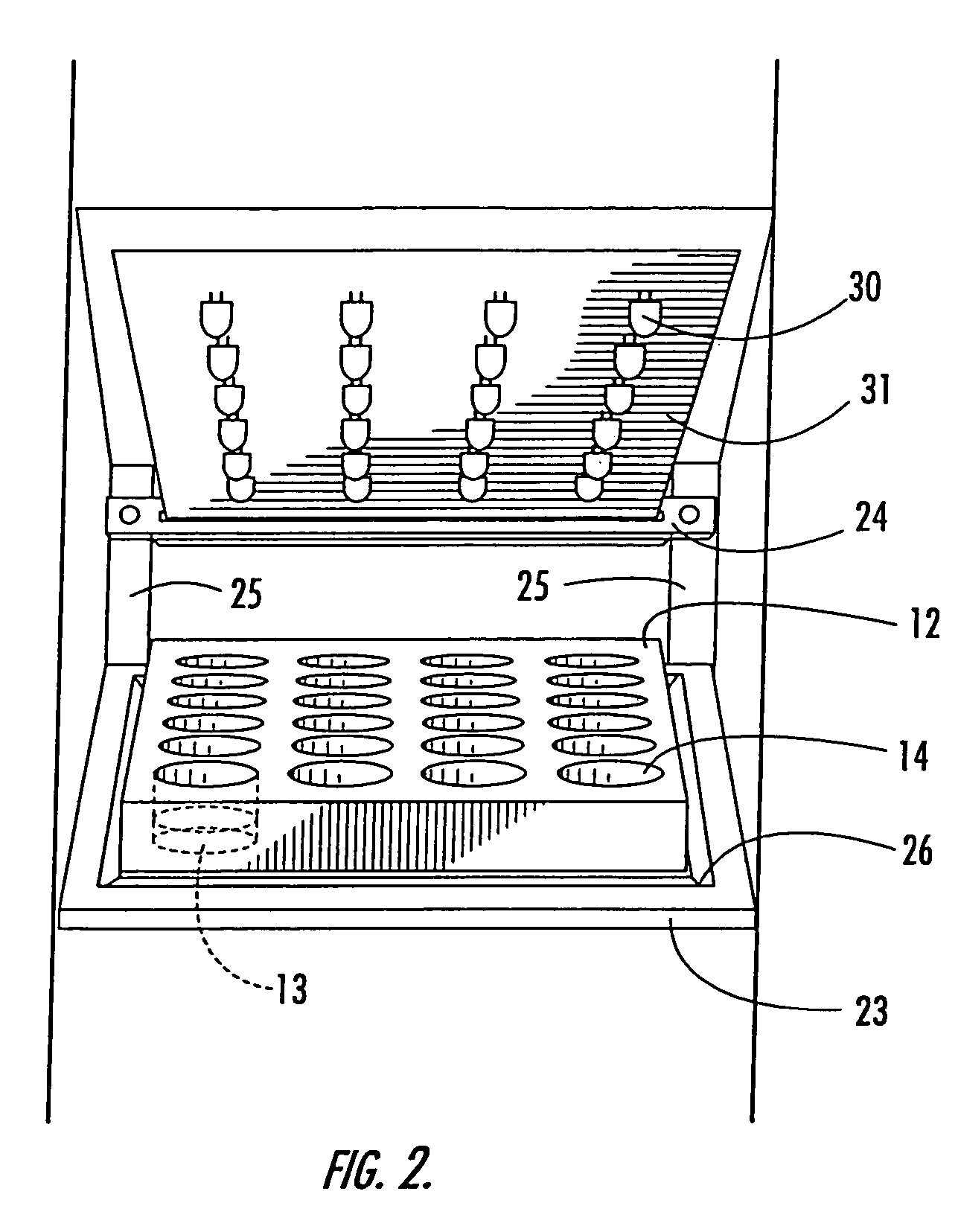

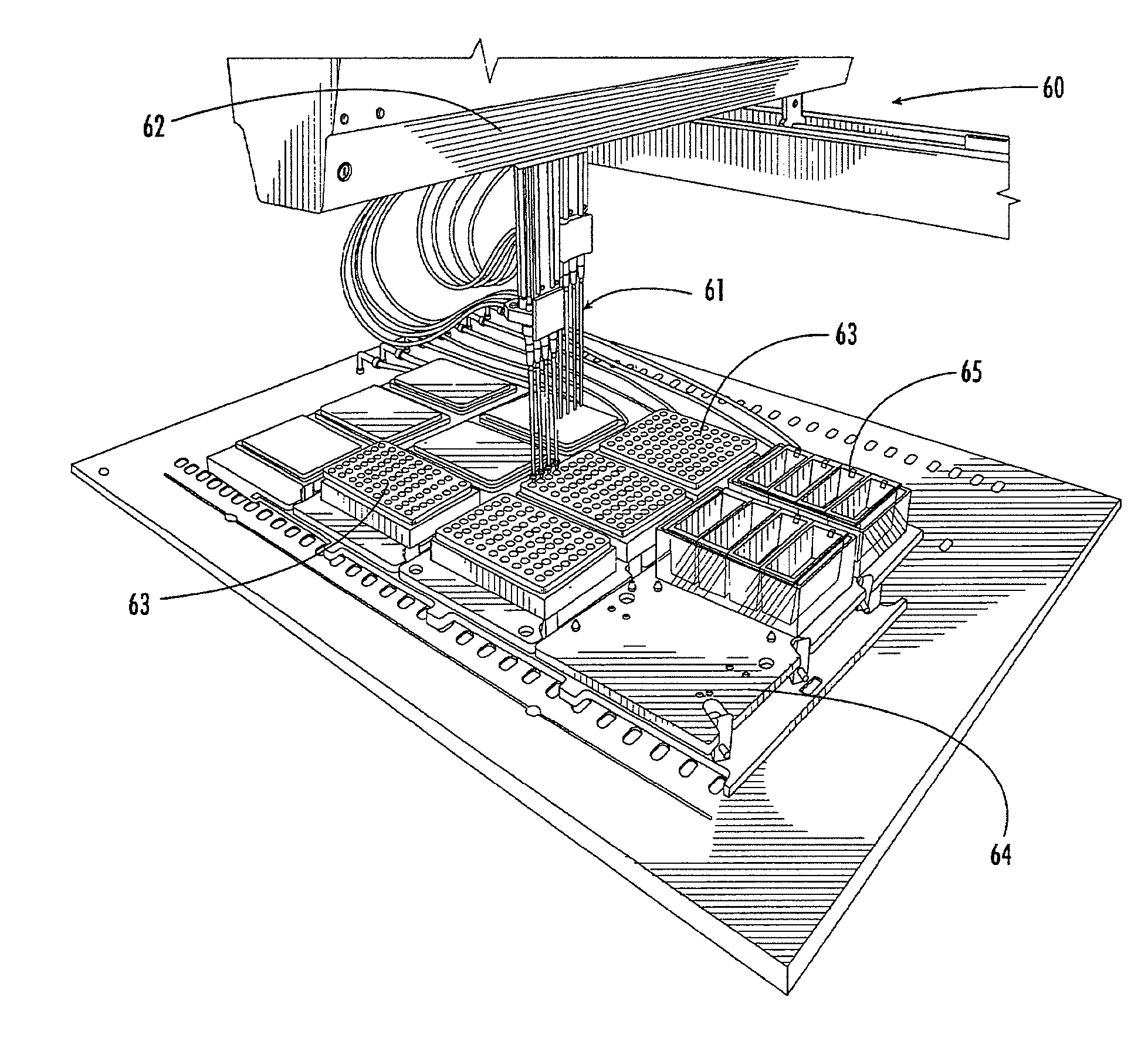

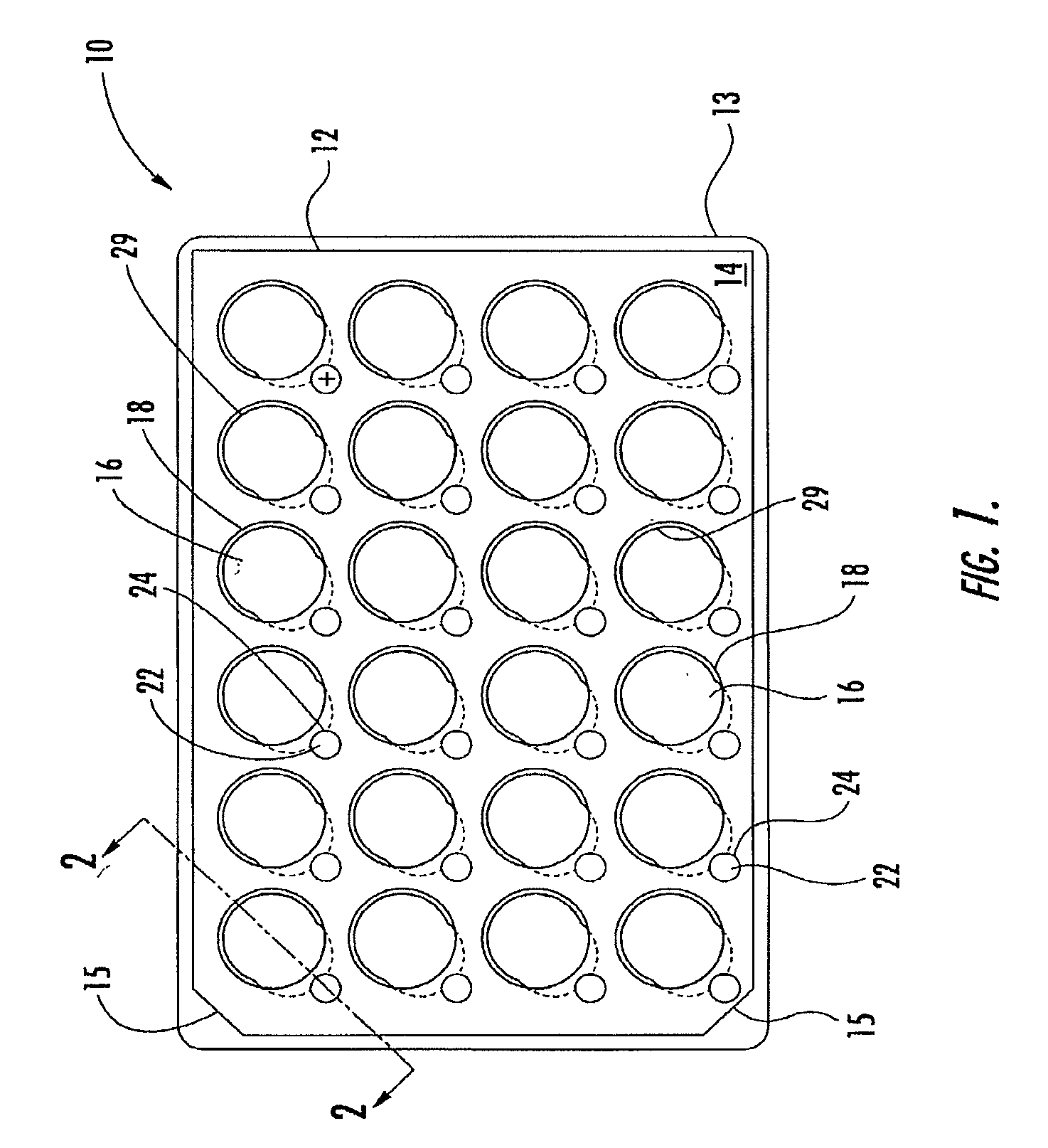

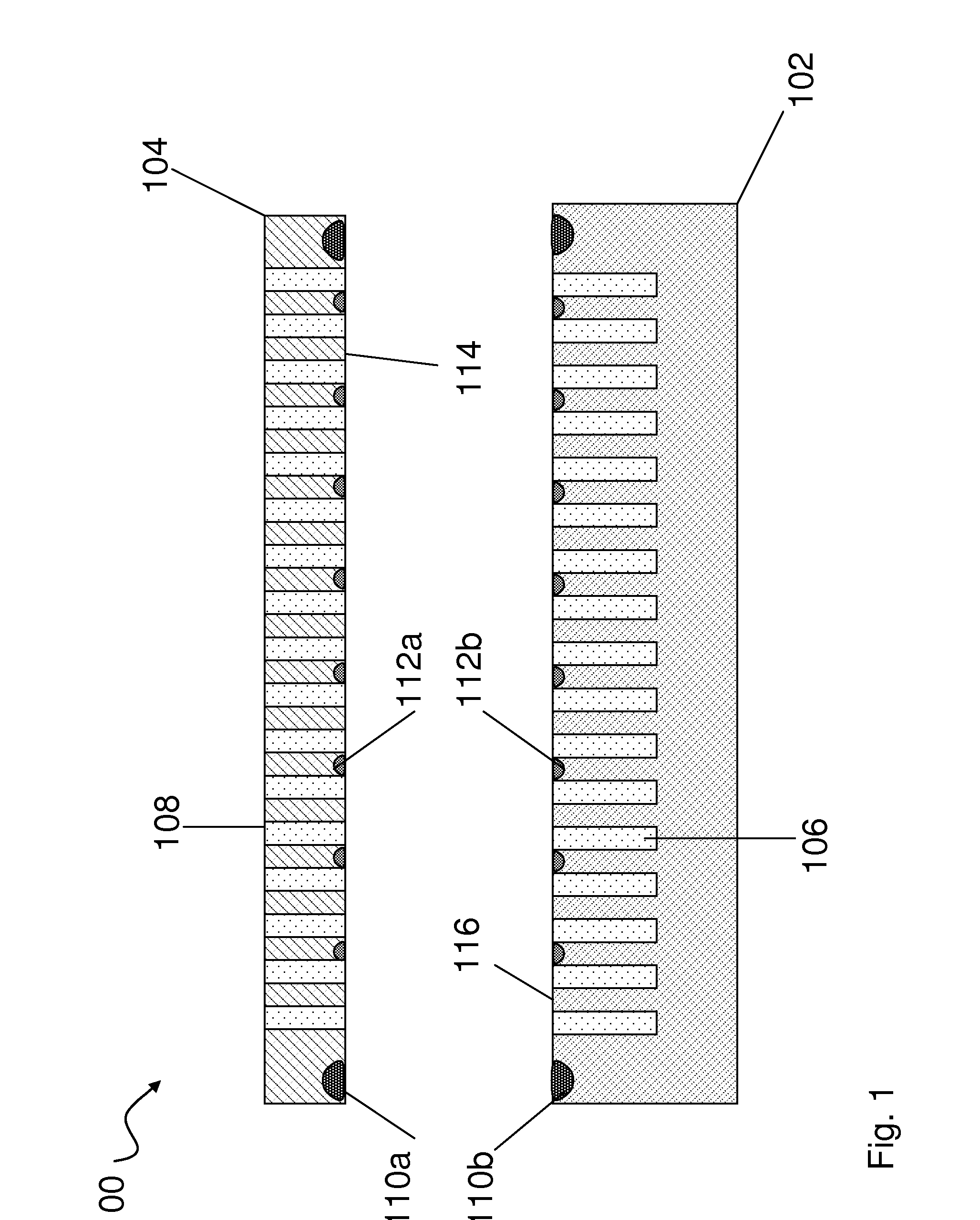

LED array for illuminating cell well plates and automated rack system for handling the same

InactiveUS7160717B2Improve storage efficiencyReduce amountBioreactor/fermenter combinationsBiological substance pretreatmentsCells/wellPlant tissue

An assembly for promoting the growth of plant tissues that includes a plurality of plates each defining an array of wells wherein each of the wells contains a tissue sample. Support for the plates is provided by a rack having a plurality of vertically stacked shelves that may include one or more register depressions that urge the plates into predetermined positions. Light for the tissue samples is provided by a plurality of light-emitting diode arrays each mounted on a circuit board. Each circuit board is supported by a respective card edge connector of the rack so that the light-emitting diodes are in proximity to the plates supported on one of the shelves therebelow. Preferably, the light-emitting diode array corresponds to the well array supported in the registered position on the shelf therebelow so that each light-emitting diode is centered above a respective one of the wells.

Owner:BIOLEX THERAPEUTICS INC

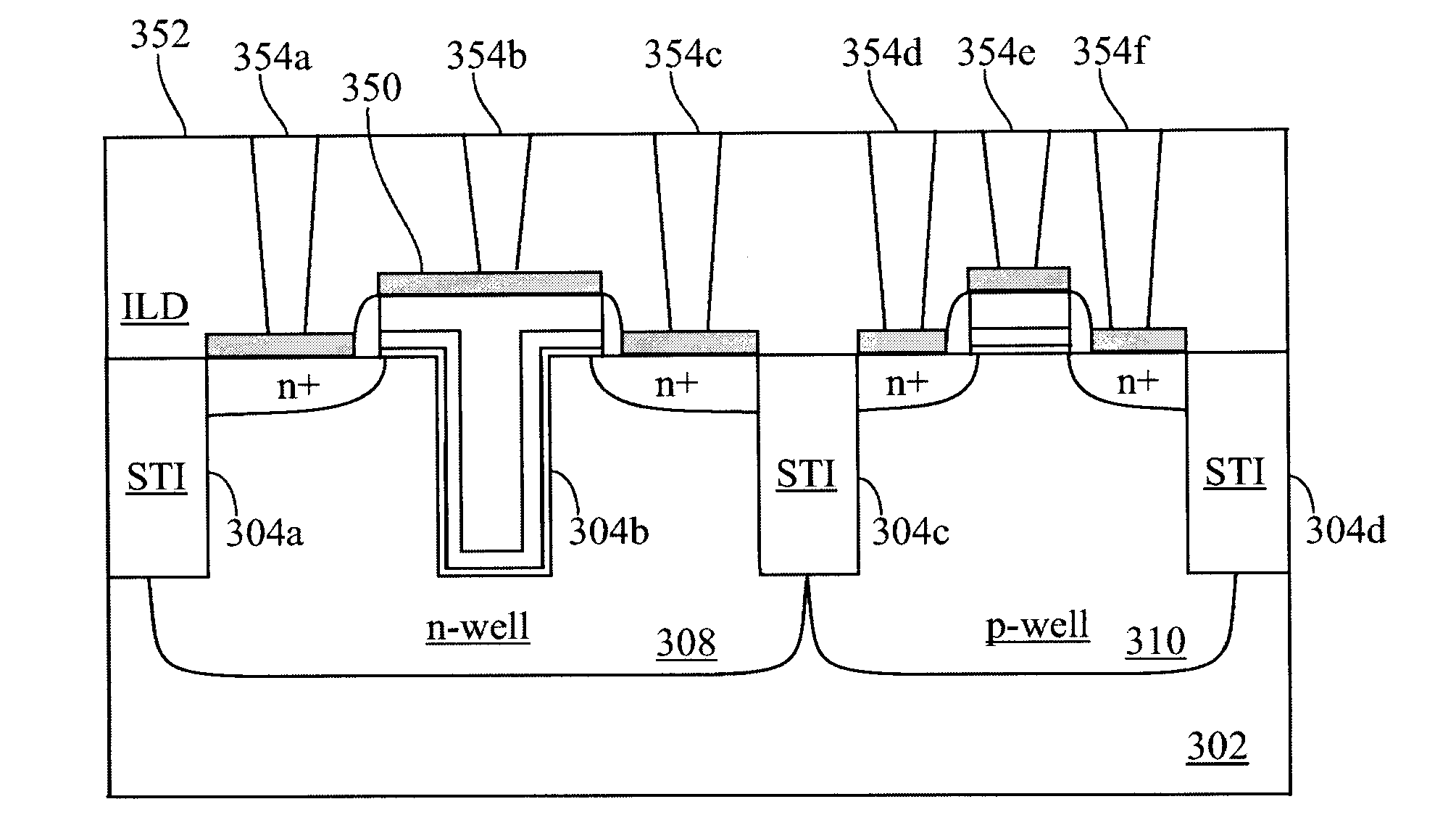

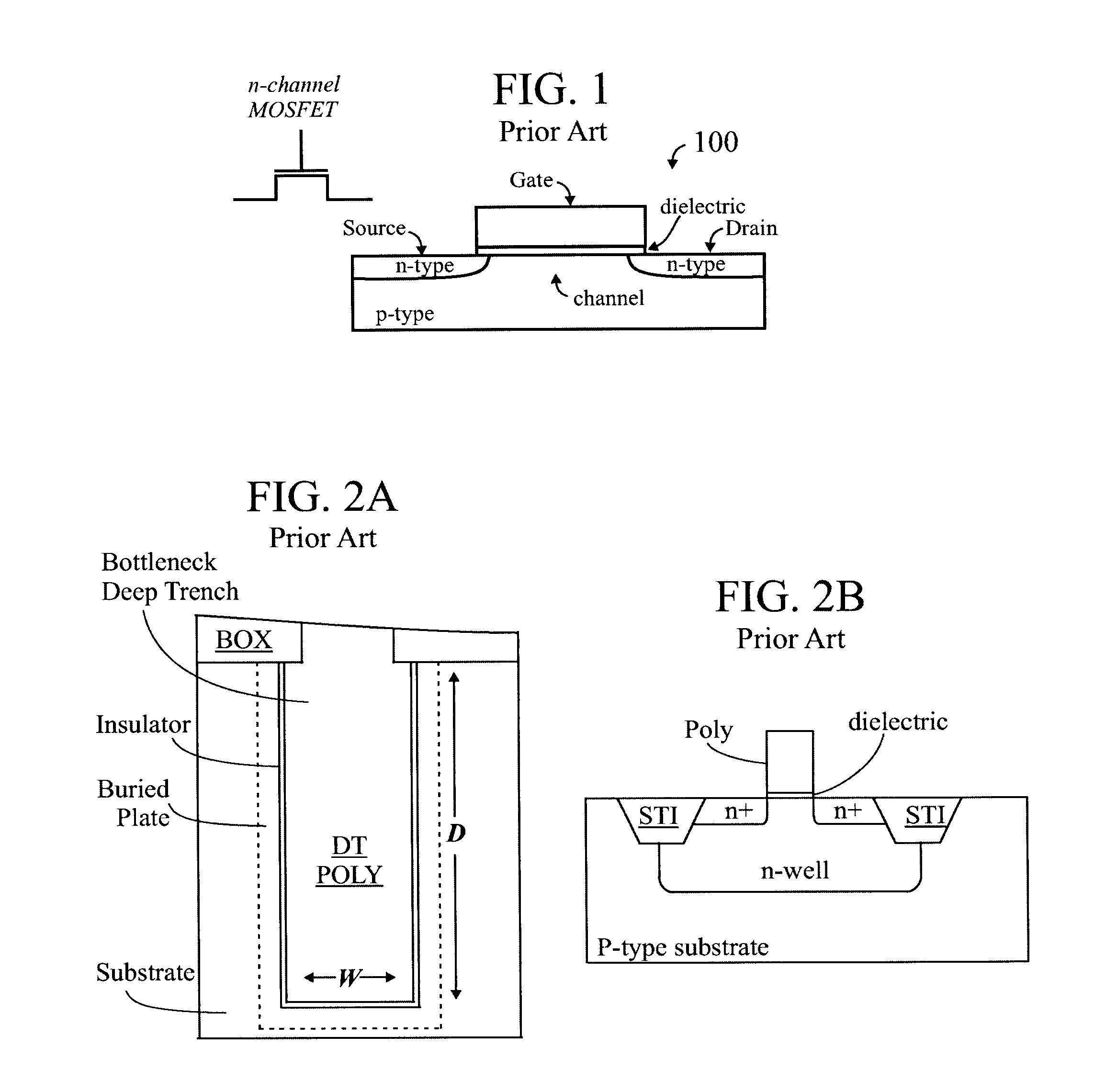

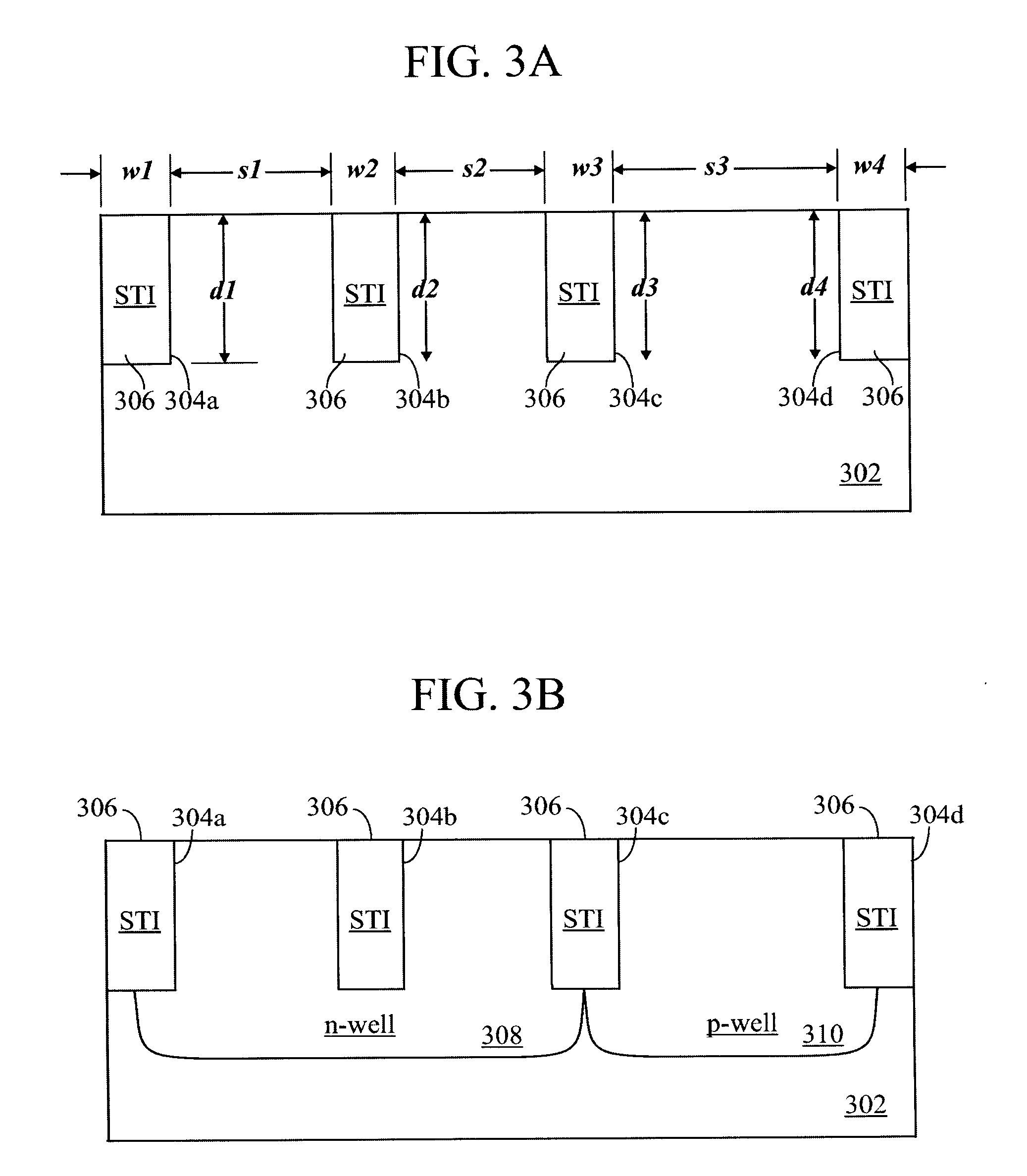

Shallow trench capacitor compatible with high-k / metal gate

InactiveUS20090242953A1Improve performanceHigh densityTransistorSolid-state devicesCapacitanceCells/well

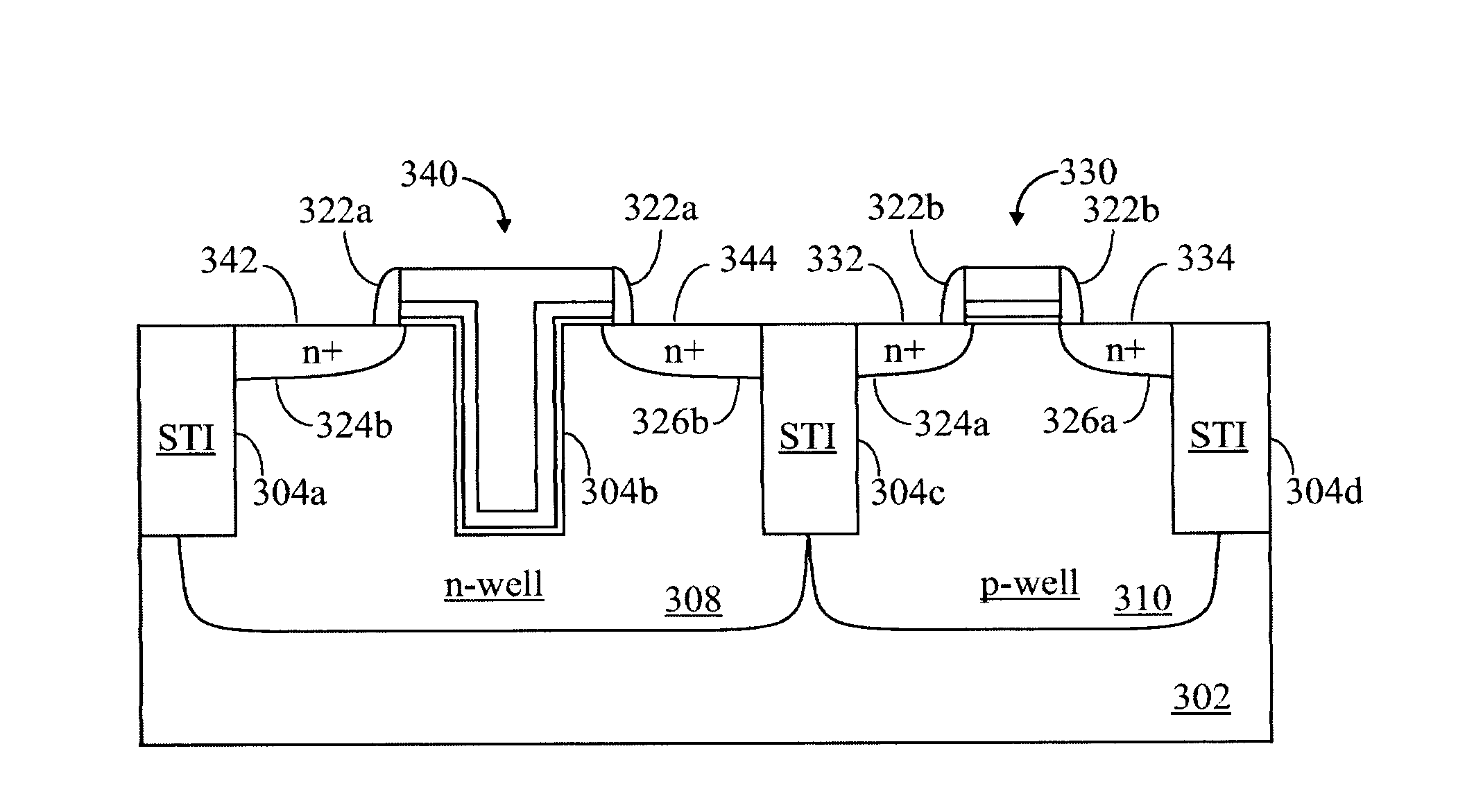

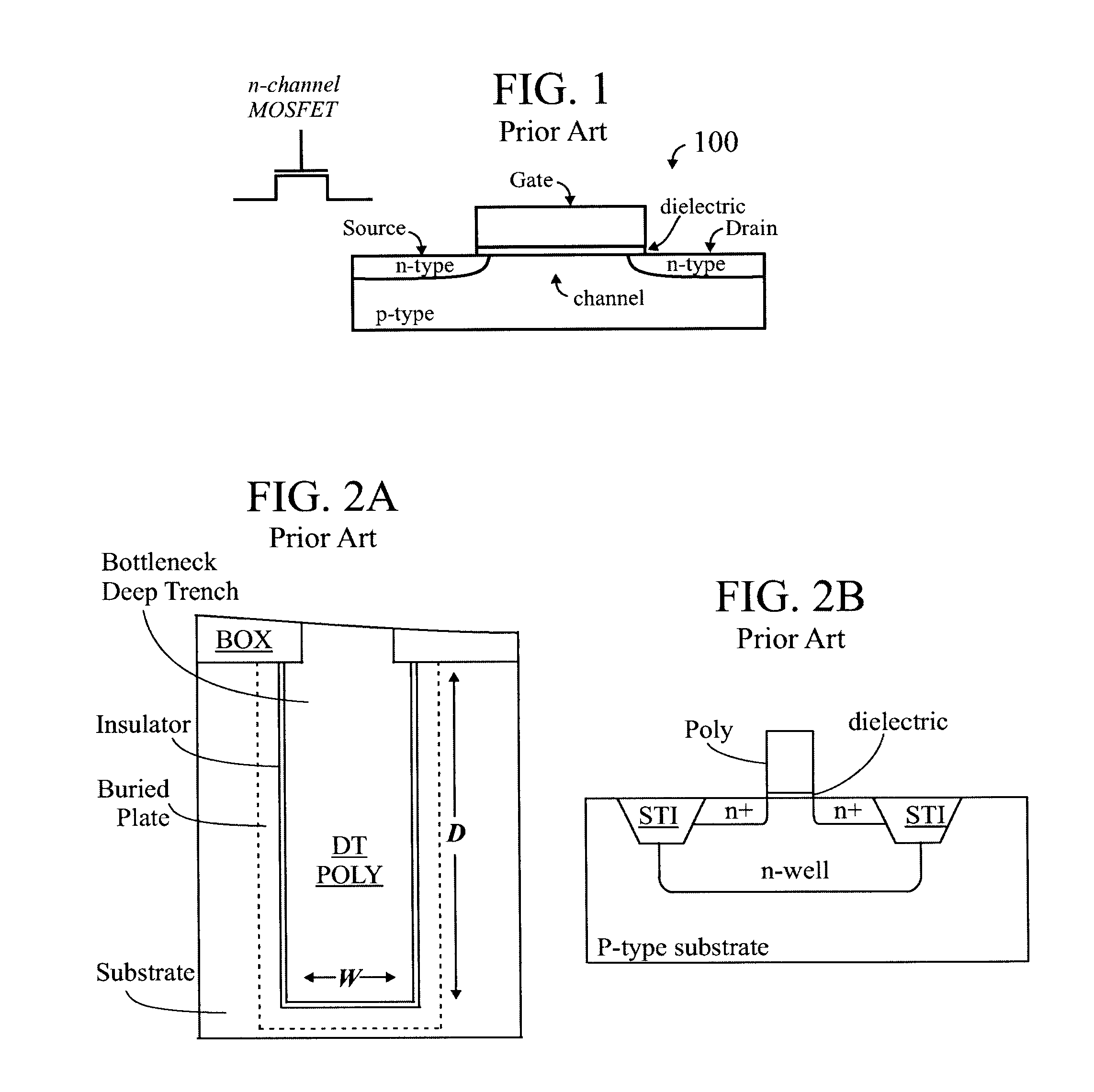

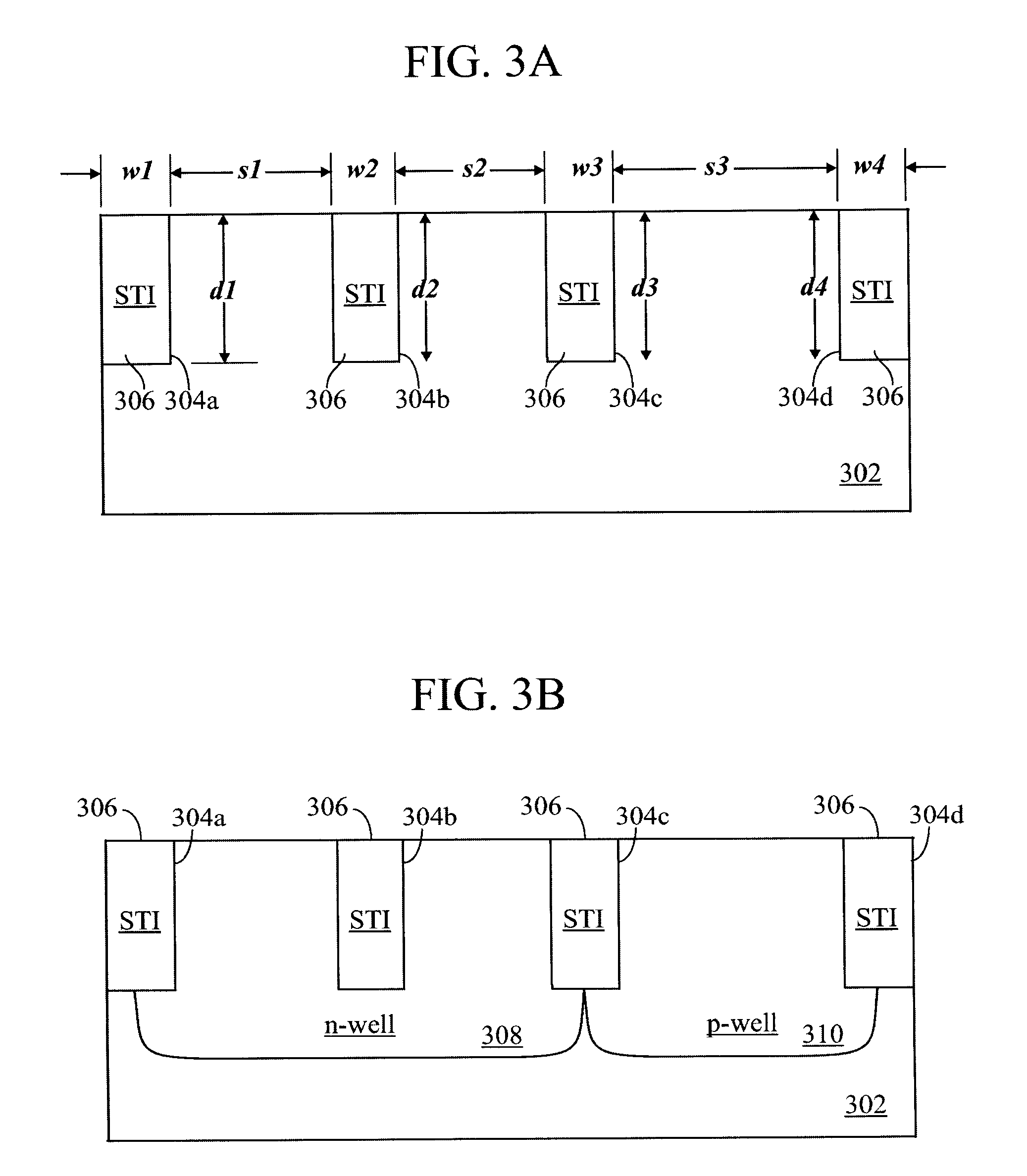

Forming a shallow trench capacitor in conjunction with an FET by forming a plurality of STI trenches; for the FET, implanting a first cell well having a first polarity between a first and a second of the STI trenches; for the capacitor, implanting a second cell well having a second polarity in an area of a third of the STI trenches; removing dielectric material from the third STI trench; forming a gate stack having a first portion located between the first and the second of the STI trenches and a second portion located over and extending into the third trench; and performing a source / drain implant of the same polarity as the second cell well, thereby forming a FET in the first cell well, and a capacitor in the second cell well. The second polarity may be opposite from the first polarity. An additional implant may reduce ESR in the second cell well.

Owner:GLOBALFOUNDRIES US INC

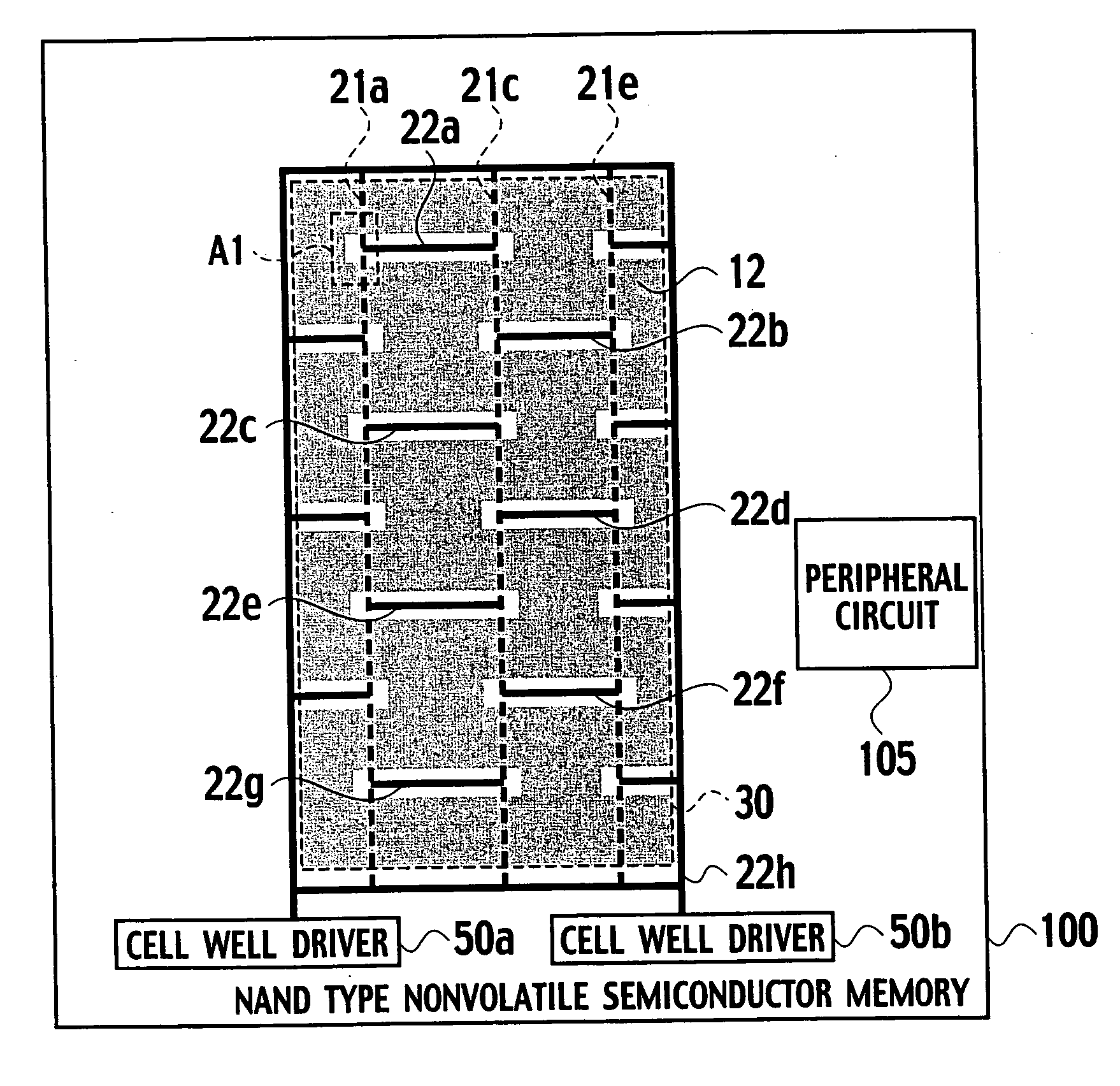

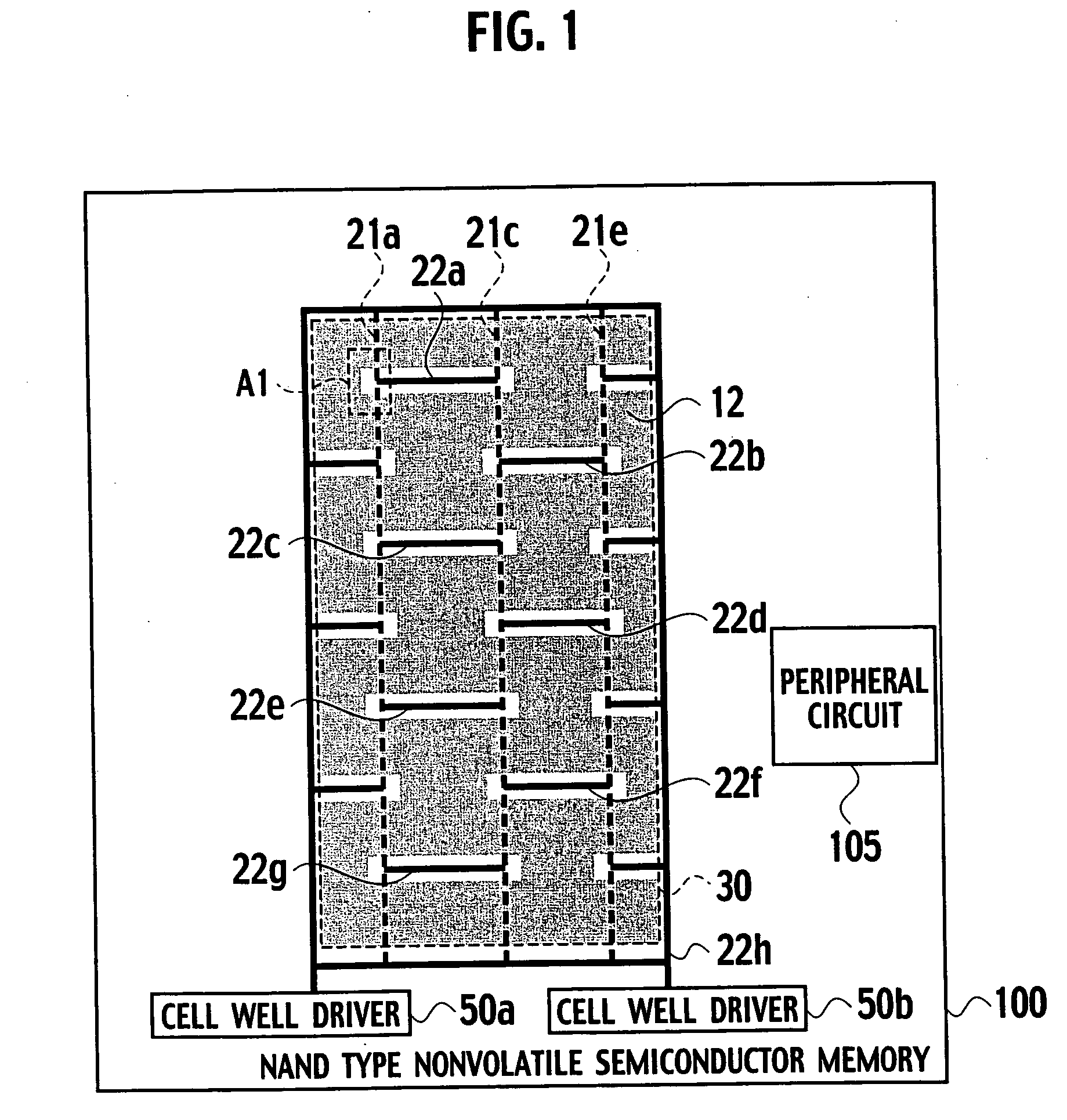

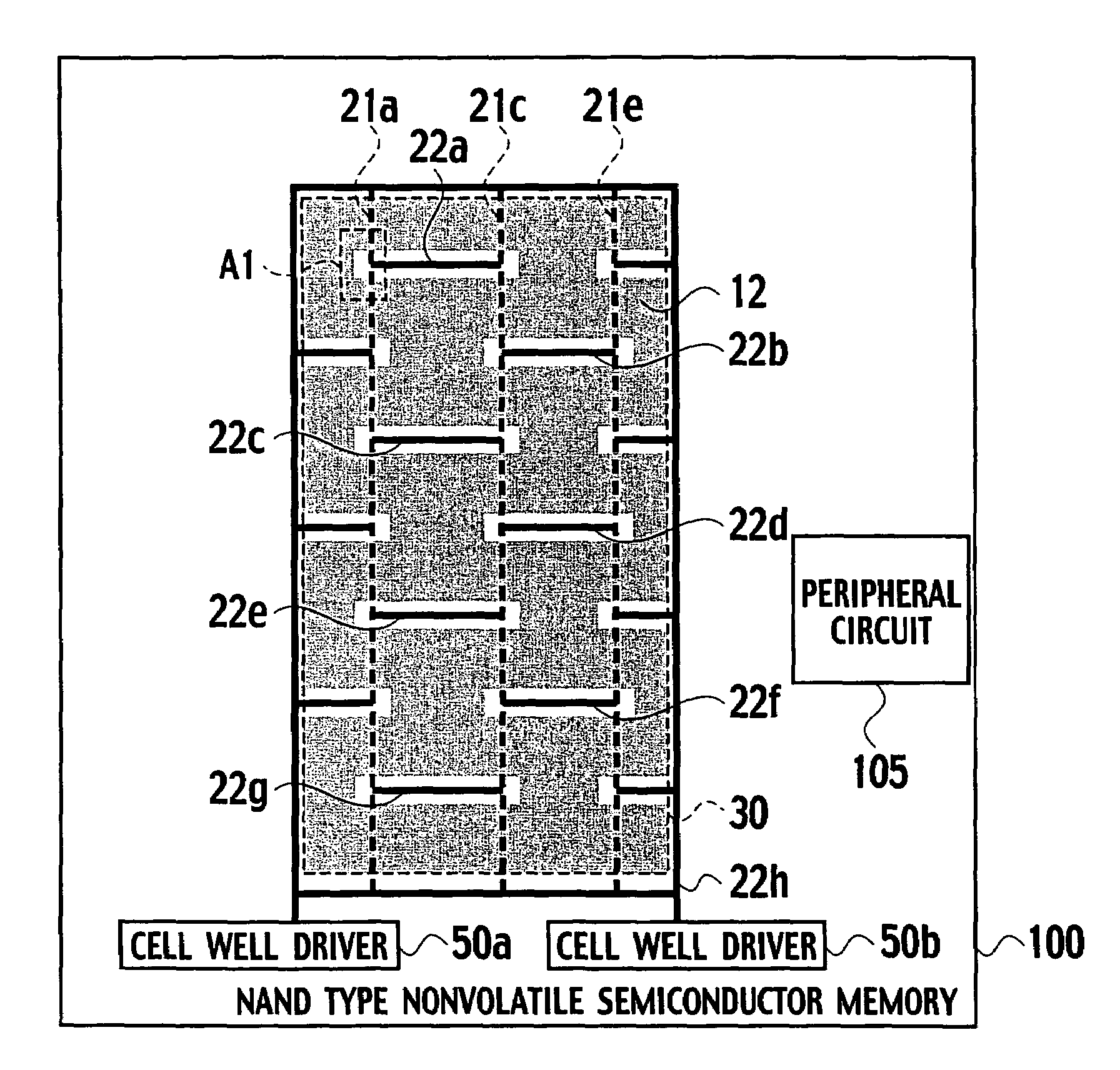

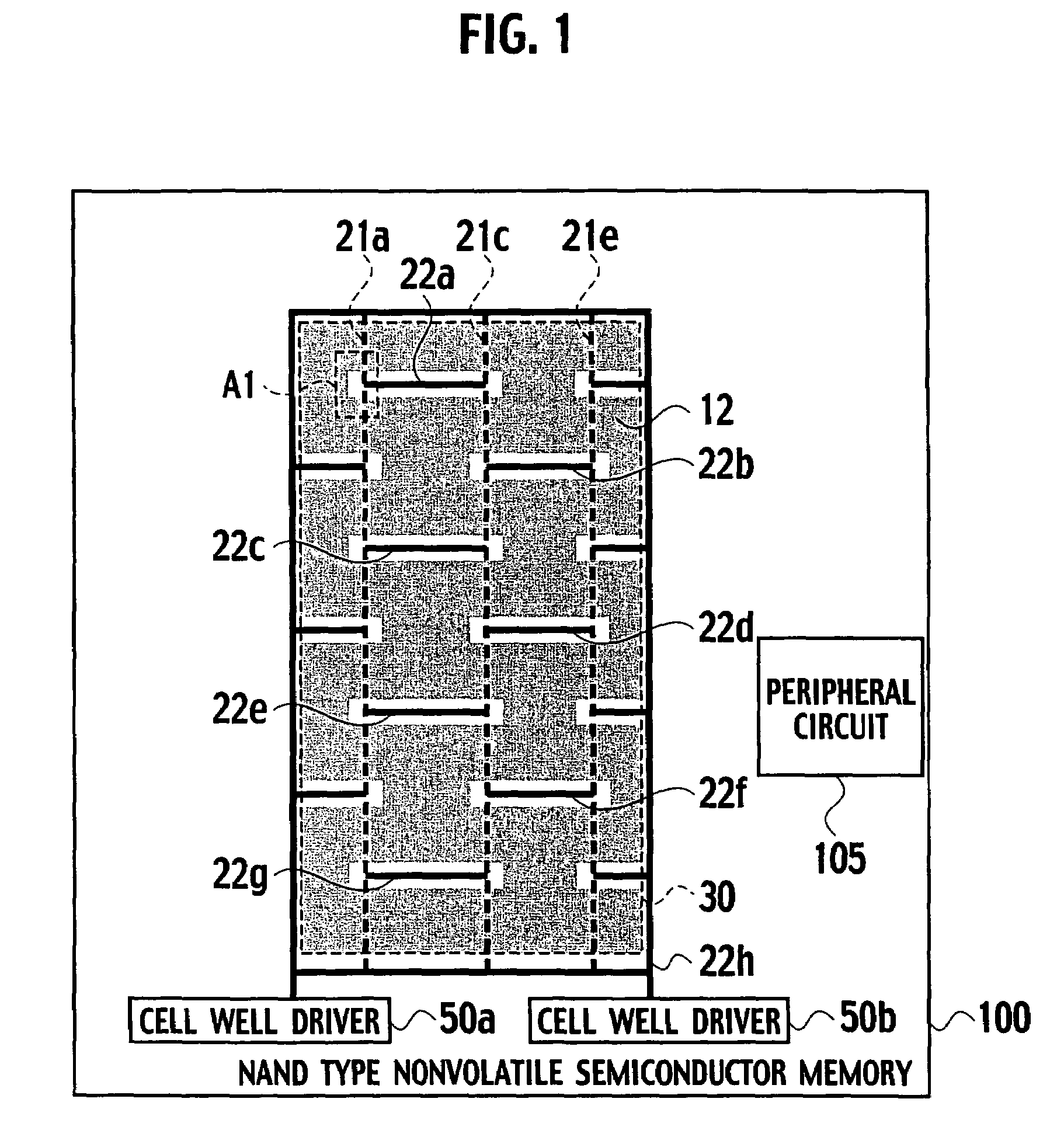

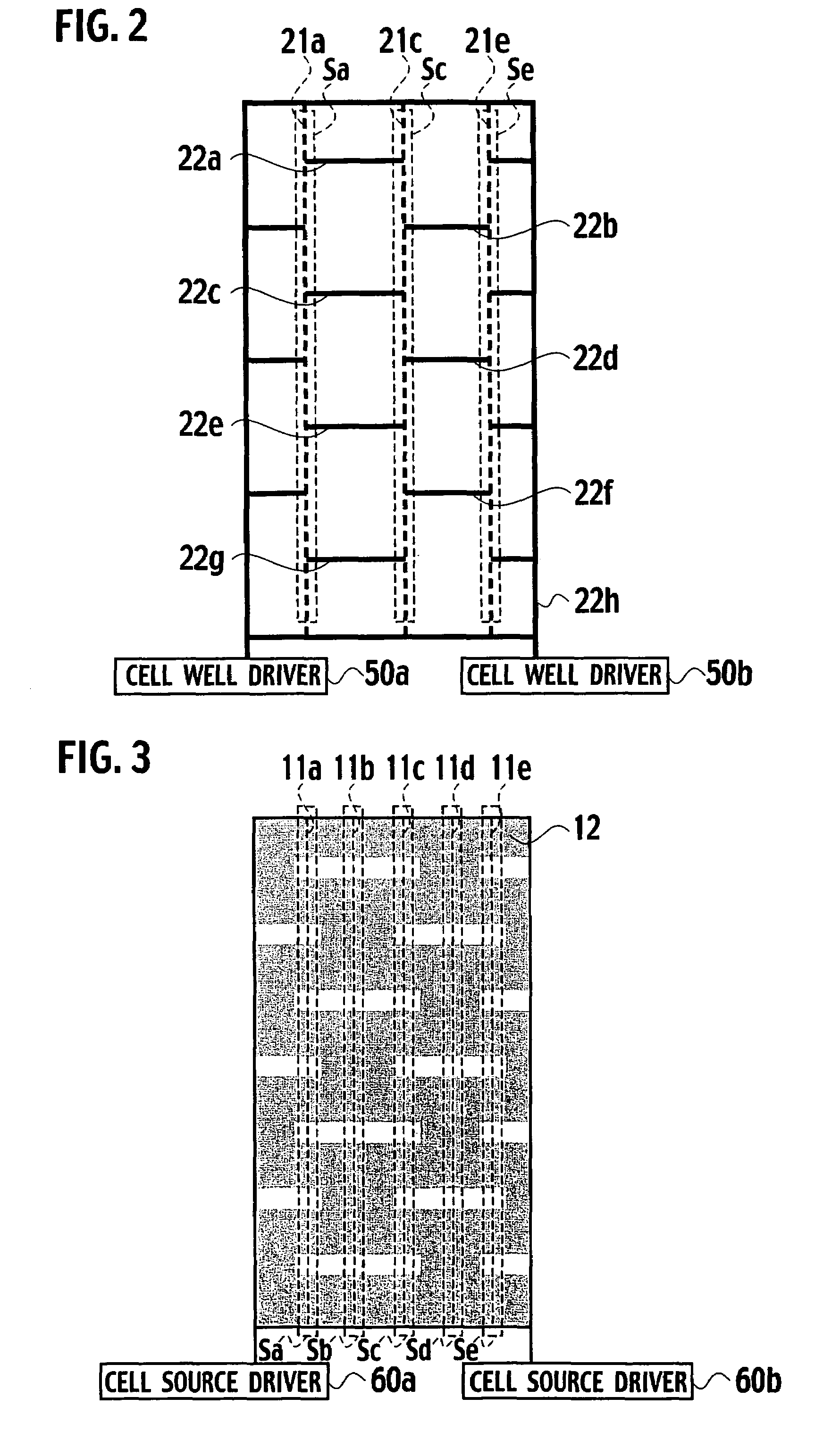

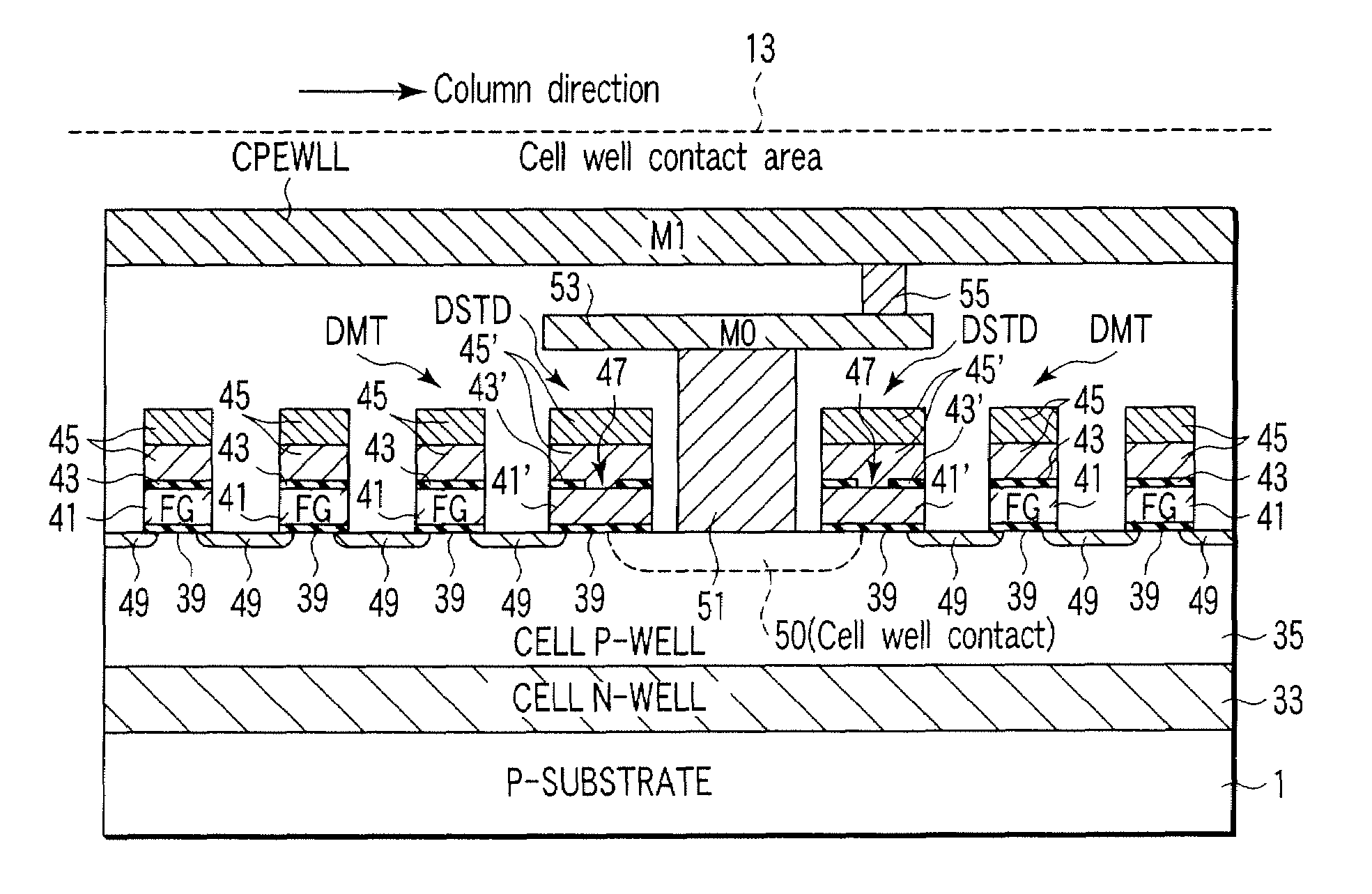

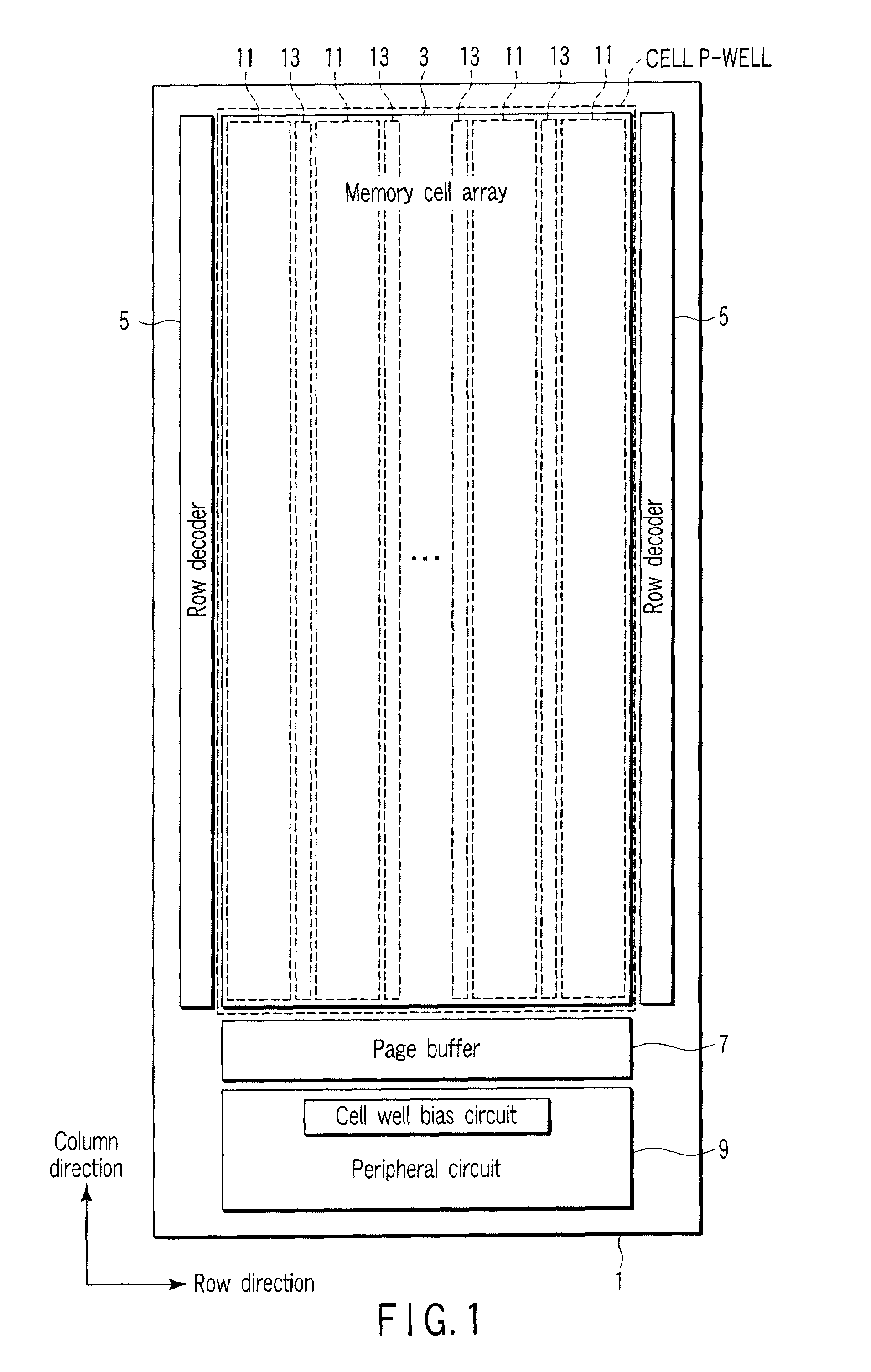

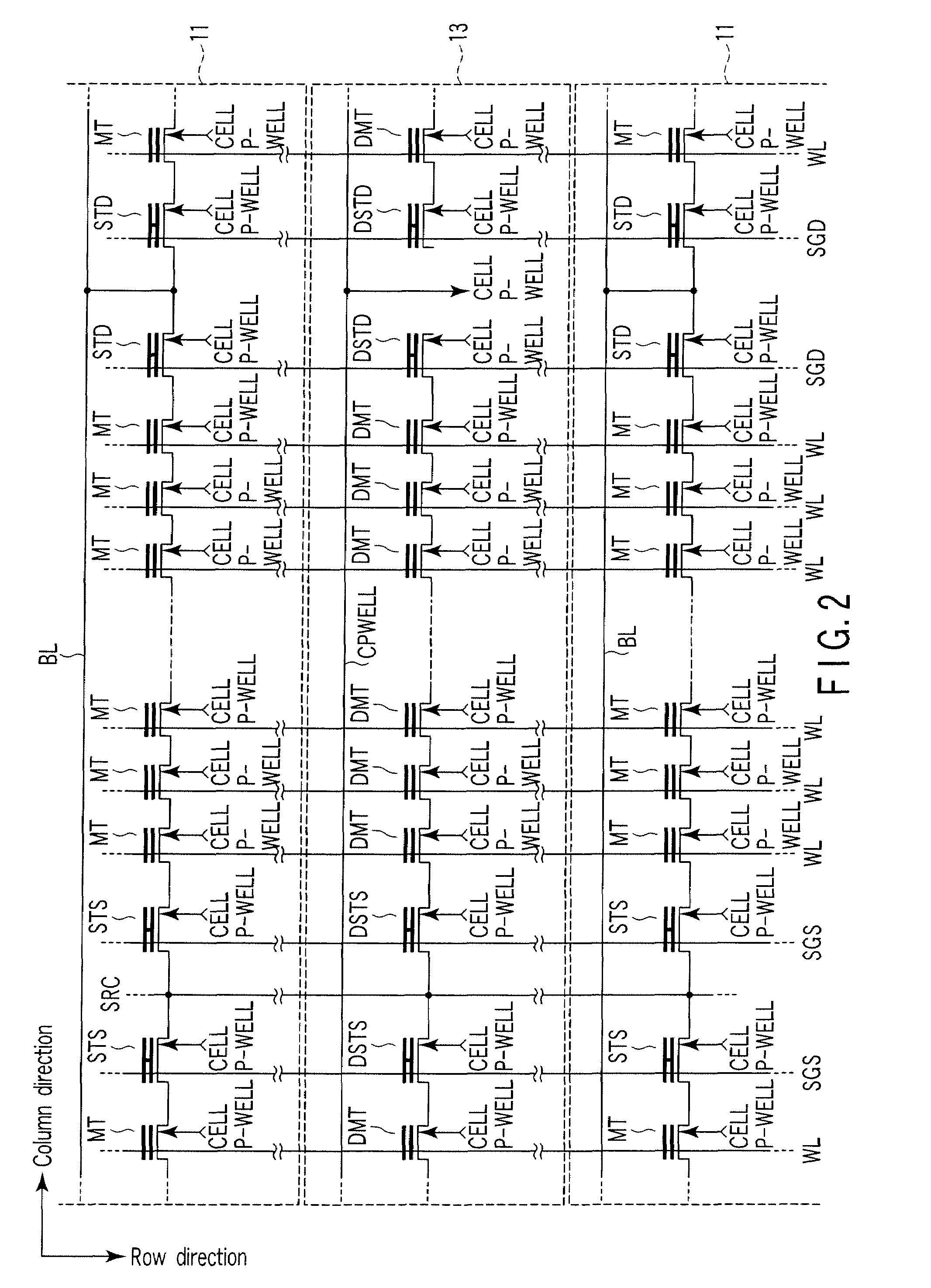

Nonvolatile semiconductor memory having a plurality of interconnect layers

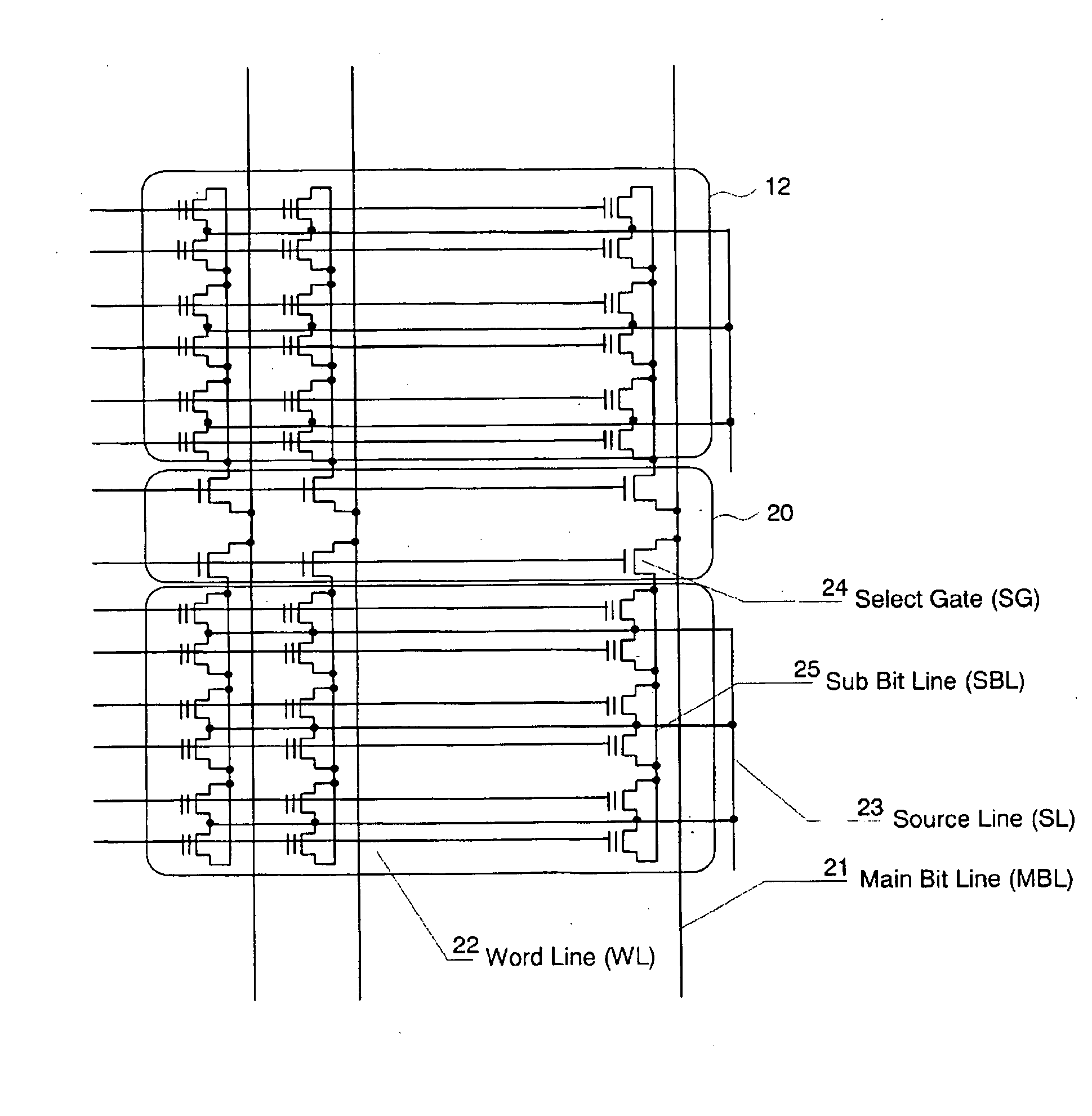

A nonvolatile semiconductor memory includes a memory cell array including horizontally aligned memory cell columns, each including vertically arranged memory cell transistors and select transistors selecting the memory cell transistors; first cell well lines connecting well regions in which the memory cell columns are formed; second cell well lines arranged in an interconnect layer above the first cell well lines and connecting the first cell well lines to one another electrically; and a cell source line connecting source terminals of the select transistors in each memory cell column.

Owner:KIOXIA CORP

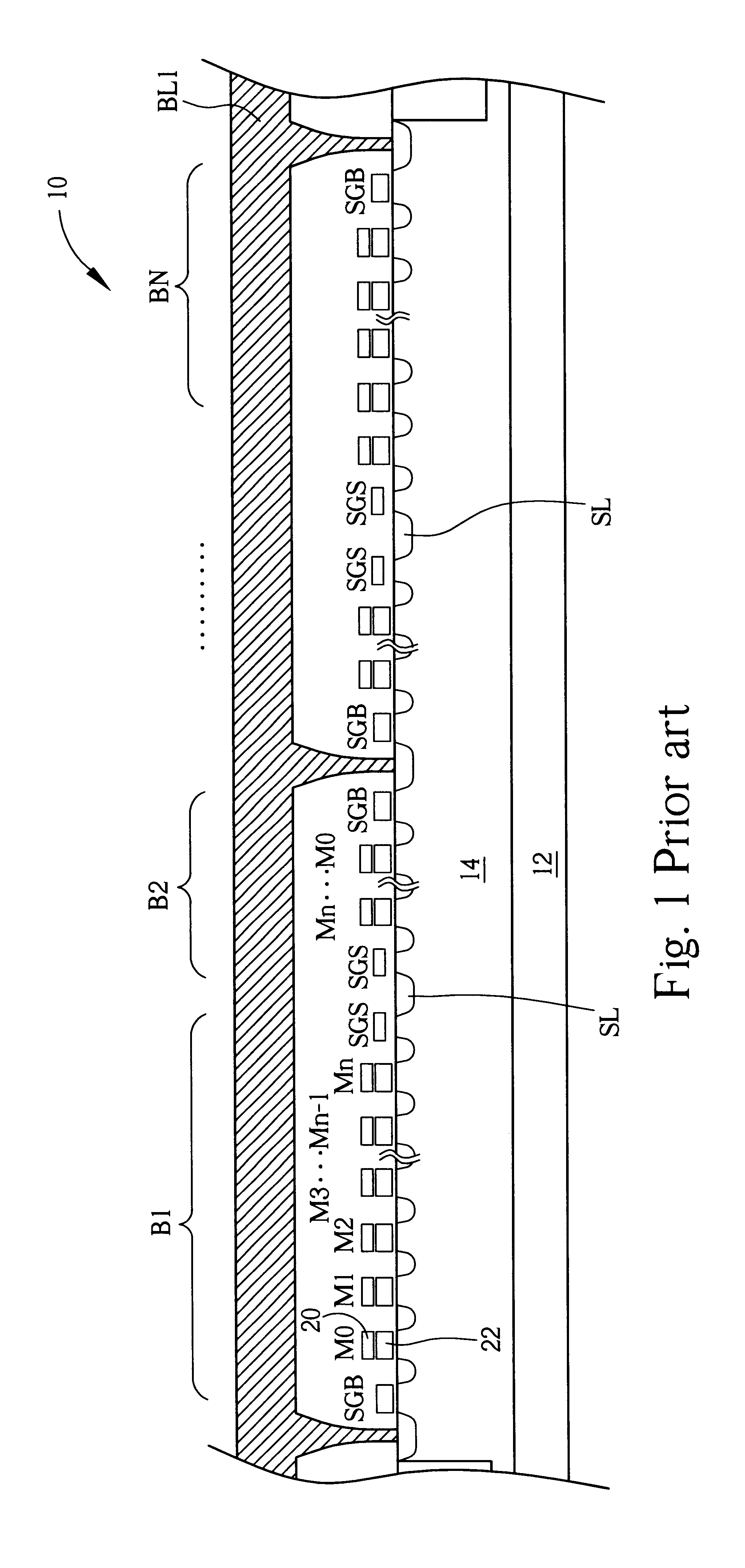

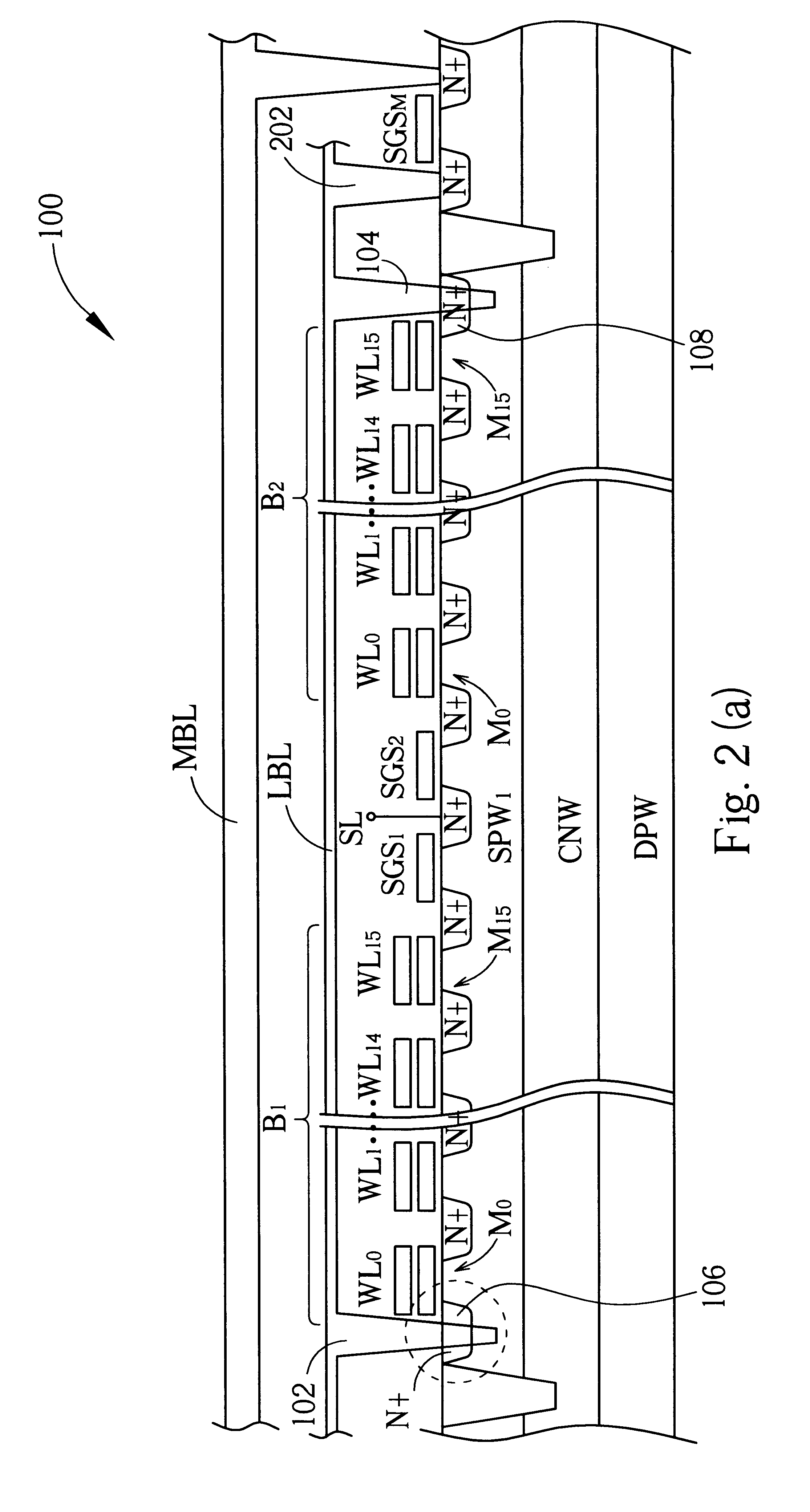

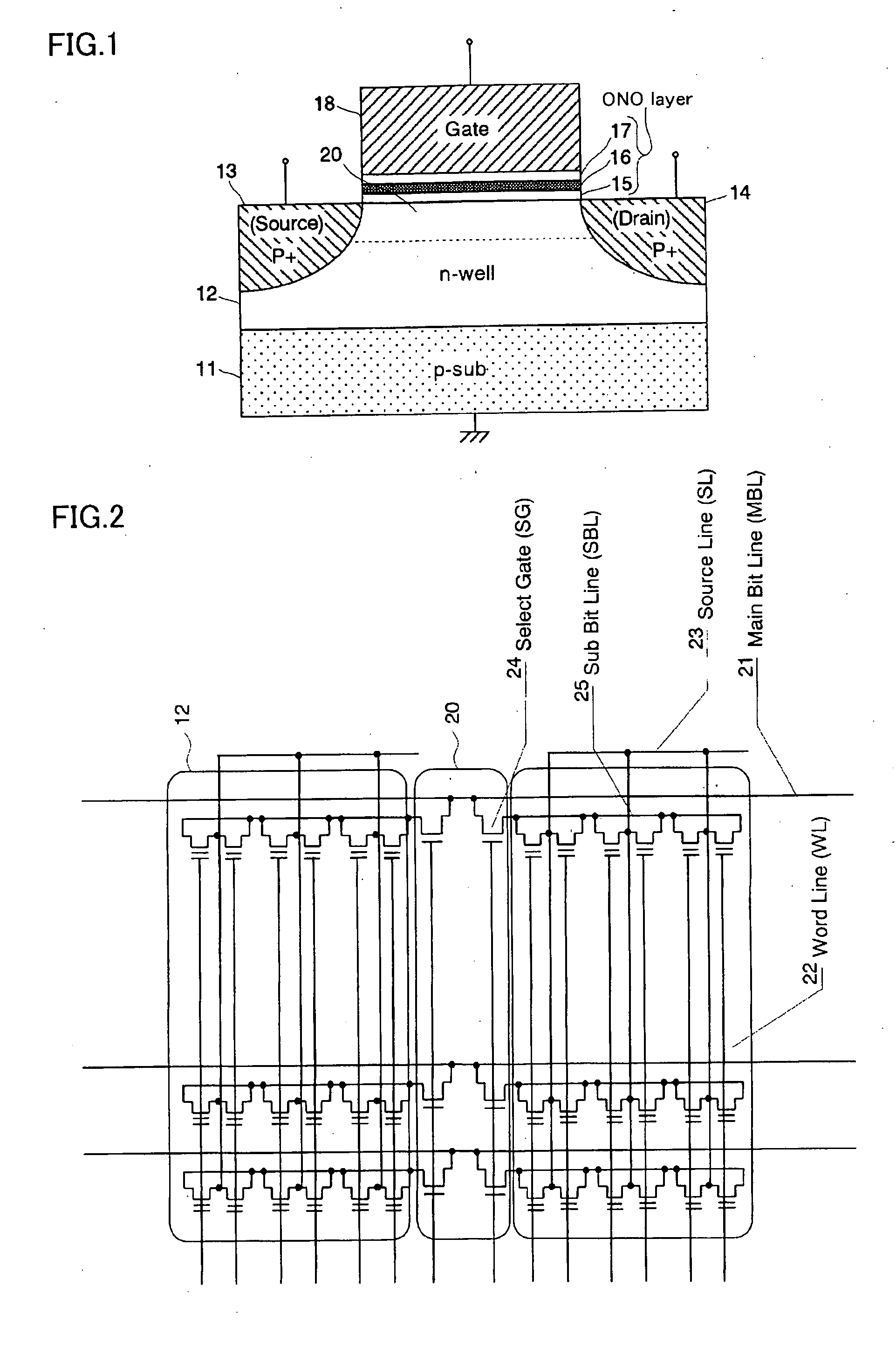

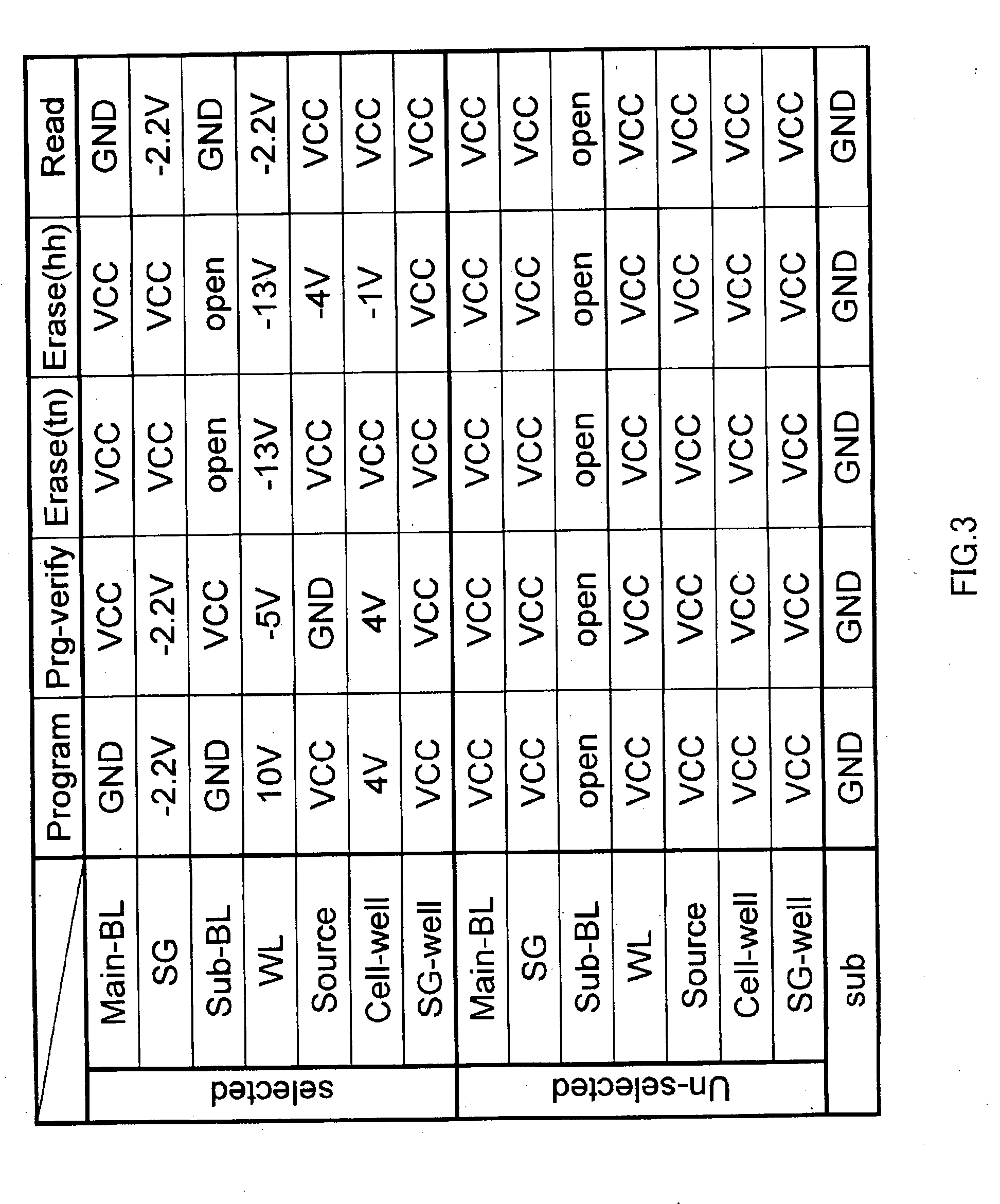

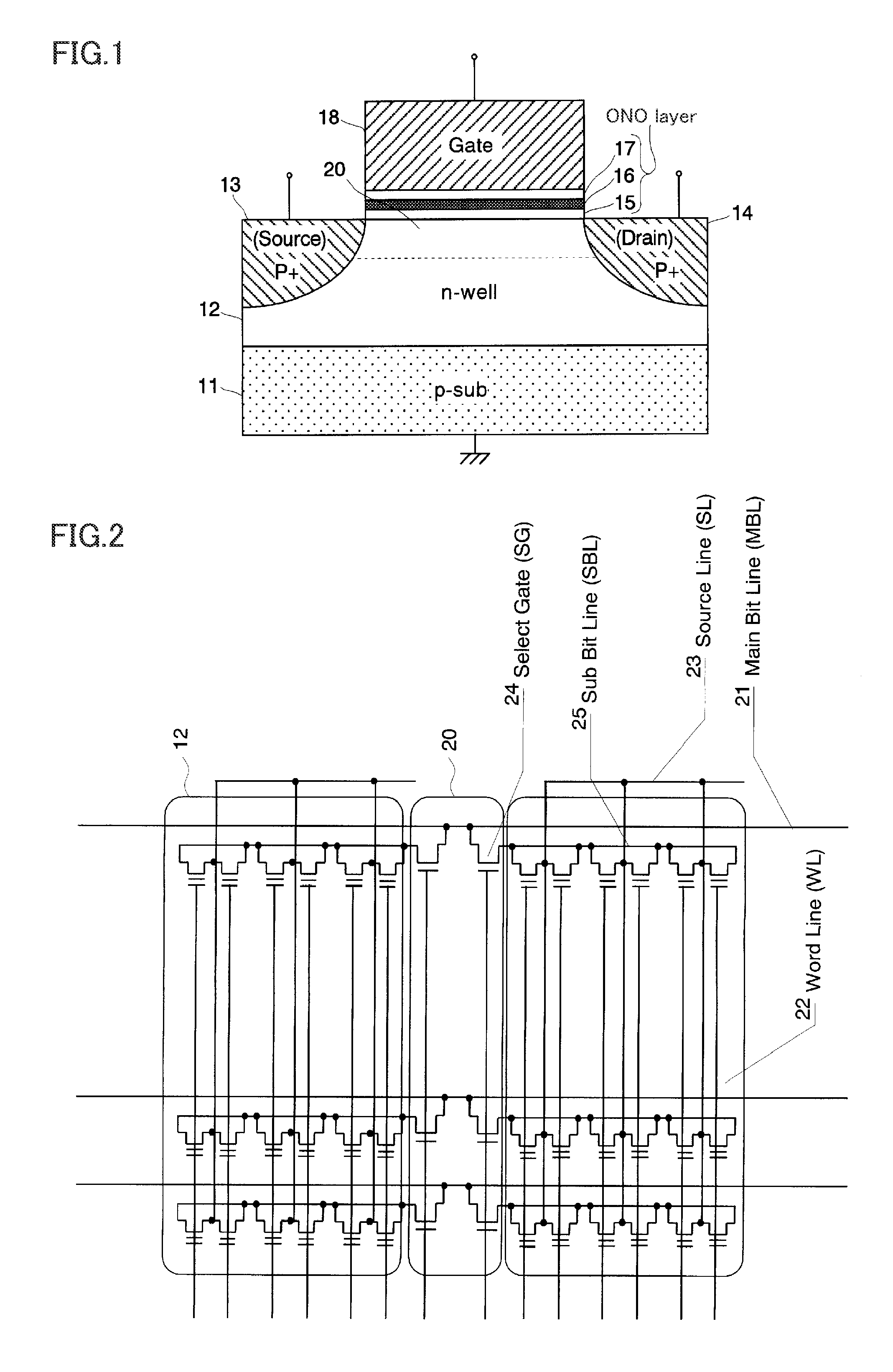

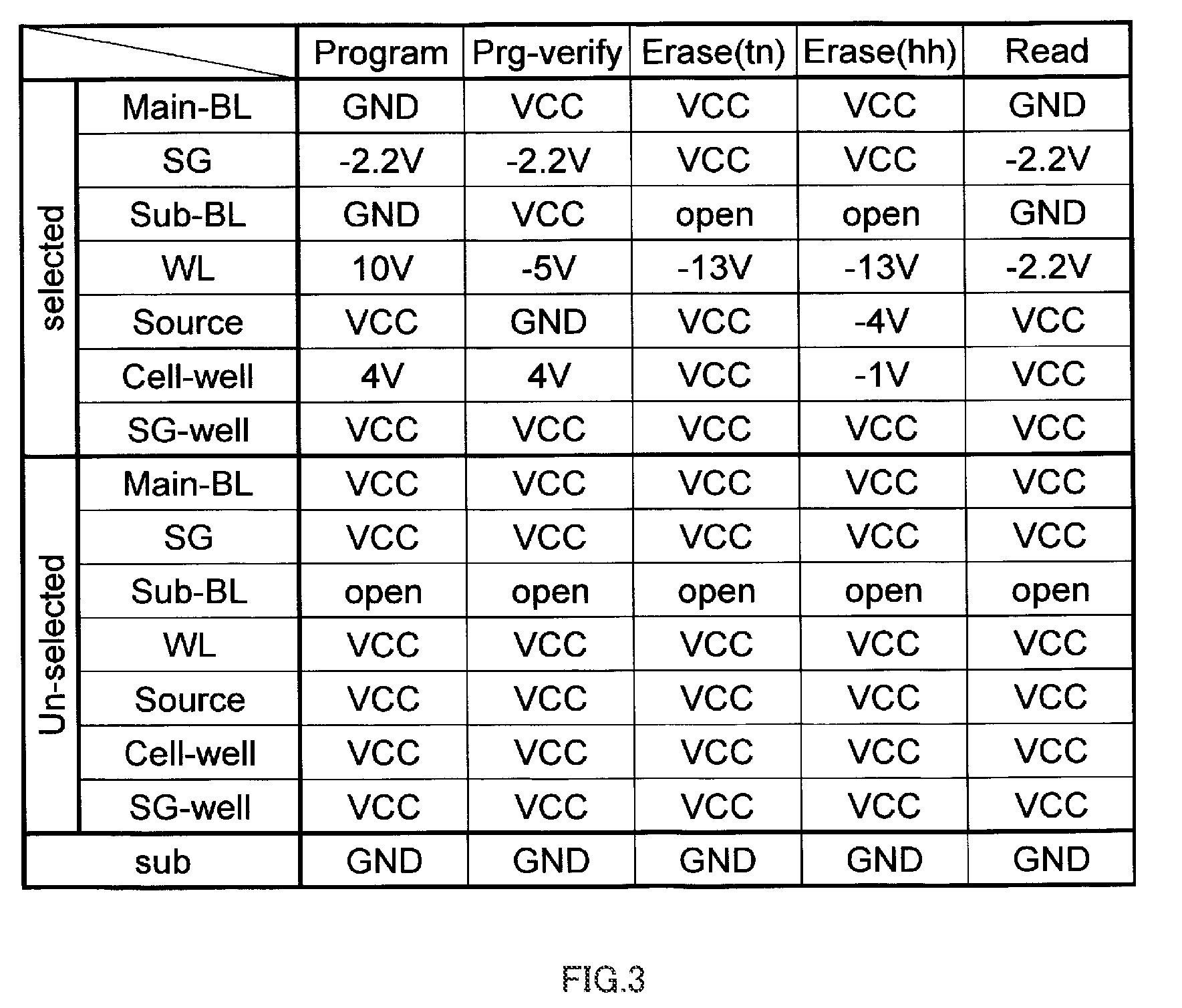

Bi-directional Fowler-Nordheim tunneling flash memory

A low-voltage nonvolatile memory array includes a cell well of a first conductivity type formed in a substrate; columns of buried bit lines of a second conductivity type formed within the cell well, wherein columns of the buried bit lines are isolated from each other and each is further divided into of sub-bit line segments with deeply doped source wells of the first conductivity type connected to the cell well; a plurality of memory cell blocks serially arranged over one of the columns of buried bit lines, wherein a memory cell block corresponds to a sub-bit line segment, and each memory cell block includes at least one memory transistor having a stacked gate, source, and drain; and a local bit line overlying the memory cell blocks and electrically connected to the drain of the memory transistor via a contact plug short-circuiting the drain and the subjacent buried bit line.

Owner:POWERCHIP SEMICON CORP

Calcium sulphate composite bone renovation material, preparation method and application thereof

InactiveCN101269241AHigh activityGood physical and chemical propertiesBone implantOsteoblastBiocompatibility Testing

The invention belongs to the tissue engineering field, in particular relates to a calcium sulfate composite material and a preparation method and purpose thereof, aiming at providing a calcium sulfate composite material which can be used as bone substitute material. The calcium sulfate composite material is mainly composed of calcium sulfate and a strontium-containing compound, wherein, the mol weight of the strontium accounts for 0.01-0.5 percent of the total mol weight of calcium and strontium. The calcium sulfate composite material creatively compounds the strontium-containing compound into the medical calcium sulfate so as to increase the activity of the material, causes the material to be able to slowly release the osteogenesis promoting element strontium partially during repairing process at the bone defect site. In addition, experiences prove that the calcium sulfate composite material of the invention has fine physical and chemical properties and biocompatibility, can be attached by osteogenesis cells well, and can well repair the bond defect, and is an excellent bone substitute material. The preparation method of the invention is simple and reliable, and has bright application prospect.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

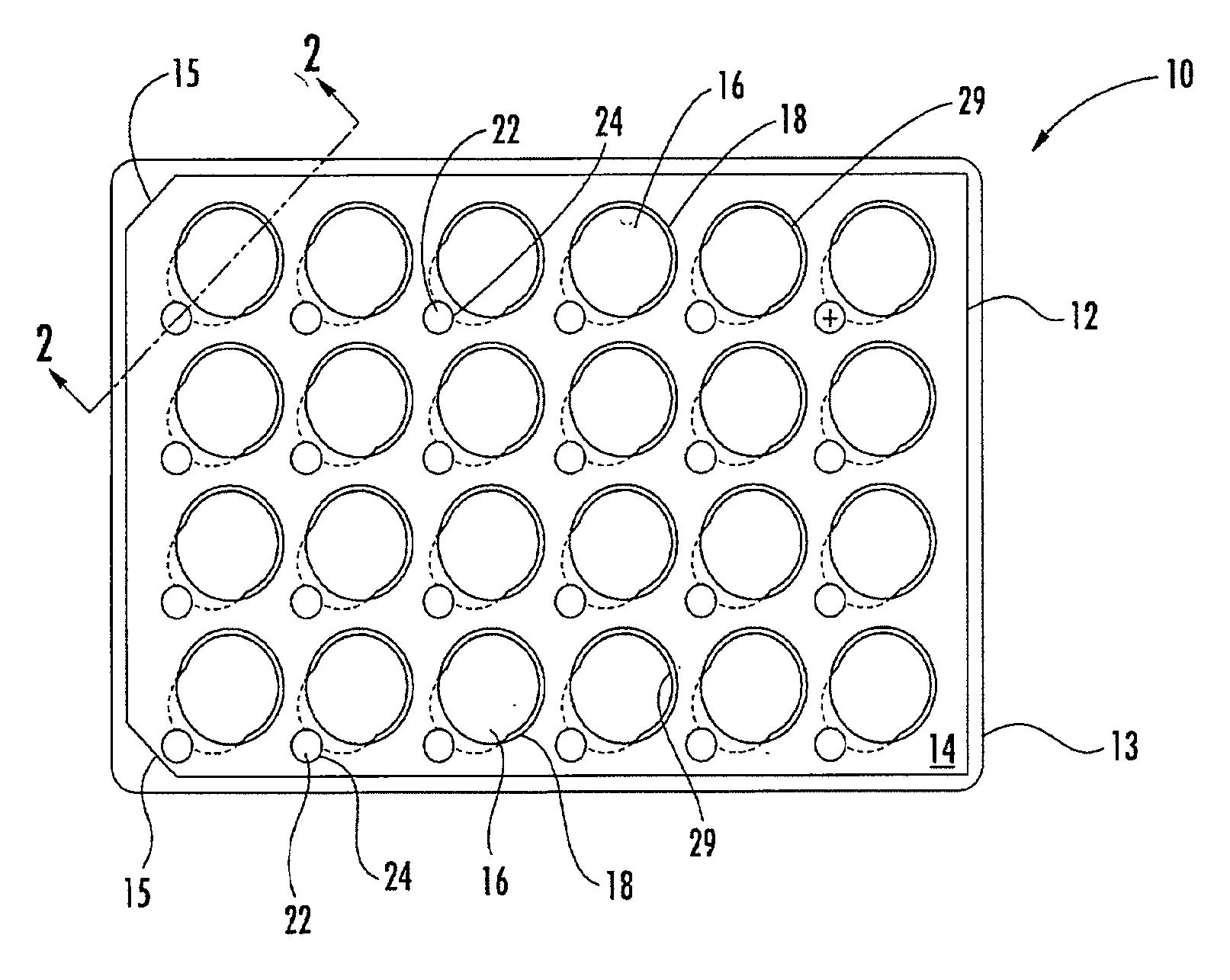

Cell tray

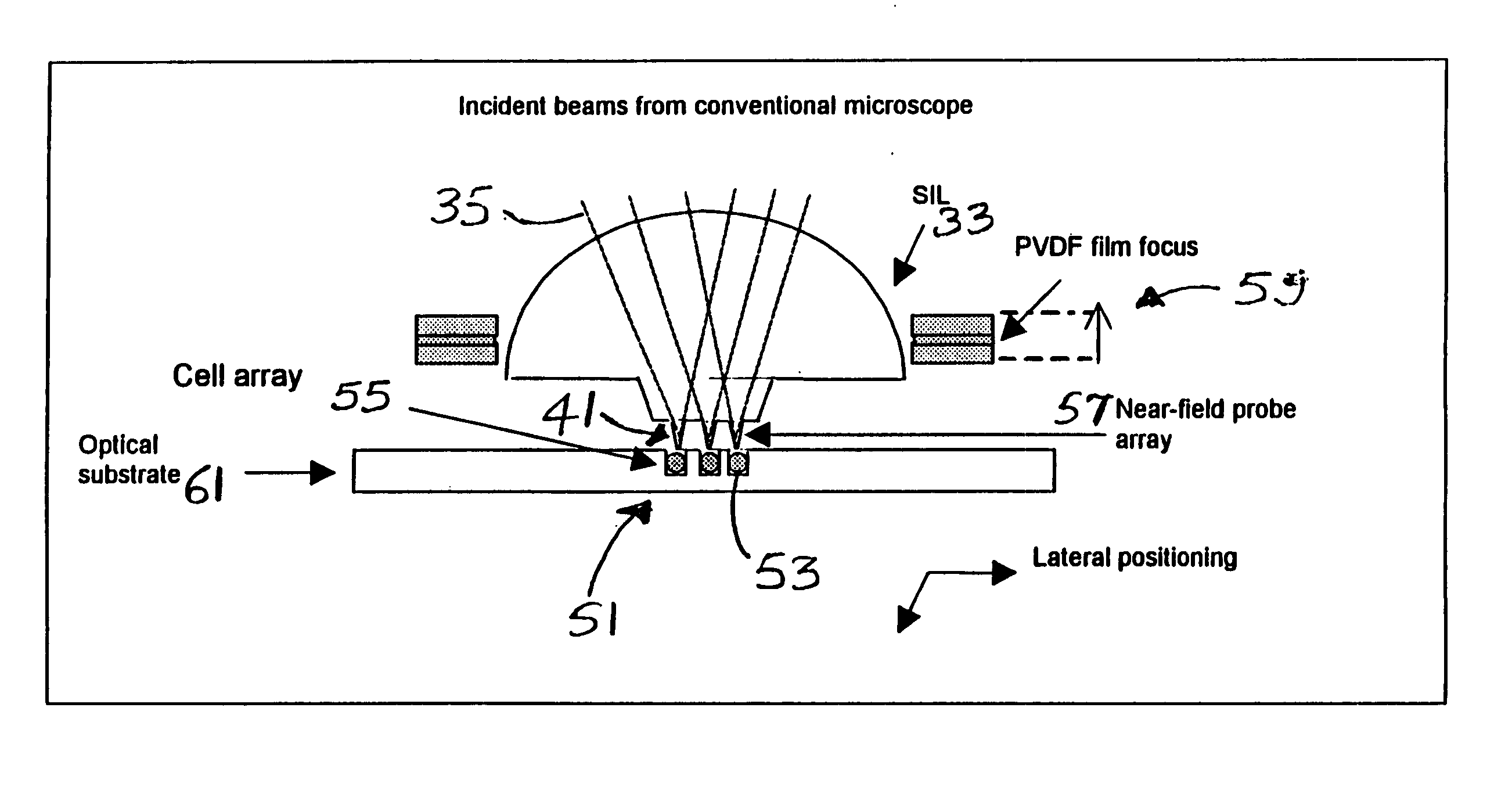

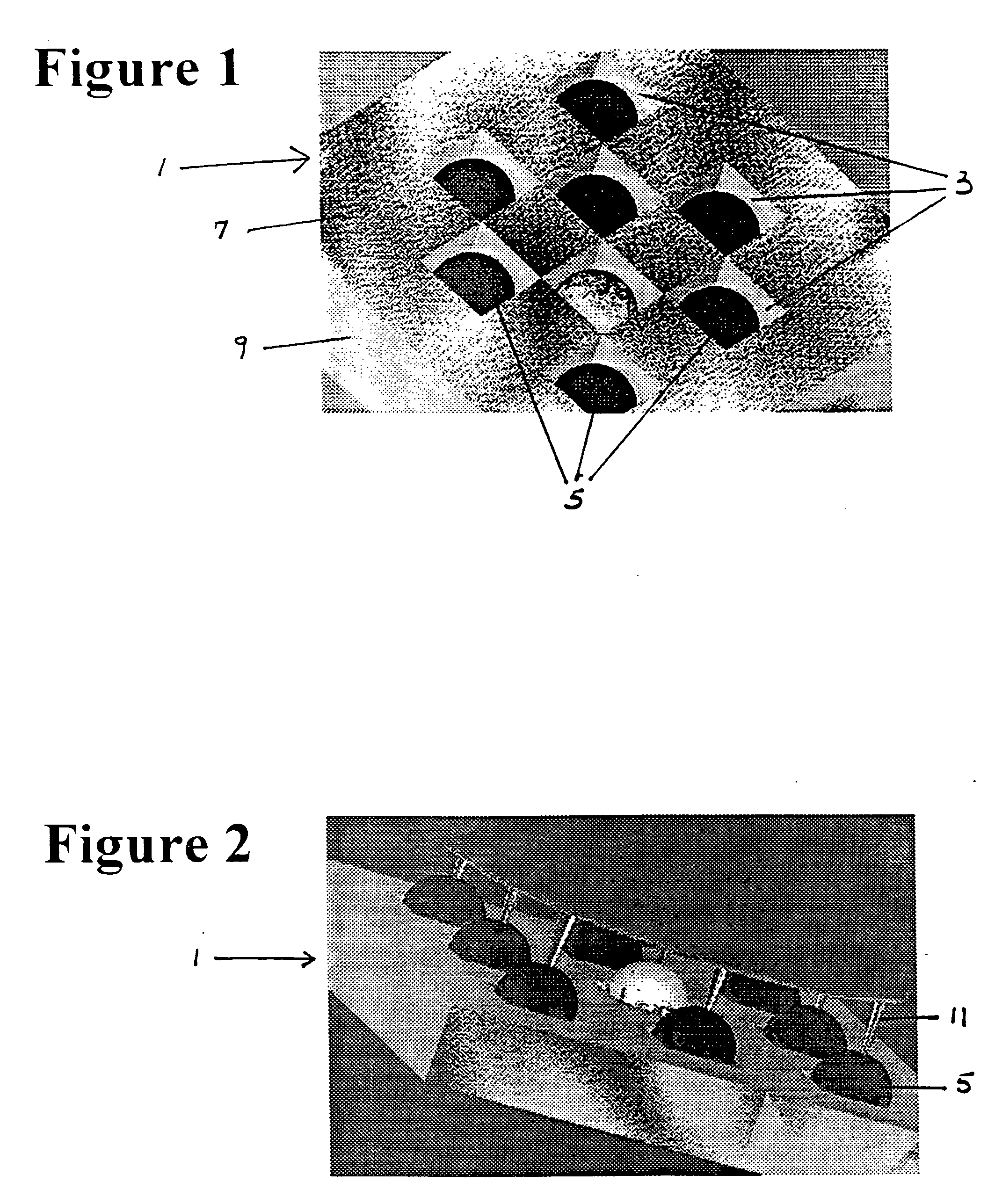

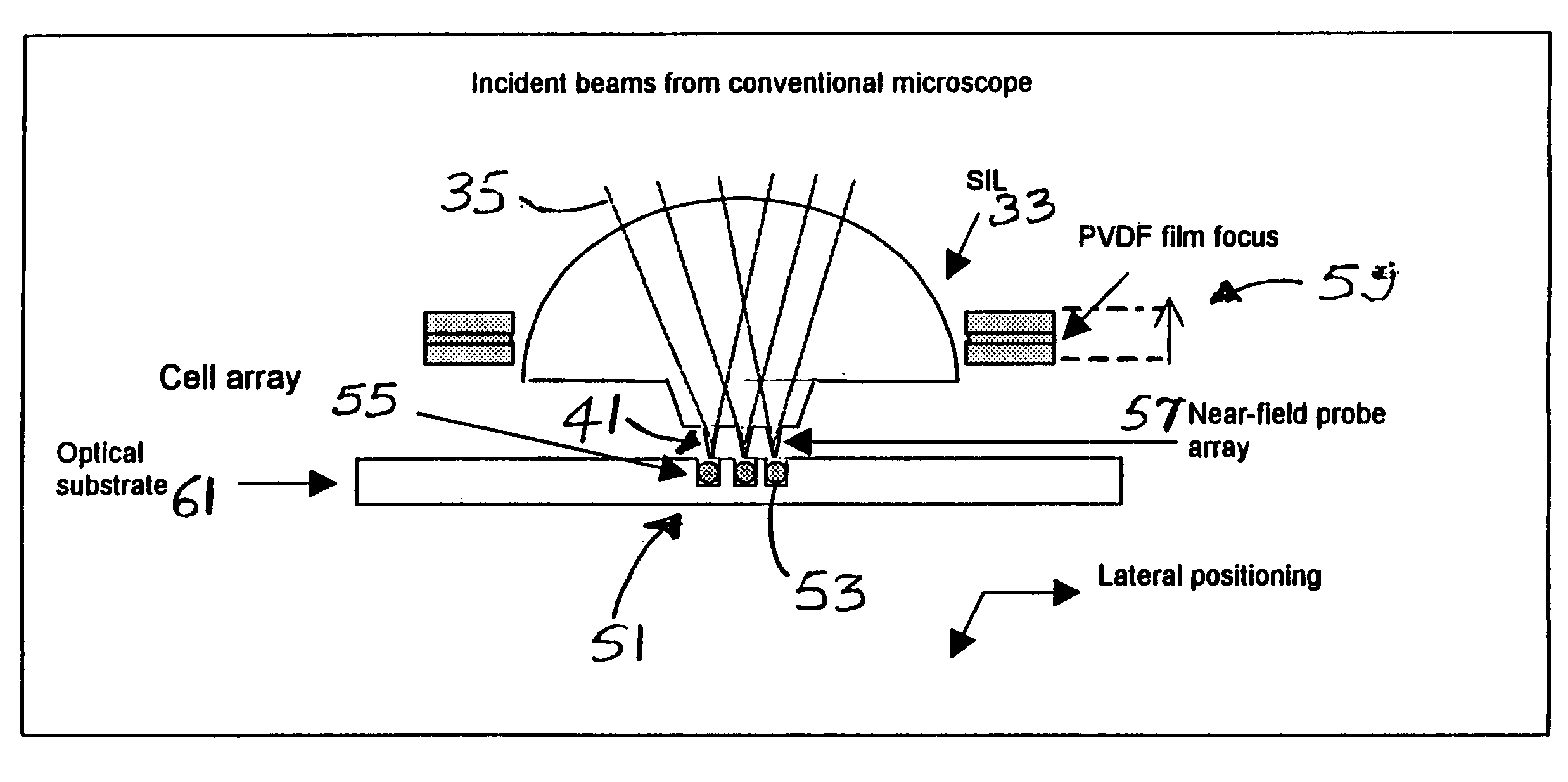

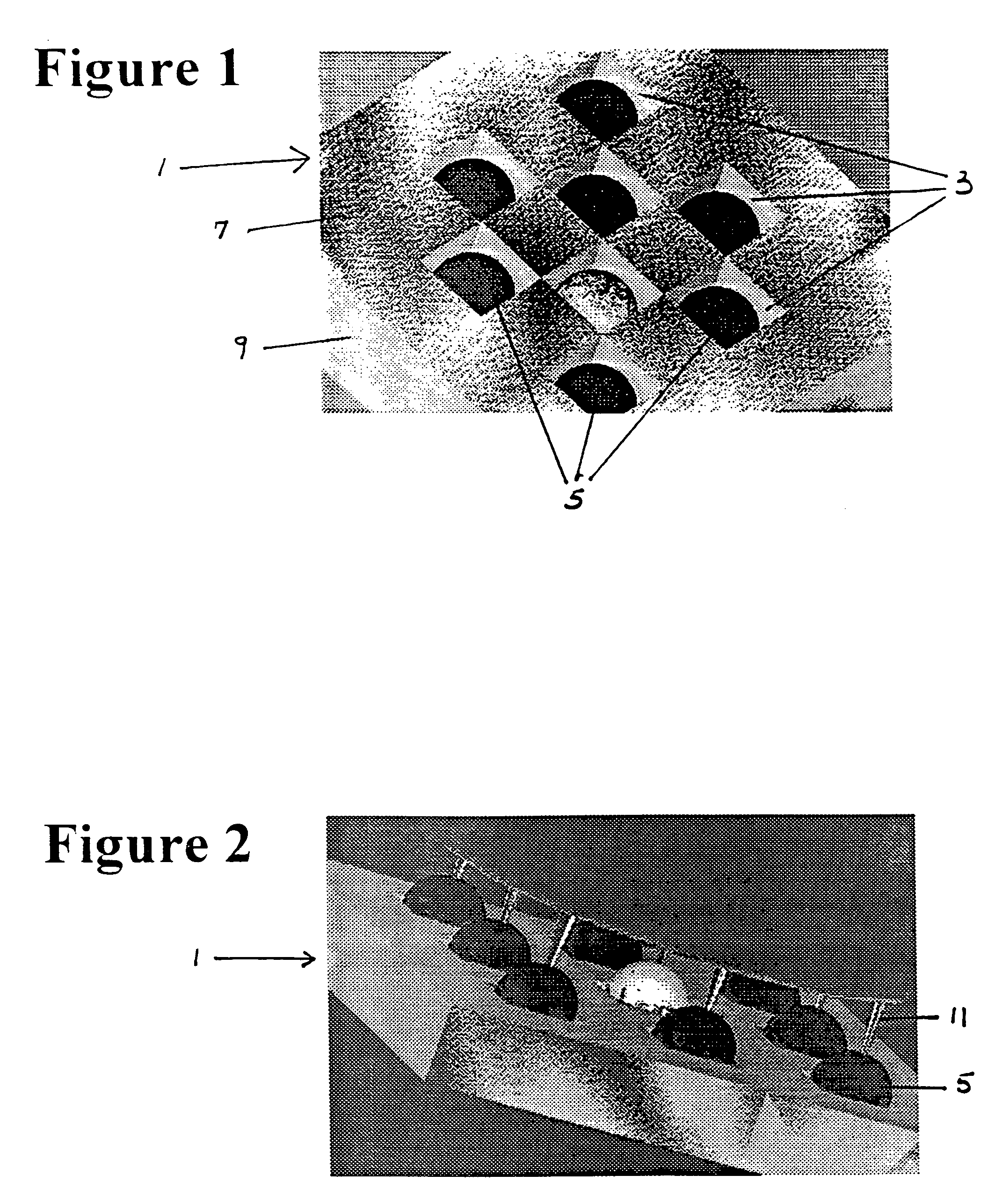

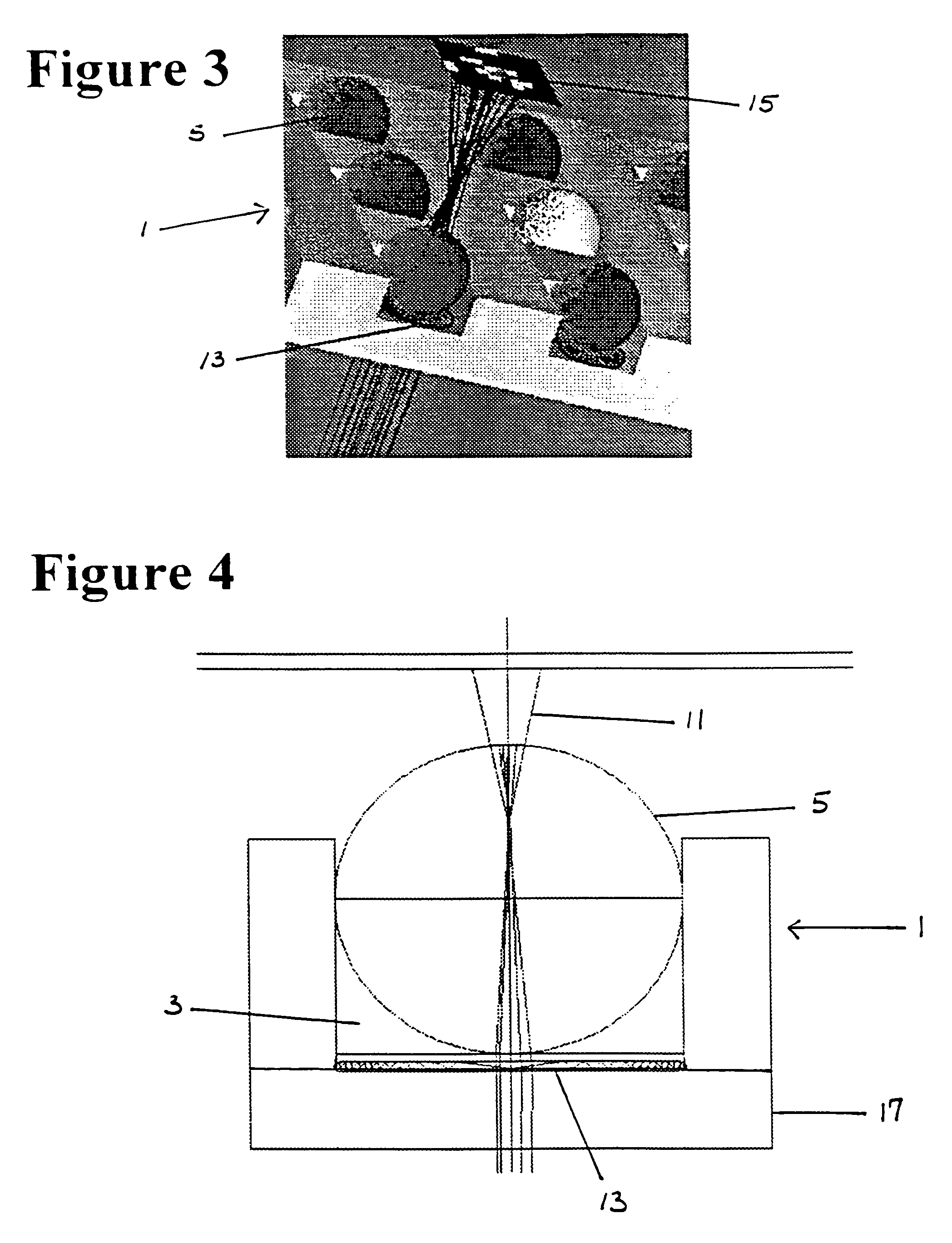

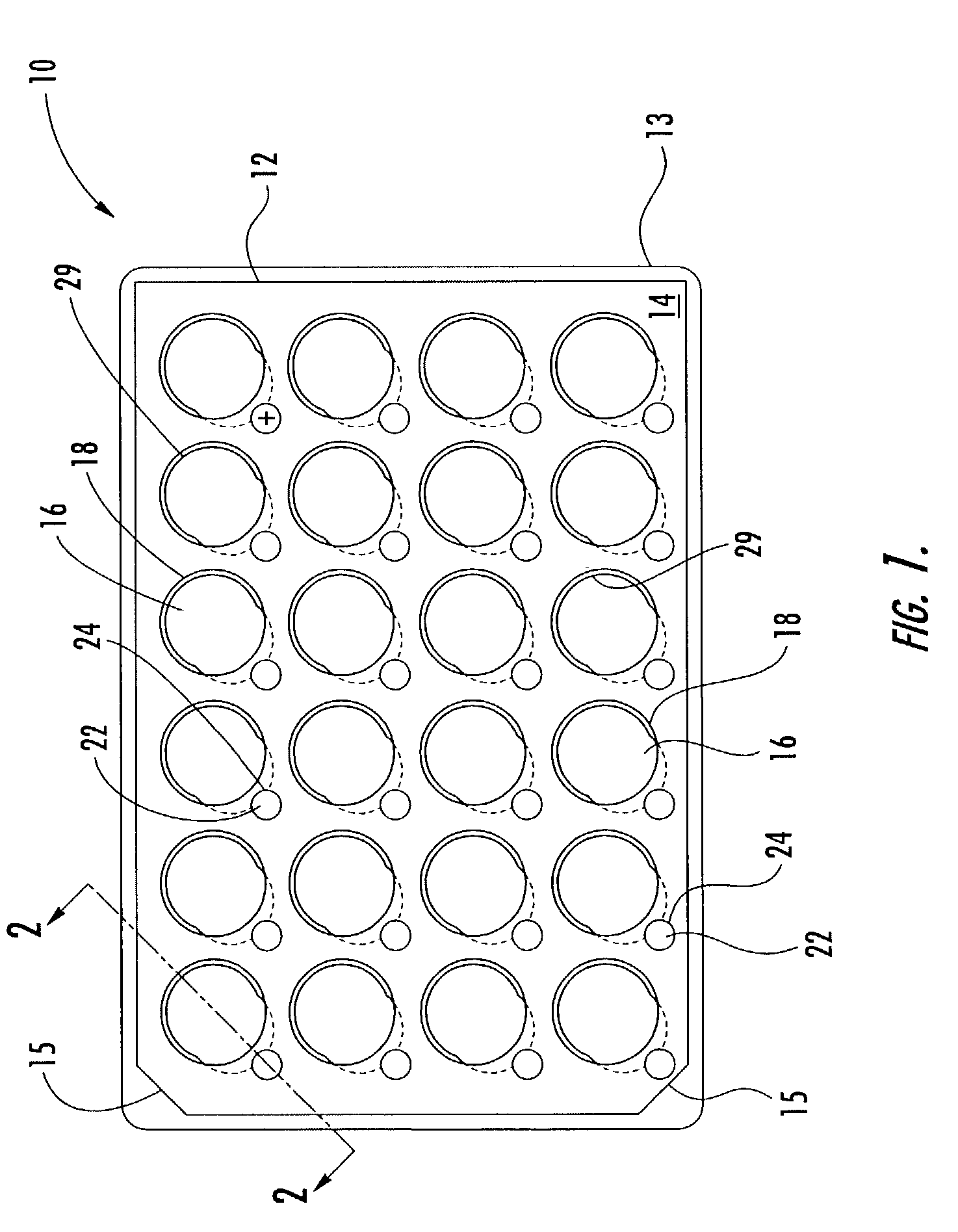

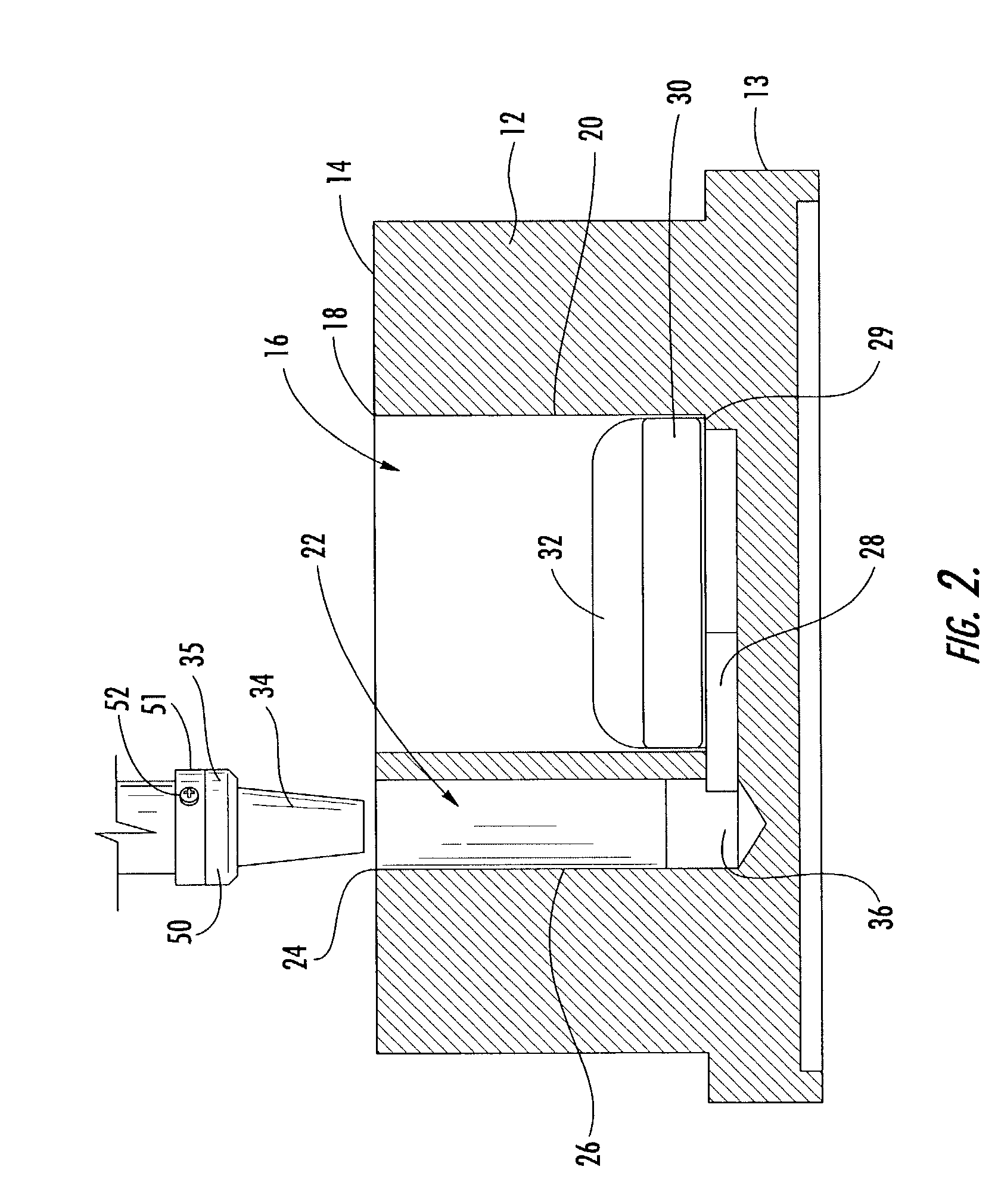

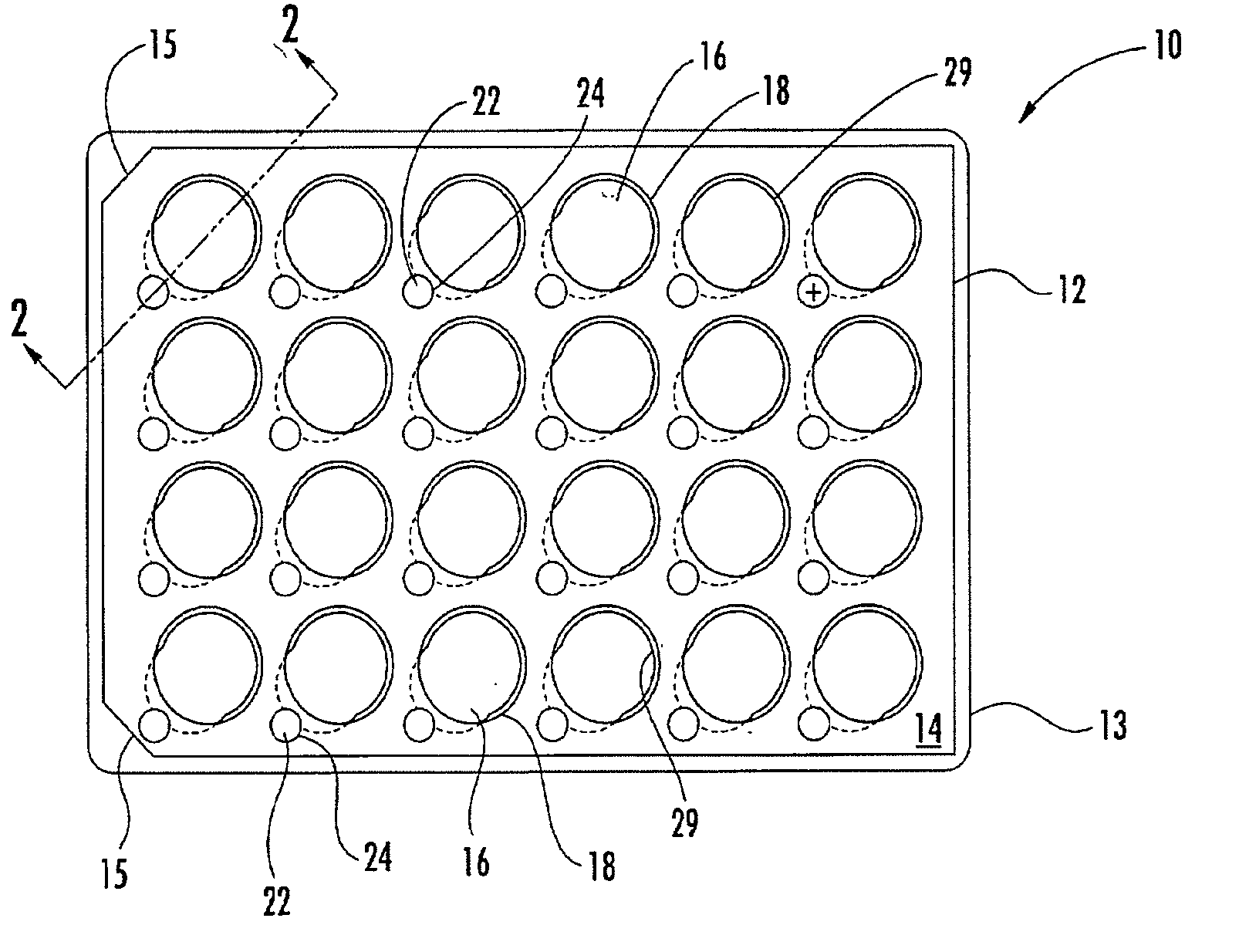

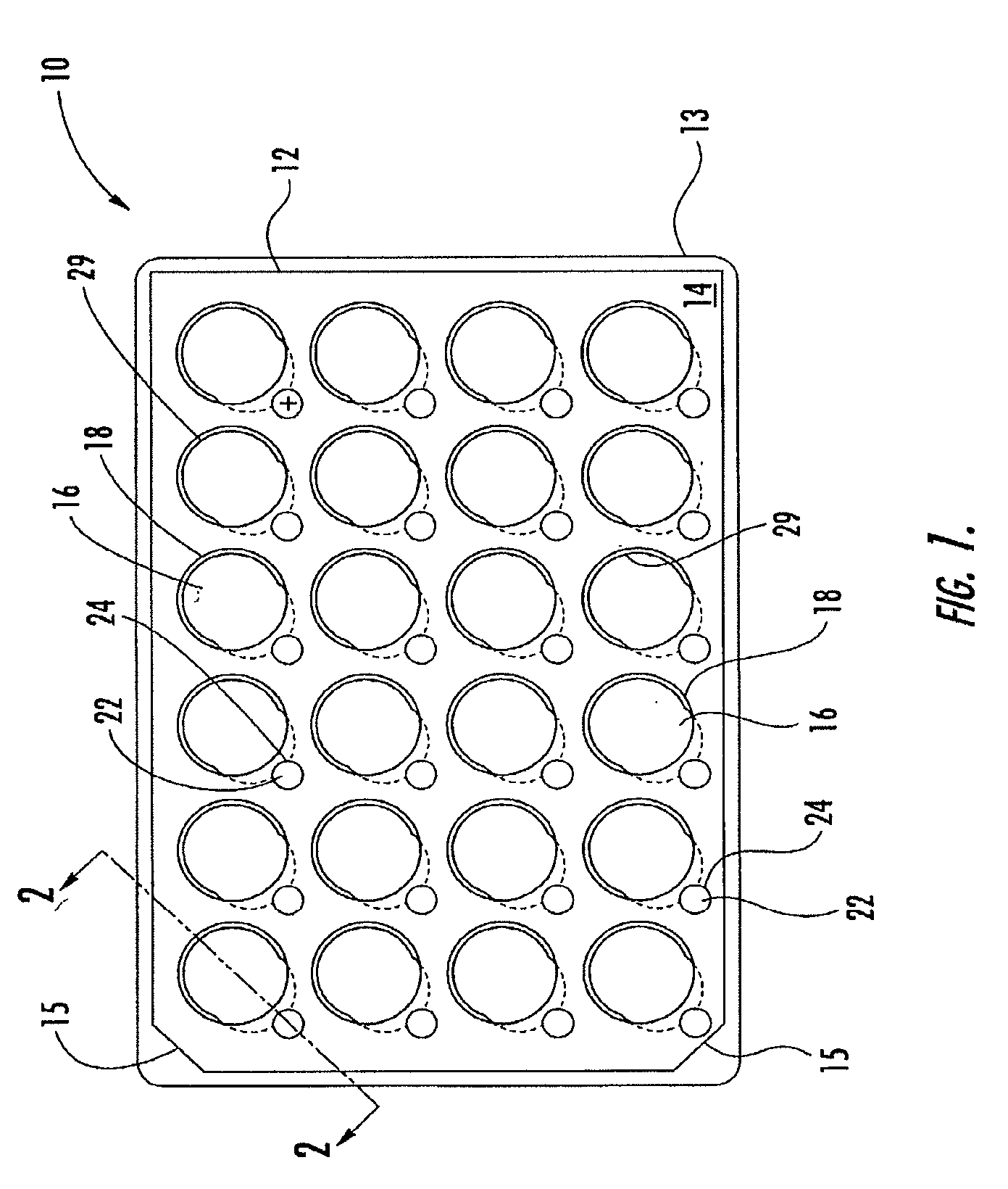

ActiveUS20060119843A1Mass productionIncrease pointsRadiation pyrometrySpectrum investigationMicroscope slideMulti dimensional

A cell tray has a multi-dimensional array of cells in precise, equally spaced wells (cubicles or silos) containing medium of interest. The ordered cell array enables automated processing as well as simultaneous monitoring and analyzing of a large matrix of cells, biological fluids, chemicals and / or solid samples. The invention is an integrated device and is fabricated into substrates similar to microscope slides. The ordered array of cells in precise locations helps in parallel analysis and processing of cells simultaneously. Each cell cubicle or silo in the array is located equidistant from its nearest neighbors in an orthogonal direction. The location of each well can be precisely measured and recorded in an automated processing system. Included in the bottom of each cell well is an optional micro-lens. An array of probes provides parallel cell processing and monitoring capabilities, including microinjection and microscope analysis. The cell tray when integrated with the Precision Optical Intracellular Near Field Imaging / Spectroscopy Technology (POINT or NANOPOINT) device results in sub-wavelength high-resolution imaging with a nanosensor array capable of imaging inner regions of living cells without destroying its natural environment.

Owner:NANOPOINT

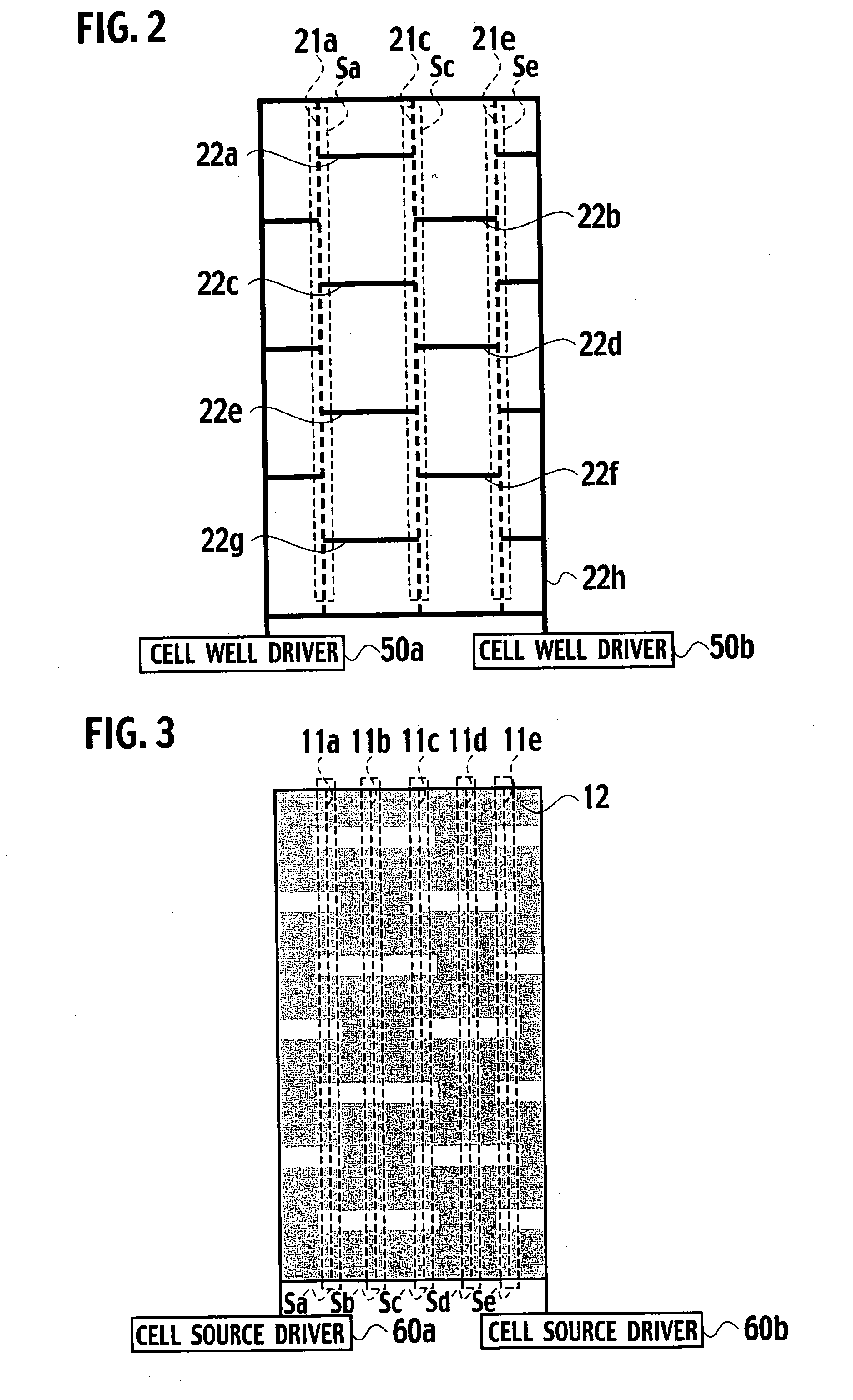

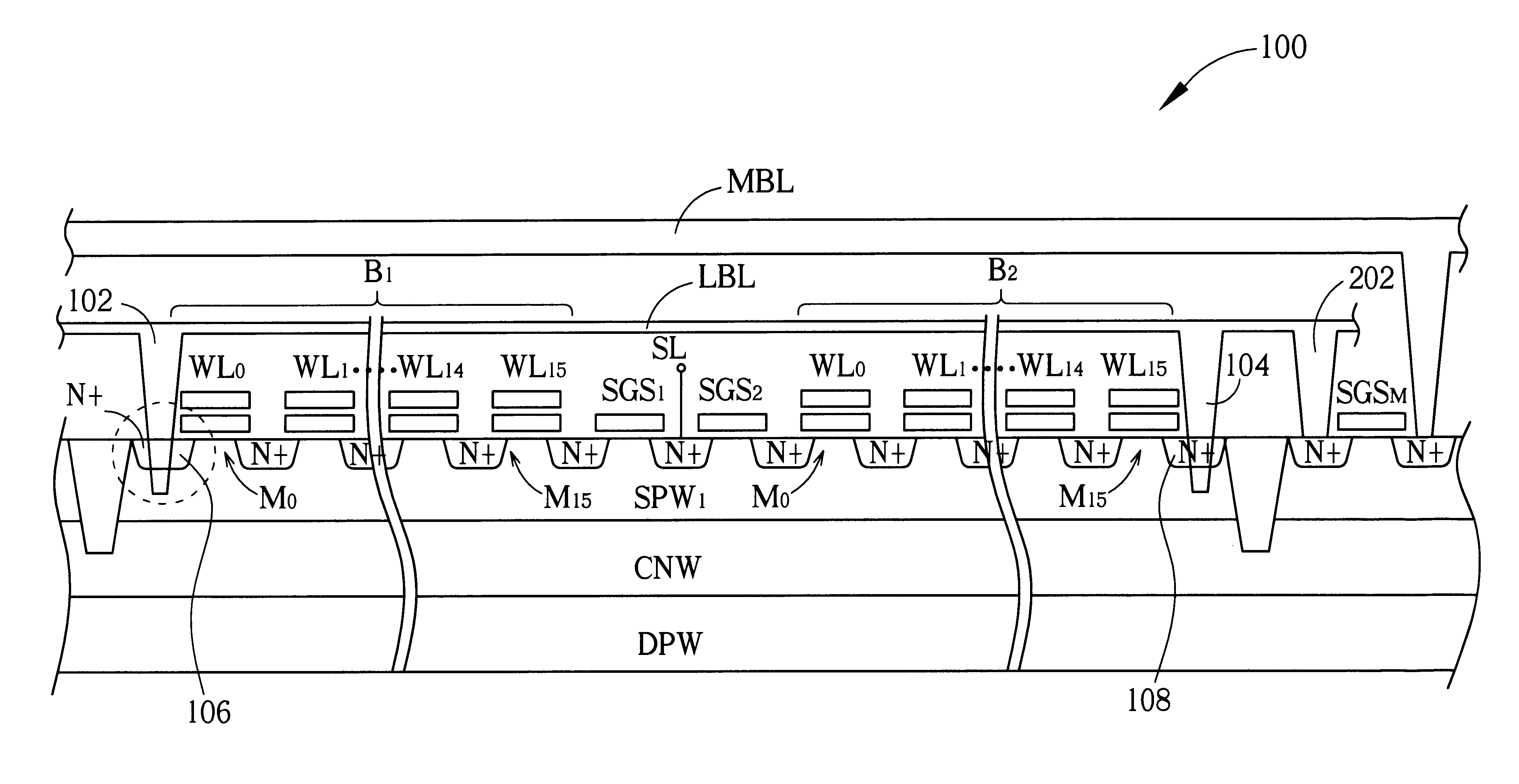

Nonvolatile semiconductor memory having a plurality of interconnect layers

A nonvolatile semiconductor memory includes a memory cell array including horizontally aligned memory cell columns, each including vertically arranged memory cell transistors and select transistors selecting the memory cell transistors; first cell well lines connecting well regions in which the memory cell columns are formed; second cell well lines arranged in an interconnect layer above the first cell well lines and connecting the first cell well lines to one another electrically; and a cell source line connecting source terminals of the select transistors in each memory cell column.

Owner:KIOXIA CORP

Shallow trench capacitor compatible with high-K / metal gate

InactiveUS7875919B2Improve performanceMore capacitanceTransistorSolid-state devicesCells/wellEngineering

Forming a shallow trench capacitor in conjunction with an FET by forming a plurality of STI trenches; for the FET, implanting a first cell well having a first polarity between a first and a second of the STI trenches; for the capacitor, implanting a second cell well having a second polarity in an area of a third of the STI trenches; removing dielectric material from the third STI trench; forming a gate stack having a first portion located between the first and the second of the STI trenches and a second portion located over and extending into the third trench; and performing a source / drain implant of the same polarity as the second cell well, thereby forming a FET in the first cell well, and a capacitor in the second cell well. The second polarity may be opposite from the first polarity. An additional implant may reduce ESR in the second cell well.

Owner:GLOBALFOUNDRIES US INC

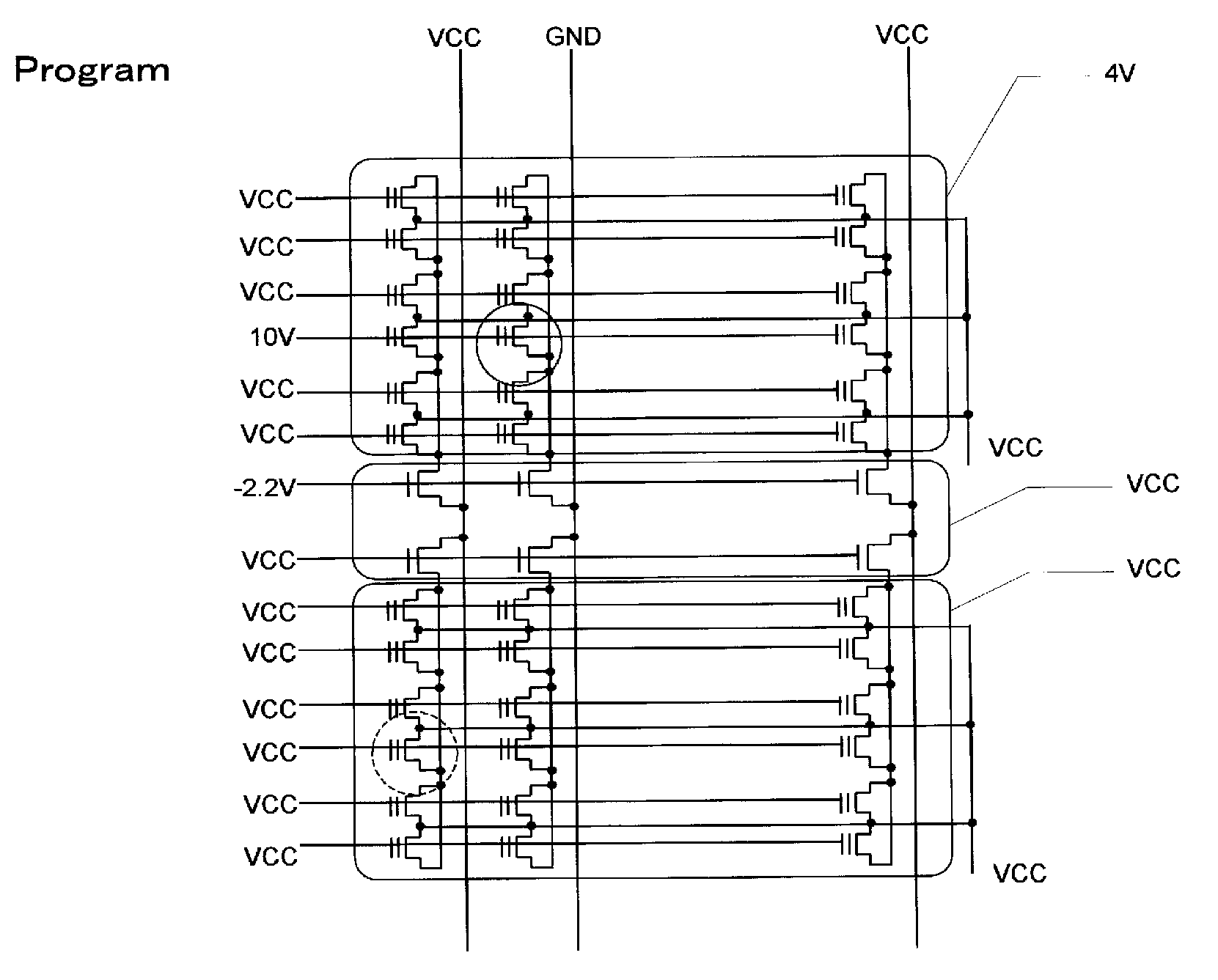

Nonvolatile Semiconductor Memory

InactiveUS20070230251A1Minimizes potential differenceGenerate efficientlySolid-state devicesRead-only memoriesCells/wellPotential difference

A hot electron (BBHE) is generated close to a drain by tunneling between bands, and it data writing is performed by injecting the hot electron into a charge storage layer. When Vg is a gate voltage, Vsub is a cell well voltage, Vs is a source voltage and Vd is a drain voltage, a relation of Vg>Vsub>Vs>Vd is satisfied, Vg−Vd is a value of a potential difference required for generating a tunnel current between the bands or higher, and Vsub−Vd is substantially equivalent to a barrier potential of the tunnel insulating film or higher.

Owner:GENUSION

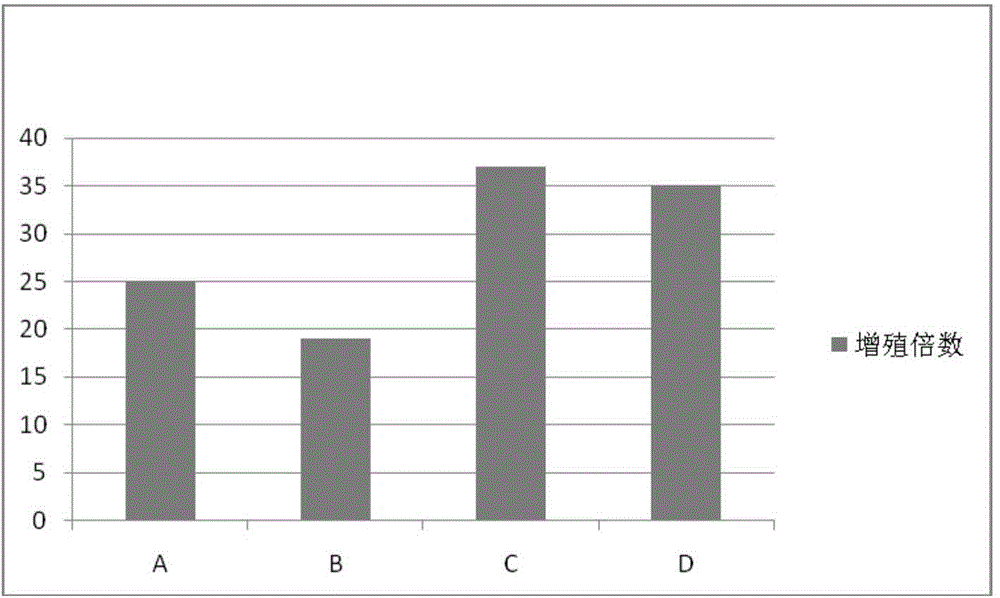

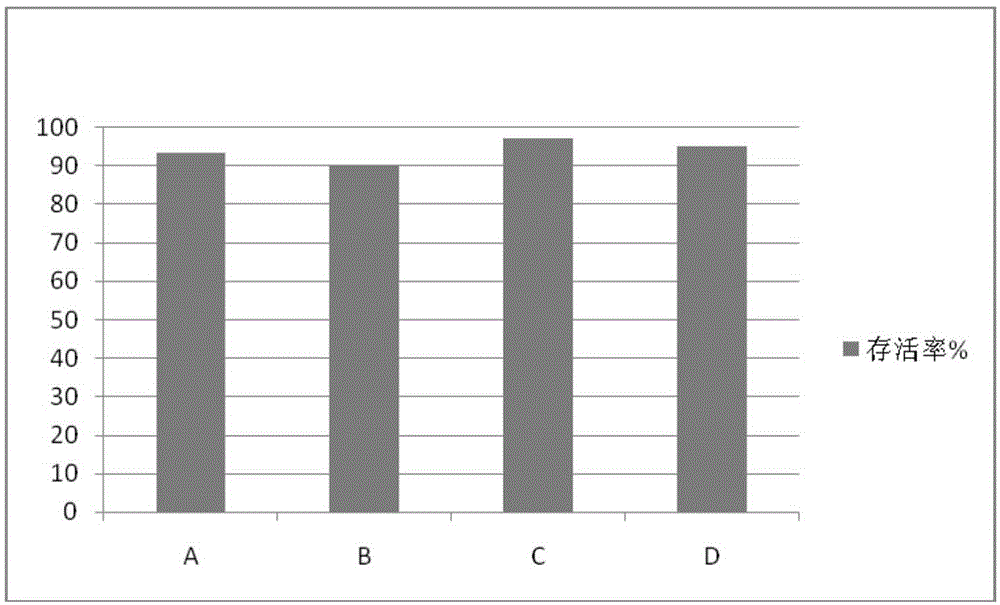

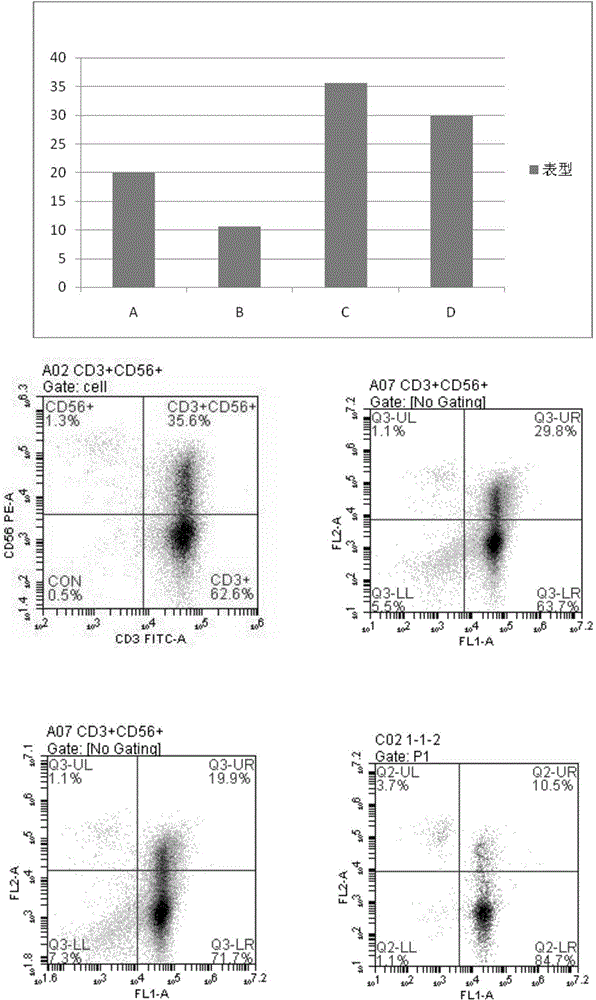

Animal protein-free immune cell serum-free medium and using method thereof

ActiveCN104450614ASuitable for growthImprove proliferation efficiencyBlood/immune system cellsSerum free mediaCells/well

The invention discloses the field of culture in vitro of immune cells and particularly relates to an animal protein-free immune cell serum-free medium and a culture method thereof, wherein the culture medium is a liquid culture medium. The culture medium per liter comprises the following components: 1400-1500mg of amino acids, 70-75mg of vitamins, 9800-10000mg of salts, 9500-9700mg of organic matters and 76-80mg of proteins. The culture medium prepared by the invention satisfies the special condition required by growth of immune cells well, so that the culture medium is more suitable for growth of immune cells, thereby remarkably improving the cell proliferation efficiency and the biological potency. The culture medium overcomes the defect that in the prior art, batches are different in quality caused by diversity of human or animal serum and component limited donors added into the culture medium, the quality is easy to control, the culture medium is not polluted due to the quality of serum, and the tumor-killing rate effect is good and the cost is low.

Owner:上海安库生医生物科技有限公司

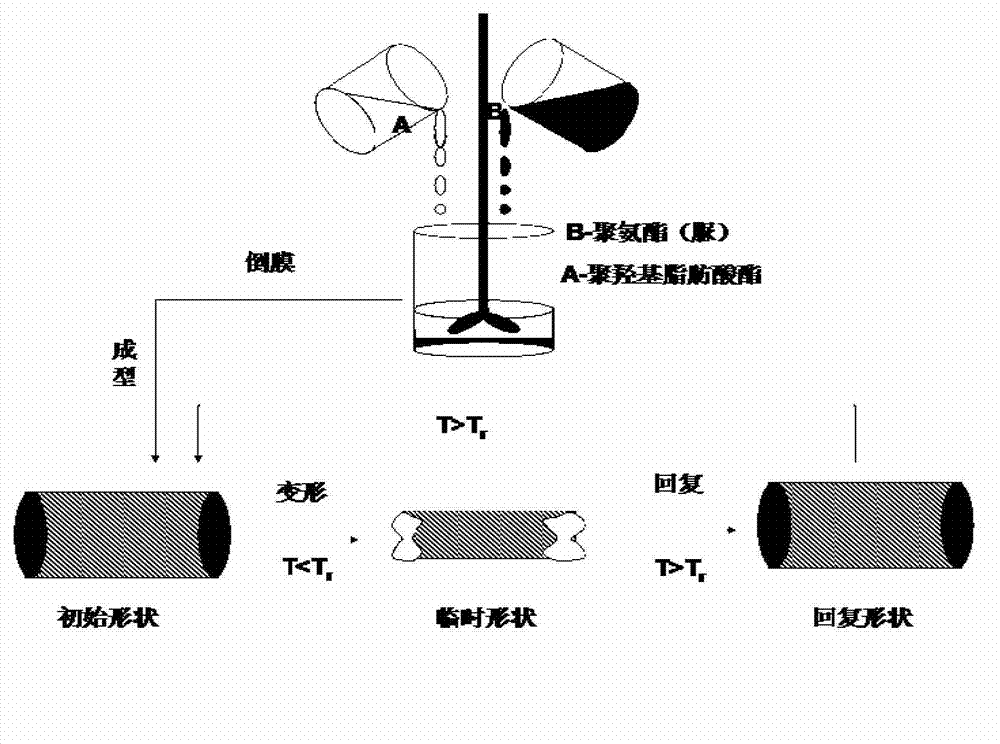

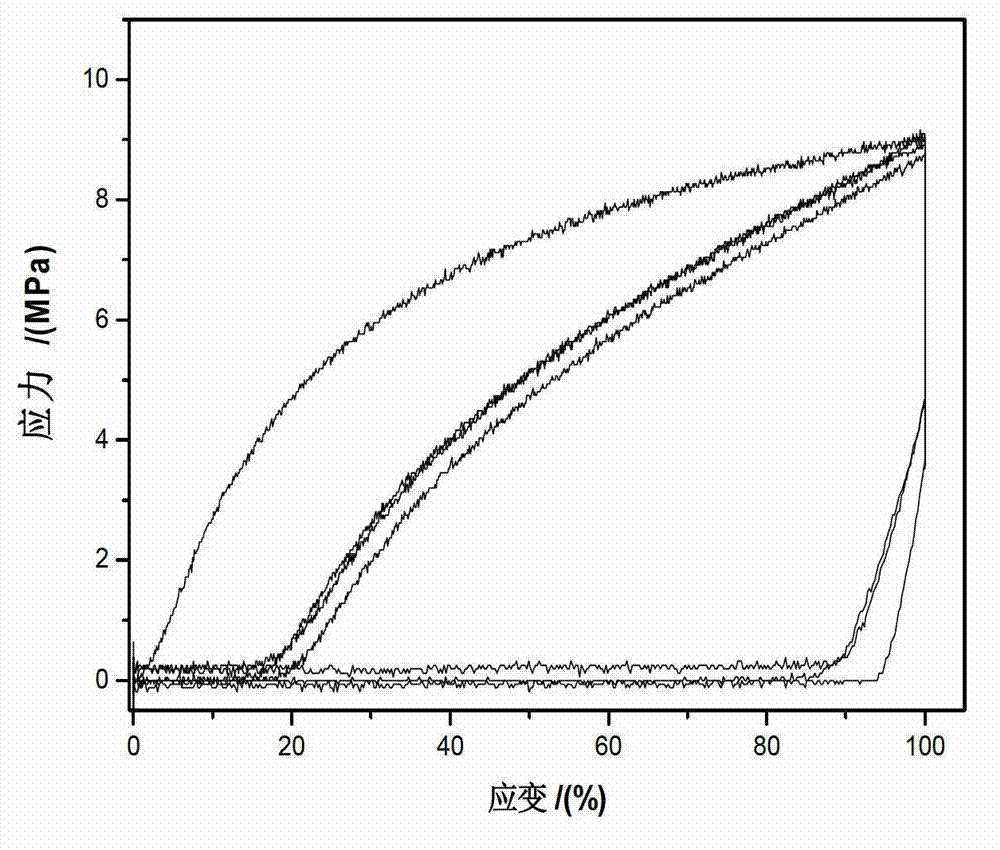

Material based on polyhydroxyalkanoate and preparation method and application of material

The invention relates to the technical field of intelligent materials, and provides a shape memory composite material based on polyhydroxyalkanoate. The composite material comprises the following components in parts by weight: 30-70 parts of polyhydroxyalkanoate, 30-70 parts of polyurethane, and 0-10 parts of compatilizer, wherein the molecular weight of polyhydroxyalkanoate is greater than 10,000 g / mol; polyurethane is prepared by isocyanate and micromolecular alcohol or amine with the molecular weight less than 600 g / mol; and the content of isocyanate and micromolecular alcohol or amine in polyurethane is greater than 70 wt%. The invention further provides a preparation method of the material based on polyhydroxyalkanoate, and the application of the material based on polyhydroxyalkanoate in the aspects of biomedical engineering, textile, toys and daily supplies. The material has good biological compatibility, does not form thrombi when contacted with blood, is integrated with tissue cells well, and has a shape memory function, the shape fixing rate is greater than 80%, and the shape recovery rate is greater than 80%.

Owner:SHENZHEN UNIV

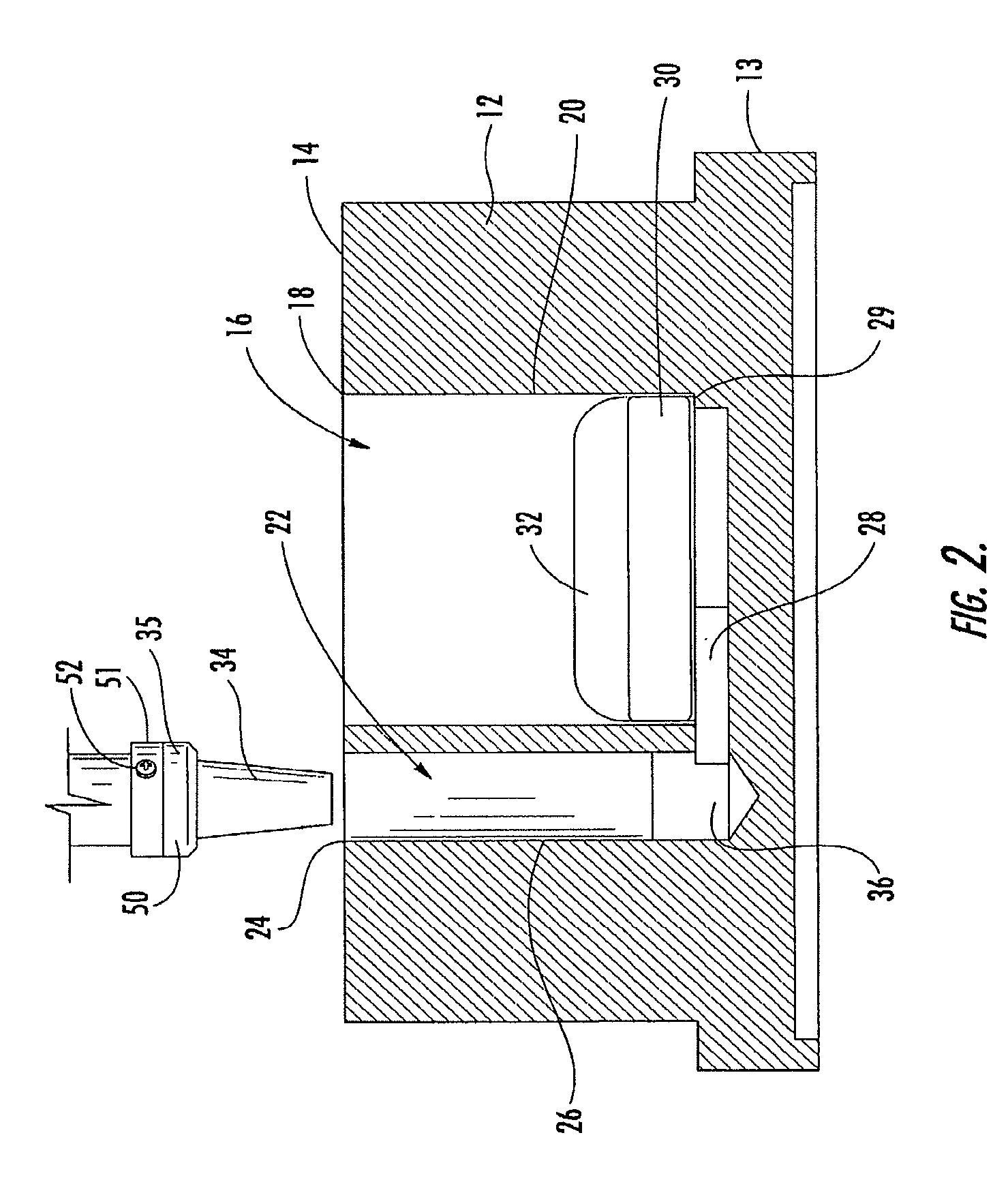

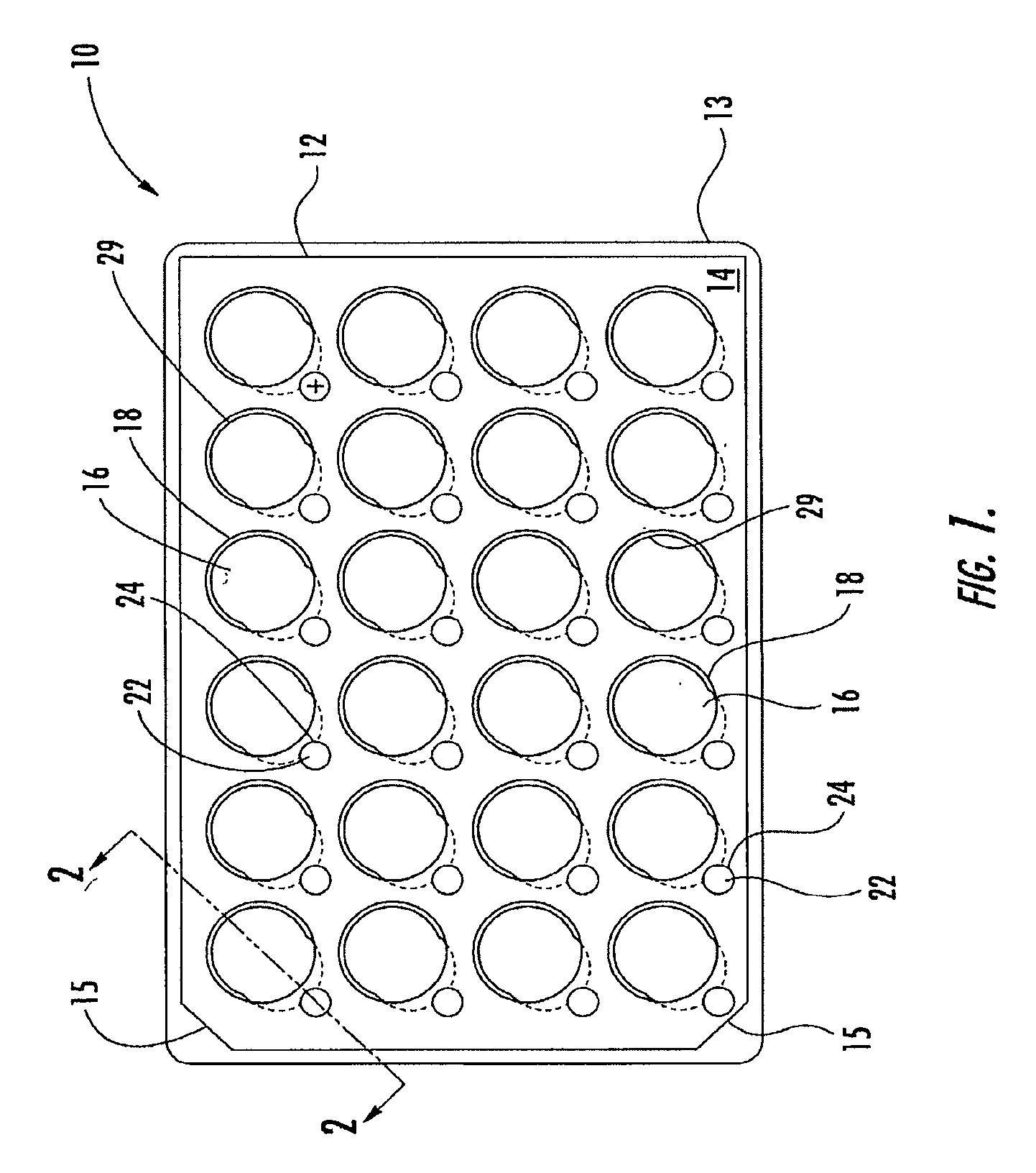

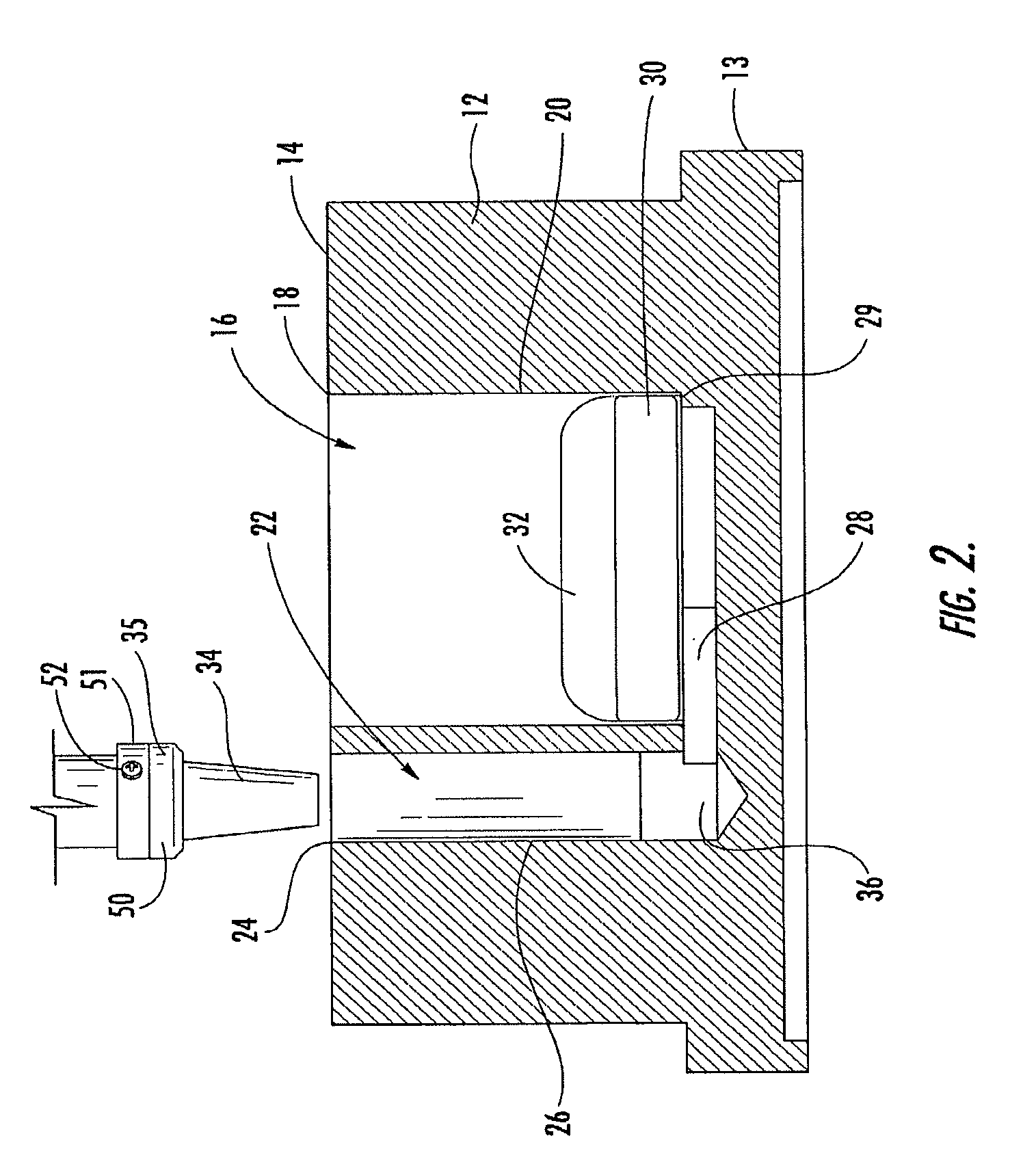

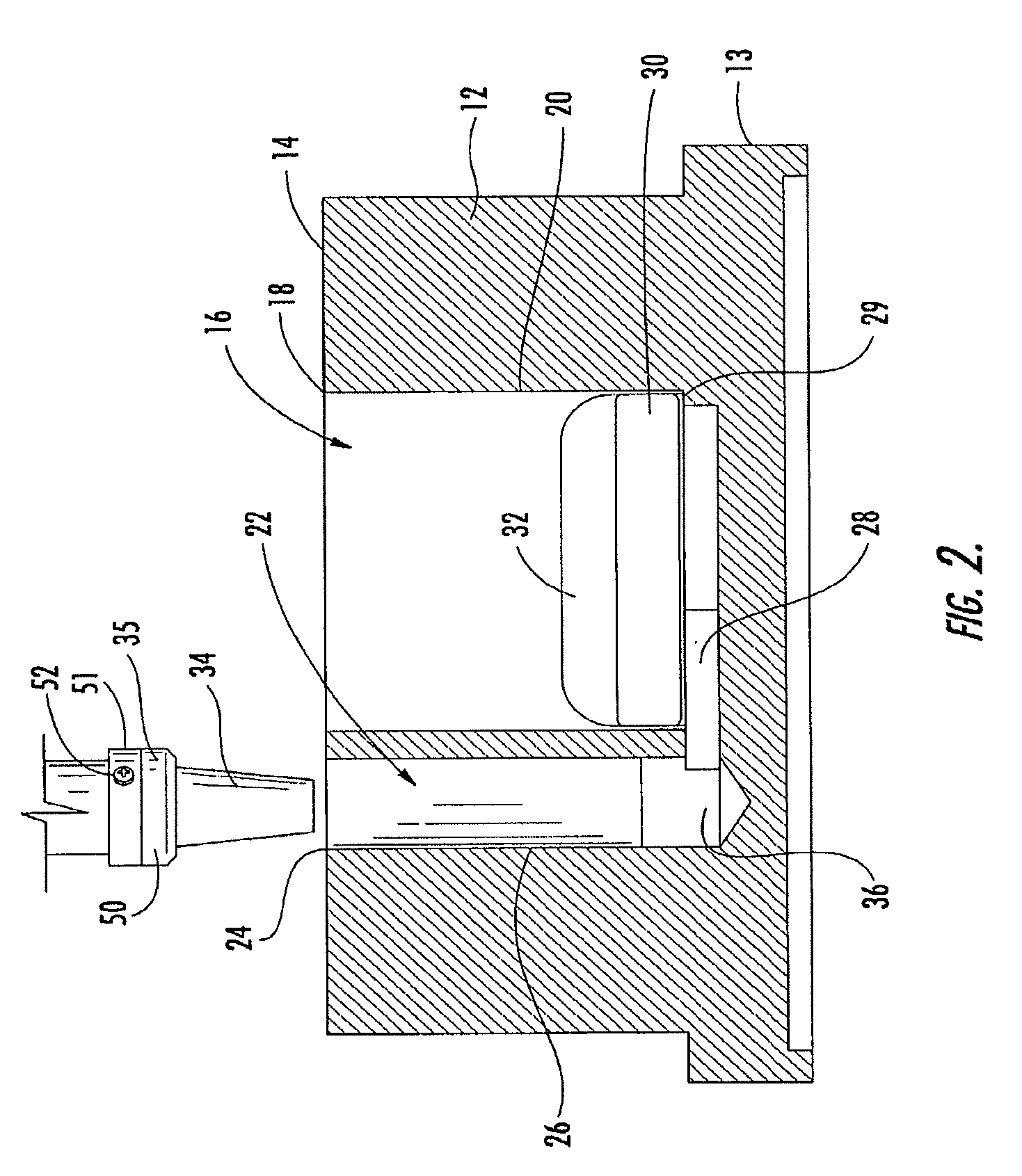

Plate and method for high throughput screening

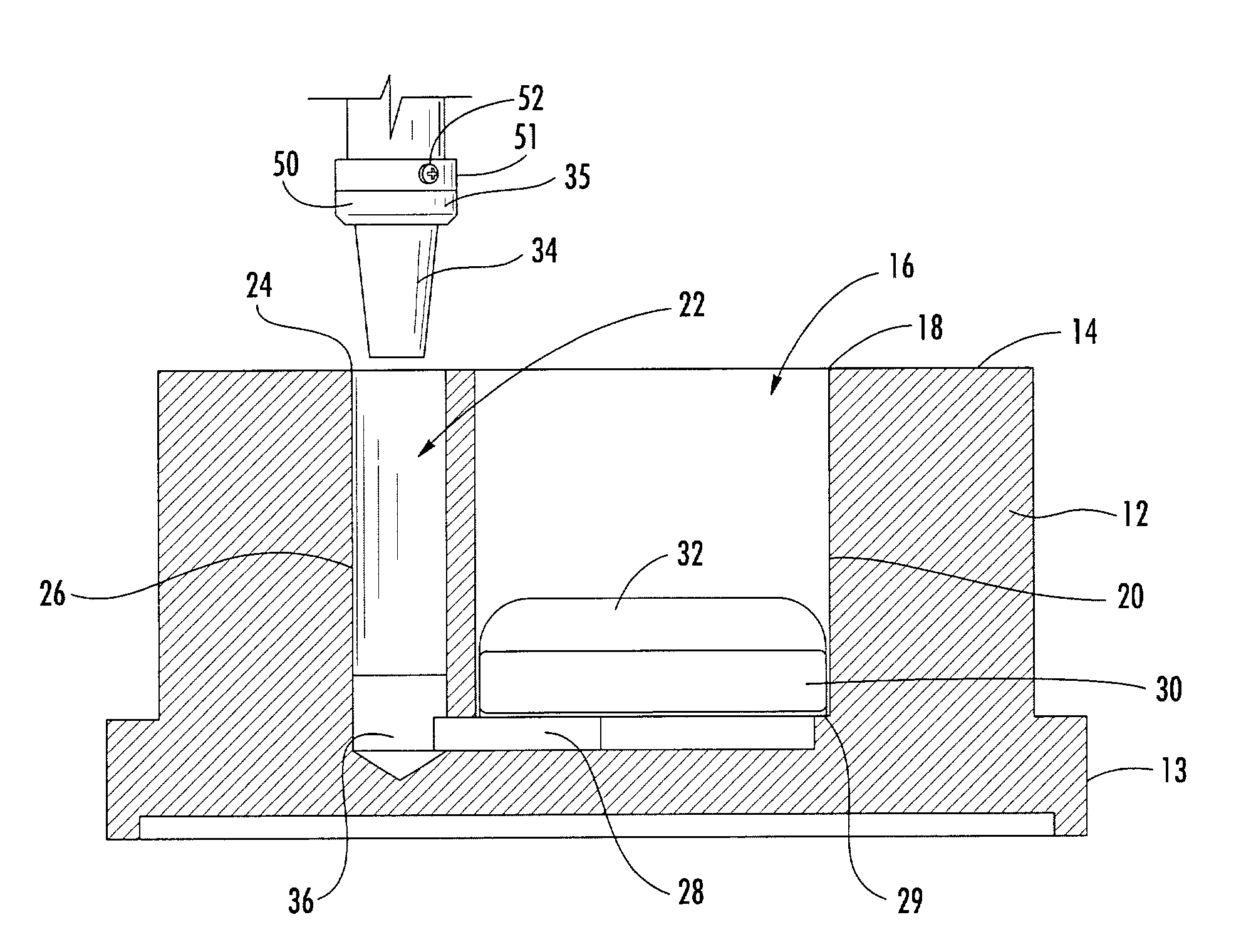

InactiveUS20080102518A1Promote growthAvoid adjustmentBioreactor/fermenter combinationsBiological substance pretreatmentsCells/wellHigh-Throughput Screening Methods

A multiple well plate and method for media exchange, including a body defining a plurality of cell wells each connected via a channel to one of a plurality of aspiration holes, is provided. The cell wells contain a porous, hydrophilic frit which is suspended on a ledge above a reservoir of fluid media and supports a tissue sample. The properties of the frit wick the fluid media upwards to supply the tissue sample with nutrients for growth and proliferation. Old media is aspirated from the wells by a liquid handling device which inserts a pipette tip into the aspiration holes. The pipette tip applies a suction pressure which draws the media out of the cell well, through the channel, into the aspiration hole and out through the pipette tip. New media is dispersed through the pipette tip and directly into the cell well.

Owner:BIOLEX THERAPEUTICS INC

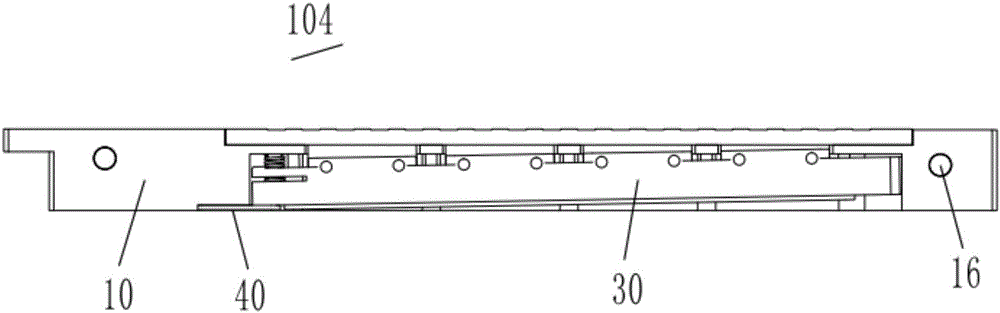

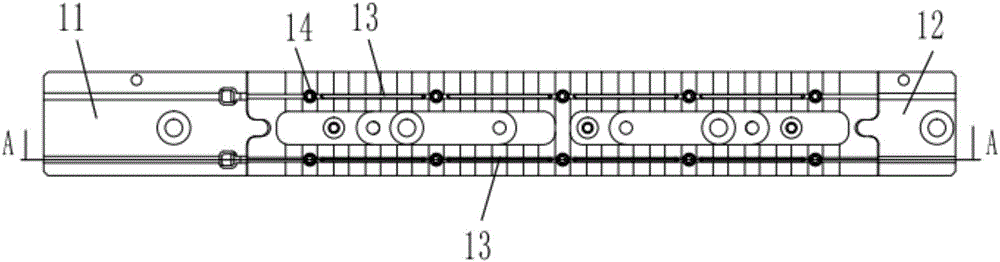

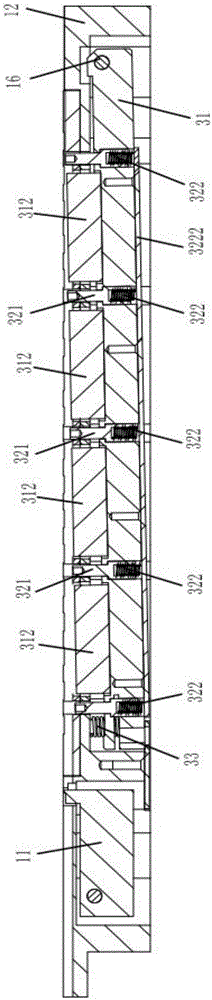

Positioning device and method for welding of solder strip of crystalline silicon cell and series welding machine

ActiveCN106392355AWon't breakFully contactedWelding/cutting auxillary devicesAuxillary welding devicesCells/wellEngineering

A positioning device for welding of a solder strip of a crystalline silicon cell comprises a mounting base, a lift mechanism, and a driving mechanism. A groove for positioning a solder strip is formed in the mounting base, such that the solder strip running through the groove directly faces a main gate line on the back of a cell placed on the mounting base up and down. Through holes in spaced distribution are formed in the groove of the mounting base. The lift mechanism runs through the through holes. The driving mechanism drives the lift mechanism to move upwards in the through holes of the mounting base such that a solder strip in the groove of the mounting base is lifted up to come into close contact with a main gate line on the back of a cell placed on the mounting base. According to an embodiment of the present invention, a solder strip for connection with the back of a cell can be aligned with the main gate line on the shady face of the cell well; in addition, the case of rosin joint or failure in welding due to that a cell may not contact with a solder strip due to deformation thereof and the characteristics of a manufacturing process is avoided, and the problem of unstable welding of a solder strip with the main gate line of a cell is solved; and the welding quality of the series welding process for cells is improved. Furthermore, the present invention also provides a series welding machine.

Owner:NINGXIA XN AUTOMATION EQUIP CO LTD

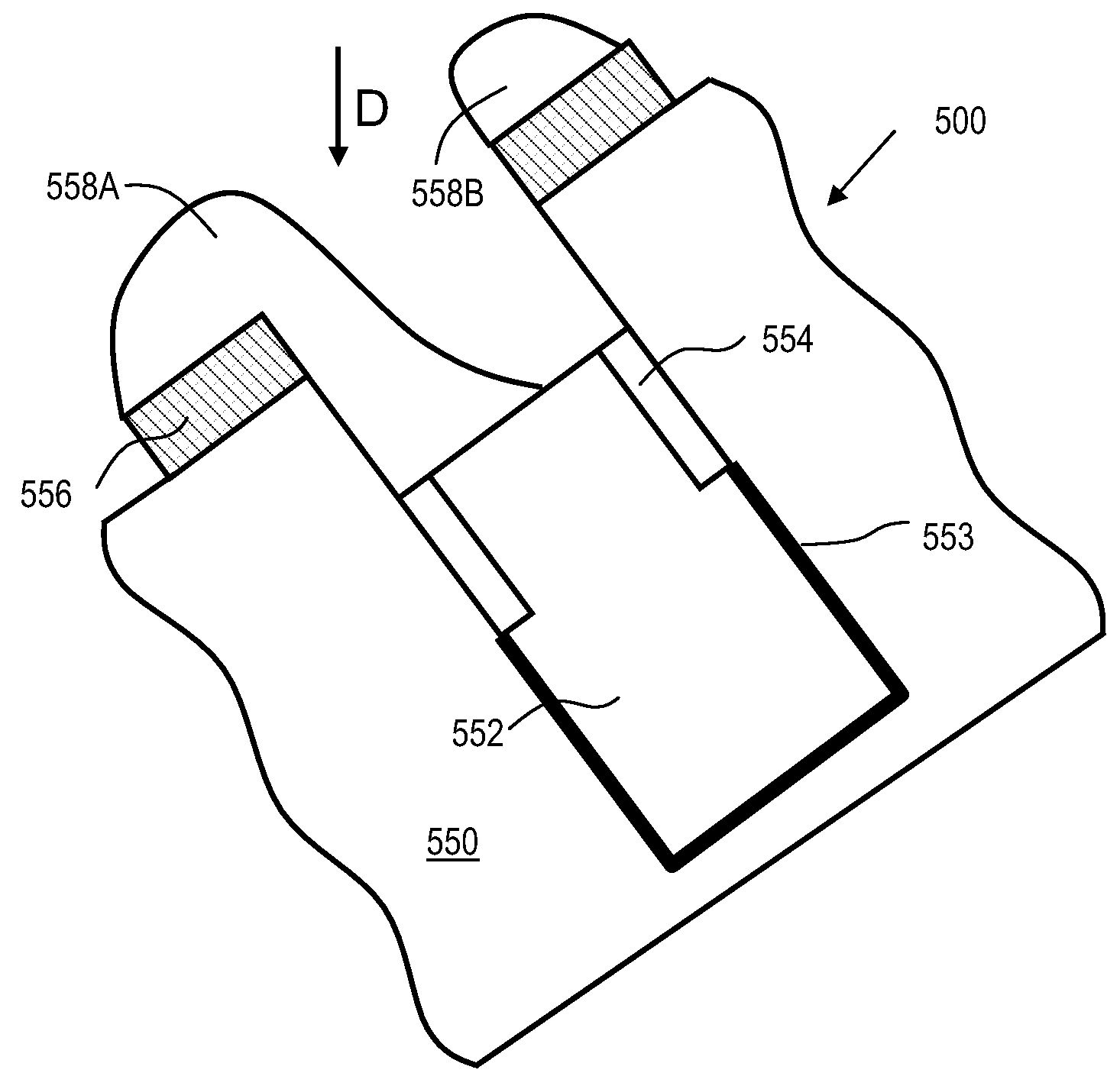

Systems and methods for active microfluidic cell handling

InactiveUS20100159590A1Bioreactor/fermenter combinationsBiological substance pretreatmentsCells/wellMicrofluidic channel

A method and system for providing a cell support system are described. The method and system include providing a first block, a second block coupled to the first block, and a plurality of microfluidic channels. The first block includes a plurality of cell wells therein. The second block includes a plurality of through holes therethrough. The plurality of holes are in fluid communication with at least one corresponding cell well of the plurality of cell wells. The plurality of microfluidic channels are in fluid combination with at least a portion of the plurality of cell wells and are configured to provide an active fluid flow with the portion of the plurality of cell wells.

Owner:NANOPOINT

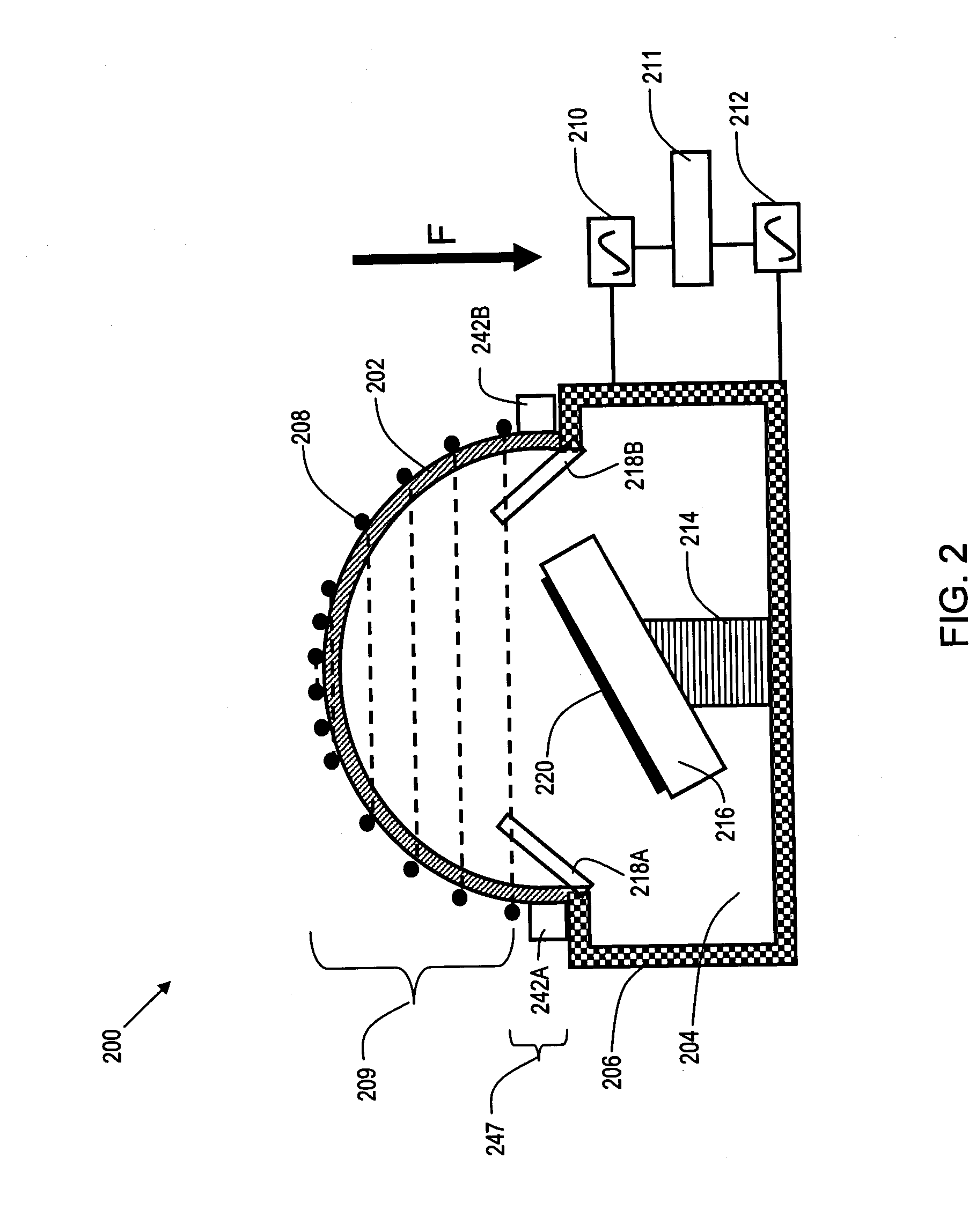

Method and apparatus for angular high density plasma chemical vapor deposition

Forming a shallow trench capacitor in conjunction with an FET by forming a plurality of STI trenches; for the FET, implanting a first cell well having a first polarity between a first and a second of the STI trenches; for the capacitor, implanting a second cell well having a second polarity in an area of a third of the STI trenches; removing dielectric material from the third STI trench; forming a gate stack having a first portion located between the first and the second of the STI trenches and a second portion located over and extending into the third trench; and performing a source / drain implant of the same polarity as the second cell well, thereby forming a FET in the first cell well, and a capacitor in the second cell well. The second polarity may be opposite from the first polarity. An additional implant may reduce ESR in the second cell well.

Owner:ALSEPHINA INNOVATIONS INC

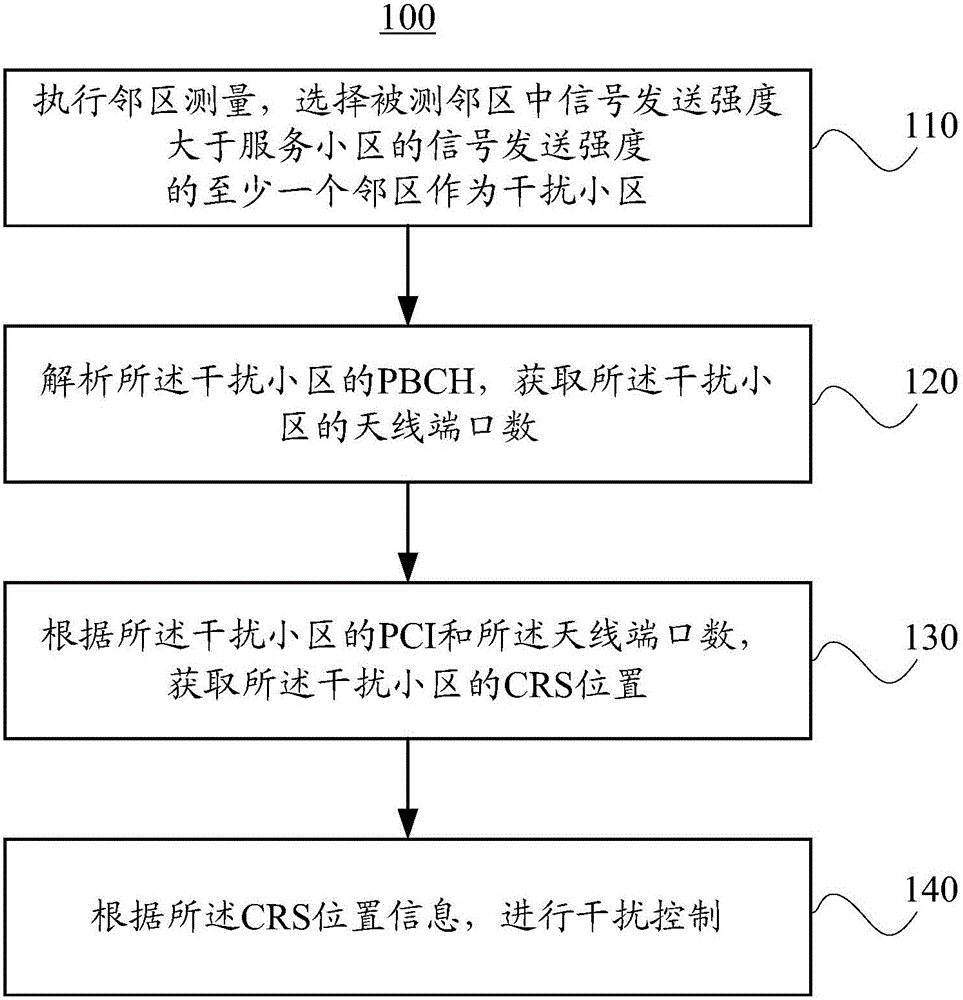

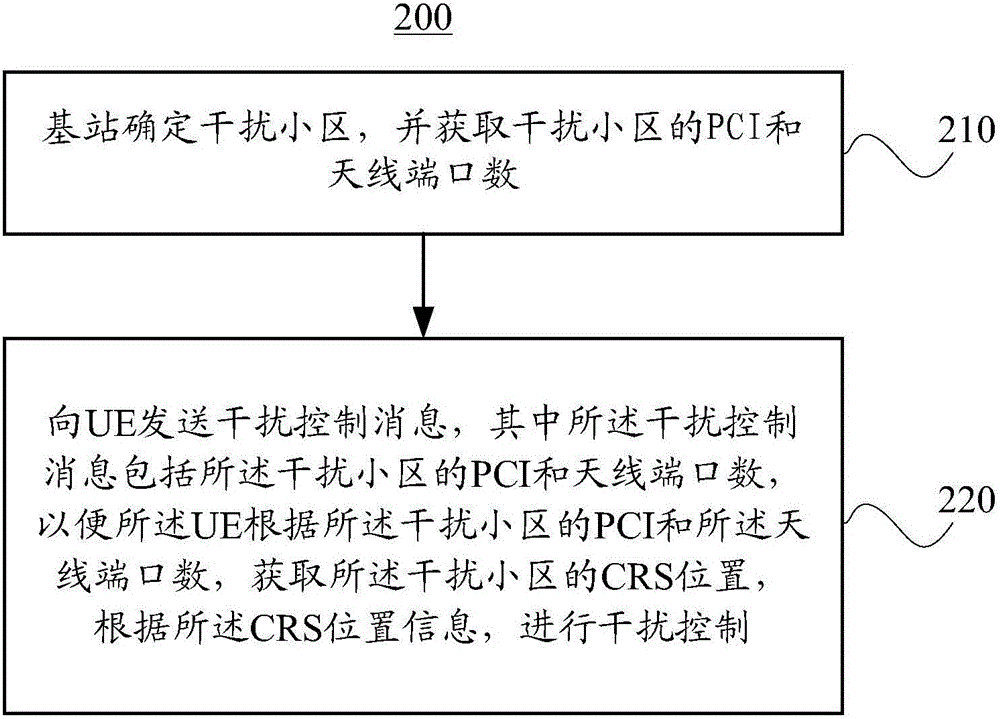

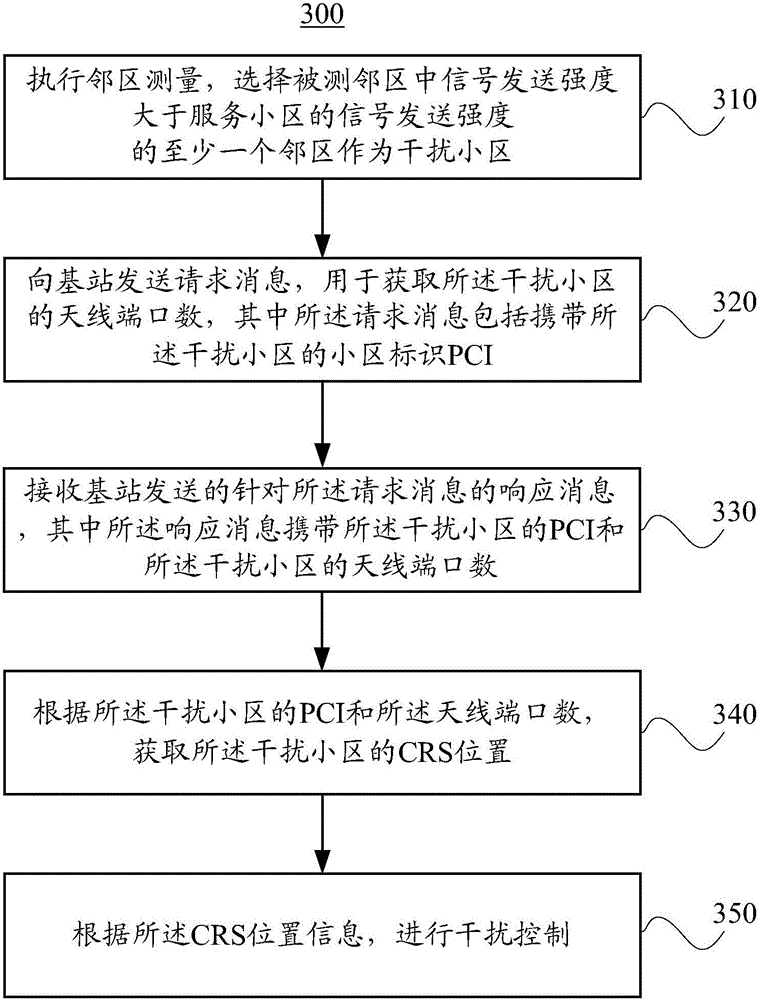

Interference control method and device

ActiveCN105792277AReduce distractionsImprove communication qualityNetwork traffic/resource managementCells/wellBroadcast channels

The invention relates to an interference control method and device. The interference control method comprises the following steps: executing adjacent area measurement, and selecting at least one adjacent area whose signal sending intensity is larger than the signal sending intensity of a service cell in measured adjacent areas as an interference cell; analyzing a physical broadcast channel PBCH of the interference cell to obtain an antenna port number of the interference cell; obtaining a cell reference signaling CRS position of the interference cell according to a physical cell identifier PCI and the antenna port number of the interference cell; and carrying out interference control according to the CRS position information. According to the interference control method provided by the embodiment of the invention, the interference of adjacent area signals to user equipment in the service cell is weakened, and thus the call quality of the user equipment in the service cell is improved; and some hotspot cells better share the business burden of a macro cell.

Owner:HUAWEI TECH CO LTD

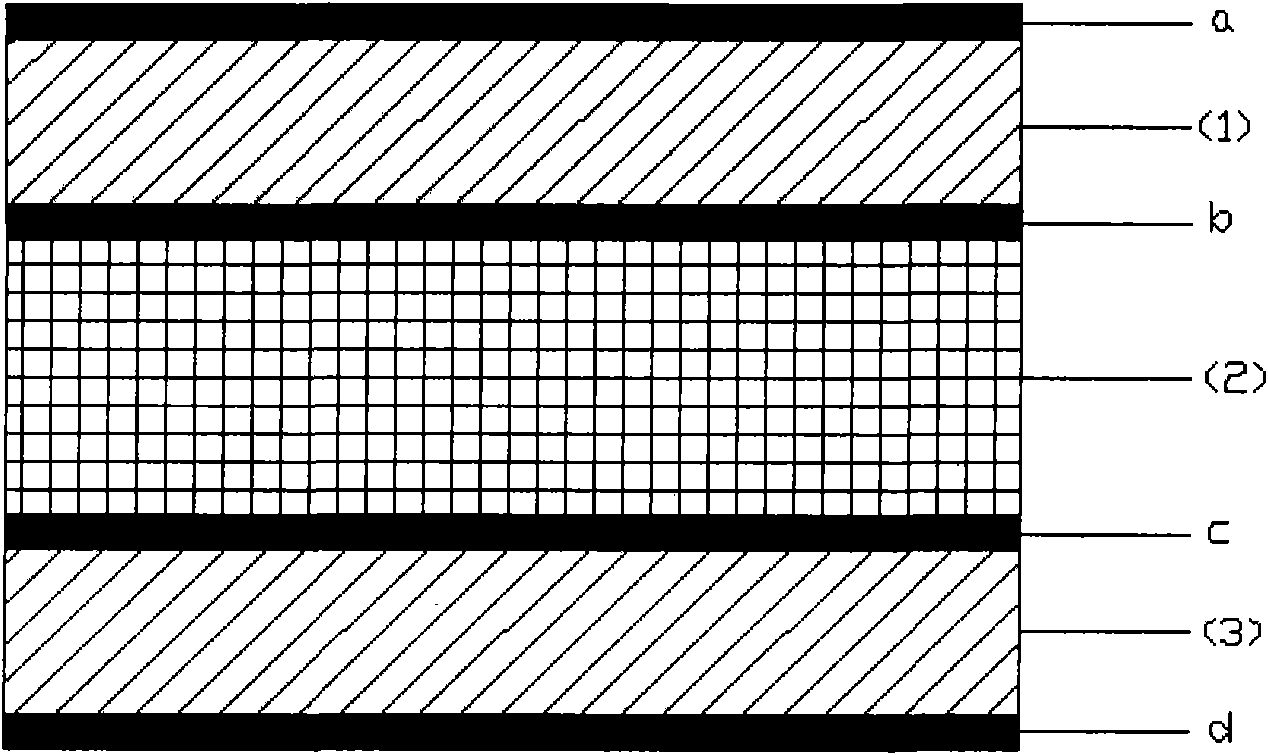

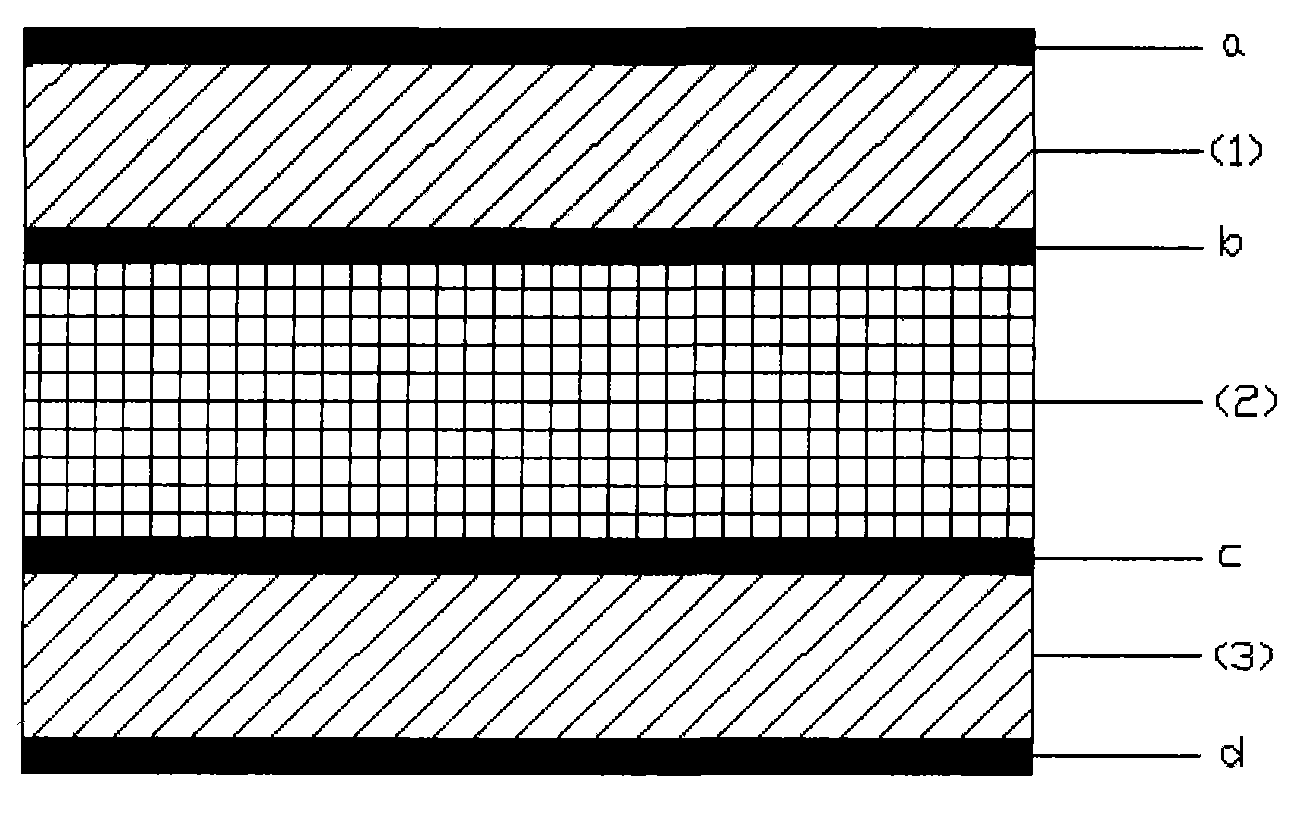

Rear panel composite film for solar photovoltaic cell assembly, and preparation method for rear panel composite film

InactiveCN102468353AImprove stabilityHigh degree of localizationSynthetic resin layered productsPhotovoltaic energy generationCompound aCells/well

The invention relates to a rear panel composite film for a solar photovoltaic cell assembly, and a preparation method for the rear panel composite film. The rear panel composite film for the solar photovoltaic cell assembly is formed by compounding a polytetrafluoroethylene (PTFE) rotary cut film (1) with thickness of 0.028 to 0.040mm, a polyethylene terephthalate (PET) film (2) with the thickness of 0.17 to 0.35mm, a PTFE rotary cut film (3) with the thickness of 0.028 to 0.040mm, and hydrophilic films a, b, c, and d, wherein the hydrophilic films a, b, c, and d are arranged on upper and lower surfaces of the PTFE rotary cut film (1) and the PTFE rotary cut film (3). The preparation method comprises the following steps of: coating adhesives on the upper and lower surfaces of the PET film respectively, arranging the PET film between the PTFE films and the hydrophilic films, hot-pressing, and bonding and curing to obtain the rear panel composite film. Import raw materials are not used in the rear panel composite film, so cost is greatly reduced, and domestication degree is improved. Moreover, the rear panel composite film can be adhered to a glue film of a solar photovoltaic cell well.

Owner:天津市天塑科技集团有限公司技术中心

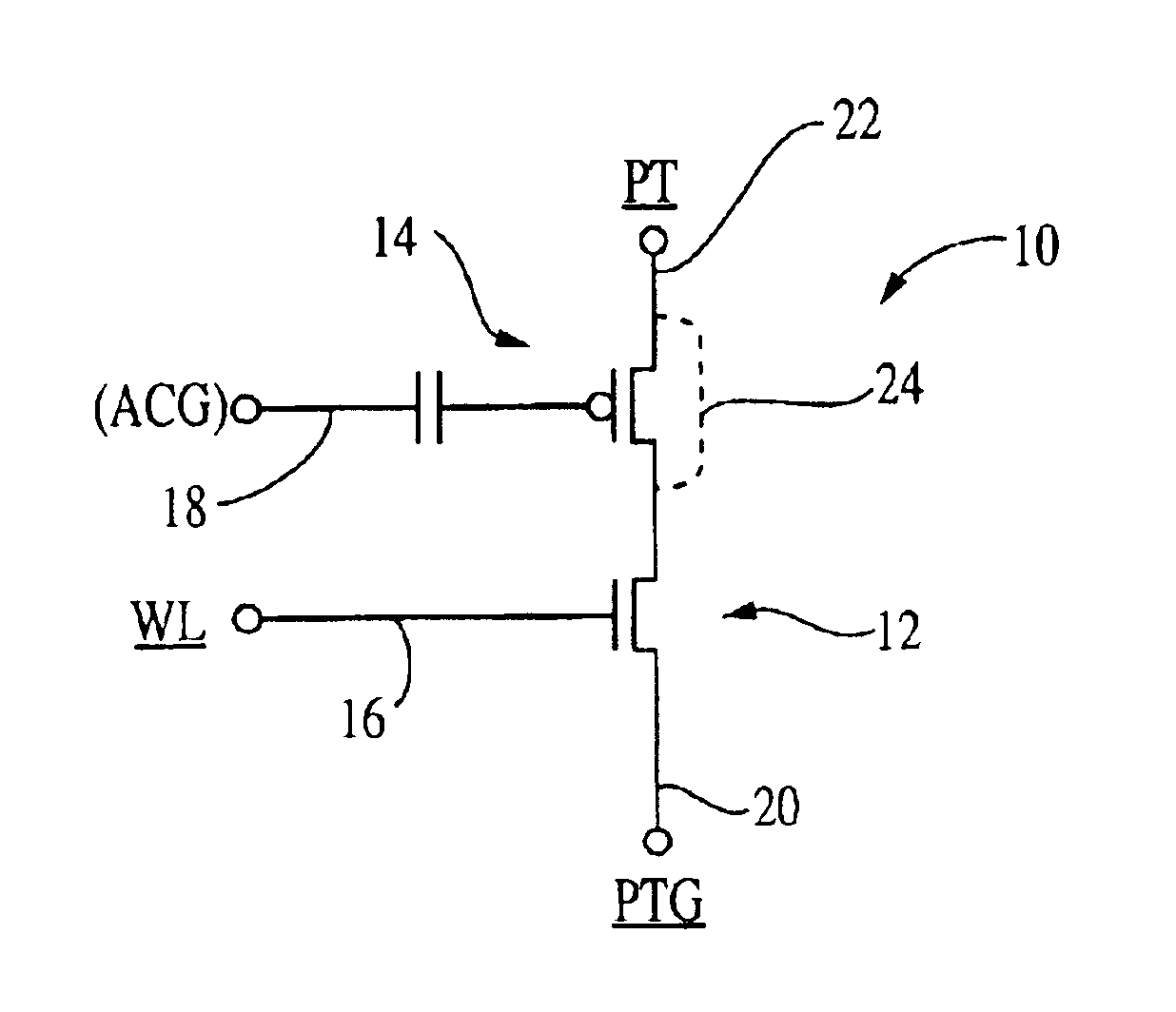

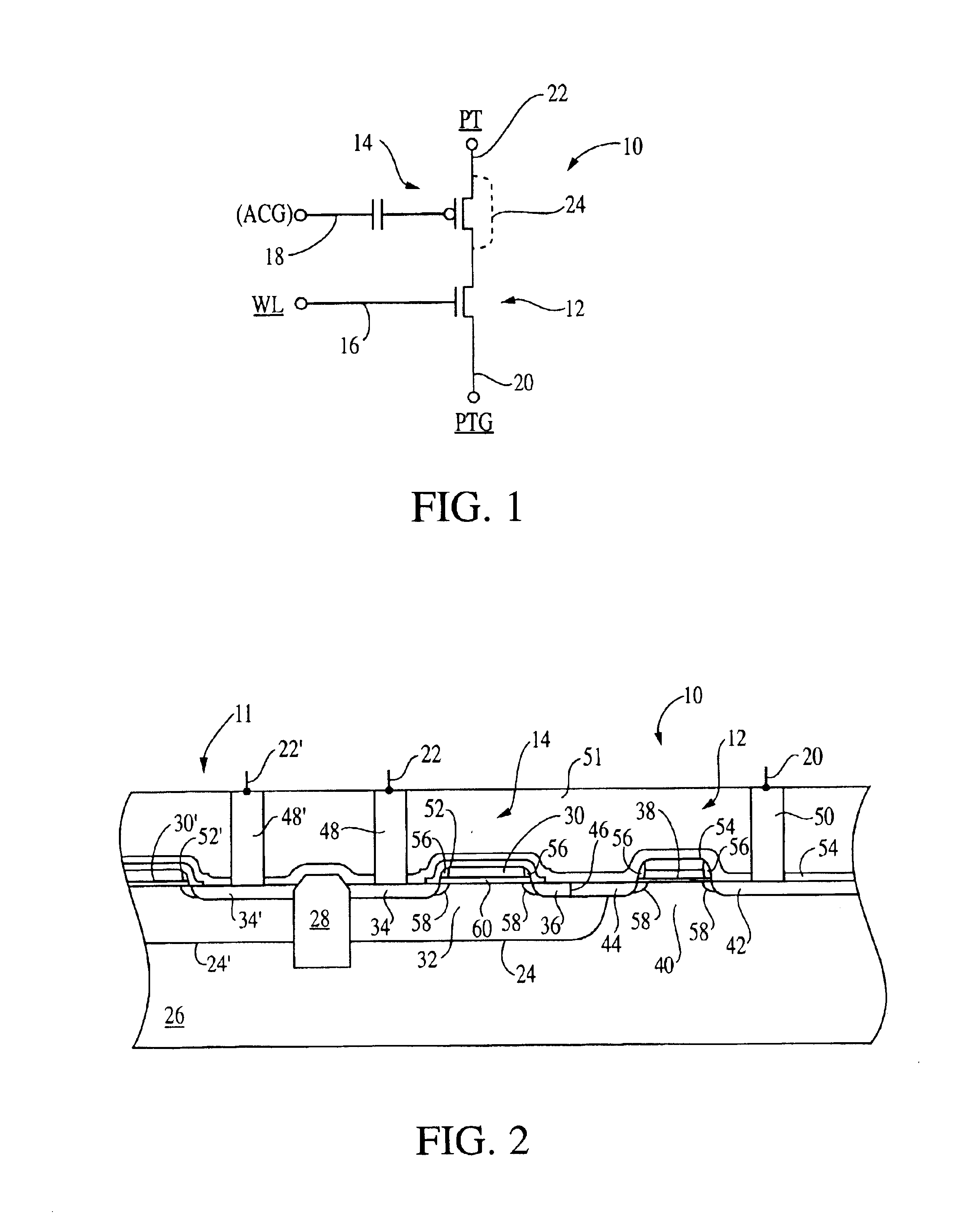

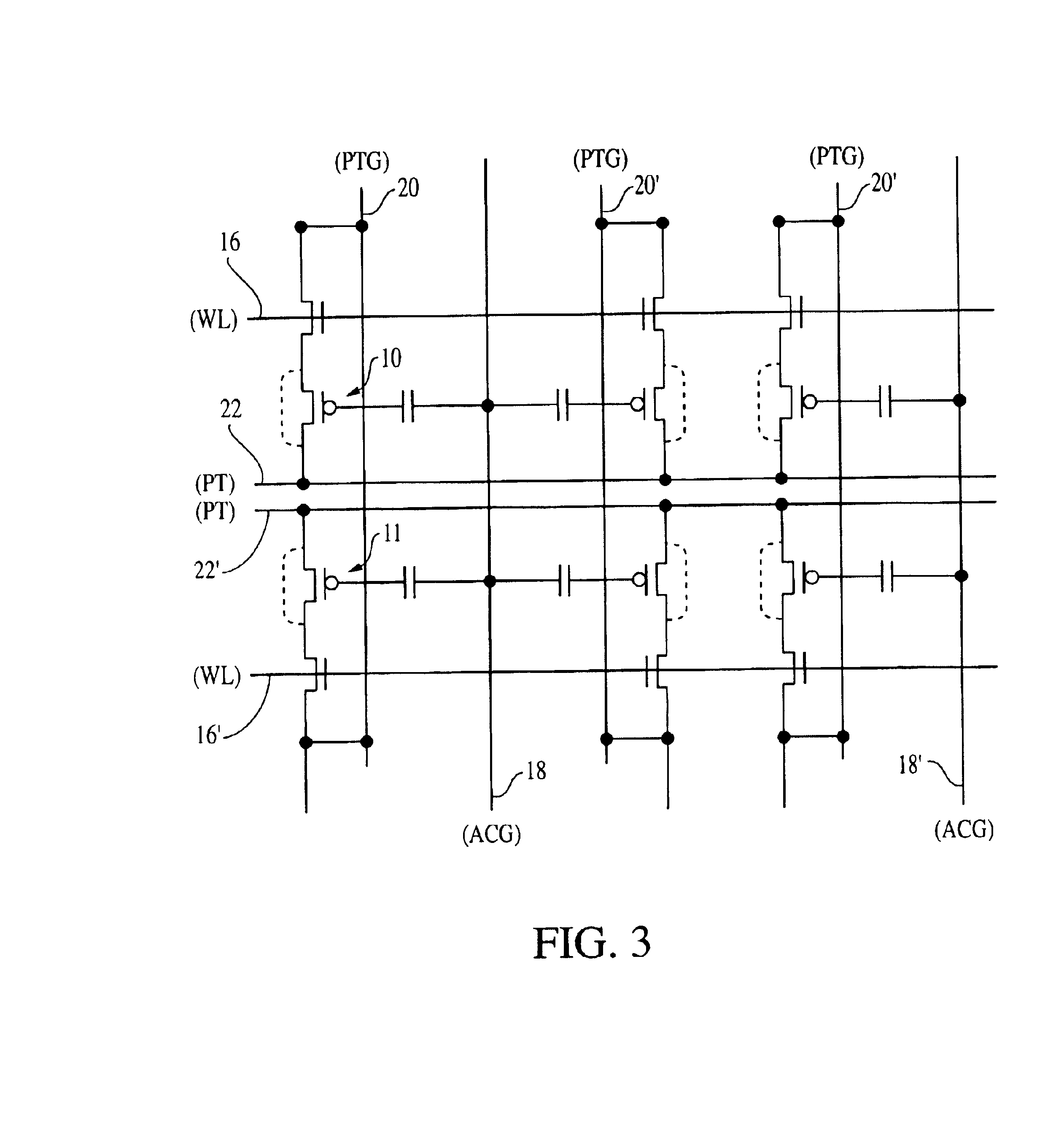

EEPROM cell having a floating-gate transistor within a cell well and a process for fabricating the memory cell

An EEPROM memory device includes a substrate of a first conductivity type having a cell well region of a second conductivity type therein. A floating-gate transistor of the first conductivity type resides in the cell well region and includes a first region separated from a second region by a channel region. A write transistor of the second conductivity type resides in the substrate and includes a first region separated from a second region by a channel region. The second region partially extends into the cell well region and forms a p-n junction with the second region of the floating-gate transistor. The process for fabricating the EEPROM device includes forming the cell well region in the substrate by creating a retrograde doping profile. In operation, the EEPROM device transfers electrons between the cell well region and the floating-gate electrode during both programming and erasing operations.

Owner:LATTICE SEMICON CORP

Plate and method for high throughput screening

InactiveUS20080096270A1Promote growthAvoid adjustmentBioreactor/fermenter combinationsBiological substance pretreatmentsCells/wellPipette

A multiple well plate and method for media exchange, including a body defining a plurality of cell wells each connected via a channel to one of a plurality of aspiration holes, is provided. The cell wells contain a porous, hydrophilic frit which is suspended on a ledge above a reservoir of fluid media and supports a tissue sample. The properties of the frit wick the fluid media upwards to supply the tissue sample with nutrients for growth and proliferation. Old media is aspirated from the wells by a liquid handling device which inserts a pipette tip into the aspiration holes. The pipette tip applies a suction pressure which draws the media out of the cell well, through the channel, into the aspiration hole and out through the pipette tip. New media is dispersed through the pipette tip and directly into the cell well.

Owner:BIOLEX THERAPEUTICS INC

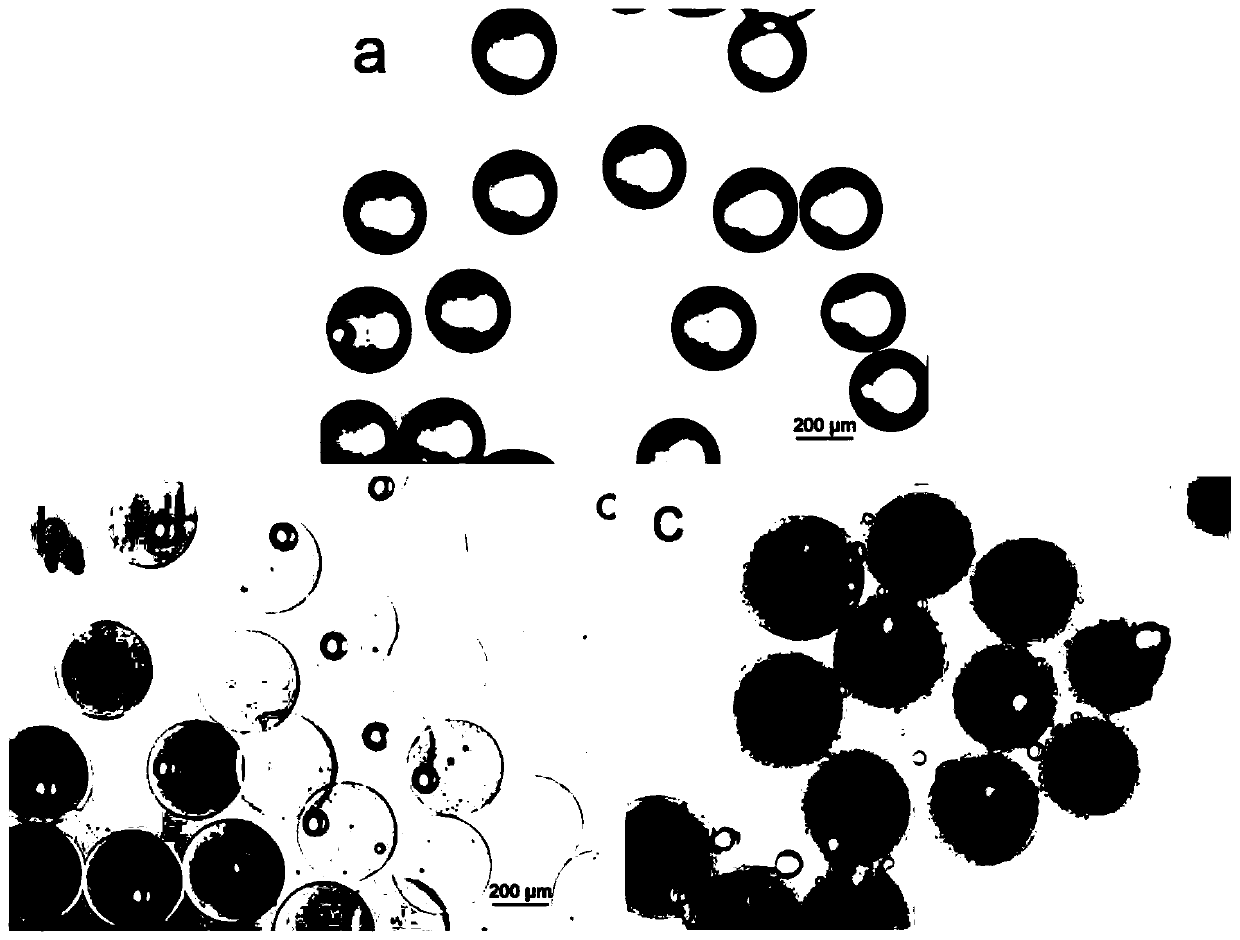

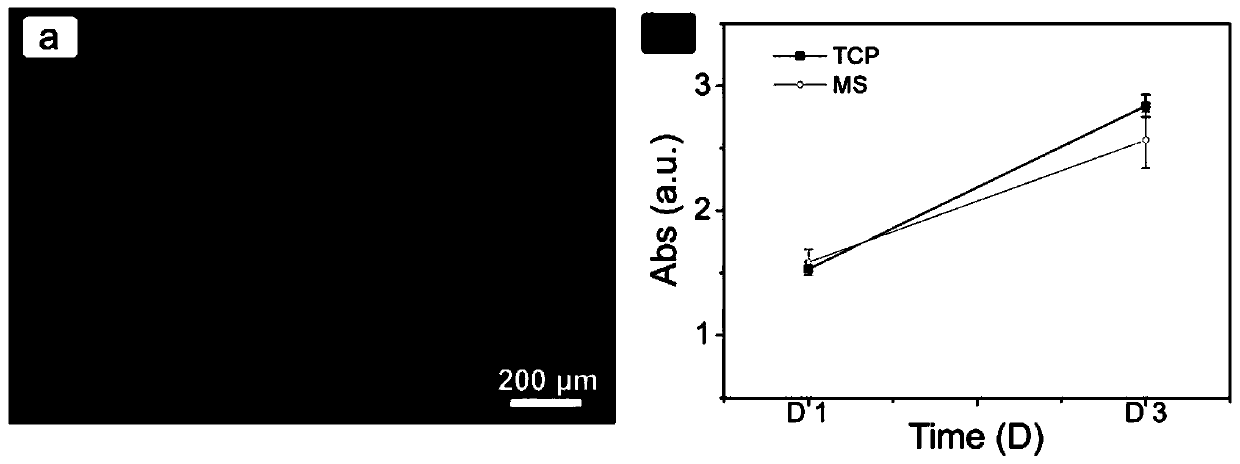

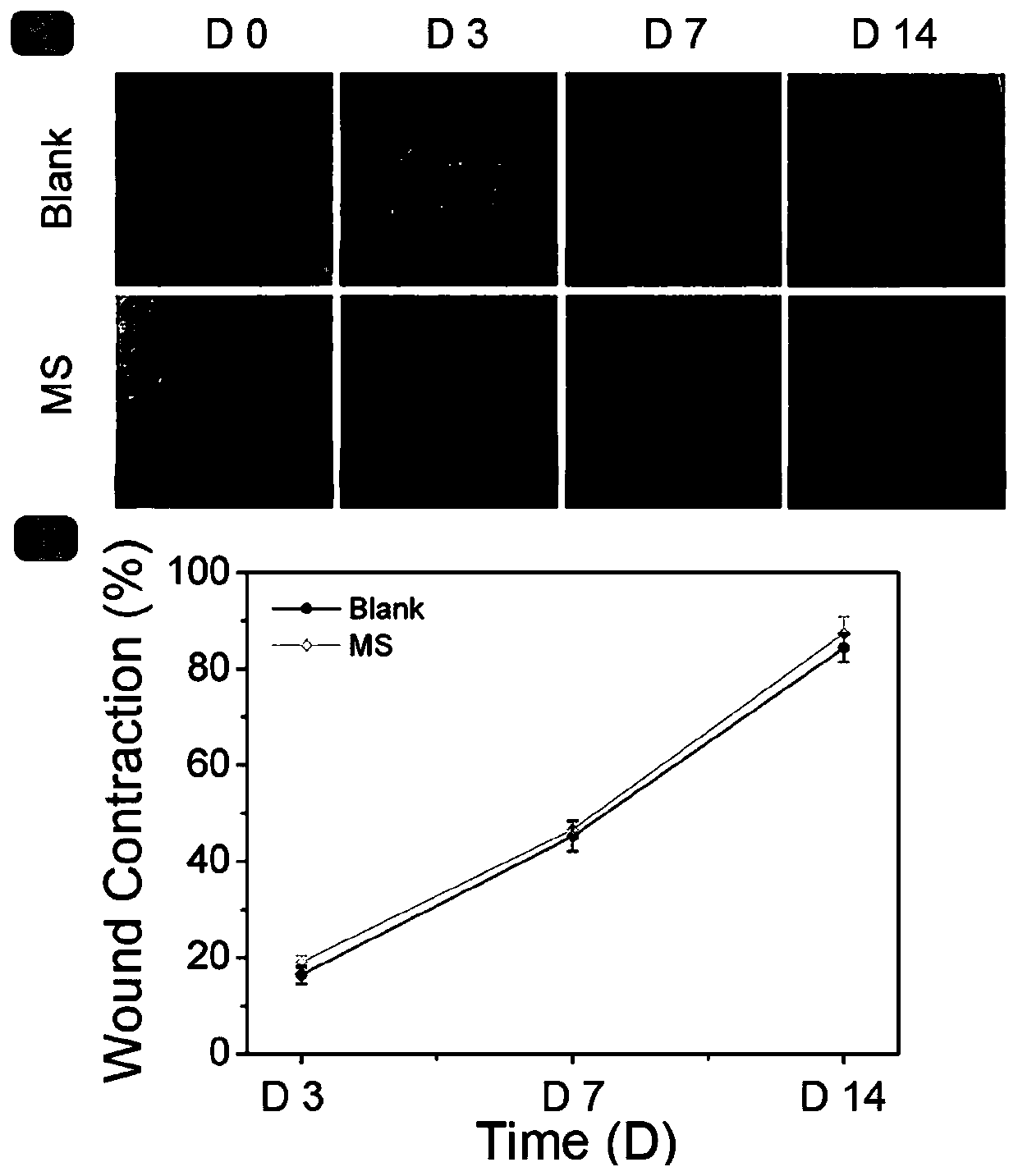

Preparation method of gelatin microspheres and application thereof

The invention discloses a preparation method of gelatin microspheres and an application thereof. The preparation process comprises the following steps: S1. a gelatin aqueous solution is used as the internal phase; an oil phase is an external phase, and the flow rates of the inner and outer phases are respectively controlled by a microfluidic device to be 1 to 10 [mu]L / min and 20 to 200 [mu]L / min;and the external phase is the collected phase, and the micro-droplets are collected; and S2. the collected micro-droplets are gelatinized at 4 to 12 DEG C, the oil phase on the surface is removed, anda crosslinking reaction is carried out with a genipin solution for 1 h, and after the reaction is completed, the gelatin microspheres are obtained by separation. The gelatin microsphere of the invention not only has a simple preparation process, is safe to the cells, is non-toxic, and has certain mechanical strength, can load the cells well, does not affect the activity of the cells, and can be applied as a cell carrier; the gelatin microsphere has a certain promoting effect on the healing of diabetic wounds and the formation of wound blood vessels, also has a good degradation effect, and canbe used as an accelerator drug for wound healing and blood vessel formation.

Owner:SUN YAT SEN UNIV

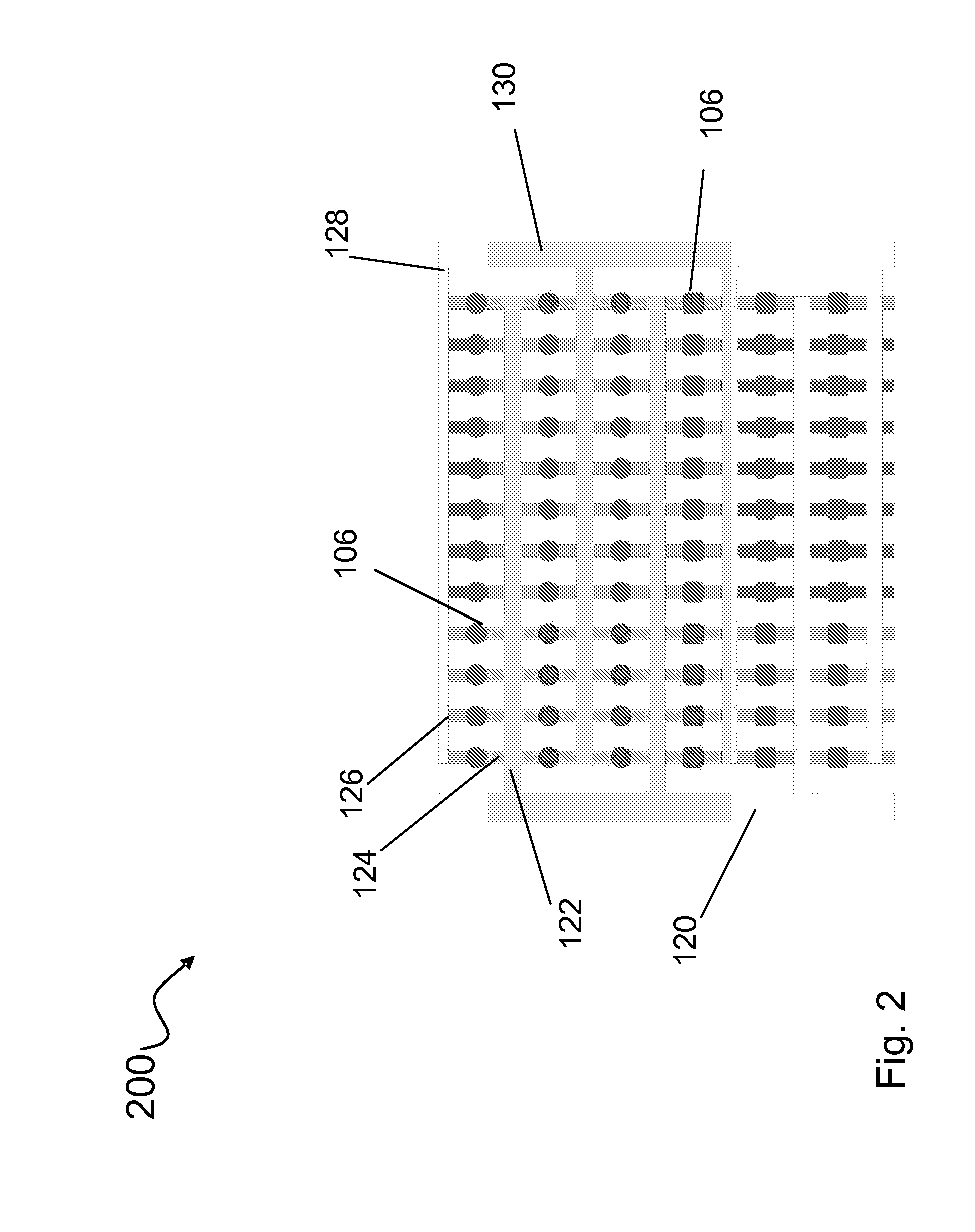

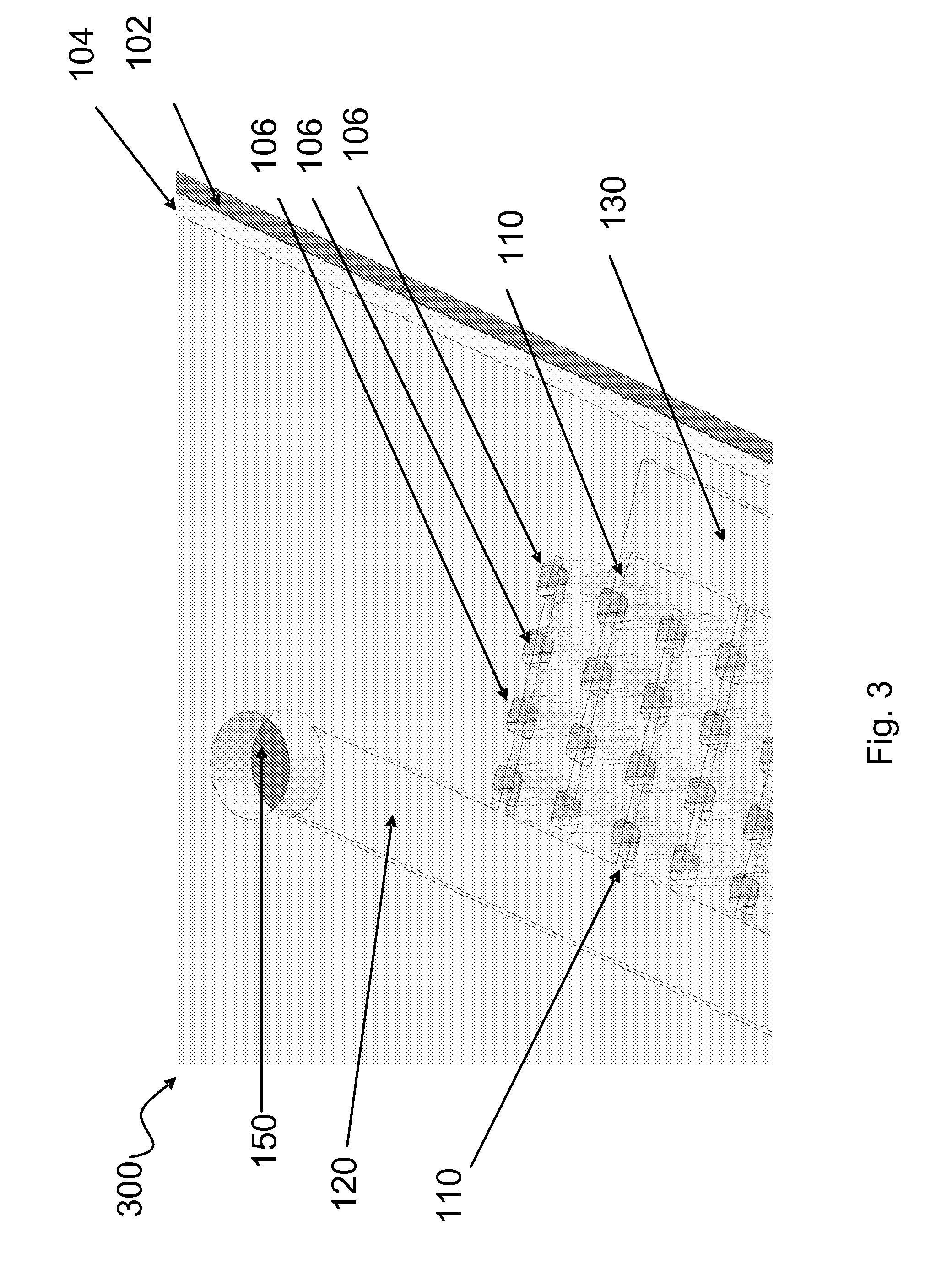

Cell tray

ActiveUS7190449B2Increase pointsRadiation pyrometrySpectrum investigationMicroscope slideHigh resolution imaging

A cell tray has a multi-dimensional array of cells in precise, equally spaced wells (cubicles or silos) containing medium of interest. The ordered cell array enables automated processing as well as simultaneous monitoring and analyzing of a large matrix of cells, biological fluids, chemicals and / or solid samples. The invention is an integrated device and is fabricated into substrates similar to microscope slides. The ordered array of cells in precise locations helps in parallel analysis and processing of cells simultaneously. Each cell cubicle or silo in the array is located equidistant from its nearest neighbors in an orthogonal direction. The location of each well can be precisely measured and recorded in an automated processing system. Included in the bottom of each cell well is an optional micro-lens. An array of probes provides parallel cell processing and monitoring capabilities, including microinjection and microscope analysis. The cell tray when integrated with the Precision Optical Intracellular Near Field Imaging / Spectroscopy Technology (POINT or NANOPOINT) device results in sub-wavelength high-resolution imaging with a nanosensor array capable of imaging inner regions of living cells without destroying its natural environment.

Owner:NANOPOINT

Method for extracting hesperidin in dried tangerine or orange peel by using enzymolysis approach

The invention provides a method for extracting hesperidin in dried tangerine or orange peel by using an enzymolysis approach and relates to the field of medicines. Because citrus and other peels are enriched in pectin, and dissolution of active ingredients in cells is hindered by the pectin. According to the method disclosed by the invention, the pectin between cell walls of medicinal materials and cells is subjected to enzymolysis by adopting pectinase, so that the cell wells are destroyed, the hesperidin is fully dissolved, and the aim of obviously improving the hesperidin extraction rate is achieved. The method can be used for extracting the hesperidin in medicinal materials such as the dried tangerine or orange peel, fructus aurantii and immature bitter orange. The method disclosed by the invention has the advantages that the operation is simple, organic solvent residues are avoided, the environmental pollution is avoided, special equipment is not needed, the production safety is high, large-scale enterprise production is promoted, and the like.

Owner:JINHUA VOCATIONAL TECH COLLEGE

Plate and method for high throughput screening

InactiveUS7326385B2Improve consistencyEfficient removalBioreactor/fermenter combinationsBiological substance pretreatmentsCells/wellHigh-Throughput Screening Methods

A multiple well plate and method for media exchange, including a body defining a plurality of cell wells each connected via a channel to one of a plurality of aspiration holes, is provided. The cell wells contain a porous, hydrophilic frit which is suspended on a ledge above a reservoir of fluid media and supports a tissue sample. The properties of the frit wick the fluid media upwards to supply the tissue sample with nutrients for growth and proliferation. Old media is aspirated from the wells by a liquid handling device which inserts a pipette tip into the aspiration holes. The pipette tip applies a suction pressure which draws the media out of the cell well, through the channel, into the aspiration hole and out through the pipette tip. New media is dispersed through the pipette tip and directly into the cell well.

Owner:SYNTHON BIOPHARMACEUTICALS BV

Nonvolatile Semiconductor Storage Device and Method for Writing Therein

InactiveUS20080273387A1Minimize the differenceGenerate efficientlySolid-state devicesRead-only memoriesCells/wellPotential difference

A hot electron (BBHE) is generated close to a drain by tunneling between bands, and bit data writing is performed by injecting the hot electron into a charge storage layer. When Vg is a gate voltage, Vsub is a cell well voltage, Vs is a source voltage and Vd is a drain voltage, a relation of Vg>Vsub>Vs>Vd is satisfied, Vg−Vd is a value of a potential difference required for generating a tunnel current between the bands or higher, and Vsub−Vd is substantially equivalent to a barrier potential of the tunnel insulating film or higher.

Owner:GENUSION

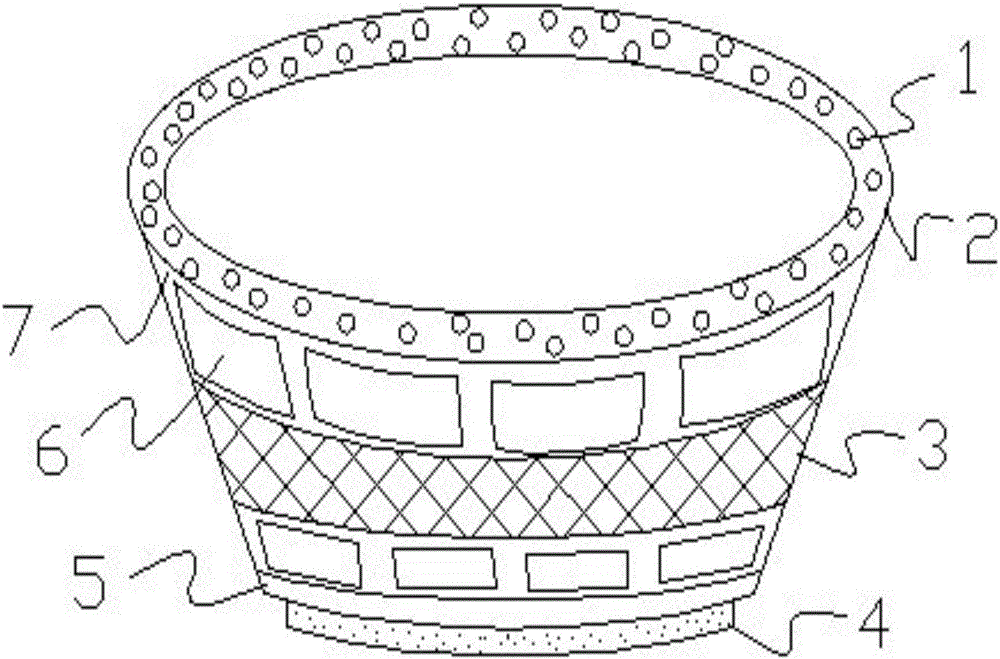

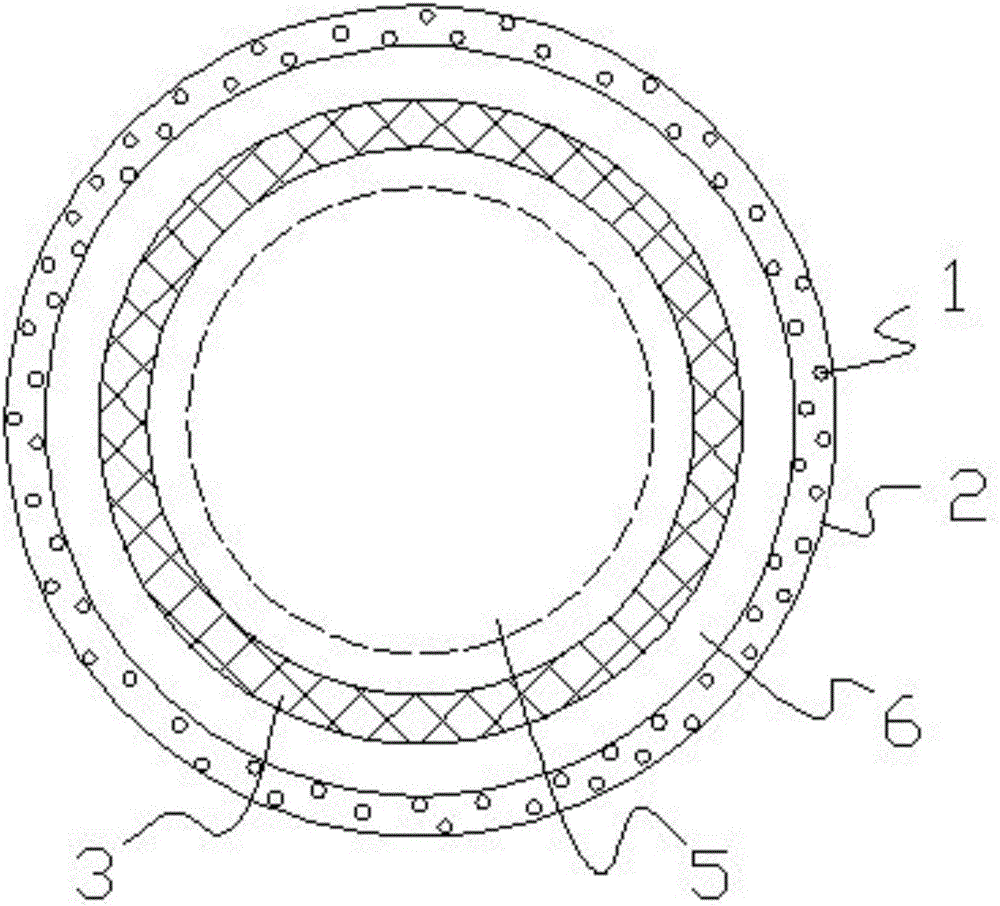

Child bathtub with heating function

A child bathtub with a heating function mainly comprises a bathtub base, a bathtub side wall and bathtub holding parts on the upper portion. A compressible rubber ring is arranged in the middle of the bathtub side wall and divides the bathtub side wall into an upper portion and a lower portion. Solar cells are fixedly arranged on the outer surface of the upper portion and the outer surface of the lower portion of the bathtub side wall respectively. Due to the fact that the compressible rubber ring has high flexibility, the bathtub can be pressed downwards, the upper portion and the lower portion of the bathtub side wall coincide, occupied space is reduced, and accordingly the bathtub is convenient to carry or store; when a child takes a bath in the child bathtub in the sun, the solar cells well utilize space of the outer surface of the bathtub and absorb solar heat to heat water in the bathtub and maintain the water temperature not decreased.

Owner:茹朝贵

EEPROM array with well contacts

Owner:KIOXIA CORP

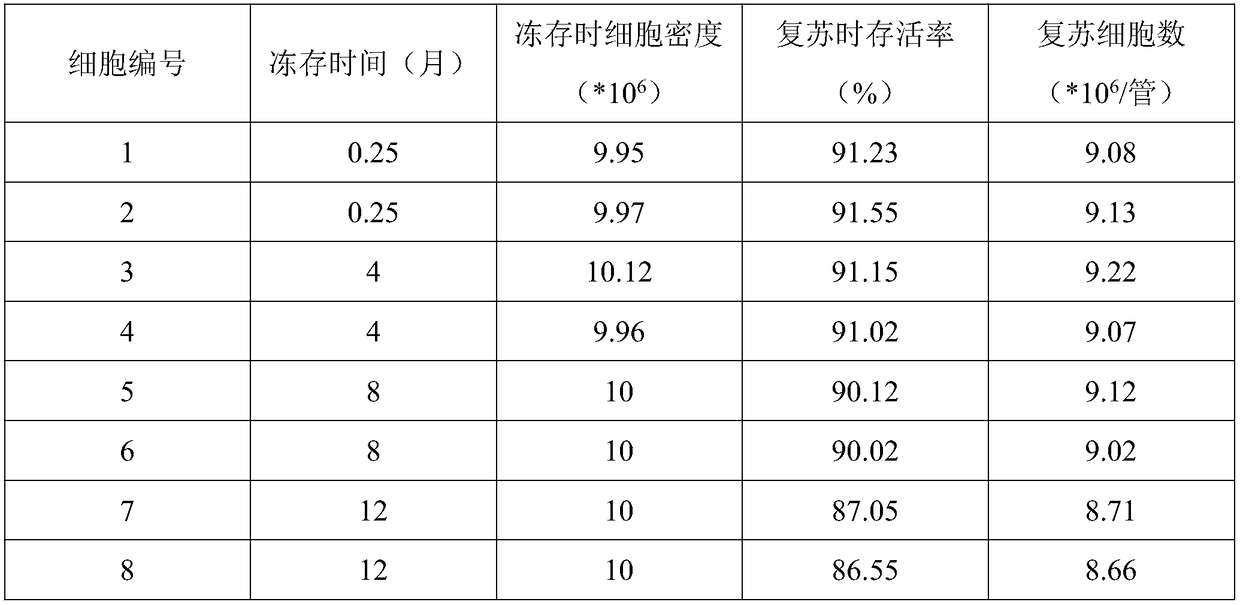

Method for preserving immune cells and cell cryopreservation solution

InactiveCN108513973ASimple stepsEasy to operateDead animal preservationCulture mediumsIMMUNOLOGIC CELLS

The invention relates to the technical field of cell preservation, in particular to a method for preserving immune cells and a cell cryopreservation solution. The method comprises the following stepsof firstly, collecting peripheral blood; secondly, separating the peripheral blood; thirdly, adding the cell cryopreservation solution into the peripheral blood for cryopreservation. The cell cryopreservation solution contains, by volume, a cell basal culture medium, fetal bovine serum and dimethyl sulfoxide. The method for preserving the immune cells is simple in step and easy to operate, the fetal bovine serum has the advantages of wide source and low price, the cost decrease is facilitated, and the method is convenient to popularize and apply; the immune cells are cryopreserved and recovered in the cell cryopreservation solution and then subjected to induced culture, and the survival rate is 90% or above, it is shown through the detection on various indexes of the immune cells that thefunctions of the immune cells keep complete, and it shows that the cell cryopreservation solution can maintain the physiological functions of the immune cells well and has great significance for clinical treatment.

Owner:广州沙艾生物科技有限公司

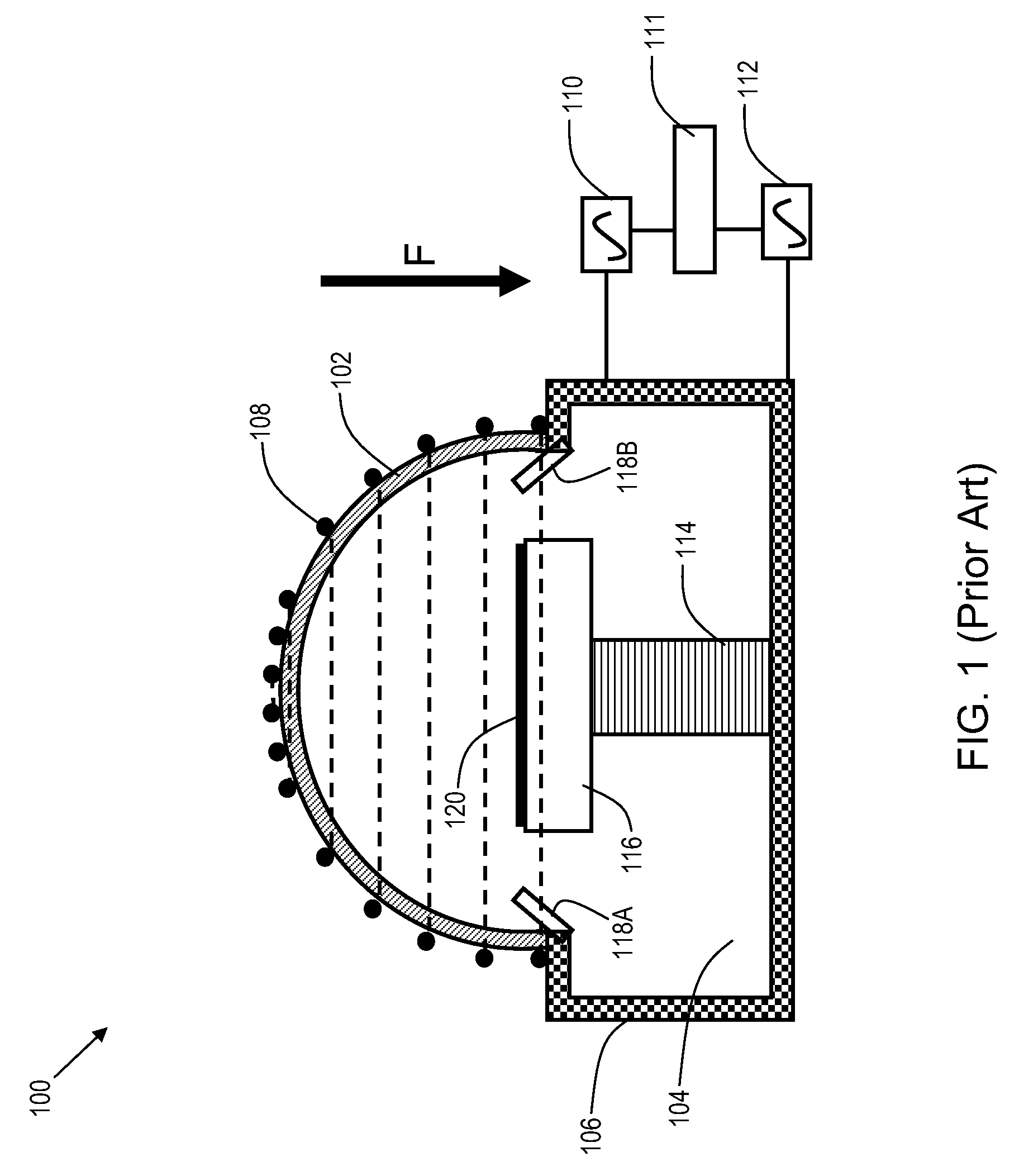

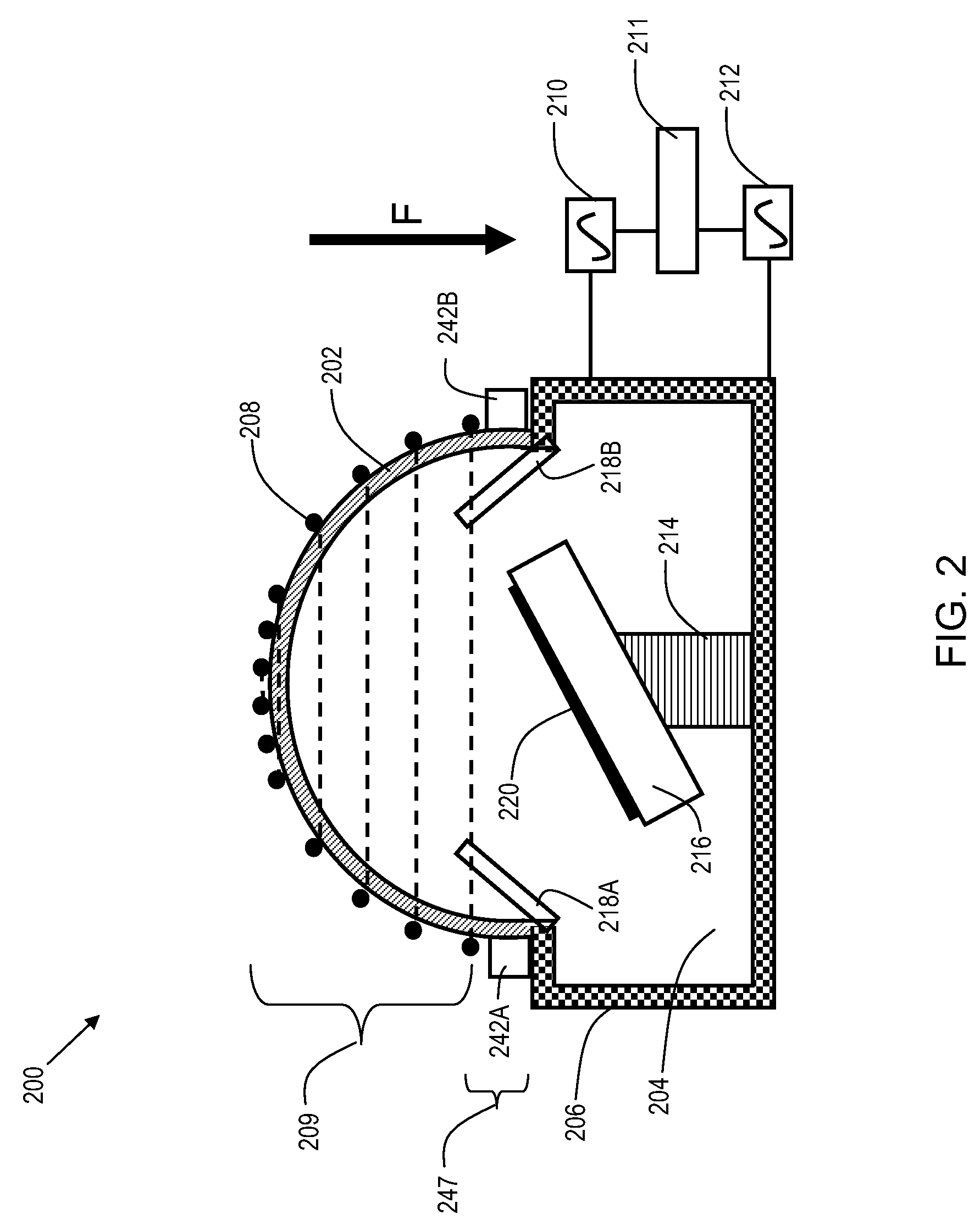

Method and apparatus for angular high density plasma chemical vapor deposition

Owner:ALSEPHINA INNOVATIONS INC

Plate and method for high throughput screening

InactiveUS20080096272A1Promote growthAvoid adjustmentBioreactor/fermenter combinationsBiological substance pretreatmentsCells/wellHigh-Throughput Screening Methods

A multiple well plate and method for media exchange, including a body defining a plurality of cell wells each connected via a channel to one of a plurality of aspiration holes, is provided. The cell wells contain a porous, hydrophilic frit which is suspended on a ledge above a reservoir of fluid media and supports a tissue sample. The properties of the frit wick the fluid media upwards to supply the tissue sample with nutrients for growth and proliferation. Old media is aspirated from the wells by a liquid handling device which inserts a pipette tip into the aspiration holes. The pipette tip applies a suction pressure which draws the media out of the cell well, through the channel, into the aspiration hole and out through the pipette tip. New media is dispersed through the pipette tip and directly into the cell well.

Owner:BIOLEX THERAPEUTICS INC

Method for obtaining high-purity proteins from wild nettles

ActiveCN104530203AReduce extraction timePeptide preparation methodsPlant peptidesCells/wellPlant cell

The invention belongs to the field of natural organic chemistry, relates to a method for extracting and separating high-purity plant proteins from nettles, and in particular relates to a method for extracting the high-purity plant proteins by utilizing a superhigh pressure technique. The method has the advantages that low-temperature or constant-temperature extraction is carried out by utilizing the superhigh pressure technique, so that the maintenance of the plant protein activity is facilitated; extracted solvents can flow into the plant cells well by utilizing the superhigh pressure technique, so that high extraction efficiency of the plant proteins is realized; the extraction time is short and the energy consumption is low; the content of impurities is reduced, and the protein purity is high; the extraction process is simple and environmental-friendly. According to the method, the nettles used as the raw materials are degreased and extracted by using alkali water as an extraction solvent under the superhigh pressure condition, and the extracting liquid is subjected to centrifuge, acid sediment, washing, drying and the like to obtain the high-purity plant proteins.

Owner:DAXINGANLING LINGOBERRY BOREAL BIOTECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com