Method for preparing phenol acetone using moving bed reactor

A moving bed reactor, phenol acetone technology, applied in chemical instruments and methods, oxygen-containing compound preparation, carbon-based compound preparation, etc., can solve the problems of low selectivity of phenol and acetone, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

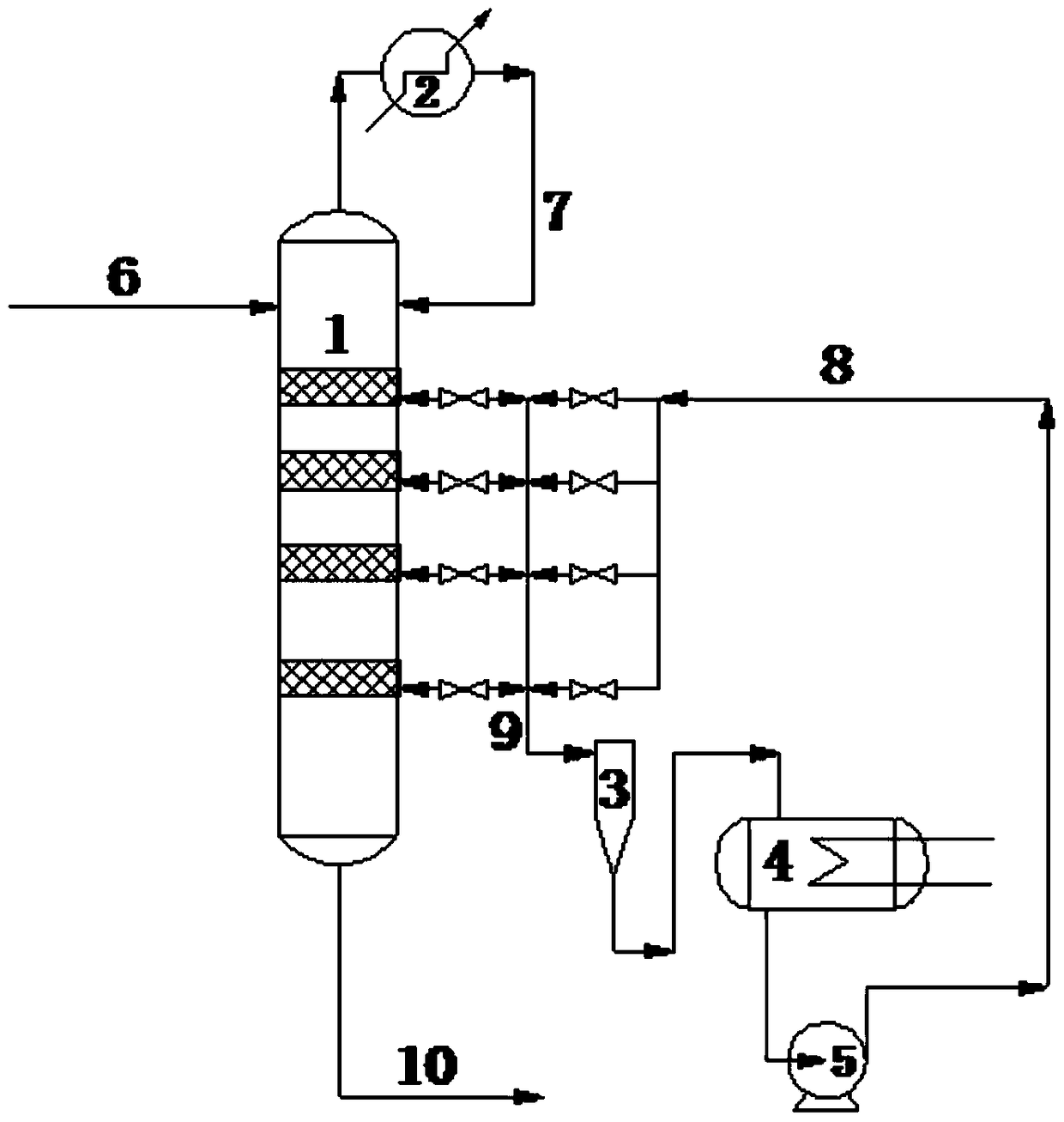

[0017] Take the 100,000 tons / year phenol acetone plant of production scale as example, adopt moving bed reactor of the present invention (as figure 1 As shown), the CHP raw material enters from the top of the reactor, contacts the solid catalyst with the gravity flow, and simultaneously undergoes a decomposition reaction and generates a large amount of heat of formation. The heat generated by the CHP decomposition reaction evaporates the liquid phase acetone in the decomposition product into a gas phase And discharged from the top of the reactor, the discharged gas phase acetone exchanges heat with circulating cooling water in the condenser set above the reactor, and removes the heat of decomposition reaction, while the gas phase acetone condenses into a liquid phase and returns to the reactor. During the normal decomposition reaction process of the catalyst bed, the evaporation and boiling of acetone produces bubbling, so that the catalyst particles are in a flowing state with...

Embodiment 2

[0019] According to the conditions described in embodiment 1, only the production scale of the phenol acetone plant is changed to 200,000 tons / year, adopt the process method of the moving bed reactor of the present invention, the operating temperature of the reactor is 72 ℃, and the operating pressure is 66kPaA; Reaction The length-to-diameter ratio of the reactor is 6:1, and the reactor is filled with 4 stages of catalysts. Accordingly, the selectivity of phenol was 99.50%, and the selectivity of acetone was 99.35%.

Embodiment 3

[0021] According to the conditions described in embodiment 1, only the production scale of the phenol acetone plant is changed to 350,000 tons / year, adopt the process method of the moving bed reactor of the present invention, the operating temperature of the reactor is 72 ℃, and the operating pressure is 66kPaA; Reaction The length-to-diameter ratio of the reactor is 6:1, and the reactor is filled with 4 stages of catalysts. Accordingly, the selectivity of phenol was 99.45%, and the selectivity of acetone was 99.30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com