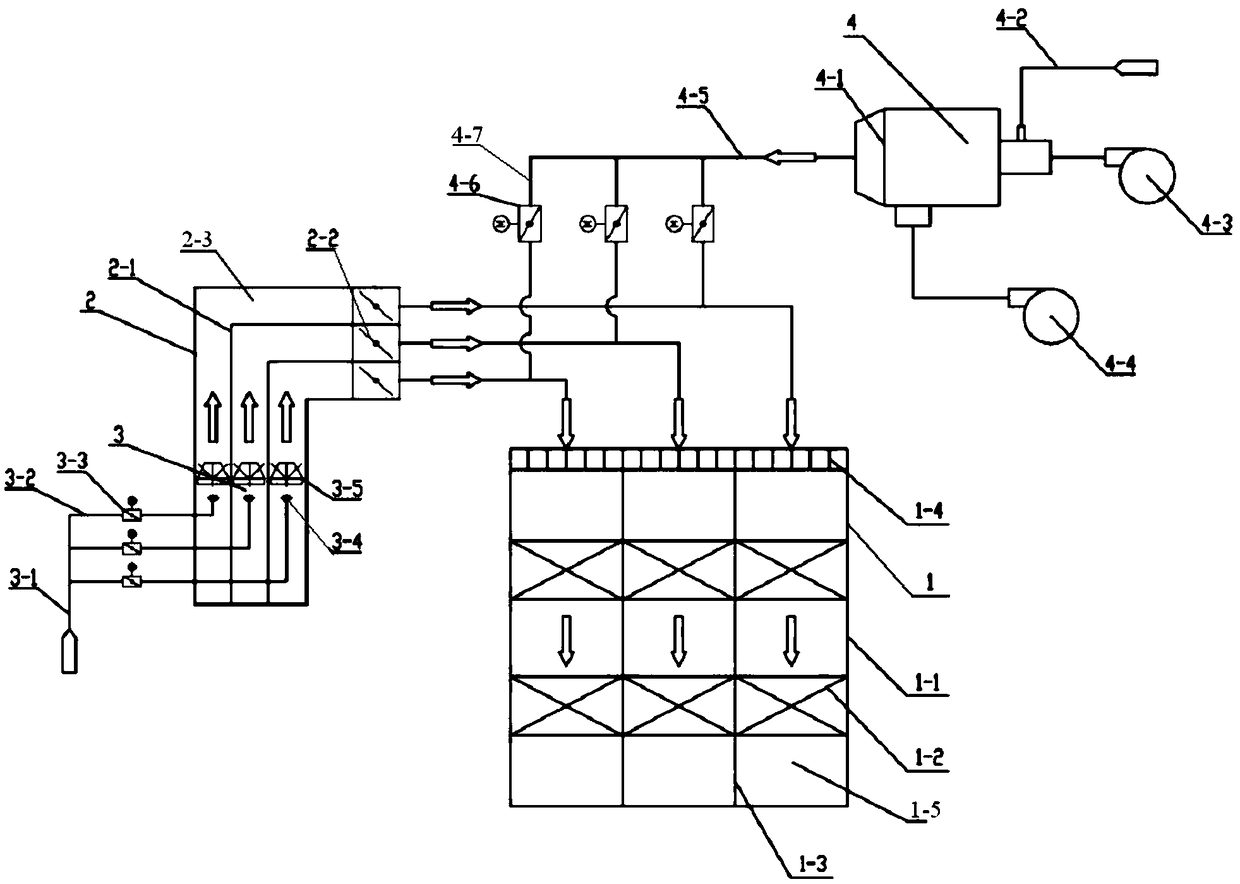

SCR flue gas denitration device with various adjustment functions

A denitrification and flue gas technology, applied in the field of flue gas denitrification, can solve the problems of substandard NOx emission, uneven distribution of ammonia and flue gas, and difficulty in ensuring uniformity, so as to improve adaptability, ensure discharge up to standard at export, and improve stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The temperature of the flue gas entering the denitrification reactor is lower than the suitable operating temperature of the catalyst, keep the flue baffles fully open, open the hot air generator, air distribution fan, temperature regulation fan and all temperature regulation baffles of the flue gas temperature adjustment unit, Through the combustion and temperature adjustment of the gas in the hot air generator, the flue gas temperature adjustment unit generates hot air at 300-500 °C, which is used to heat the flue gas to be denitrated, and can increase the temperature of the flue gas to be denitrated by 20-100 °C to achieve the optimum catalyst operating temperature. Among them, coke oven gas, blast furnace gas, natural gas or other gases, liquid or solid fuels can be used as fuel; fresh air can be blown by the air distribution fan; fresh air or flue gas after denitrification can be blown by the temperature regulating fan .

Embodiment 2

[0047] The temperature of the flue gas to be denitrated entering the denitrification reactor is higher than the suitable operating temperature of the catalyst. Keep the flue baffle fully open, turn on the temperature regulation fan and all the temperature regulation baffles of the flue gas temperature regulation unit, and the flue gas temperature regulation unit generates The low-temperature air or flue gas with the required flow rate is used to cool the flue gas to be denitrated, which can reduce the temperature of the flue gas to be denitrated by 20-50°C, reach the suitable operating temperature of the catalyst, and prevent the high temperature from adversely affecting the catalyst. The temperature-regulating fan blows in fresh air or low-temperature flue gas.

Embodiment 3

[0049] When the catalyst in the denitration reactor needs to be regenerated, the denitration device can regenerate the catalysts in each sub-section of the denitration reactor on-line in turn.

[0050] The specific method is: close the flue baffle corresponding to the sub-section and ensure that the flue baffles of other sub-sections are fully opened; open the hot air generator, air distribution fan, temperature adjustment fan of the flue gas temperature adjustment unit and the temperature adjustment of the corresponding sub-section The baffle and ensure that the temperature control baffles of other partitions are fully closed; through the combustion of gas in the hot air generator and the temperature regulation of the flue gas temperature regulation unit to generate hot air at about 350 ° C, the heating makes the temperature of the catalyst in this sub-section rise to The required regeneration temperature enables the ammonium bisulfate deposited on the catalyst to be heated an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com