Material based on polyhydroxyalkanoate and preparation method and application of material

A technology of polyhydroxyalkanoate and polyhydroxyalkanoate, which is applied in the field of polyhydroxyalkanoate-based materials and its preparation, can solve the problems of lack of composition adjustment and shape memory function, and achieve good integration and good biocompatibility , the effect of extensive application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

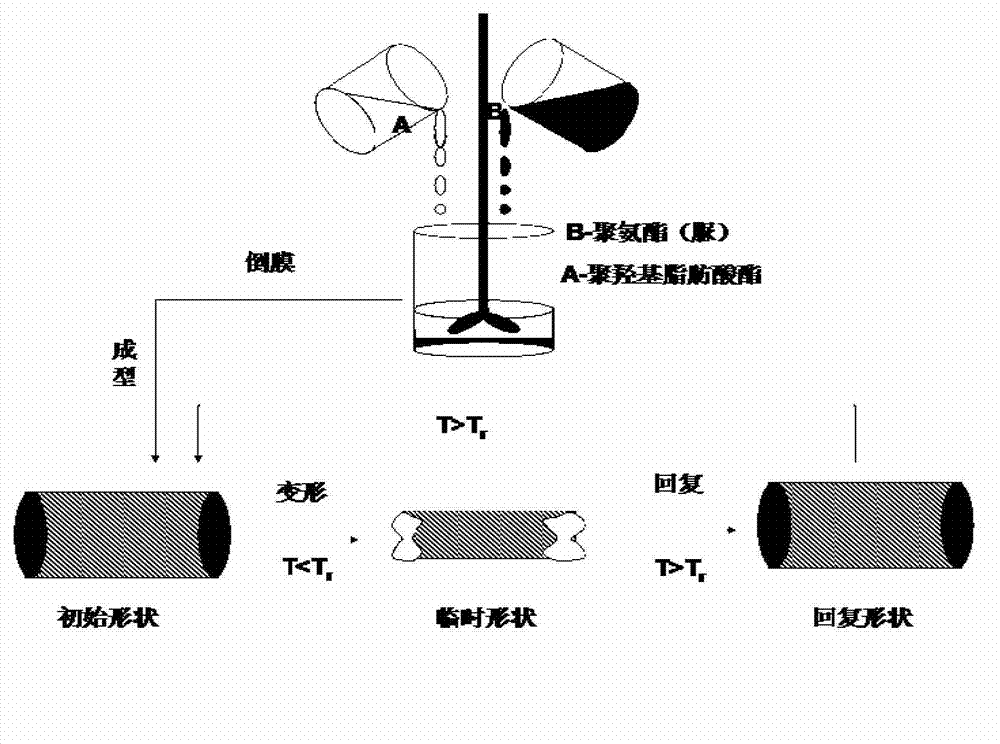

[0038] In a three-necked flask, add dimethyl sulfoxide as a solvent, then add liquefied MDI, raise the temperature by 60°C, then slowly add 1,4-dihydroxybutane (BDO) into the solution, keep the temperature for 2 hours, A polyurethane hard segment solution with a mass fraction of 10wt% was prepared.

[0039] At the same time, the commercial resin poly(3-hydroxybutyrate-4-hydroxybutyrate) solution dimethyl sulfoxide was used as a solvent, and mechanically stirred and dissolved in a water bath at 50°C for 24 hours to obtain a uniform 10wt% poly(3 -Hydroxybutyrate-4-hydroxybutyrate) solution.

[0040] Subsequently, 50 parts of polyurethane and 50 parts of poly(3-hydroxybutyrate-4-hydroxybutyrate) solution were uniformly mixed mechanically to obtain a uniform composite solution, and a solution of the polyhydroxy fatty acid-based material was obtained.

[0041] Further, the solution of the polyhydroxy fatty acid-based material was poured into a film, oven-dried at 100° C. for 48 ho...

Embodiment 2

[0044] In a three-necked flask, add N,N-dimethylformamide as a solvent, then add liquefied MDI, raise the temperature to 60°C, then slowly add N,N-bis(2-hydroxyethyl)isonicotinamide to the solution , keeping the temperature for 2 hours to prepare a 10wt% pyridine polyurethane solution.

[0045] At the same time, the commercial resin poly(3-hydroxybutyrate) solution N,N-dimethylformamide was used as a solvent, and mechanically stirred and dissolved in a water bath at 50°C for 24 hours to obtain a uniform 10wt% poly(3-hydroxybutyrate) butyrate) solution.

[0046] Subsequently, 55 parts of pyridine polyurethane, 40 parts of poly(3-hydroxybutyrate) solution, and 5 parts of terephthalic acid were uniformly mixed mechanically to obtain a uniform composite solution, and the solution of the polyhydroxy fatty acid-based material was obtained.

Embodiment 3

[0048] The commercial resin poly(3-hydroxybutyrate) was dissolved in chloroform as a solvent, refluxed in a water bath at 50°C, and mechanically stirred for 24 hours to obtain a uniform 10wt% polyβ-hydroxybutyrate-β- Hydroxyvalerate solution.

[0049] Subsequently, take 40 parts of poly-β-hydroxybutyrate-β-hydroxyvalerate / chloroform solution into a 500mL burner, add 20 parts of TDI, 39 parts of hydroquinone glycol polycondensate (BA1EO) , 1 part of water and 1 mL of polyurethane tin catalyst, mechanically vigorously stirred for about 30 minutes, the mixture was mixed evenly, and the reaction began to expand, and then placed in an oven at 120° C. to continue the reaction for 5 to 8 hours to obtain the polyhydroxy fatty acid-based material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com