Online regeneration method of filter element of dust remover for filtering high-temperature combustible dust

A dust collector and filter element technology, applied in chemical instruments and methods, separation methods, dispersed particle filtration, etc., can solve the problems affecting normal production, low temperature of dust removal bags, low equipment utilization rate, etc., to improve filtration efficiency and service life. , good promotion and use value, the effect of improving filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

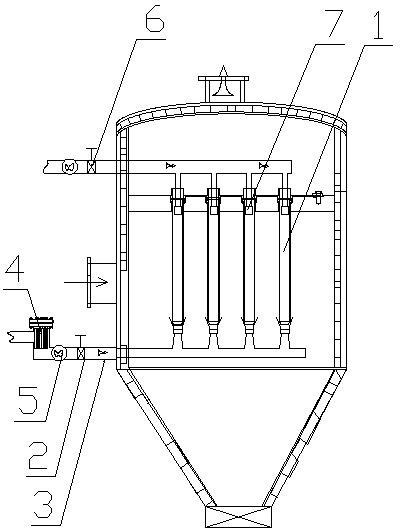

[0023] Such as figure 1 As shown, an on-line regeneration method of a filter element of a dust collector for filtering high-temperature combustible dust includes an oxygen-lean combustion link between an oxygen-poor gas sent to the outside of the filter element 1 of the dust collector and combustible dust on the filter element 1 of the dust collector, and the The oxygen-depleted combustion link is alternately carried out with the back-blowing and dust-cleaning link of the filter element 1 of the dust collector. The oxygen content is controlled at 2%; the temperature of the oxygen-depleted gas in the oxygen-lean combustion link is 100°C; the time ratio between the oxygen-lean combustion and the backflushing soot cleaning link is 1:1, and the oxygen-lean gas includes Oxygen and nitrogen; the oxygen material delivery pipeline 3 is provided with a warming device 4 and a pressure-lifting device 5, and the gas source of the backflush gas in the described backflush cleaning link is ...

Embodiment 2

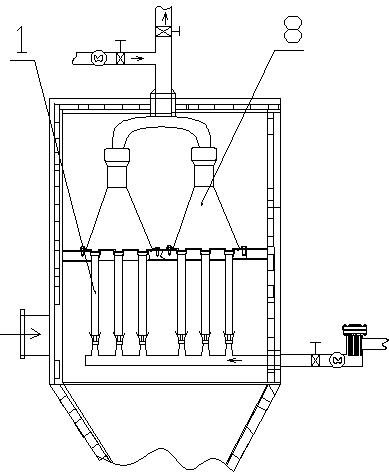

[0026] Such as figure 2 shown, combined with figure 1 In contrast, an online regeneration method for a dust collector filter element for filtering high-temperature combustible dust, the difference from Example 1 is that the oxygen content of the oxygen-depleted gas is controlled at 3%, and the oxygen-depleted gas includes oxygen and nitrogen The temperature of the oxygen-poor gas in the oxygen-lean combustion link is 100°C; the gas source of the blowback gas in the blowback soot cleaning link is the output gas of the clean air chamber of the dust collector and the mixed gas of nitrogen, and the blowback gas passes through the covered The Venturi tube 8 on the top of the filter element 1 is input into the filter element 1.

[0027] The filtration efficiency of the filter element 1 of the dust collector is increased by 5.3%, and the service time of the filter element 1 is extended by 3 times.

Embodiment 3

[0029] An online regeneration method for a dust collector filter element for filtering high-temperature combustible dust, the difference from Embodiment 1 is that the oxygen content of the oxygen-depleted gas is controlled at 4%, and the oxygen-depleted gas includes oxygen and boiler gas; The temperature of the oxygen-poor gas in the oxygen-poor combustion link is 300°C, and the gas source of the backflush gas in the backflush cleaning link is the mixed gas of the output gas of the clean air chamber of the dust collector and nitrogen.

[0030] The filtration efficiency of the filter element 1 of the dust collector is increased by 5.9%, and the service time of the filter element 1 is extended by 3 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com