Rear panel composite film for solar photovoltaic cell assembly, and preparation method for rear panel composite film

A technology of photovoltaic cells and solar energy, applied in photovoltaic power generation, electrical components, integration of renewable energy, etc., can solve the problems of dependence on imports, restrictions on the development of solar photovoltaic cells, high prices of polyvinyl fluoride and polyvinylidene fluoride, and achieve excellence Anti-aging, long-term effective protection, and the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] Example Preparation of solar photovoltaic cell module backplane composite film

[0038] 1. The polytetrafluoroethylene resin is sequentially dried, billet-made, sintered, turned, and low-temperature plasma surface treatment to obtain a polytetrafluoroethylene film and a hydrophilic film.

[0039] 2. Polyethylene terephthalate film was prepared by casting method.

[0040] 3. Coat the upper and lower surfaces of the polyethylene terephthalate film with adhesives, place the polyethylene terephthalate film between the upper and lower polytetrafluoroethylene films and the hydrophilic film, place The composite film of the back plate of the solar photovoltaic cell module is prepared by thermocompression bonding and curing of seven layers of films.

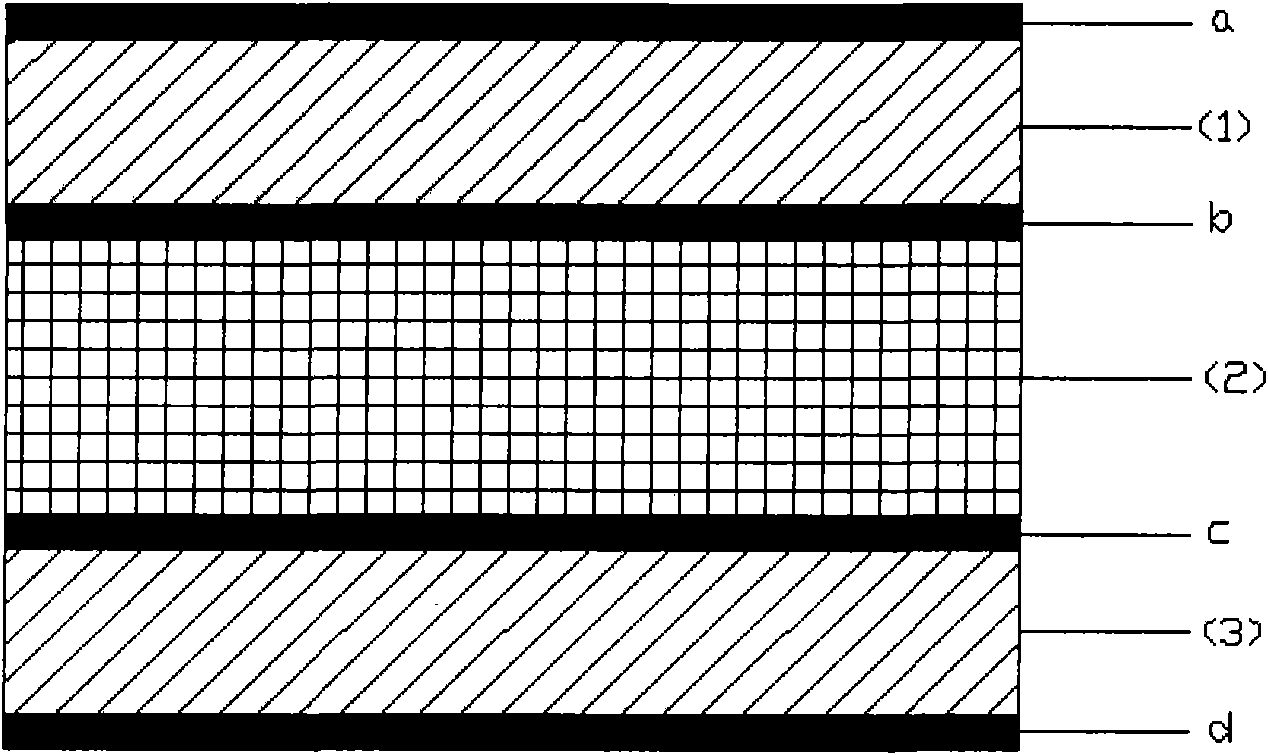

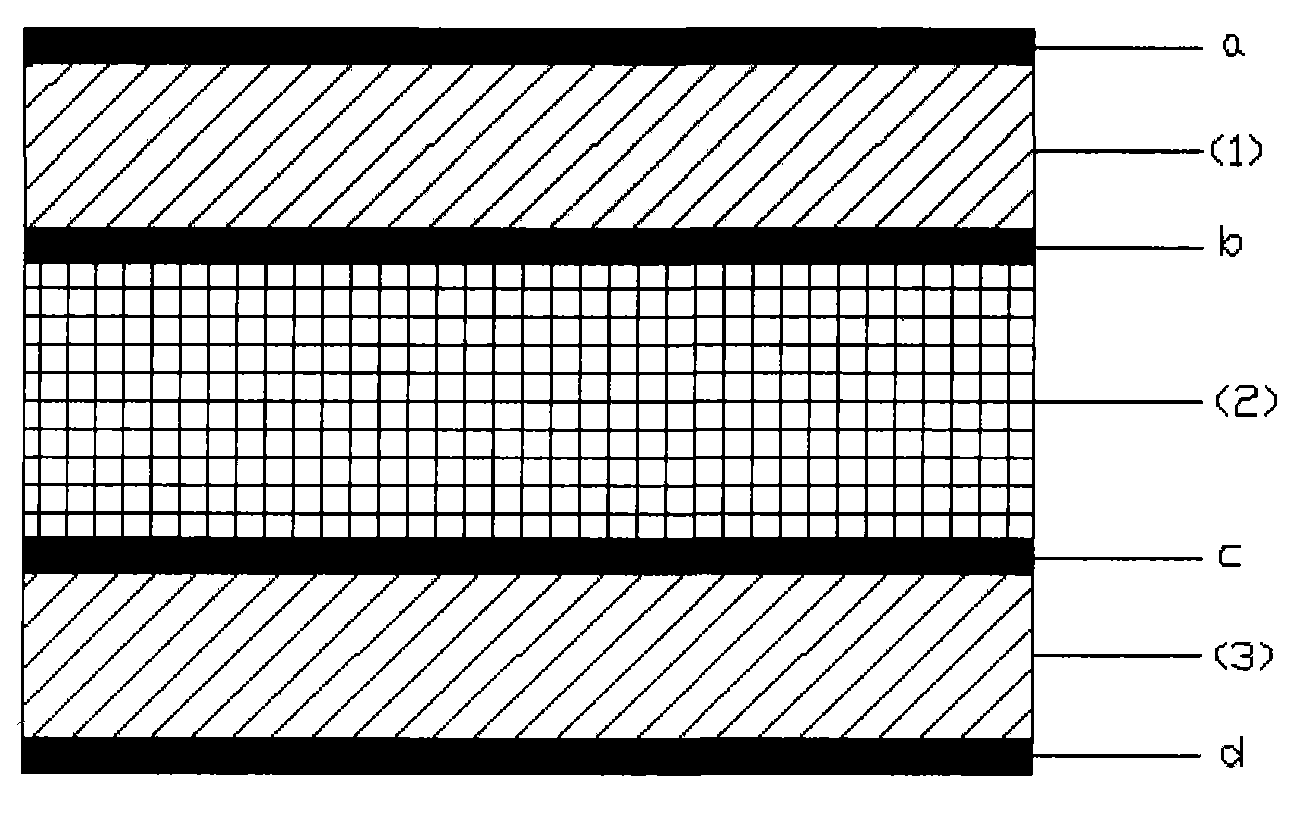

[0041] The obtained solar photovoltaic cell module backsheet composite film is composed of the following seven layers of materials:

[0042] 0.035mm thick polytetrafluoroethylene film (a layer of hydrophilic film is attached to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com