Low-temperature plasma regeneration DPF system

A low-temperature plasma and DPF technology, applied in the field of DPF systems, can solve the problems of limited regeneration efficiency, short life and high activity, and inability to participate in PM oxidation reaction, and achieve the effects of high PM oxidation efficiency, increased rate, and good regeneration effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

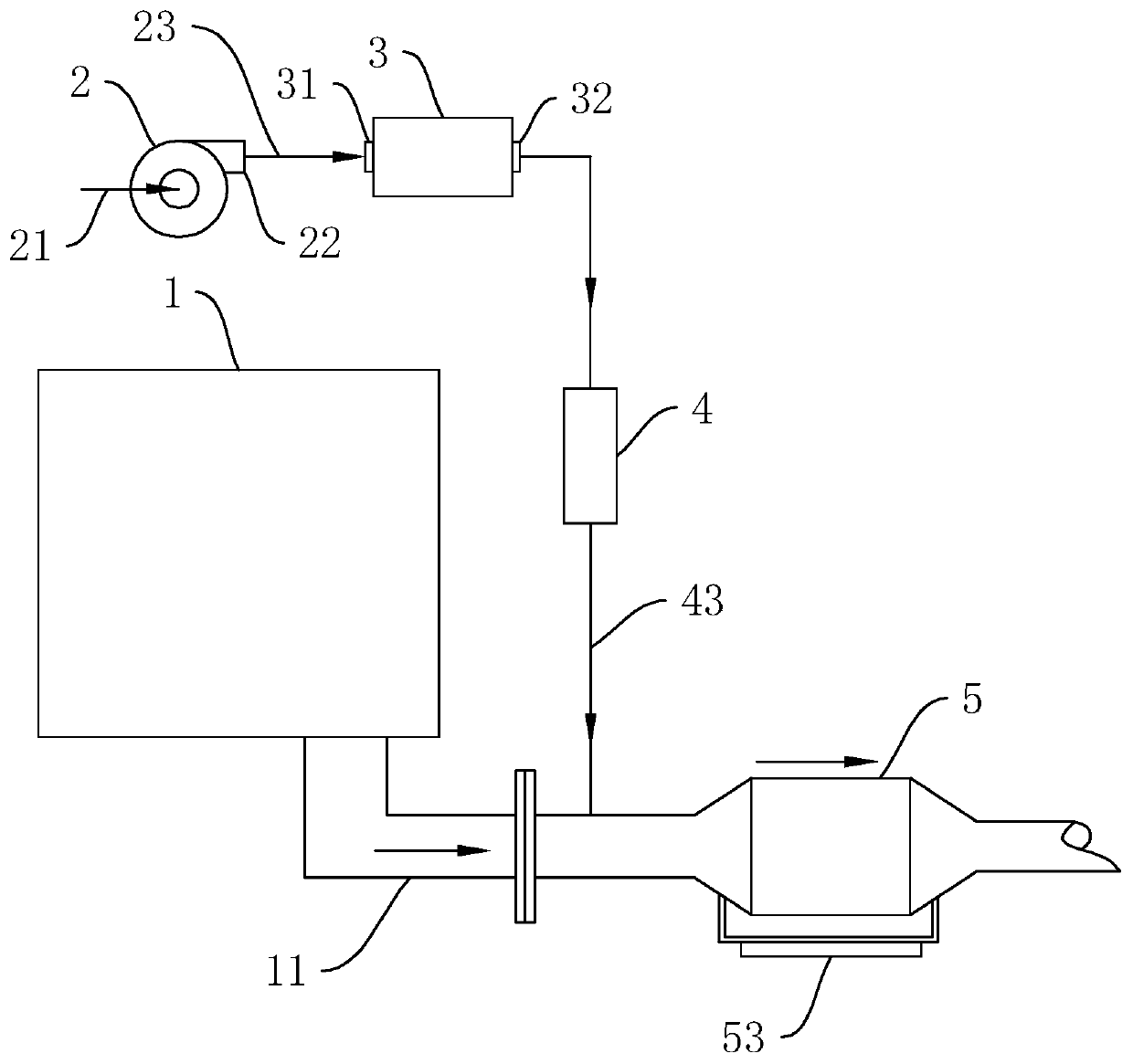

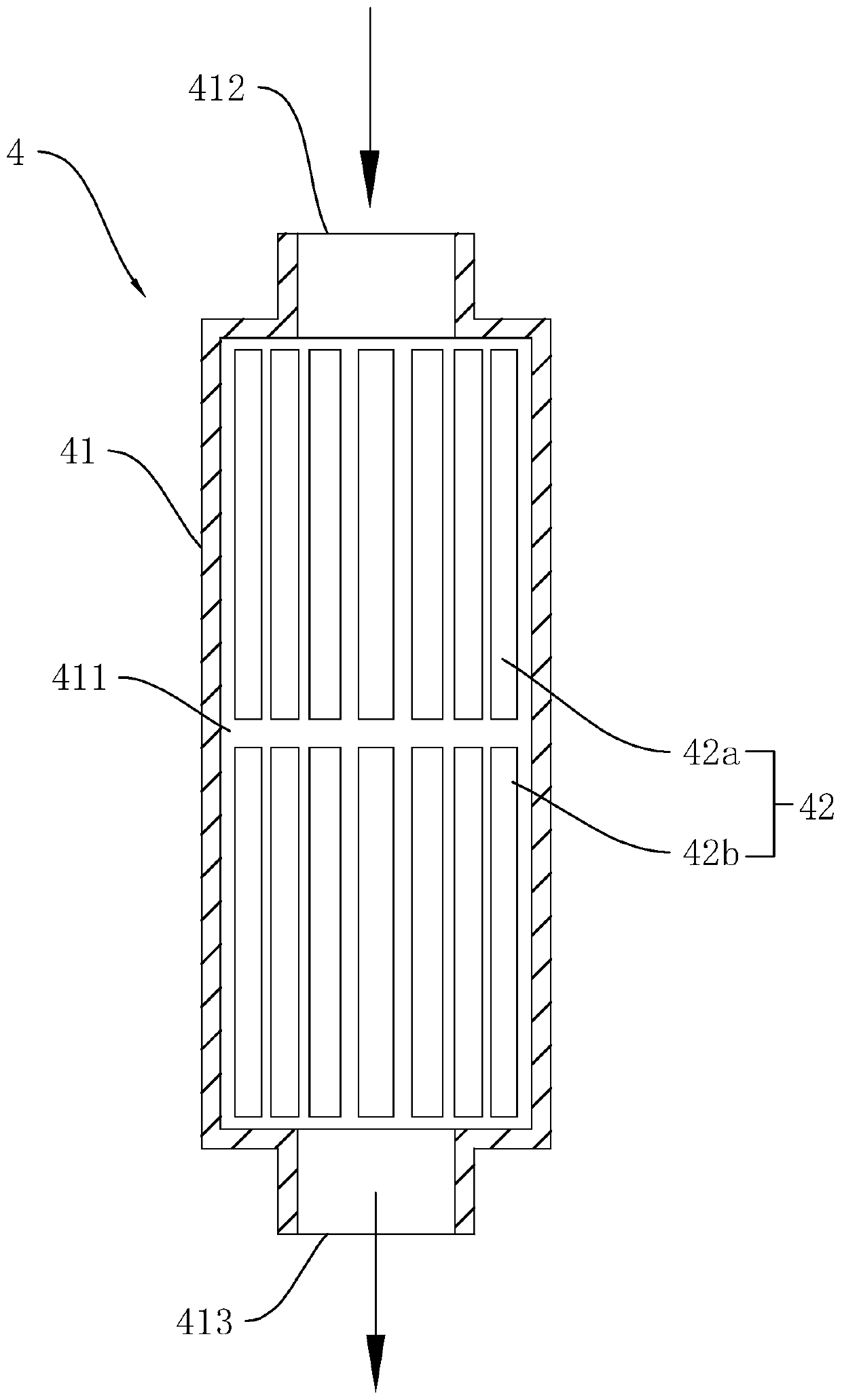

[0063] as attached figure 1 As shown, a low-temperature plasma regeneration DPF system is used in the exhaust gas treatment system of a diesel engine 1, including a supply fan 2, a first NTP generator 3, a DPF 5 and an ultraviolet converter 4.

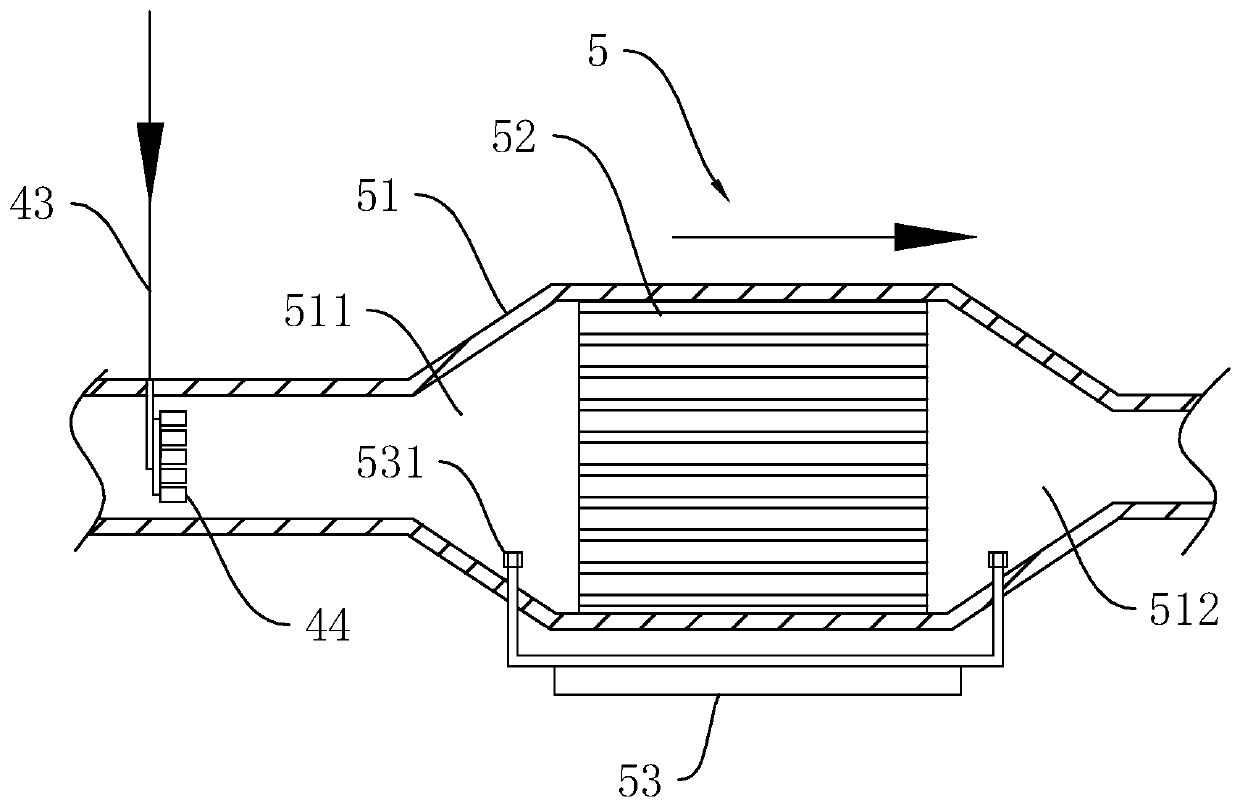

[0064] as attached figure 2 As shown, DPF5 is an existing diesel particulate filter, which can be selected according to actual conditions, including a DPF housing 51, a filter element 52 and a pressure detection mechanism 53 accommodated in the DPF housing 51. The DPF shell 51 depends on the actual situation. The DPF shell 51 is hollow inside and has openings at both ends. The two openings are the DPF inlet 511 and the DPF outlet 512 respectively.

[0065] as attached figure 1 And attached figure 2 As shown, the DPF inlet 511 is connected to the exhaust port of the diesel engine 1 by the diesel engine exhaust pipe 11, which is a prior art and can be arranged according to the actual situation. Diesel engine 1 burns diesel fuel and...

Embodiment 2

[0096] A system for regenerating a DPF with low-temperature plasma, which is improved on the basis of Embodiment 1.

[0097] as attached Figure 4 As shown, due to the comparison of NO in the pipeline environment 2 In terms of O 3 The stability of ozone is relatively poor, so the application also carried out experimental tests on the residence time of ozone at different temperatures, and found that the residence time of ozone was different at different temperatures, and the residence time decreased as the temperature increased.

[0098] as attached Figure 5 As shown, while O 3 The progress of the reaction to NO oxidation is affected by the temperature, and the application for O 3 The test of NO oxidation rate when oxidizing NO at different temperatures shows that when the reaction environment temperature is less than 300°C, the NO oxidation rate is almost maintained at 100%, and when the reaction environment temperature is greater than 300°C, the NO oxidation rate is grea...

Embodiment 3

[0107] as attached Figure 7 As shown, a system for regenerating DPF with low-temperature plasma is improved on the basis of Embodiment 2, the difference is that the DPF regeneration system includes a nitrogen oxide adsorber 8 .

[0108] as attached Figure 8 As shown, the nitrogen oxide adsorber 8 includes an adsorber shell 81 and a zeolite adsorption plate set 82 . The shape of the adsorber housing 81 can be determined according to the actual situation. It includes an adsorber inlet 811 and an adsorber outlet 812 respectively located at both ends. The adsorber inlet 811 communicates with the DPF outlet 512, and the adsorber outlet 812 is connected to an exhaust port connected to the atmosphere. Empty tube 813.

[0109] The zeolite adsorption plate group 82 includes a plurality of zeolite plates 821, and the zeolite plates 821 are fixed in the adsorber housing 81, and the fixing method can be determined according to the actual situation, and here is clamping. The zeolite p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com