On-line regeneration method of spent photocatalyst

A technology of natural organic matter and photocatalyst, which is applied in the field of regeneration of expired photocatalysts to achieve an efficient regeneration method, promote regeneration effect, and improve regeneration efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

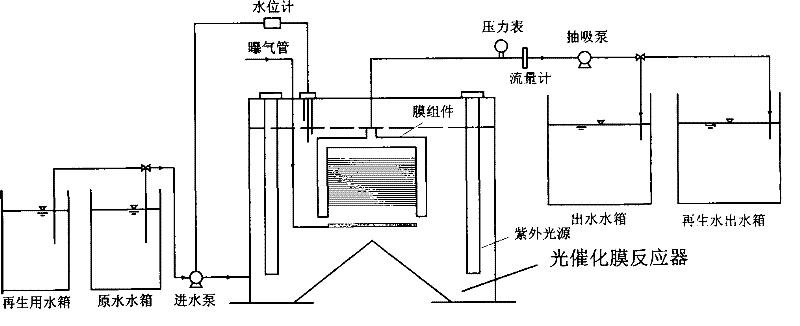

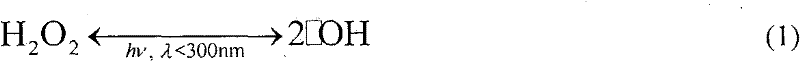

[0010] Specific embodiment one: the on-line regeneration method of the exhausted photocatalyst described in this embodiment is carried out according to the following steps: one, after the photocatalyst (gradually) fails in the operation process of the photocatalytic film combination process, stop the inflow of raw water, and utilize The membrane module discharges a part of the solution in the photocatalytic membrane reactor, and stops the water outlet when the liquid level of the solution in the photocatalytic membrane reactor is at two-thirds of the membrane module; 2. Pass into the photocatalytic membrane reactor The regeneration liquid is used to remove the adsorbed substances on the surface of the catalyst, and the hydraulic retention time of the regeneration liquid in the photocatalytic membrane reactor is controlled to be 10min to 480min; 3. The light source intensity of the ultraviolet light source is controlled to be 0.1 to 20mW / cm 2 The photocatalyst in the photocataly...

specific Embodiment approach 2

[0012] Specific implementation mode two: In this embodiment mode, in step one, the photocatalyst is TiO 2 powder. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0013] Specific embodiment three: In step two of this embodiment, the regeneration liquid is distilled water. The use of distilled water as the regeneration solution is because the distilled water does not contain other substances, which can prevent the deposition of other substances during the regeneration process, and can reduce the concentration of pollutants in the mixed solution, which is beneficial to the degradation of the substances deposited on the surface of the catalyst. Ineffective TiO after degrading natural organic matter 2 Regeneration was carried out, and the regeneration rate was 42%. Other steps are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com