Apparatus and method for producing lightweight aromatic hydrocarbons from acetylene in order to realize reaction regeneration

A light aromatics, reaction regeneration technology, applied in chemical instruments and methods, bulk chemical production, liquid hydrocarbon mixture production, etc., can solve the problems of lack of petroleum resources, increasing demand for aromatics, etc., to improve the conversion rate of acetylene, increase the yield efficiency and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

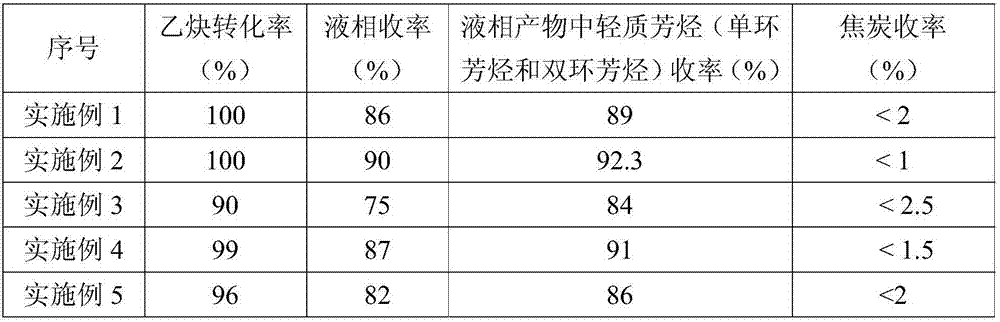

Embodiment 1

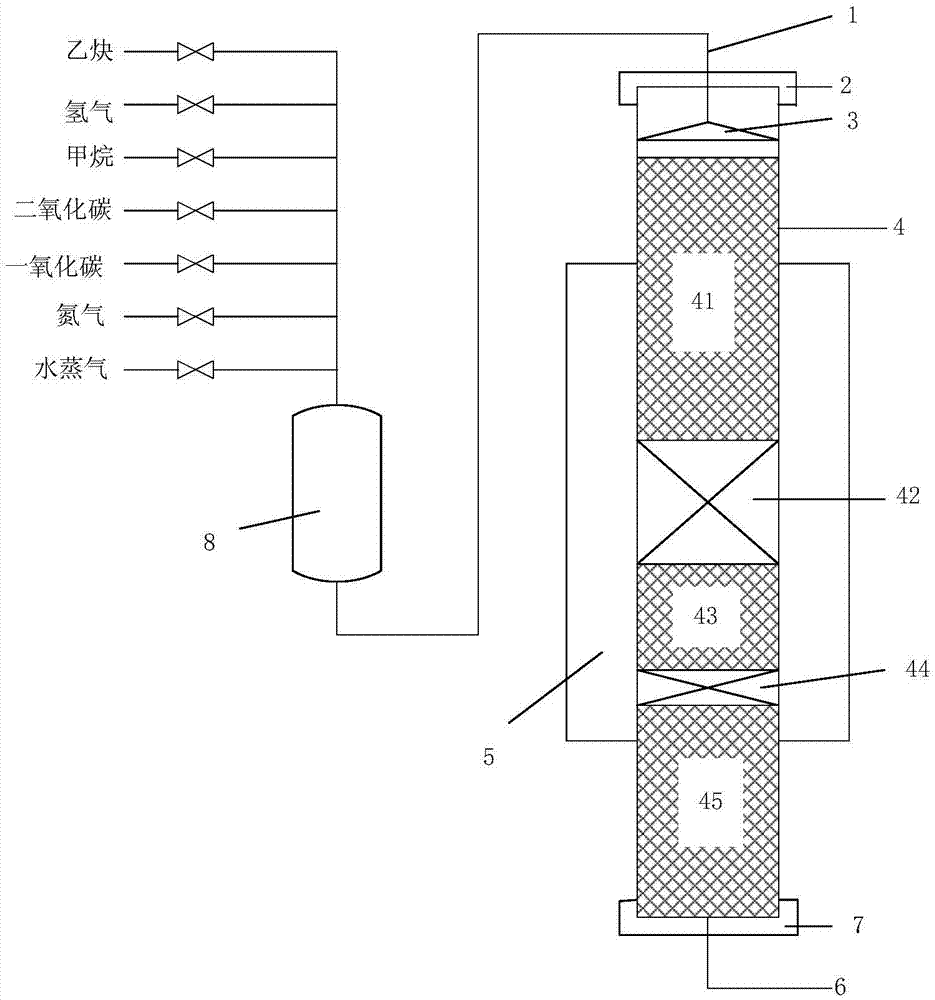

[0059] like figure 1 As shown, a device for producing light aromatics from acetylene that realizes reaction regeneration includes an inlet pipeline 1, a first sealing element 2, a second sealing element 7, a stainless steel reaction sleeve 4, a gas distributor 3, and a heating furnace 5 And discharge pipeline 6, wherein feed pipeline 1 is provided with inlet and outlet; Gas distributor 3 is arranged on the inside of stainless steel reaction sleeve pipe 4 and is positioned at the upper end of stainless steel reaction sleeve pipe 4 and communicates with the outlet of feed pipeline 1; A sealing element 2 is set at the connection between the feed pipeline 1 and the stainless steel reaction sleeve 4; the stainless steel reaction sleeve 4 is filled with ceramic honeycomb; the stainless steel reaction sleeve 4 runs through the heating furnace 5, and the heating furnace 5 is facing the stainless steel reaction sleeve 4 is heated, so that the reaction sleeve 4 is divided into a preheat...

Embodiment 2

[0067] like figure 1As shown, a device for producing light aromatics from acetylene that realizes reaction regeneration includes an inlet pipeline 1, a first sealing element 2, a second sealing element 7, a stainless steel reaction sleeve 4, a gas distributor 3, and a heating furnace 5 And discharge pipeline 6, wherein feed pipeline 1 is provided with inlet and outlet; Gas distributor 3 is arranged on the inside of stainless steel reaction sleeve pipe 4 and is positioned at the upper end of stainless steel reaction sleeve pipe 4 and communicates with the outlet of feed pipeline 1; A sealing element 2 is set at the connection between the feed pipeline 1 and the stainless steel reaction sleeve 4; the stainless steel reaction sleeve 4 is filled with ceramic honeycomb; the stainless steel reaction sleeve 4 runs through the heating furnace 5, and the heating furnace 5 is facing the stainless steel reaction sleeve 4 is heated, so that the reaction sleeve 4 is divided into a preheati...

Embodiment 3

[0075] like figure 1 As shown, a device for producing light aromatics from acetylene that realizes reaction regeneration includes an inlet pipeline 1, a first sealing element 2, a second sealing element 7, a stainless steel reaction sleeve 4, a gas distributor 3, and a heating furnace 5 And discharge pipeline 6, wherein feed pipeline 1 is provided with inlet and outlet; Gas distributor 3 is arranged on the inside of stainless steel reaction sleeve pipe 4 and is positioned at the upper end of stainless steel reaction sleeve pipe 4 and communicates with the outlet of feed pipeline 1; A sealing element 2 is set at the connection between the feed pipeline 1 and the stainless steel reaction sleeve 4; the stainless steel reaction sleeve 4 is filled with ceramic honeycomb; the stainless steel reaction sleeve 4 runs through the heating furnace 5, and the heating furnace 5 is facing the stainless steel reaction sleeve 4 is heated, so that the reaction sleeve 4 is divided into a preheat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com