Partial premixing and pre-evaporation combustion chamber with three-level oil passages

A combustor and pre-evaporation technology, which is applied in the field of aero-engines, can solve the problems of unstable combustion, long pre-mixing section, prone to spontaneous combustion and tempering, etc., and achieve the effect of ensuring stable operation and reducing pollutant emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

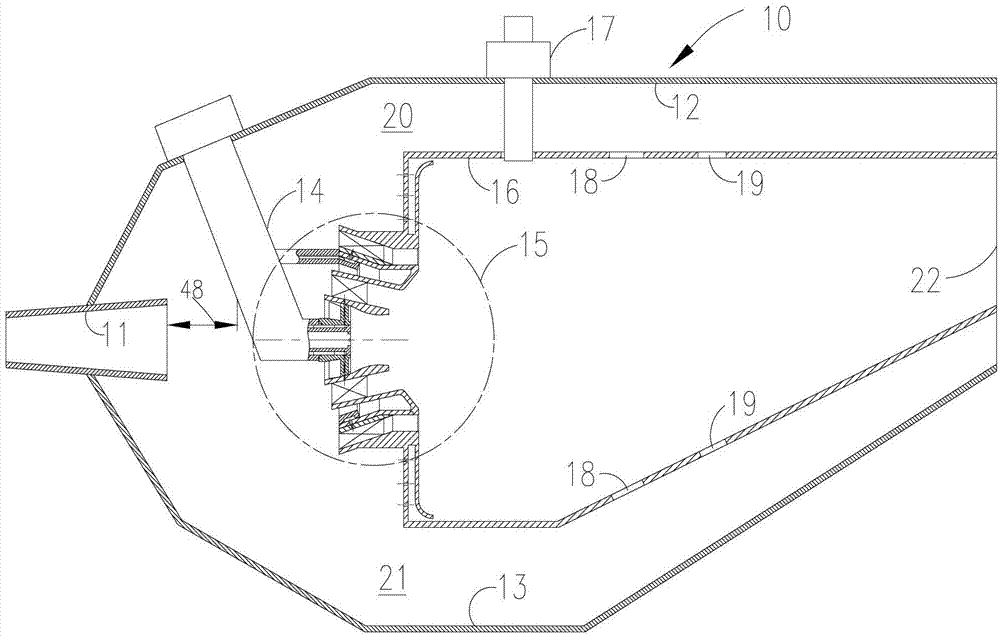

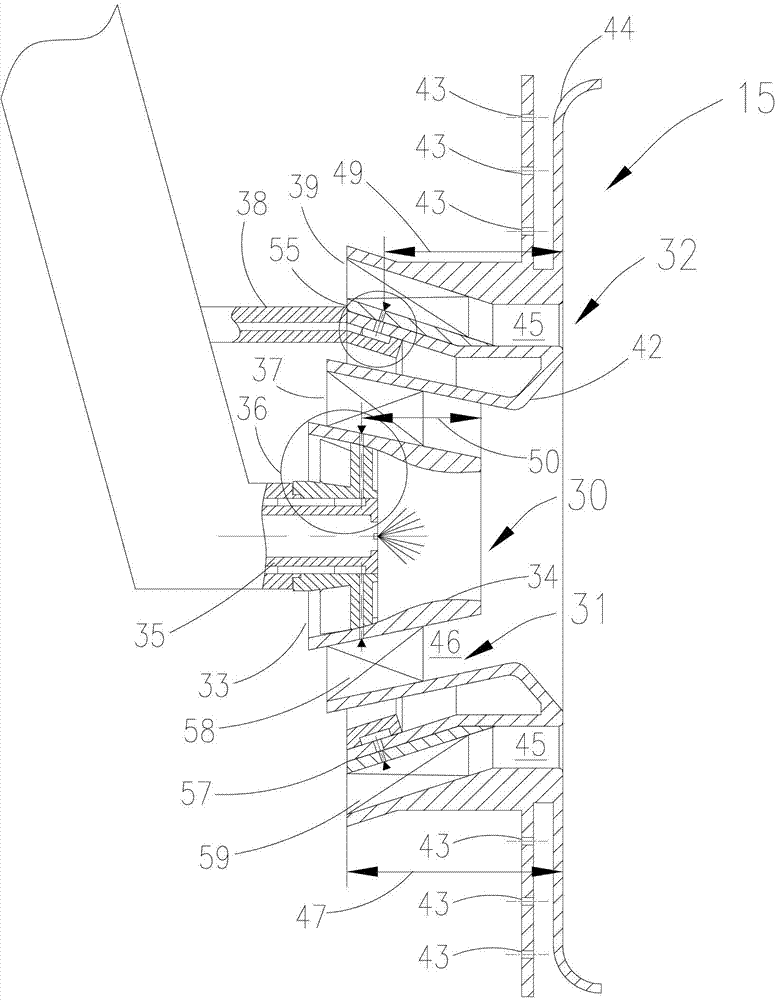

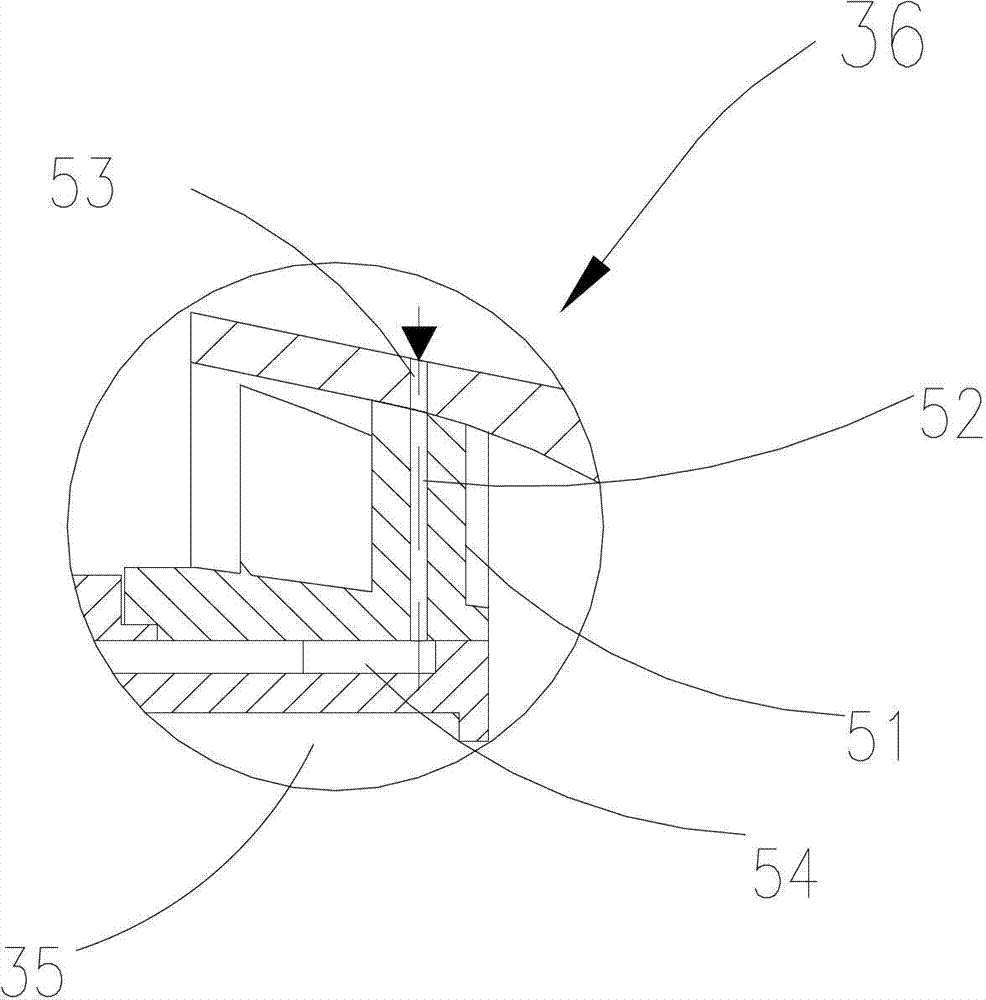

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific implementation examples.

[0025]The head scheme of the present invention adopts the three-stage DIPME (Rich / Lean Direct Injection and Lean Partial Pre-Mixing & Pre-Evaporation) mixed combustion mode of the center stage, that is, at the start and small state, the pre-combustion stage adopts rich oil direct injection ( Rich Direct Injection) combustion mode, this combustion mode is to achieve local rich oil through the pre-combustion stage composed of auxiliary oil channel centrifugal nozzle, oblique axial vortex and Venturi tube, this organization combustion mode is between premixed combustion and diffusion Between combustion; in the intermediate state (descent, return, etc.), the pre-combustion stage adopts the rich direct injection combustion mode (Rich Direct Injection, local equivalence ratio is 1.2 ~ 1.4) or lean direct injection (Lean Direct Injection,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com