Method for preparing methane-rich gas from synthesis gas

A technology of methane gas and synthesis gas, which is applied in the direction of gas fuel, chemical instruments and methods, petroleum industry, etc., can solve the problems that have not been seen in the patent disclosure or research report of the moving bed methanation reactor, and achieve easy control and lower requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

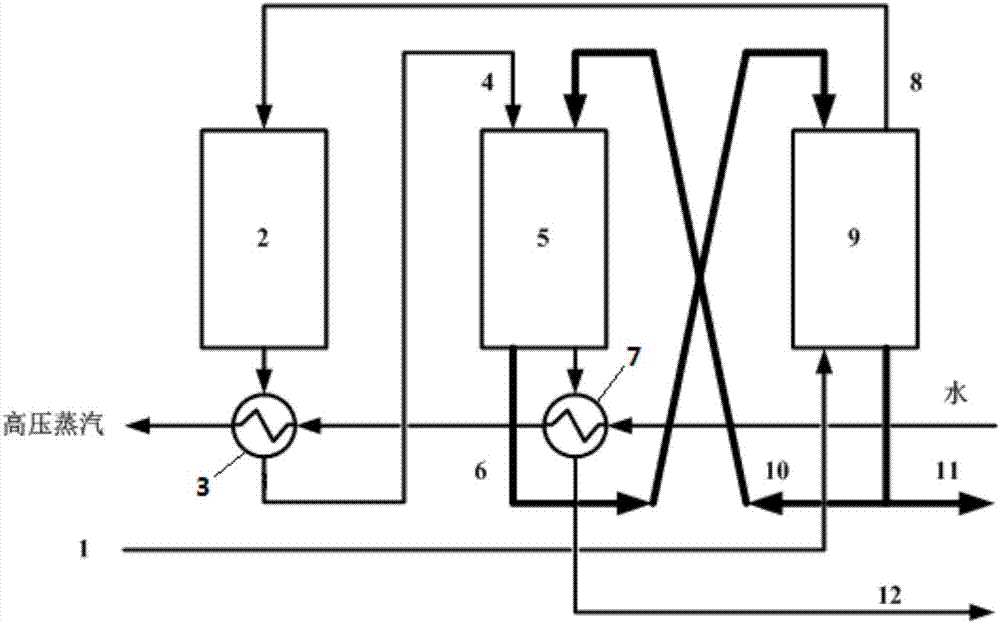

Method used

Image

Examples

Embodiment 1

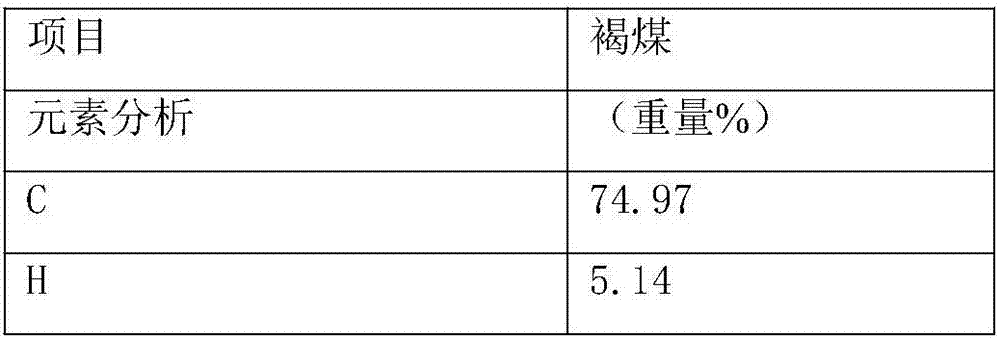

[0043] Lignite fragments with a particle size of 5-50mm (see Table 1 for chemical composition) are gasified into crude synthesis gas with oxygen / water vapor as gasification agent, and the obtained crude synthesis gas is sequentially cooled, detarred, water-gas shifted, After crude desulfurization, the net syngas (composition see Table 2) is obtained, in which (CO+H 2 ) content is 74.59% by volume, H 2 / CO molar ratio is 3.07, H 2 The S content is 5 ppm.

[0044] Table 1

[0045]

[0046]

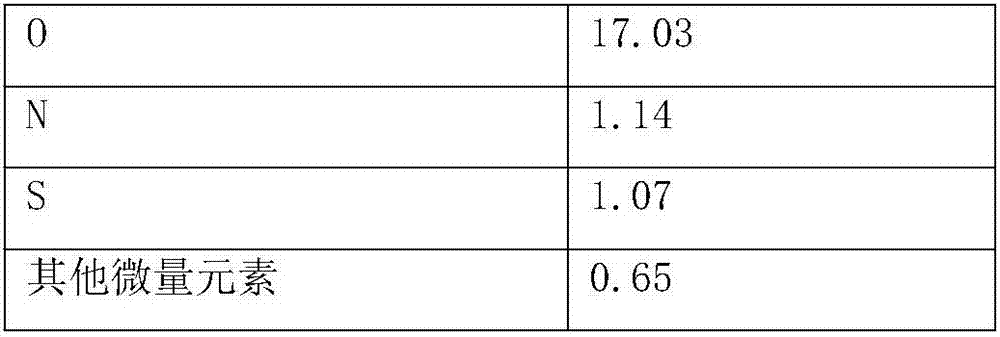

[0047] Table 2

[0048] main component

(mol%)

H 2

56.26

CO

18.33

CO 2

2.20

CH 4

20.87

N 2

1.14

Ar

0.57

C2+ hydrocarbons

0.63

h 2 S

5ppm

[0049] The first methanation reactor is a moving bed reactor, and the catalyst is a small spherical methanation catalyst with an average diameter of 2.6 mm (composition: 20.3% by weight NiO, 78.9% by weight Al 2 o 3 , 0.6 wt% Fe 2 o 3 , 0.2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com