Production method for improving productivity of alkaline furnace

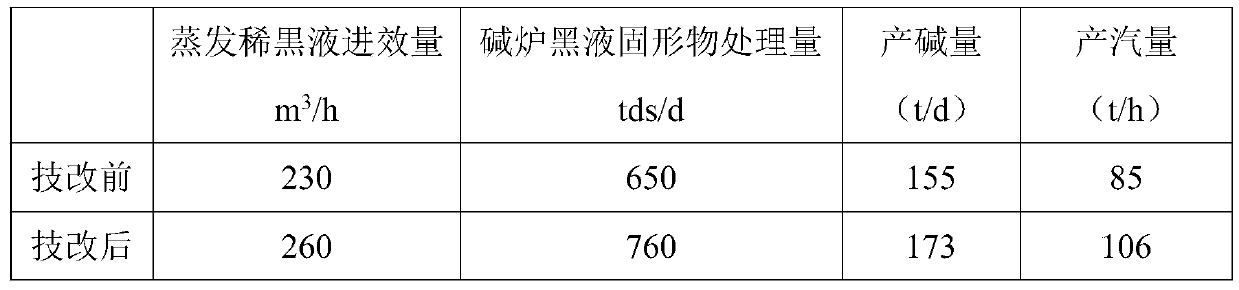

A production method and a recovery boiler technology are applied in the production field of increasing the production capacity of recovery boilers, which can solve the problems of increasing alkali production and steam production, insufficient production capacity of alkali recovery system, etc., so as to increase residence time, facilitate coordinated development and benefit significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to facilitate a better understanding of the present invention, the following examples are used to illustrate, and these examples belong to the protection scope of the present invention, but do not limit the protection scope of the present invention.

[0027] A production method for improving the production capacity of an alkali furnace, comprising the following steps:

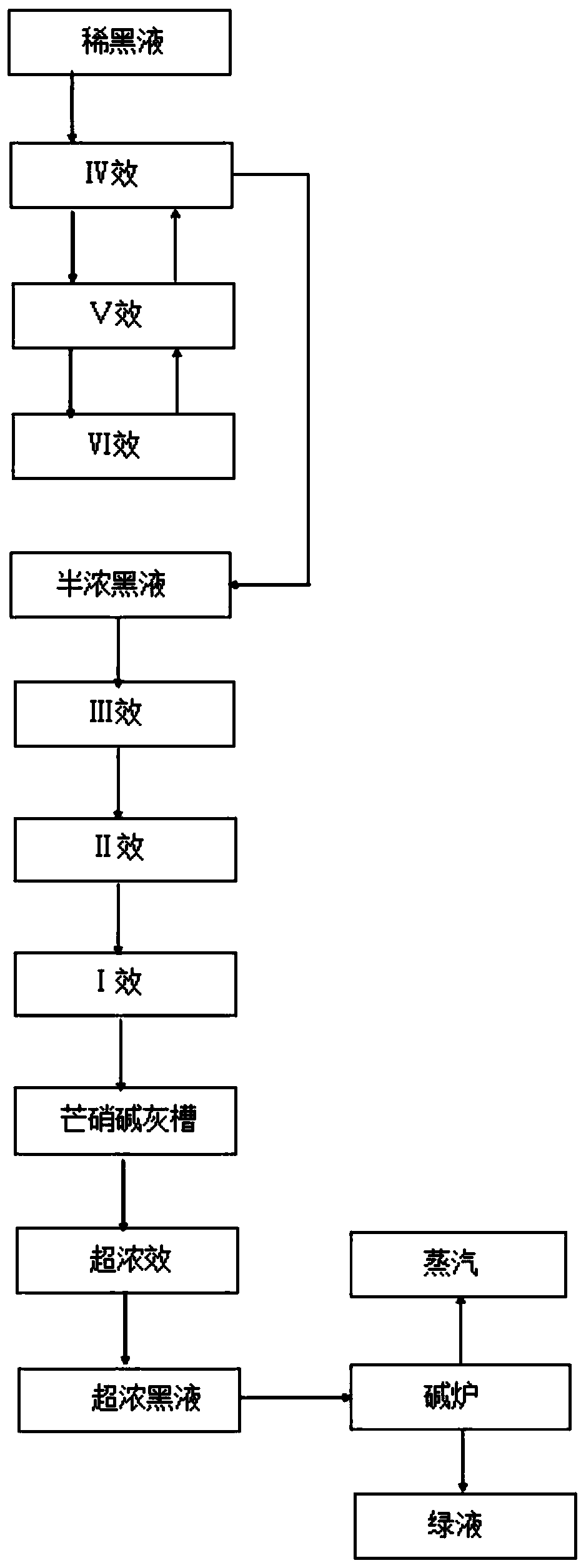

[0028] (2) Evaporation and concentration of black liquor: use effect I, effect II, effect III, effect IV, effect V, effect VI and super-concentrated effect to evaporate and concentrate coniferous wood dissolving pulp black liquor, and the concentration of black liquor after treatment will reach more than 72%. ;

[0029] (3) Air volume and air pressure ratio: the primary air volume is 40000Nm 3 / h, wind pressure 1000pa; secondary air volume 45000Nm 3 / h, wind pressure 1200pa; tertiary air volume 32000Nm 3 / h, wind pressure 1800pa air volume wind pressure ratio mode;

[0030] (3) Jet combustio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com