Patents

Literature

32results about How to "Novel and practical design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

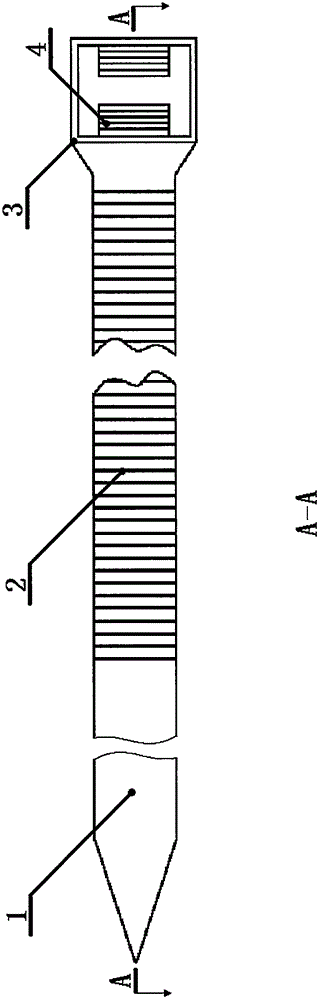

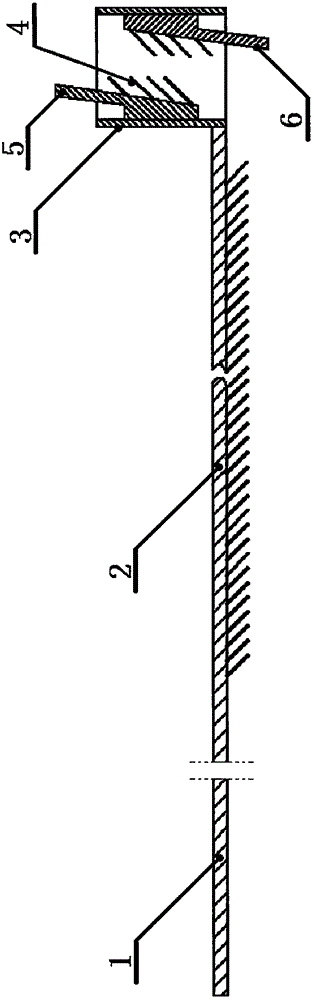

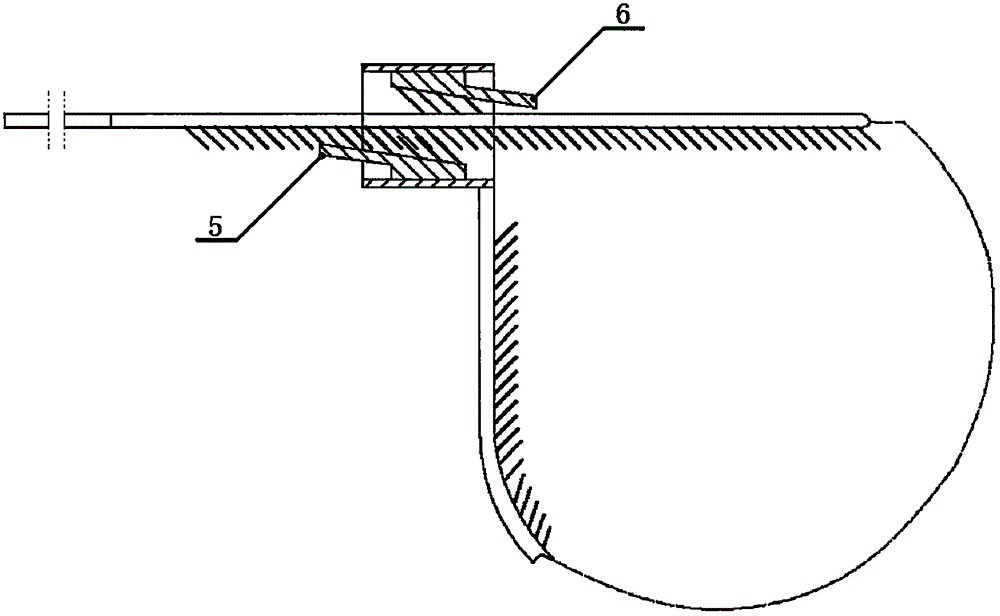

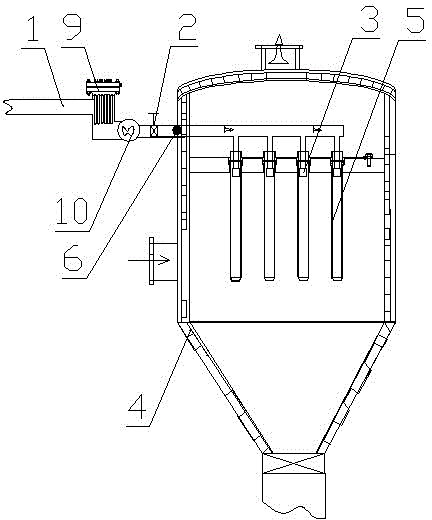

Online regeneration method of filter element of dust remover for filtering high-temperature combustible dust

InactiveCN103961954ARealize online regenerationImprove filtration efficiencyDispersed particle filtrationThermodynamicsProcess engineering

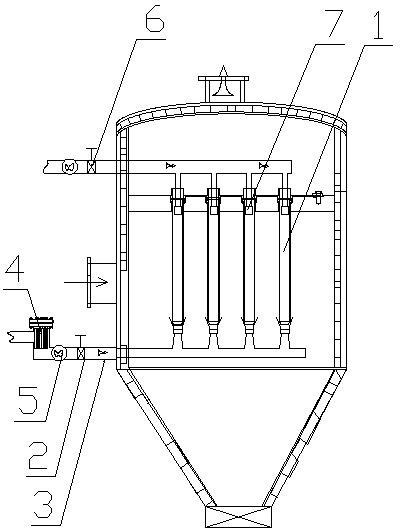

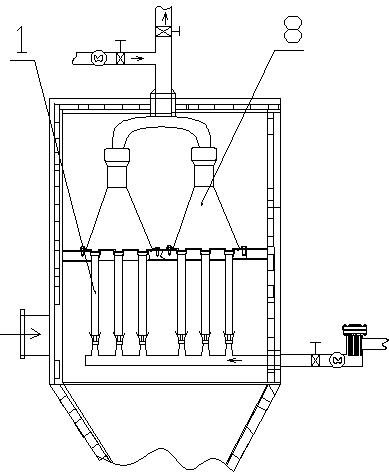

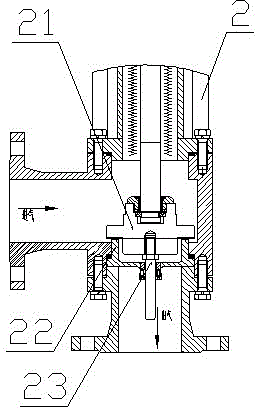

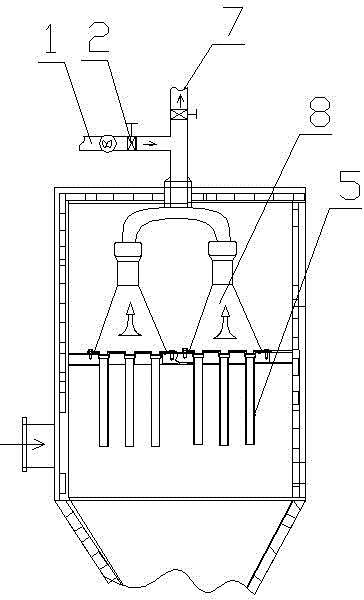

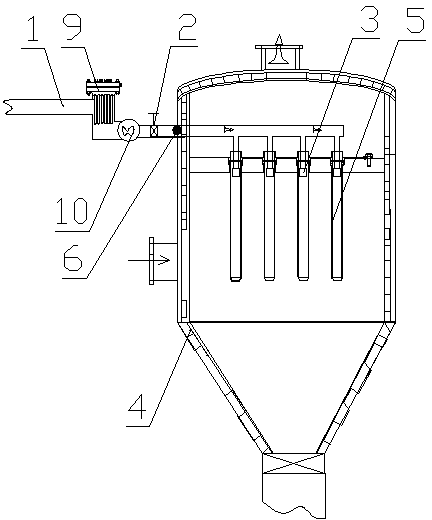

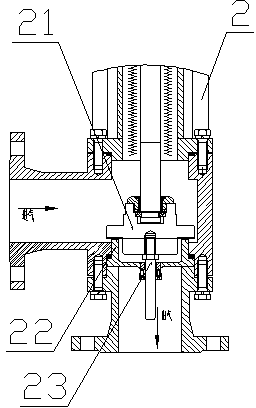

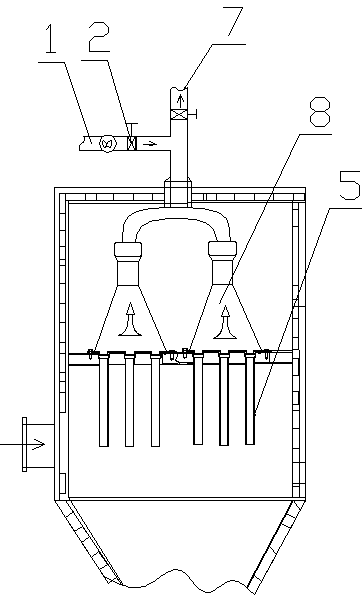

The invention discloses an online regeneration method of a filter element of a dust remover for filtering high-temperature combustible dust. The online regeneration method comprises a step of poor oxygen combustion of oxygen-poor gas sent to the outside of the filter element of the dust remover and combustible dust on the filter element of the dust remover. The oxygen content of the oxygen-poor gas is 2-17 percent, and the poor oxygen combustion step and a step of back-blow dedusting of the filter element of the dust remover are alternated. The method breaks through the limit of a traditional back-blow dedusting process, realizes online regeneration of the filter element by combination of a poor oxygen combustion technology and a back-blow dedusting measure, and can thoroughly clear blind angles of dust accumulation on the surface of the filter element so as to improve the filtering efficiency of the filter element and prolong the service life of the filter element. The online regeneration method has the advantages of being reasonable in design, low in cost and long in operation cycle, the filter element is high in regenerability and high in filtering efficiency and has good promotion and use values, equipment is safe and reliable, and the operation cost is reduced.

Owner:HENAN DRAGON INTO COAL TECH CO LTD

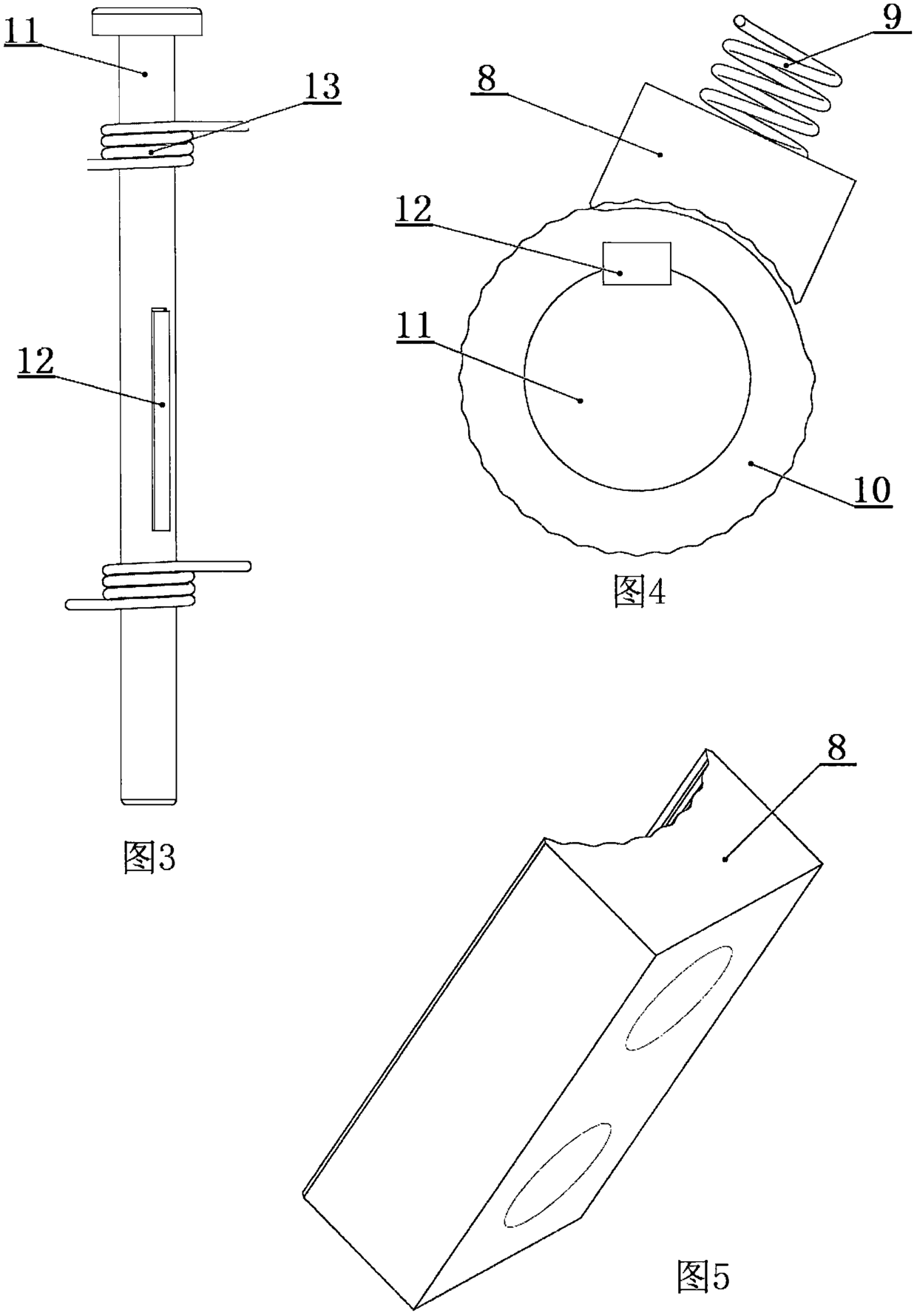

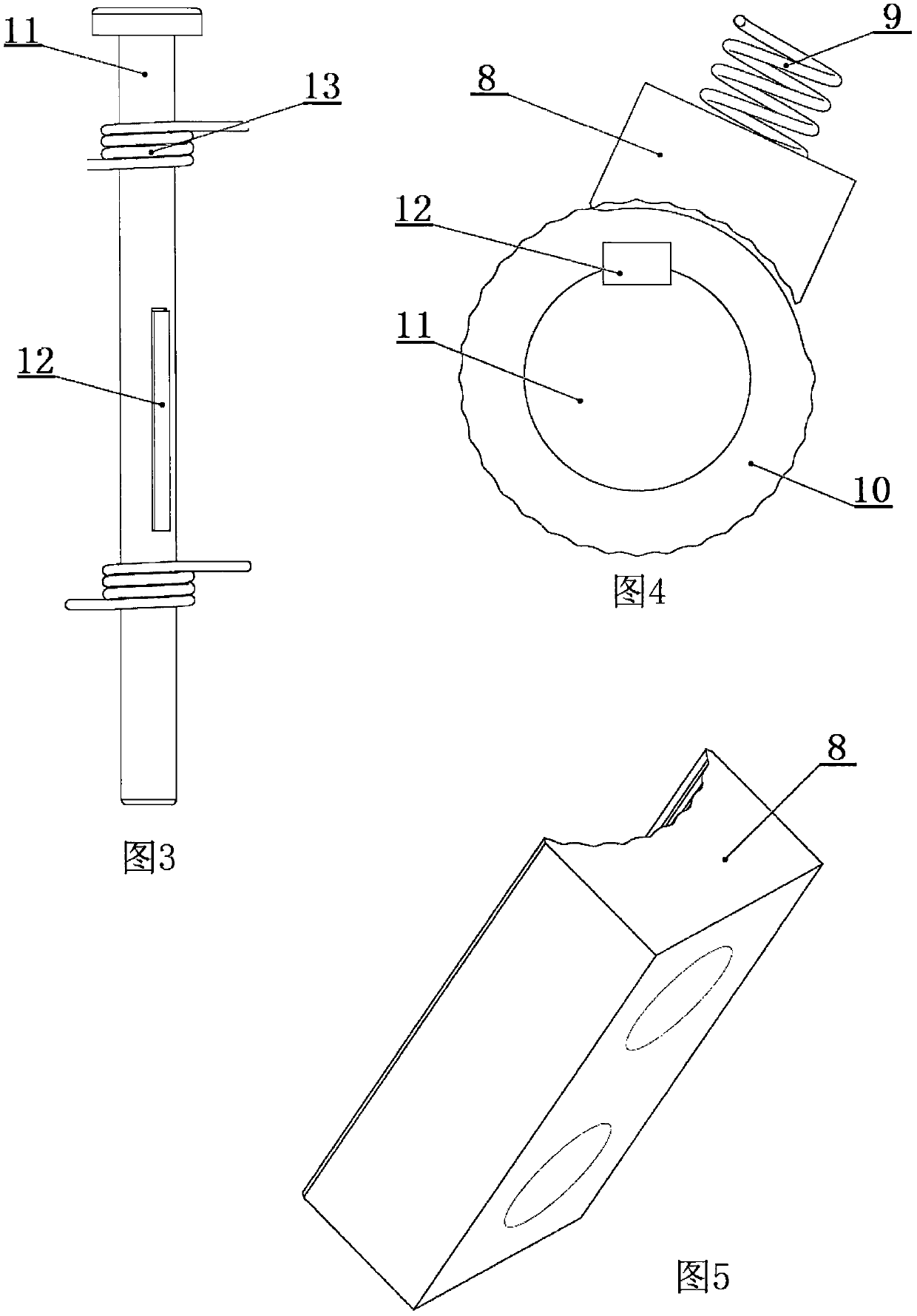

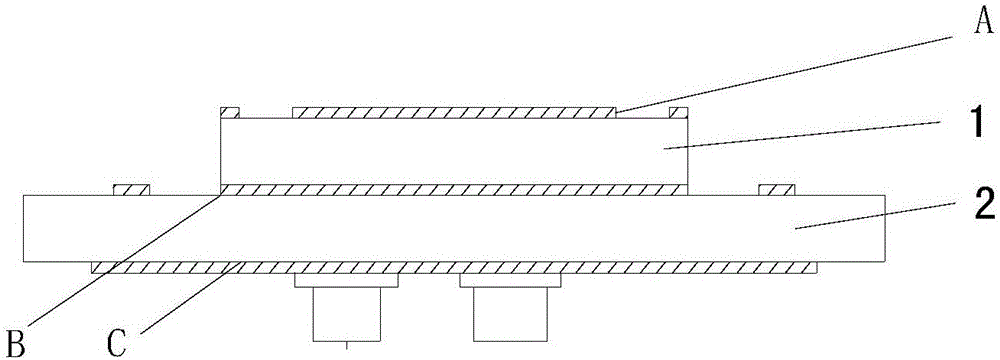

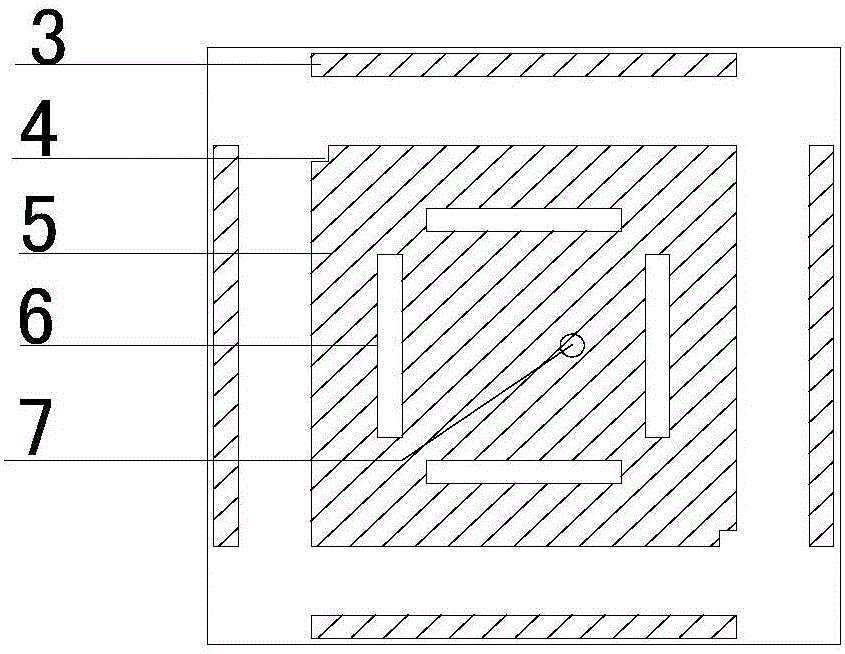

Composite slit leading dual-band and double-fed microstrip antenna with low elevation and high gain

InactiveCN103401069AOptimized low elevation gainReduce operating frequencySimultaneous aerial operationsRadiating elements structural formsDual frequencyPhysics

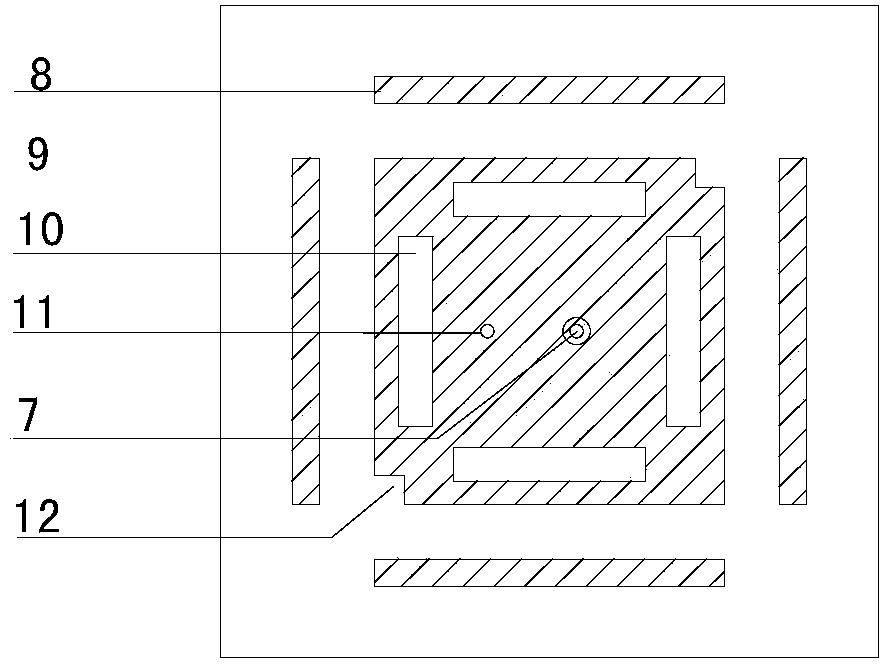

The invention provides a composite slit leading dual-band and double-fed microstrip antenna with low elevation and high gain, and relates to a microstrip antenna. The microstrip antenna is provided with an upper substrate and a lower substrate, wherein an upper patch is arranged on the upper surface of the upper substrate and provided with a main upper microstrip patch which adopts an angularly symmetrical square chamfer structure; four symmetrical leading gaps are formed in the main upper microstrip patch, and four symmetrical slit leading vibrators are arranged on the outermost periphery of the main upper microstrip patch; an interlayer patch having the same structure with the upper patch is arranged between the upper substrate and the lower substrate and provided with a main interlayer microstrip patch which adopts the angularly symmetrical square chamfer structure; four symmetrical leading gaps are formed in the main interlayer microstrip patch, space is reserved between the four symmetrical leading gaps and the edges of the main interlayer microstrip patch, and four symmetrical rodlike leading vibrators are arranged on the periphery of the main interlayer microstrip patch; and a lower patch is arranged on the lower surface of the lower substrate, and a main lower microstrip patch is arranged on the lower patch.

Owner:XIAMEN UNIV

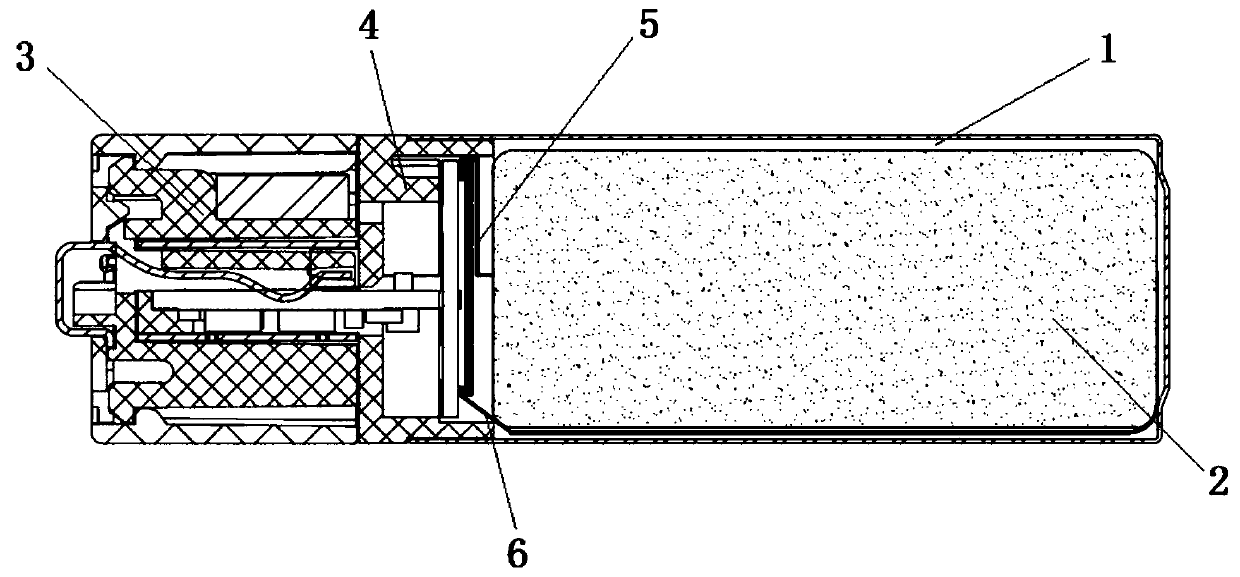

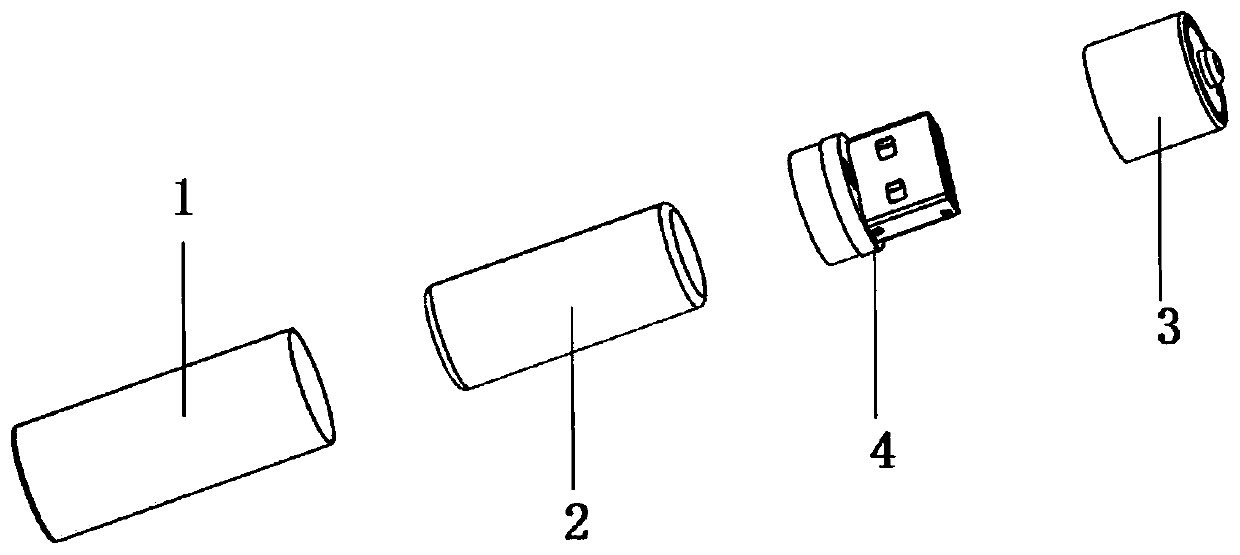

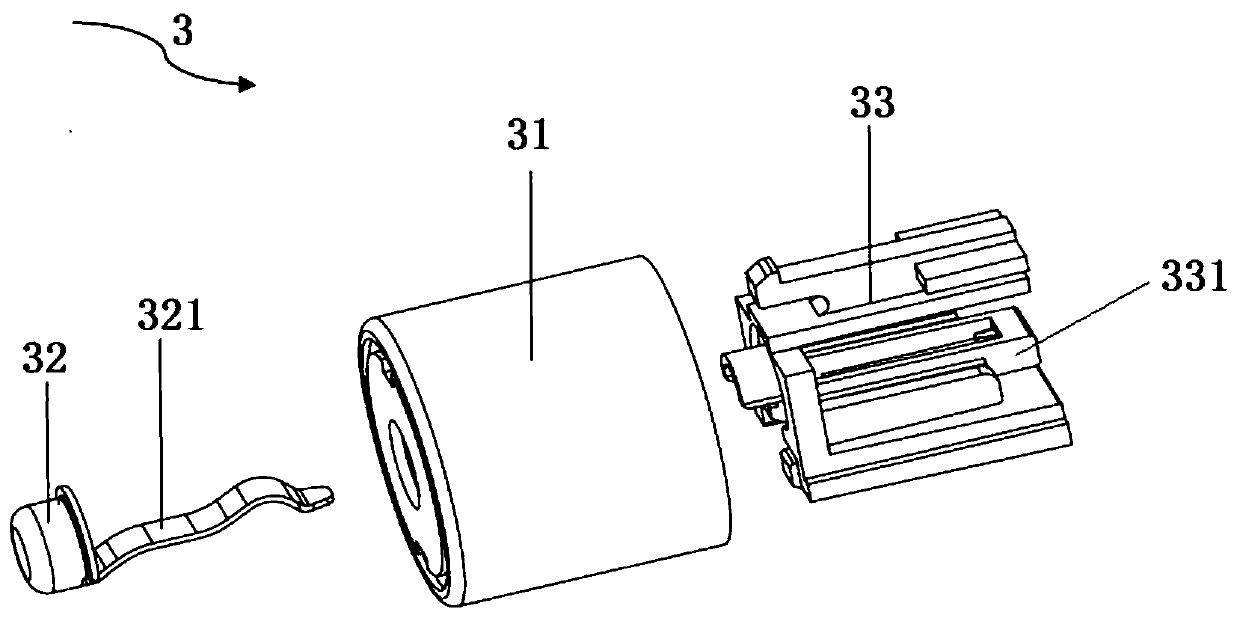

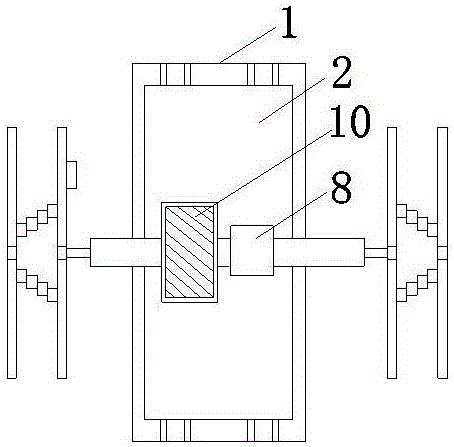

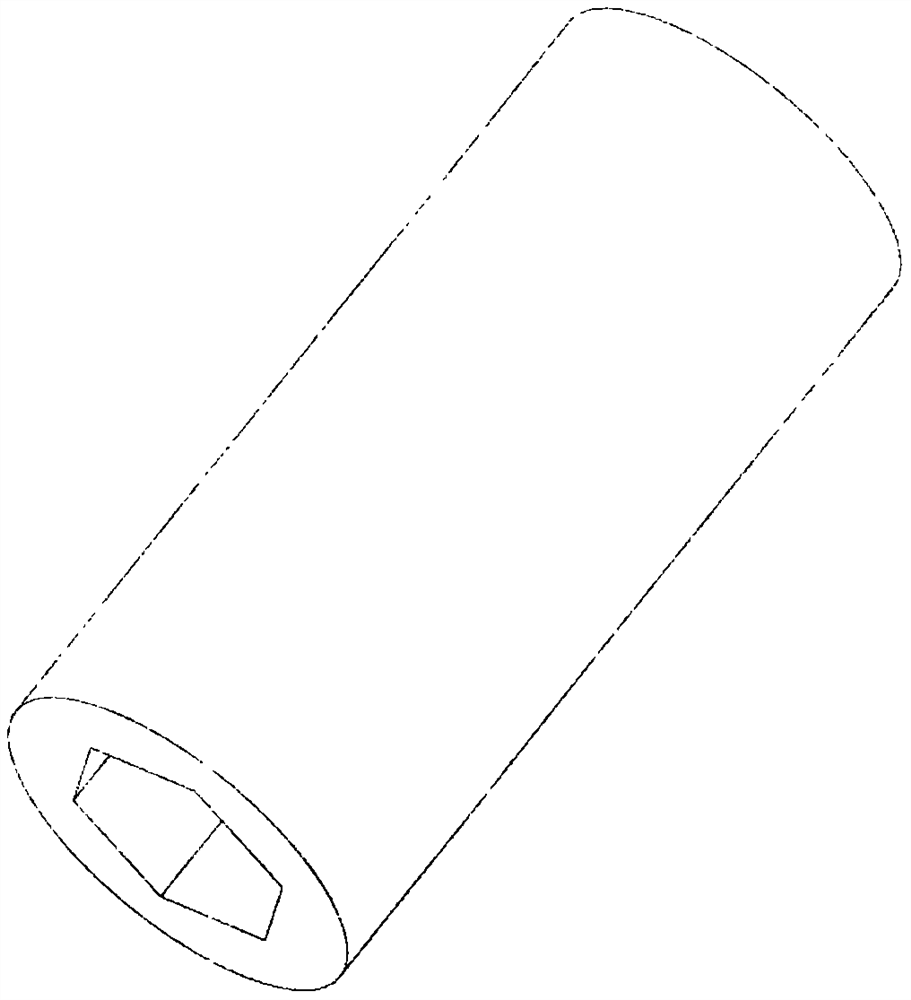

Inductive dustbin rechargeable battery

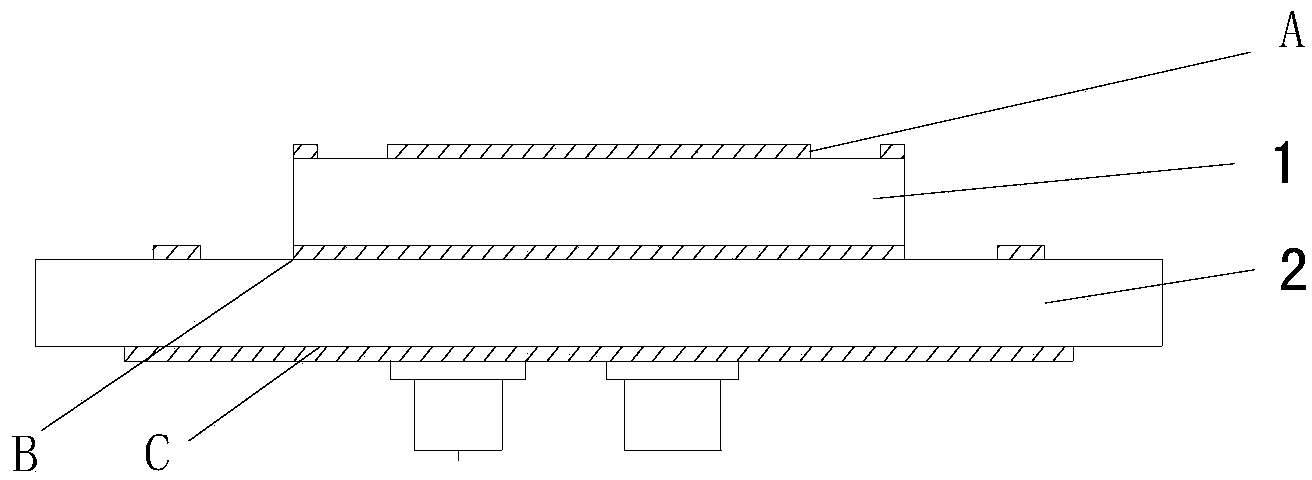

ActiveCN110138025ANovel and practical designEliminate short-circuit safety hazardsCircuit monitoring/indicationDifferent batteries chargingElectrical batteryHigh energy

The invention provides an inductive dustbin rechargeable battery, comprising a steel shell, a battery cell, an output structural component and an intermediate connection structure component, wherein the battery cell is placed in the steel shell; the lower end of the USB fixed structural component of the intermediate connection structure component sleeves the open end of the steel shell; the positive end of the battery cell is connected with the positive pole tab connection point (B+) on a PCB substrate; the negative end of the battery cell is connected with the negative pole tab connection point (B-) on the PCB substrate; the output structural component is engaged with the USB metal piece of the intermediate connection structure component; and the positive clamping output end (O+) of an electronic component is in close contact with the metal spring of the positive cap of the output structural component. The inductive dustbin rechargeable battery is convenient to manufacture, safe and reliable, and has a high energy utilization rate.

Owner:NAT ENG RES CENT OF ADVANCED ENERGY STORAGE MATERIALS SHEN ZHEN LTD CO

Nylon cable tie with double reversed hasps

ActiveCN105947407ANovel and practical designSolve the problem of continuous bundlingFlexible elementsEngineeringElectrical and Electronics engineering

The invention relates to Nylon cable ties, in particular to a Nylon cable tie with double reversed hasps, which comprises a band tail, a band body, hollow band heads, clamping teeth and the double reversed hasps, wherein each hasp comprises a first hasp body and a second hasp body which are arranged in the corresponding hollow band head, and symmetric about the center of the hollow band head; the clamping teeth in each first hasp body and those in the corresponding second hasp body face opposite directions; and one end of each of the first hasp bodies and the second hasp bodies is exposed out of the outer side surface of the corresponding hollow band head for 2 mm. The Nylon cable tie is designed to be novel and practical, that is, both sides of the Nylon cable tie can be used for encircling and tying; due to the two hasps, the Nylon cable tie can be meshed with another Nylon cable tie easily, so as to realize continuous bundling; and as one end of each of the first hasp bodies and the second hasp bodies is exposed out of the outer side surface of the corresponding hollow band head for 2 mm, a user can loosen the Nylon cable tie easily with a finger, that is, the Nylon cable tie can be used repeatedly.

Owner:昆山温仕达工具有限公司

Dust removing process of high-temperature gas with high tar and high dust

ActiveCN104056498AImprove blowback efficiencyEasy to controlDispersed particle filtrationProcess engineeringEnvironmental geology

The invention discloses a dust removing process of high-temperature gas with high tar and high dust. Related equipment comprises a blowing gas delivery pipe, a blowing valve and a nozzle, wherein the blowing valve is connected with a pressure difference detection device, and the blowing gas delivery pipe is communicated with high-temperature pressurization gas; when a filter element of a dust remover performs filtering in the positive direction, the gas pressure difference between the inside and the outside is detected by the pressure difference detection device; when the gas pressure difference reaches a preset threshold, the blowing valve is started for blowback dust removal; the blowing gas temperature is controlled to be more than 290 DEG C in the blowback dust removing process, and blowing gas forms a high-pressure expansion area in the filter element to quickly and reversely blow and remove gathered dust which is attached to the outside of the filter element; the filter process of the filter element in the positive direction is restored after the blowback dust removing process is completed. By using the dust removing process, the high-temperature blowback dust removal is realized, the dust removing process is optimized, the heat utilization rate is increased, the blowback can be intelligently controlled to guarantee continuous high-quality filtering of the filter element, the dust removing efficiency is improved and the equipment utilization rate is increased.

Owner:HENAN DRAGON INTO COAL TECH CO LTD

Illumination structure

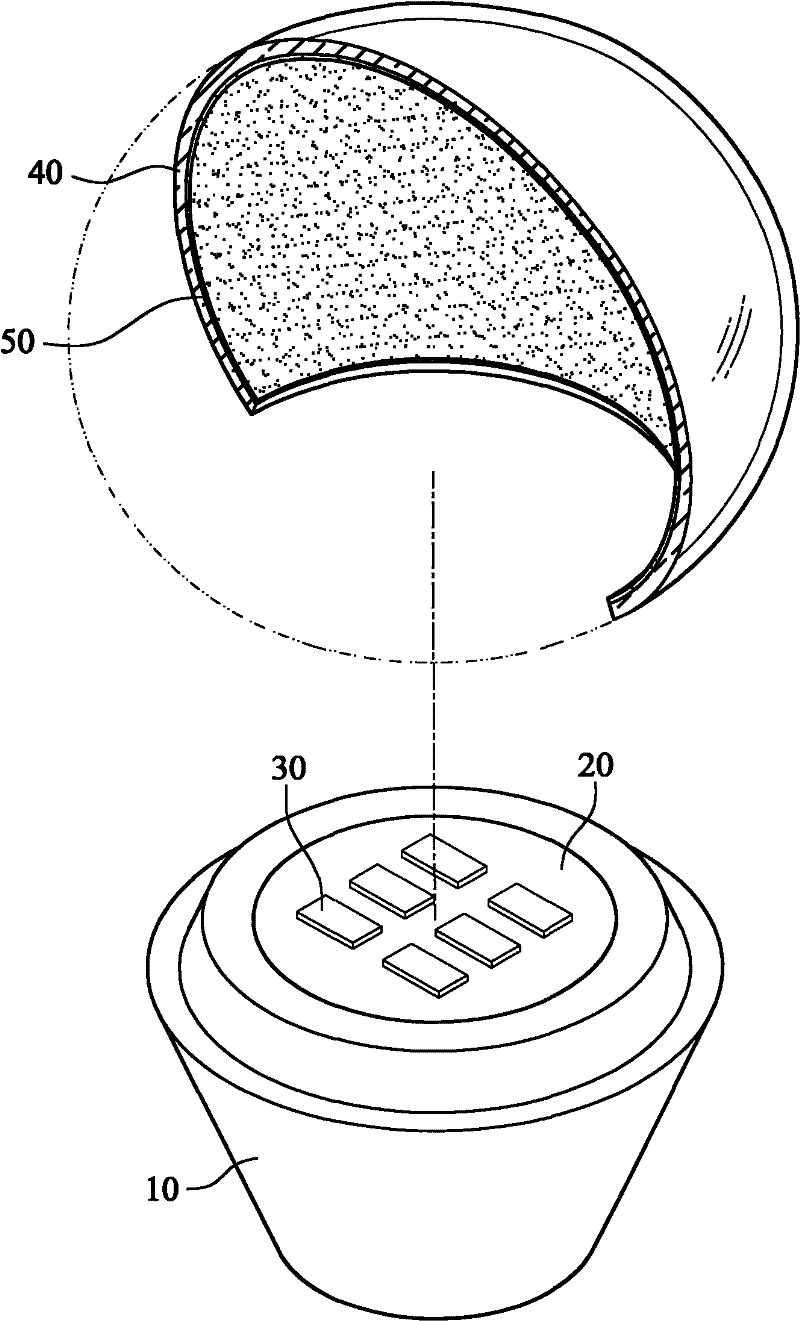

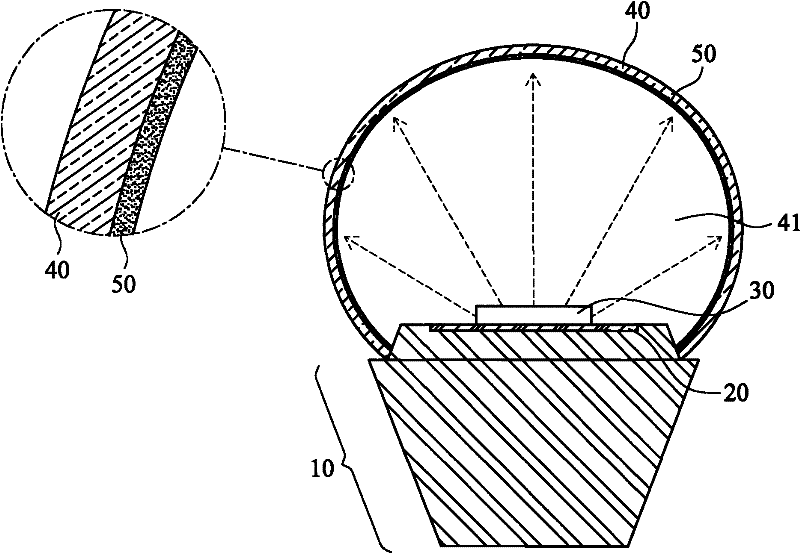

InactiveCN102221133AAvoid damageLow costPoint-like light sourceElectric lightingFluorescenceEconomic benefits

The invention relates to an illumination structure. A light-emitting diode (LED) chip is arranged in a lamp holder radiating module and is an LED bare chip without fluorescent powder or sealant; a lamp shade covers the upper side of the LED chip of the lamp holder radiating module; the inner wall of the lamp shade is uniformly coated with a fluorescent coating; a space is reserved between the LED chip and the fluorescent coating; and the fluorescent coating absorbs light rays emitted by the LED chip to emit illumination white light. Therefore, the problem that the lighting effect of the fluorescent powder on the conventional LED chip is attenuated is solved, and yield and economic benefits can be improved.

Owner:王湘云

High-temperature blowing and deashing technology for deduster

InactiveCN103961947AImprove regenerative abilityNovel and practical designDispersed particle filtrationTemperature controlFiltration

The invention discloses a high-temperature blowing and deashing technology for a deduster, and relates to equipment comprising a blowing gas conveying pipe, a blowing valve and blowing nozzles. The high-temperature blowing and deashing technology for the deduster is characterized in that the blowing gas conveying pipe is communicated with a high-temperature supercharging gas; the blowing valve is started up periodically for back blowing and deashing in the normal flow filtration process of a filter element of the deduster; in the back blowing and deashing process, the gas blowing temperature is controlled to be above 290 DEG C; the blowing gas forms a high-pressure expansion region in a filter element; deposited ash attached to the outer part of the filter element is removed rapidly; the blowing valve is shut off after the back blowing and deashing process is finished, and the normal flow filtration process of the filter element is recovered. The high-temperature blowing and deashing technology for the deduster, which is provided by the invention, breaks through the traditional low-temperature back blowing and deashing technology, filters high-temperature gases, especially the high-temperature gas of high tar and high-dust gas effectively, moreover, enables the operation temperature of the deduster to be improved by one level, improves the dedusting efficiency and energy utilization ratio, and has favorable popularization and using values.

Owner:HENAN DRAGON INTO COAL TECH CO LTD

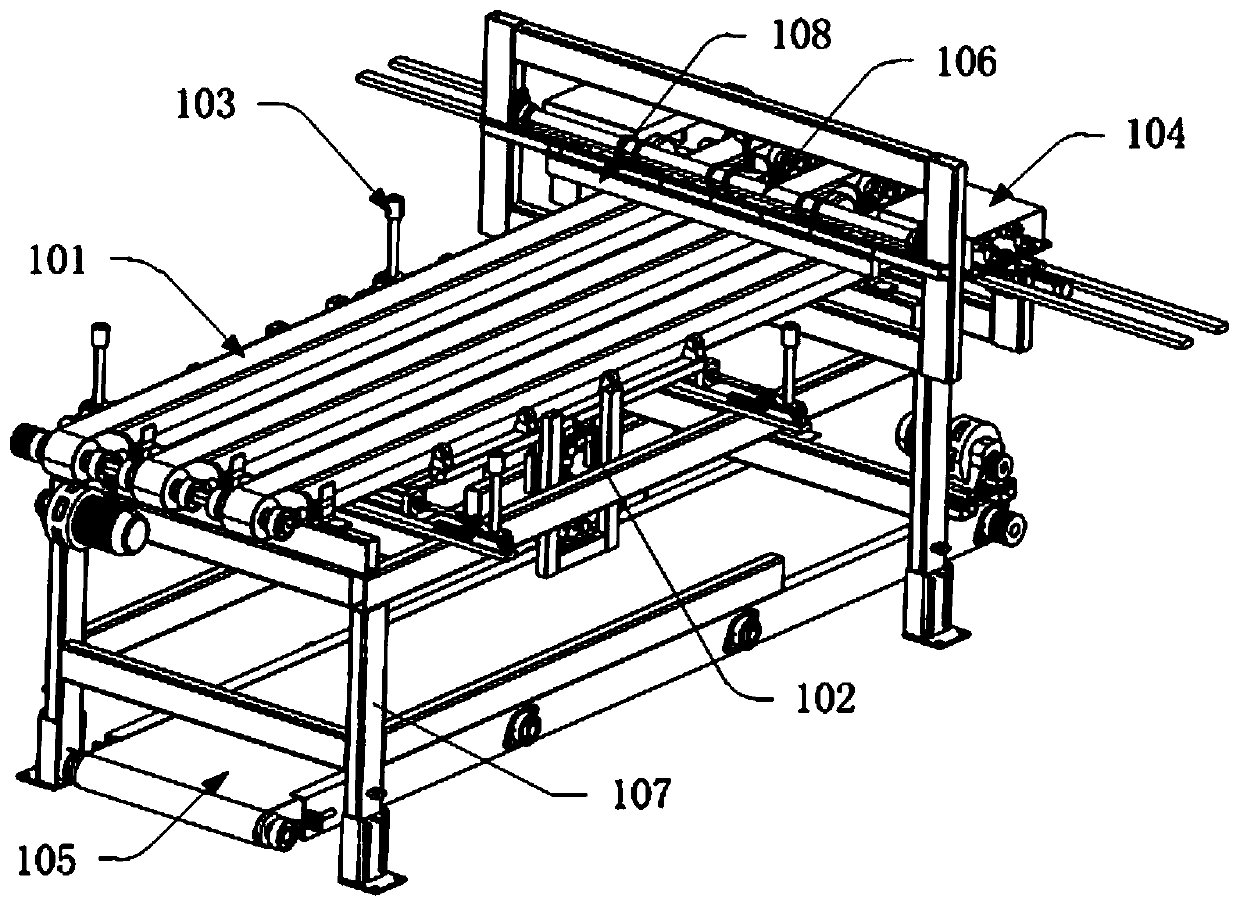

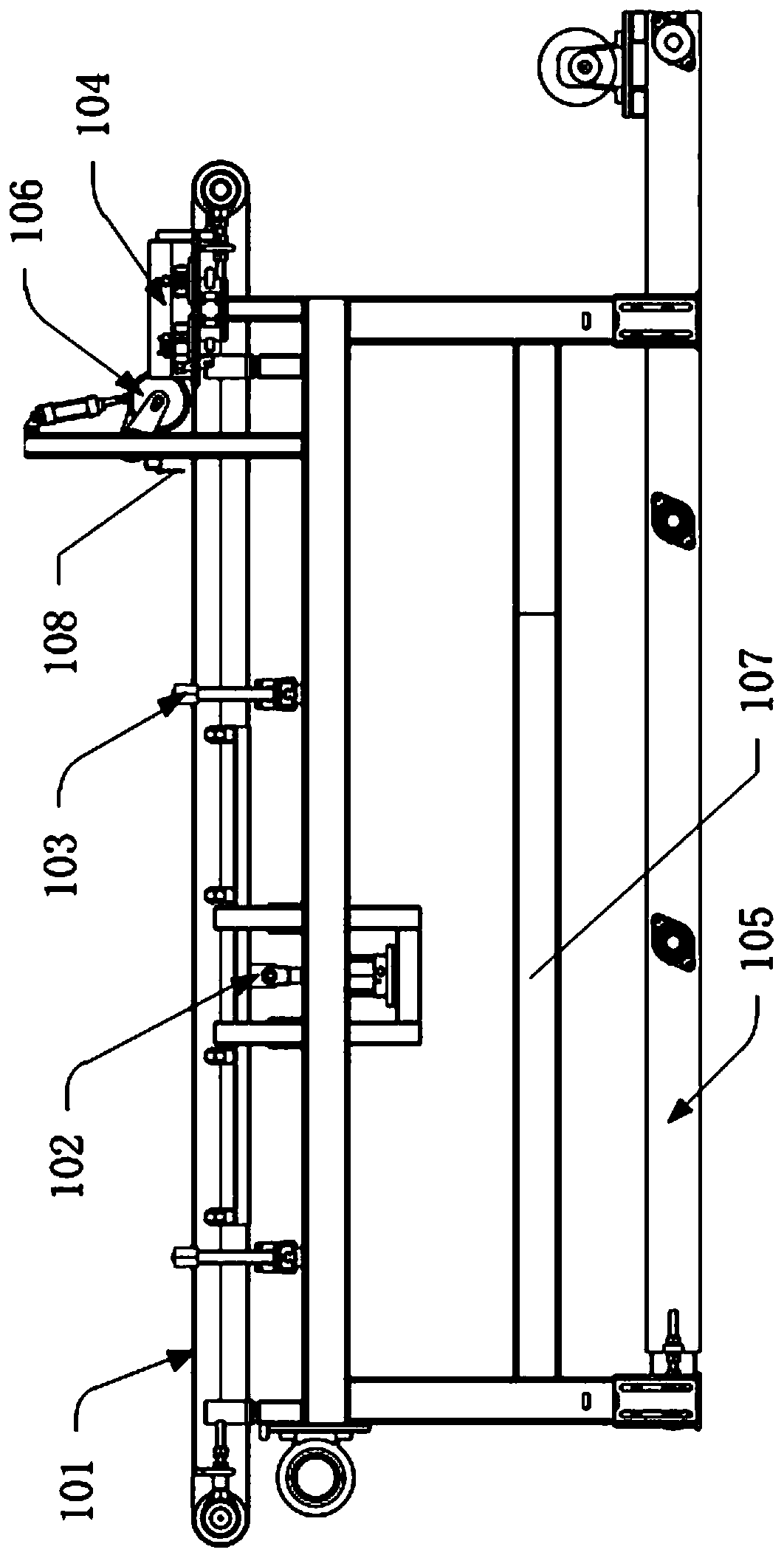

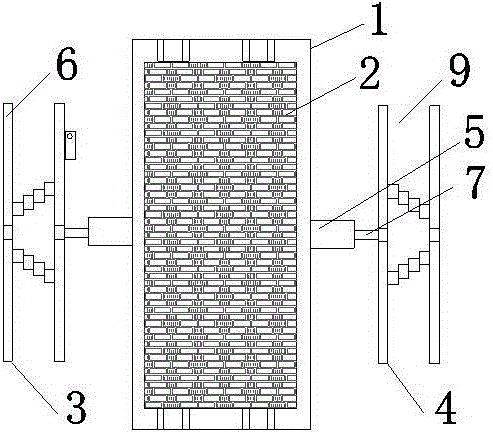

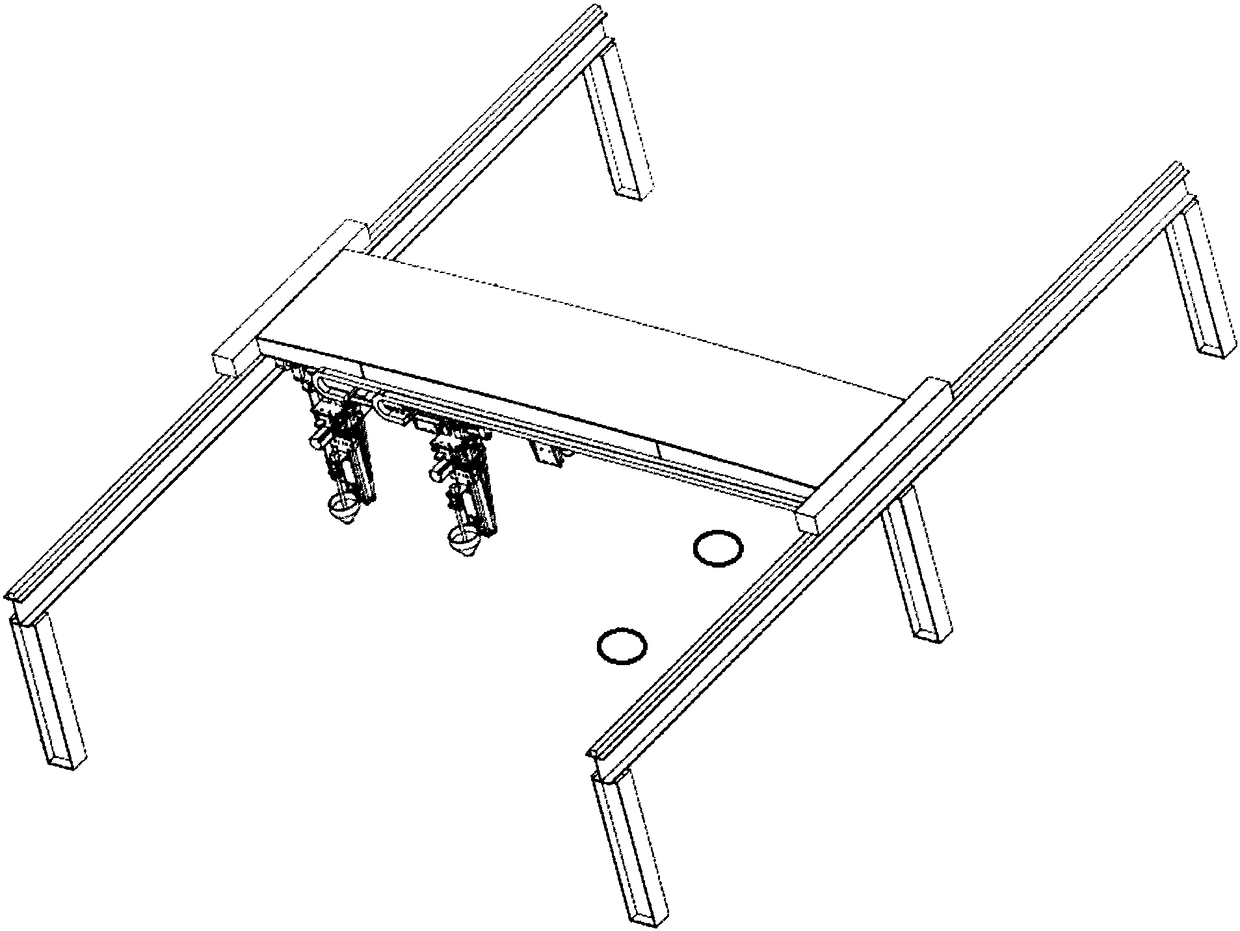

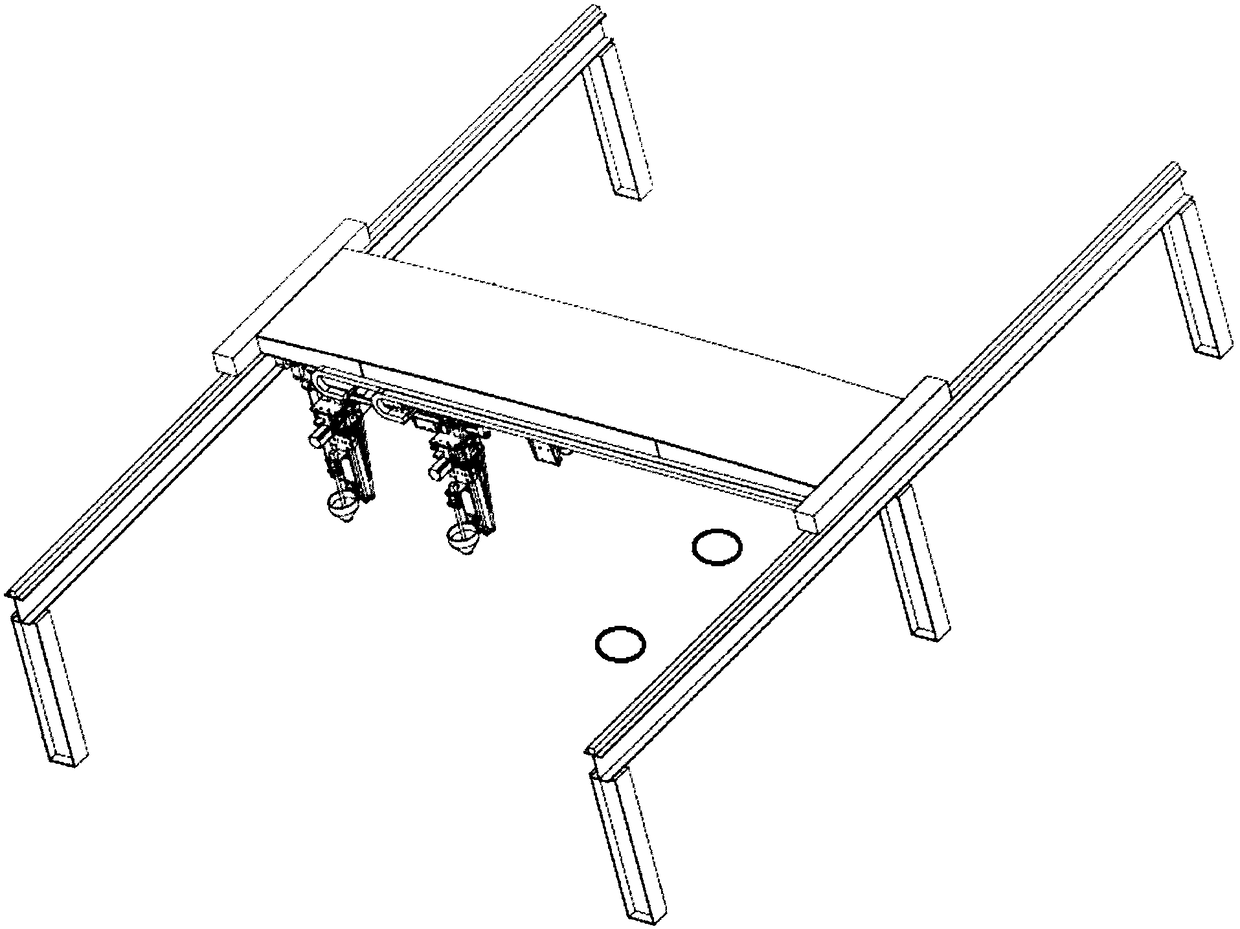

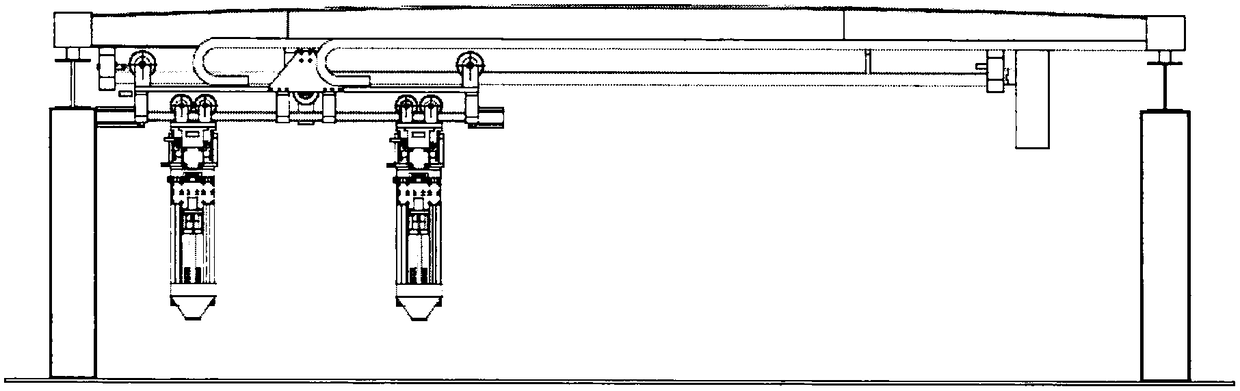

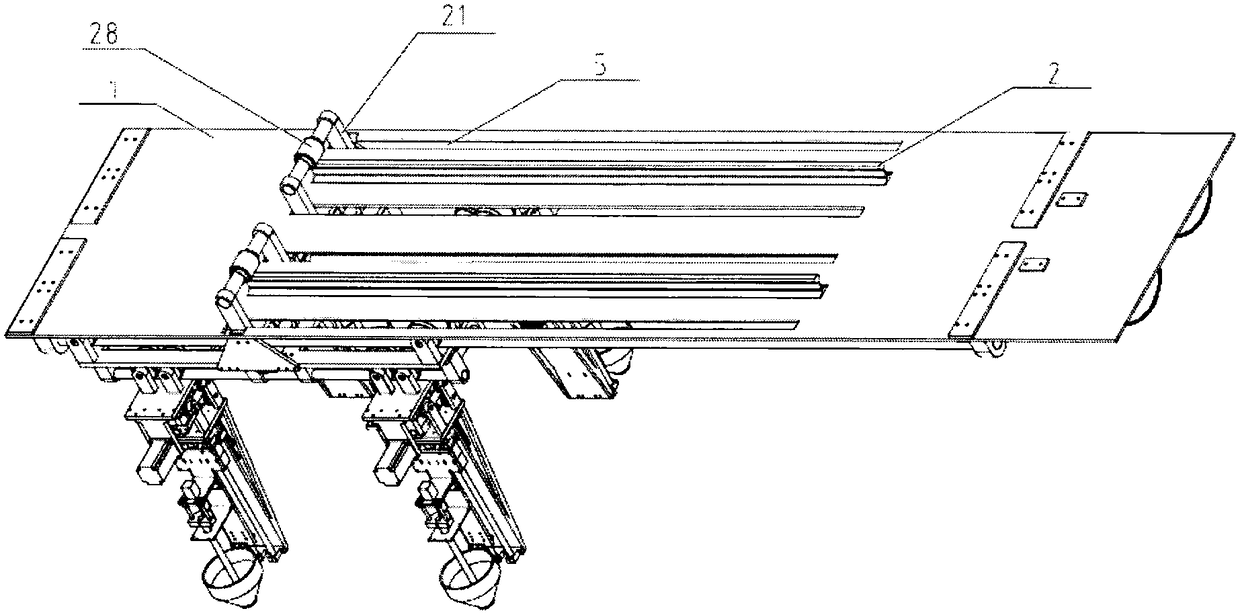

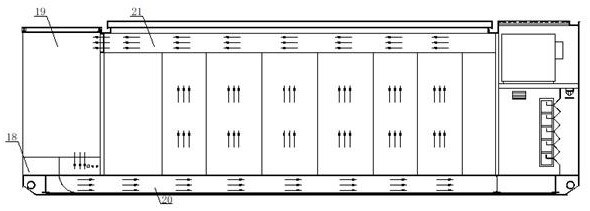

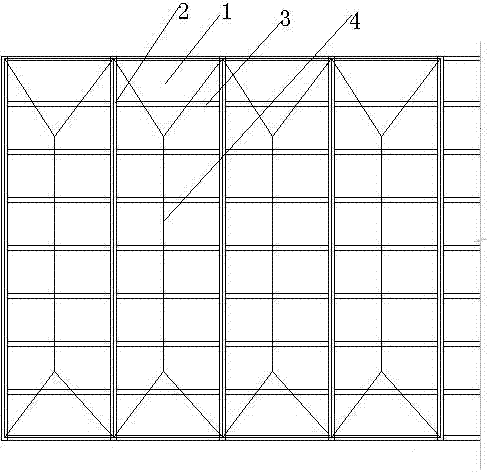

Automatic paper scraping assembly line for veneers

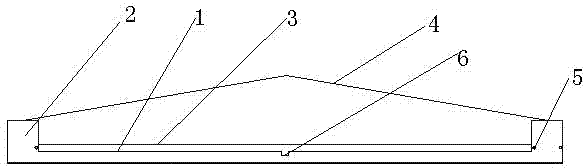

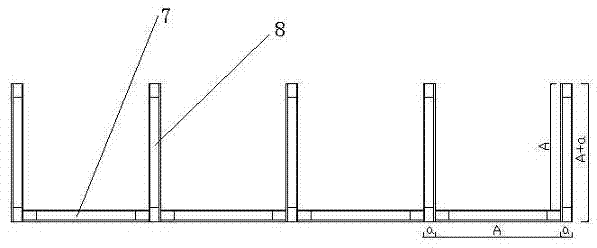

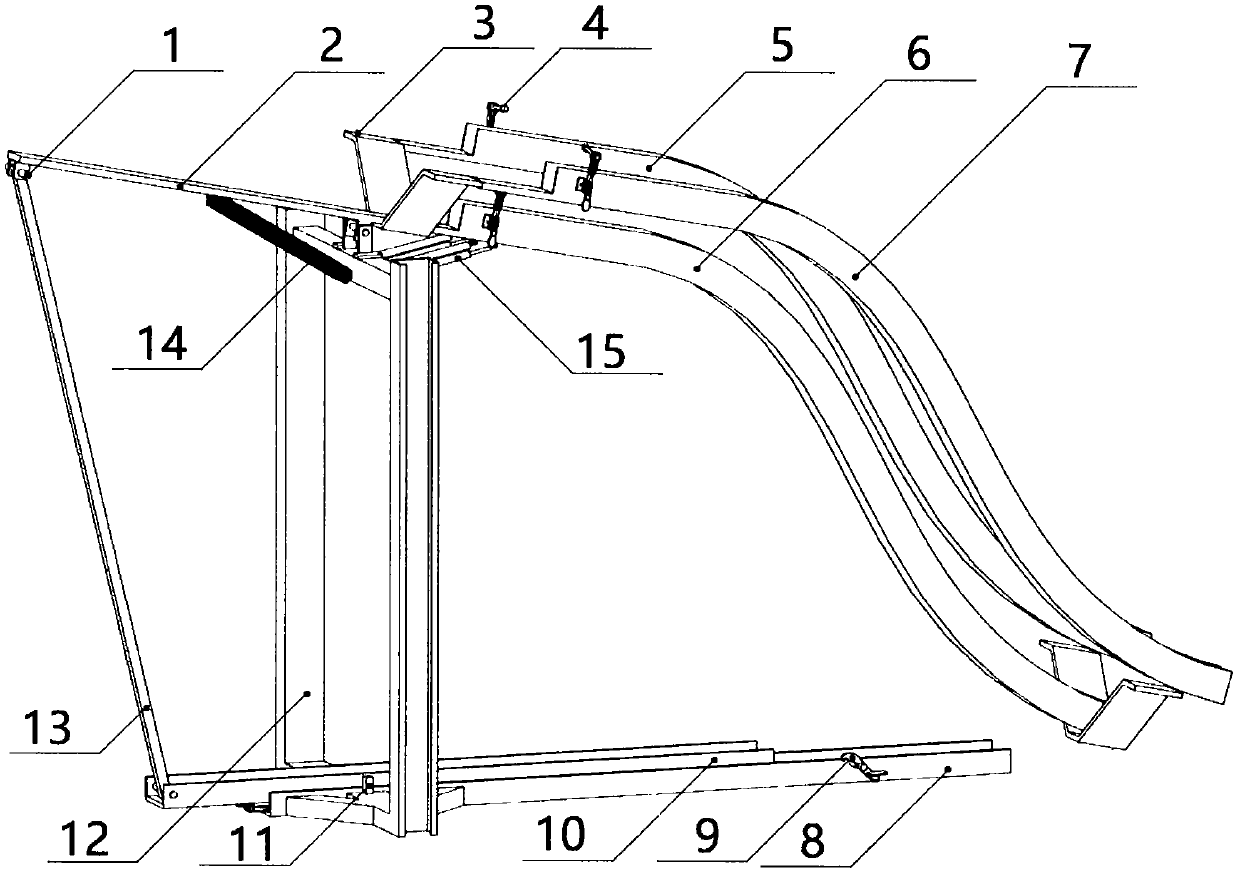

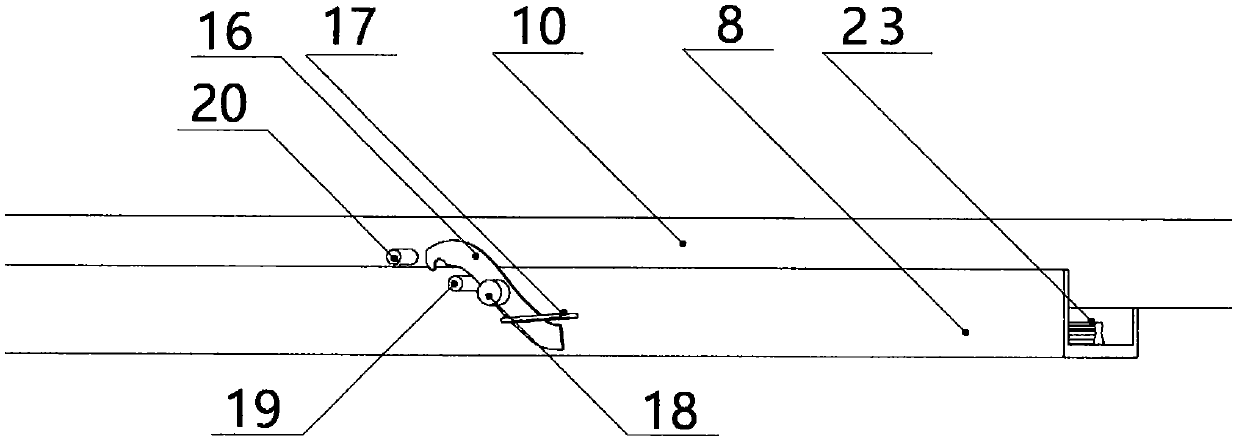

PendingCN111070349ANovel and practical designHigh degree of automationOther plywood/veneer working apparatusDomestic articlesAssembly lineStructural engineering

The invention provides an automatic paper scraping assembly line for veneers. According to the automatic paper scraping assembly line for the veneers, paper scraping of the four side surfaces of the veneers can be automatically and efficiently completed. A second conveying mechanism is arranged at the outlet end of a first conveying mechanism, the conveying direction of the second conveying mechanism is perpendicular to that of the first conveying mechanism, plate lifting mechanisms and paper scraping mechanisms located behind the plate lifting mechanisms are disposed on two sides of the firstconveying mechanism and the second conveying mechanism, positioning mechanisms are located on two sides of the first conveying mechanism and the second conveying mechanisms and located at two ends ofthe plate lifting mechanisms and can be moved closer to the center to center the lifted veneers, and a lifting mechanism is located on the outlet side of the first conveying mechanism and is locatedin front of the plate lifting mechanisms of the second conveying mechanisms; a plurality of cylindrical supporting members with the axial direction consistent with the conveying direction of the second conveying mechanism are rotatably arranged at the top of the lifting mechanism; the top surfaces of the supporting members are aligned to the conveying plane of the first conveying mechanism when the lifting mechanism is raised in position, and the top surfaces of the supporting members are arranged under the conveying plane of the second conveying mechanism when the lifting mechanism is loweredinto position; and a position detector is located on the rear side of the plate lifting mechanisms and the left rear side of the lifting mechanism.

Owner:FOSHAN SANSHUI YUSN DECORATION IND

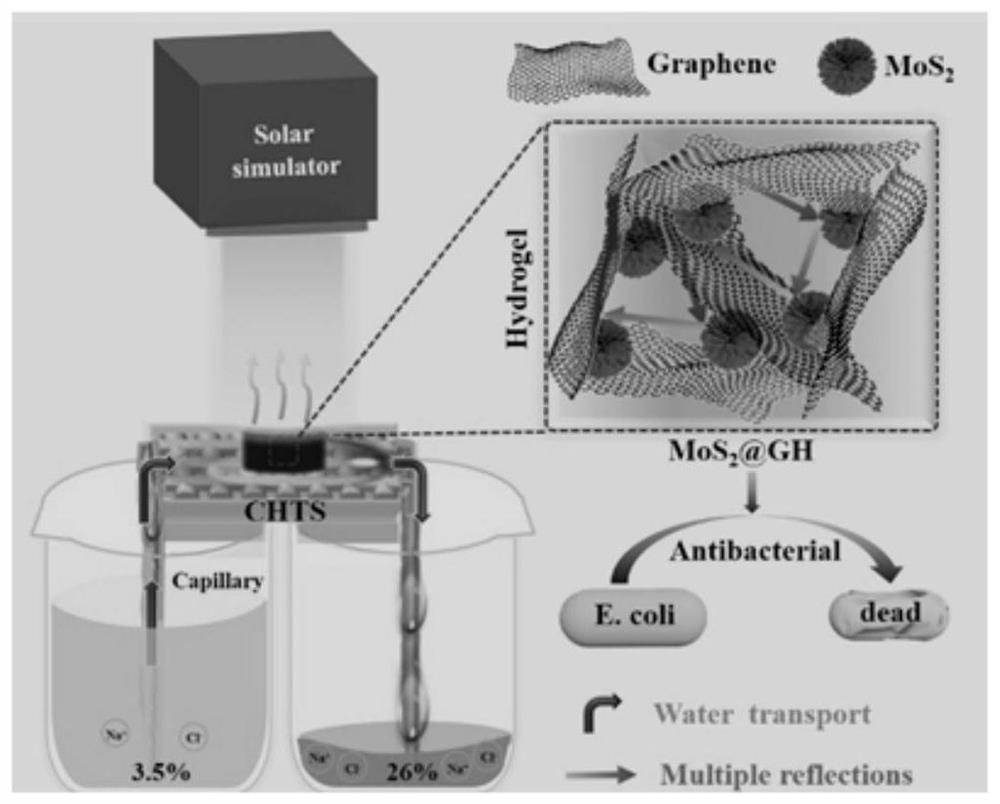

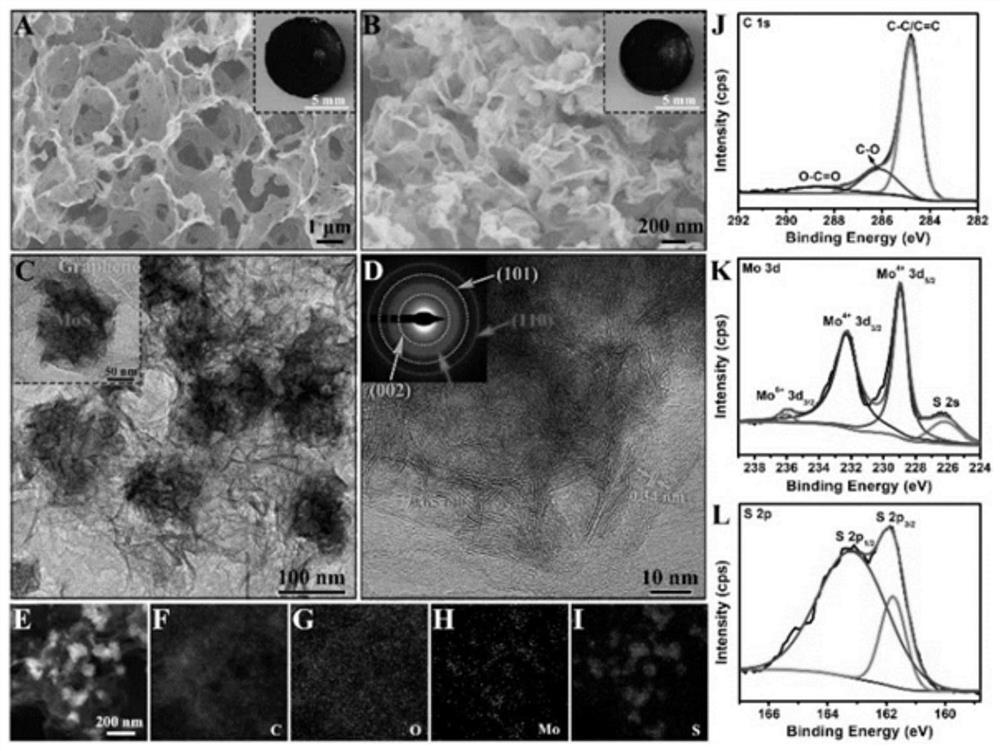

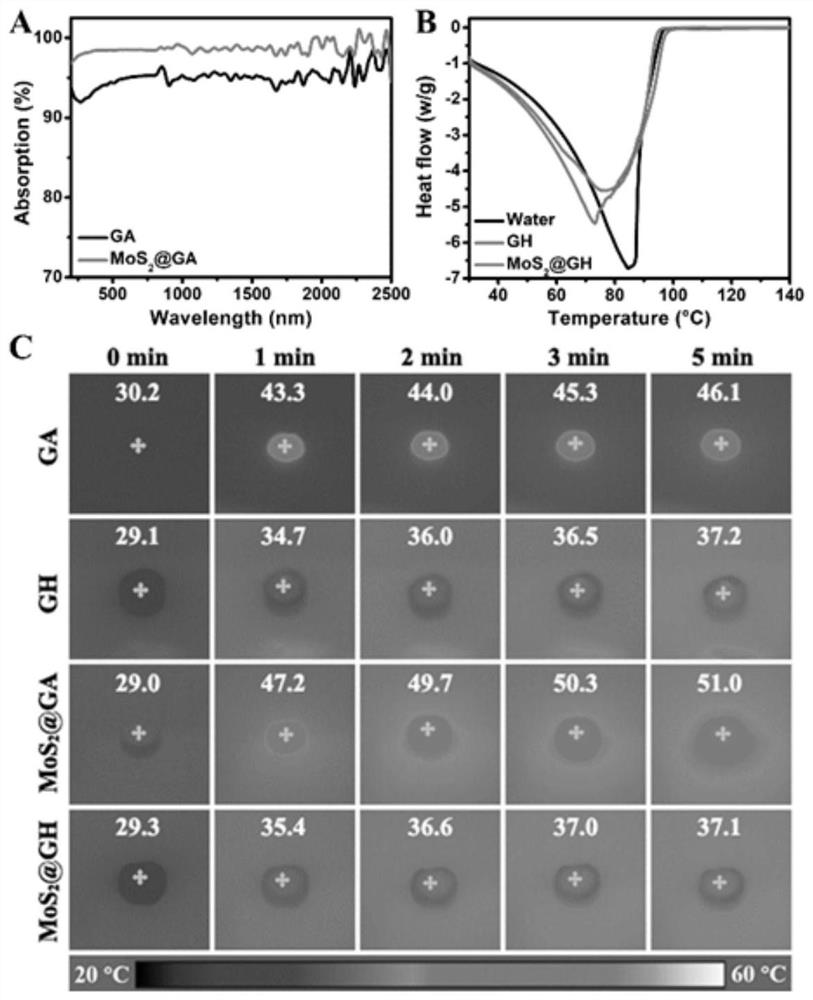

Self-water-supply type photo-thermal water evaporation device based on composite hydrogel

ActiveCN112707391AEnhanced Capture AbsorptionLower enthalpy of evaporationGeneral water supply conservationCarbon compoundsEnvironmental chemistryComposite hydrogels

The invention relates to a composite hydrogel-based self-water-supply type photo-thermal water evaporation device. Porous molybdenum disulfide MoS2 nano particles are intercalated between graphene through a one-step chemical reduction reaction. The efficient water evaporation rate of 3.2 kg m<-2>h<-1> can be achieved under illumination of 0.9 kW m<-2> and is far higher than that of an existing photo-thermal interface water evaporation system of the same type, and the device has bacterial biological pollution resistance and good stability. The provided photo-thermal interface water evaporation system is expected to realize efficient seawater desalination, and provides a solution for sustainable clean water production.

Owner:DONGHUA UNIV

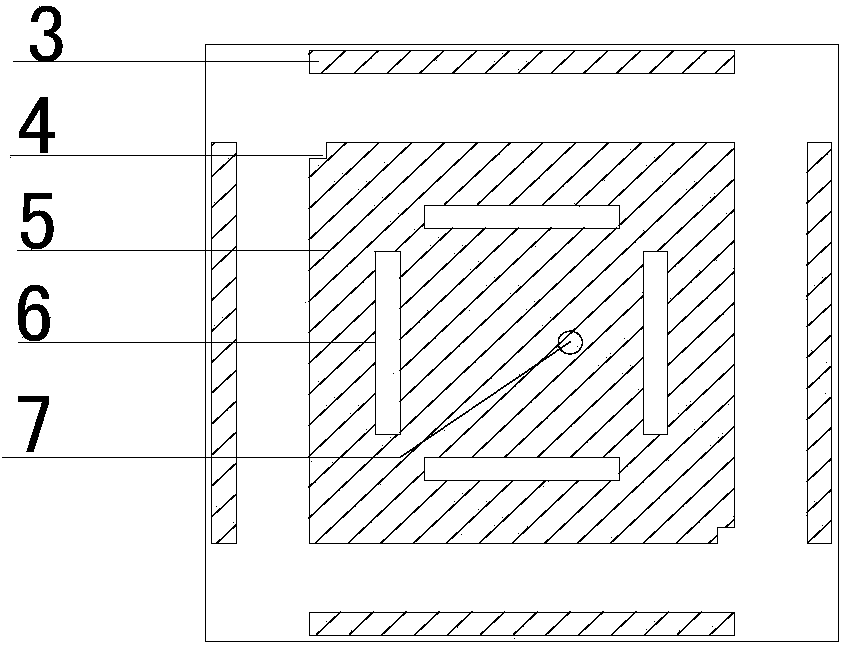

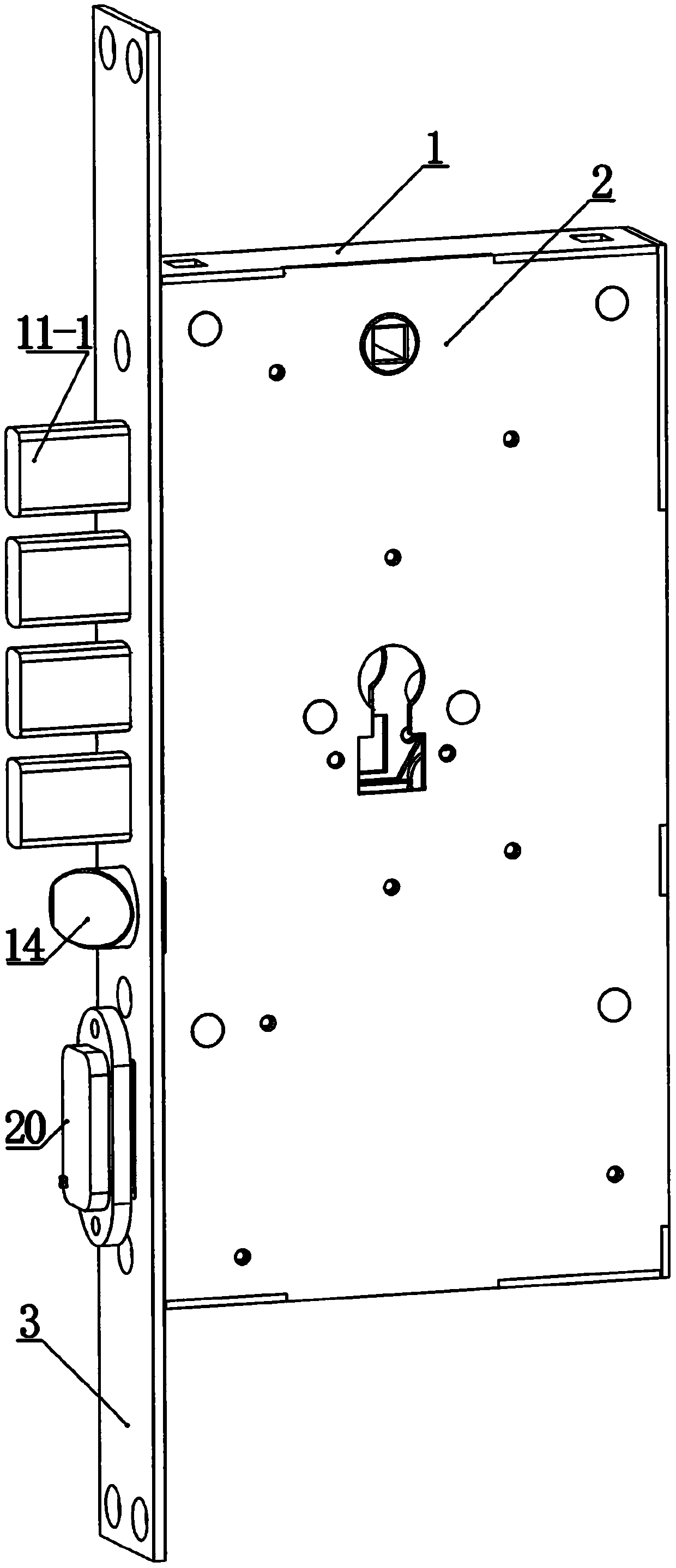

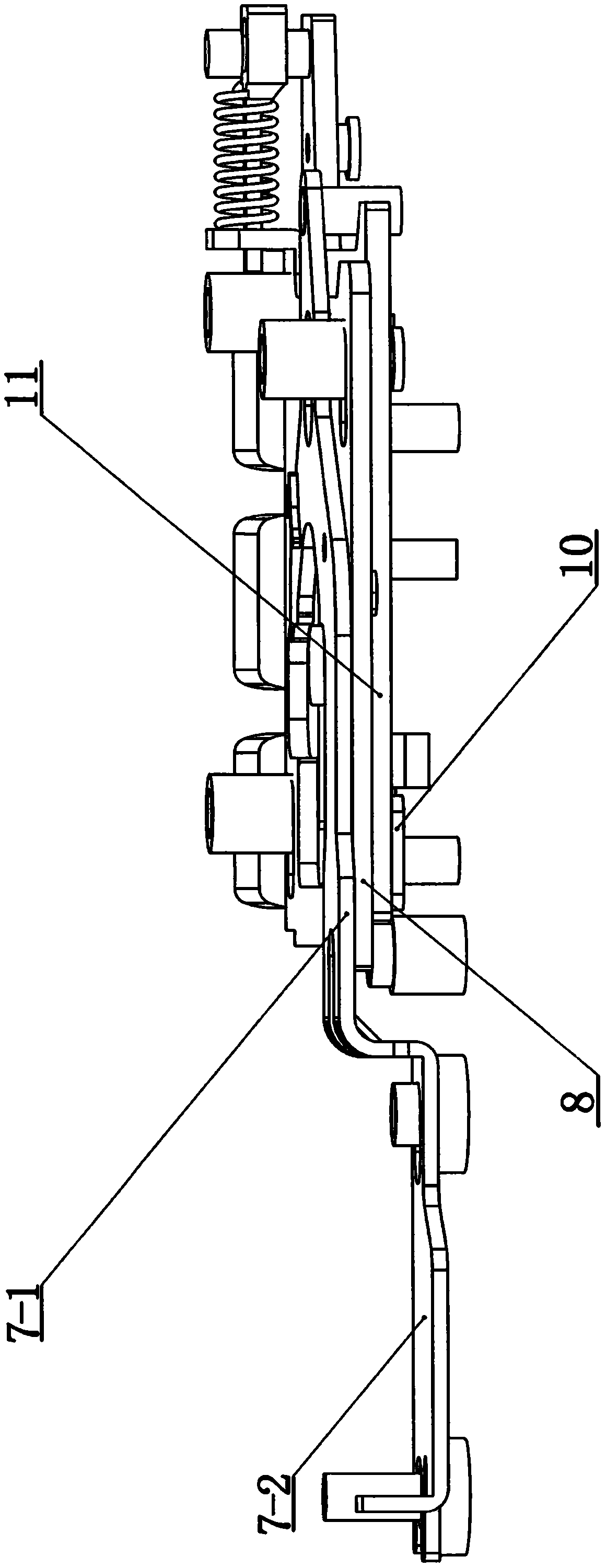

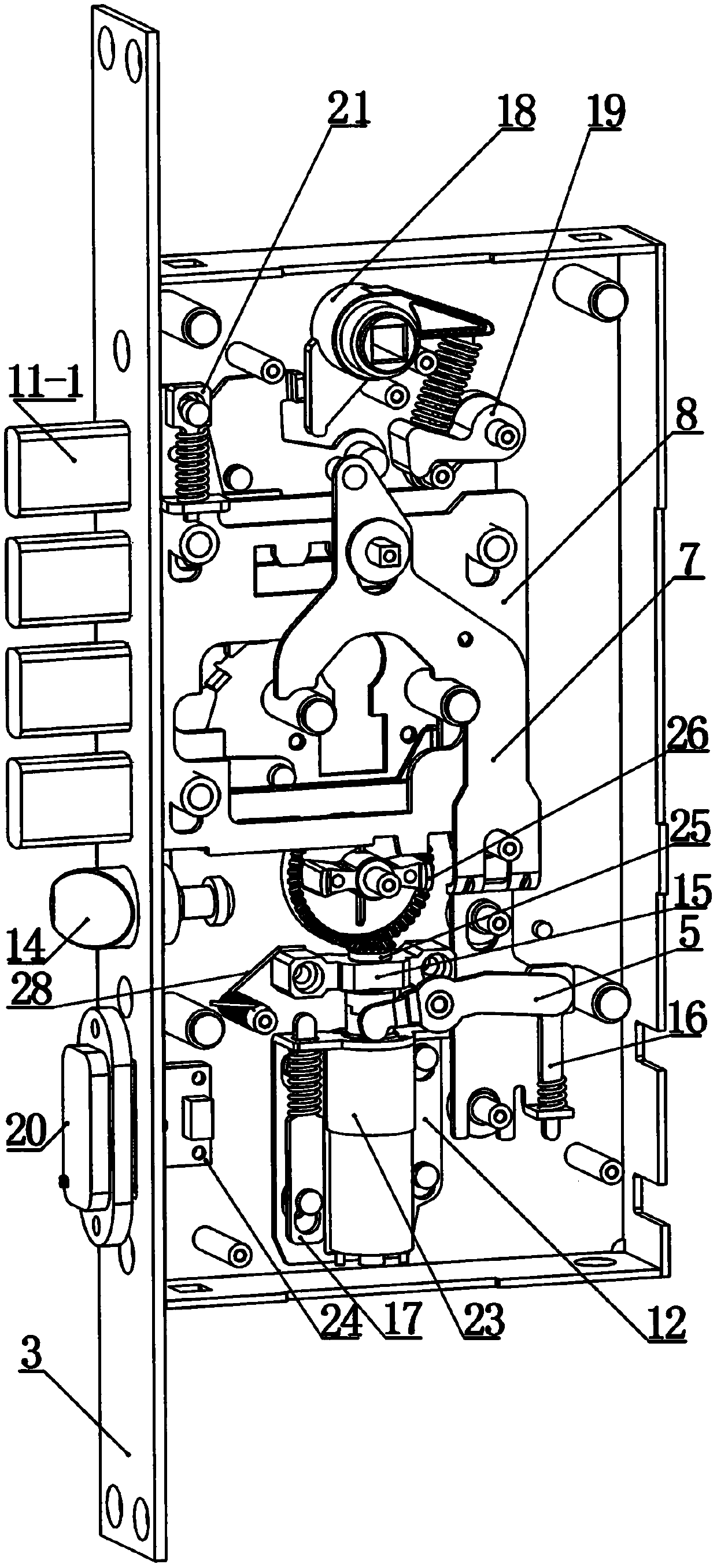

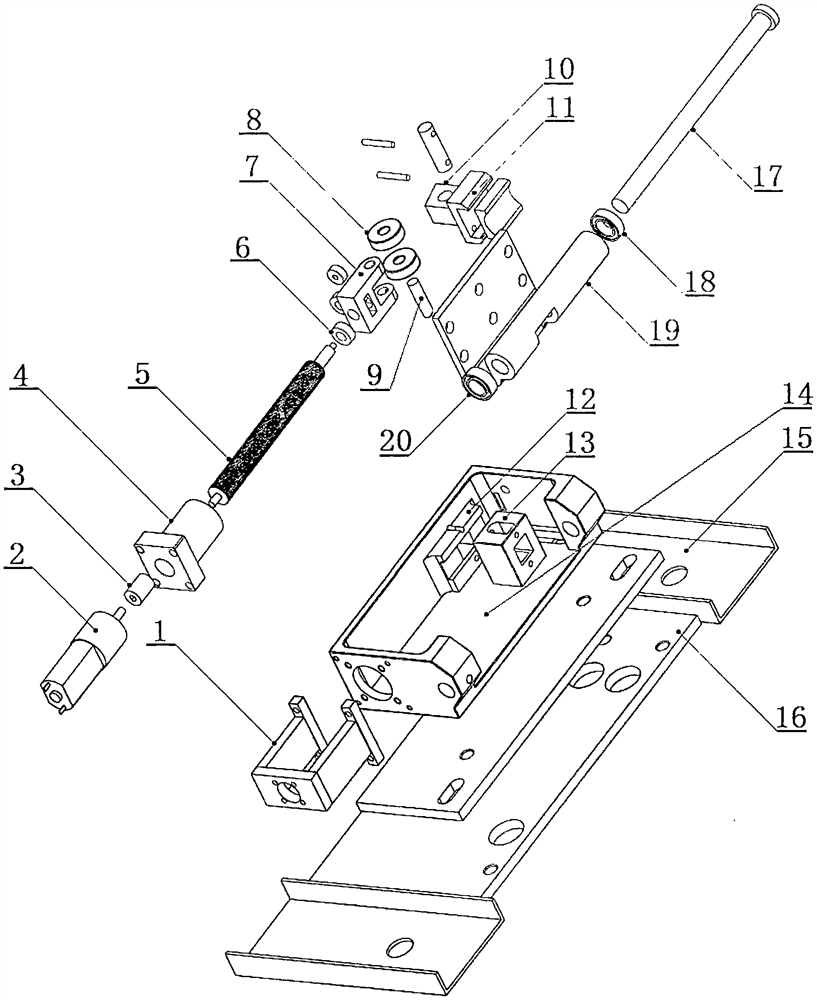

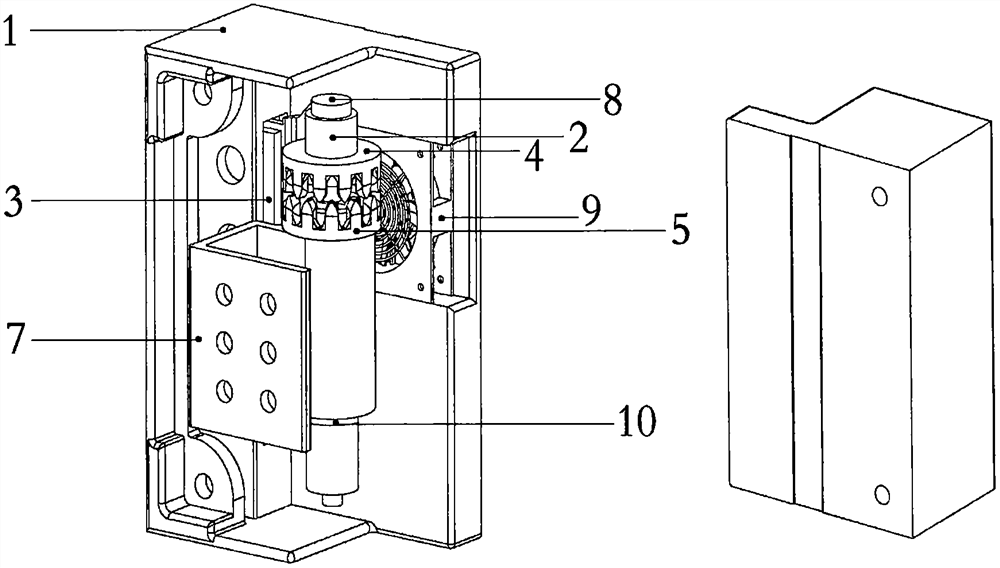

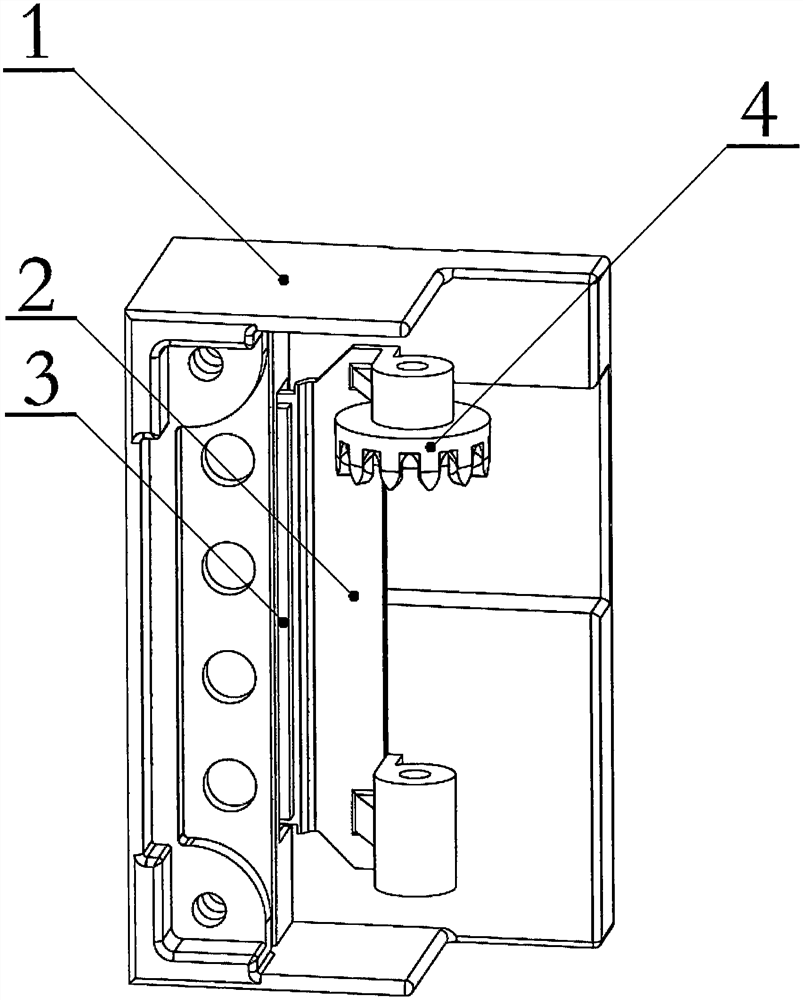

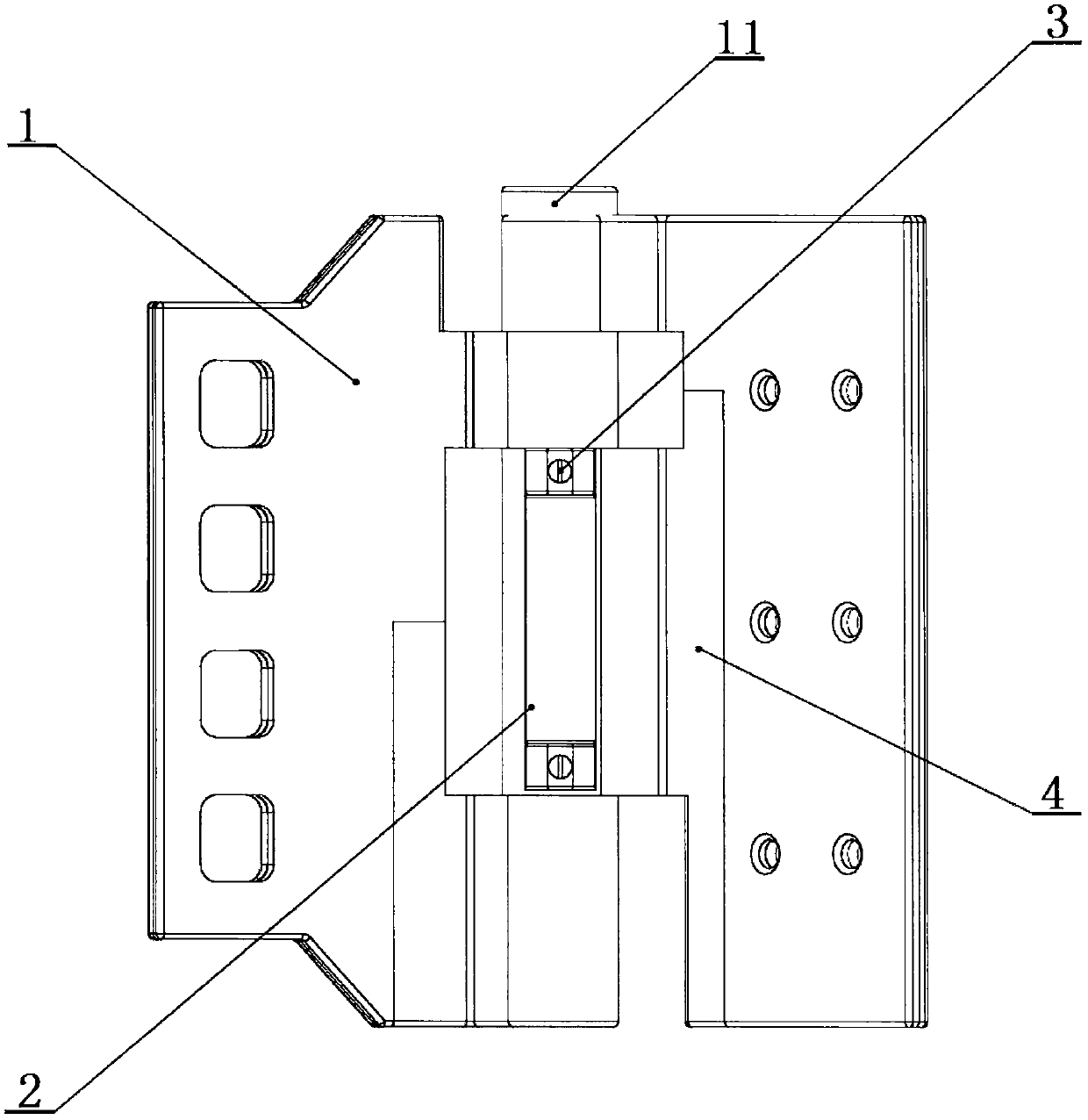

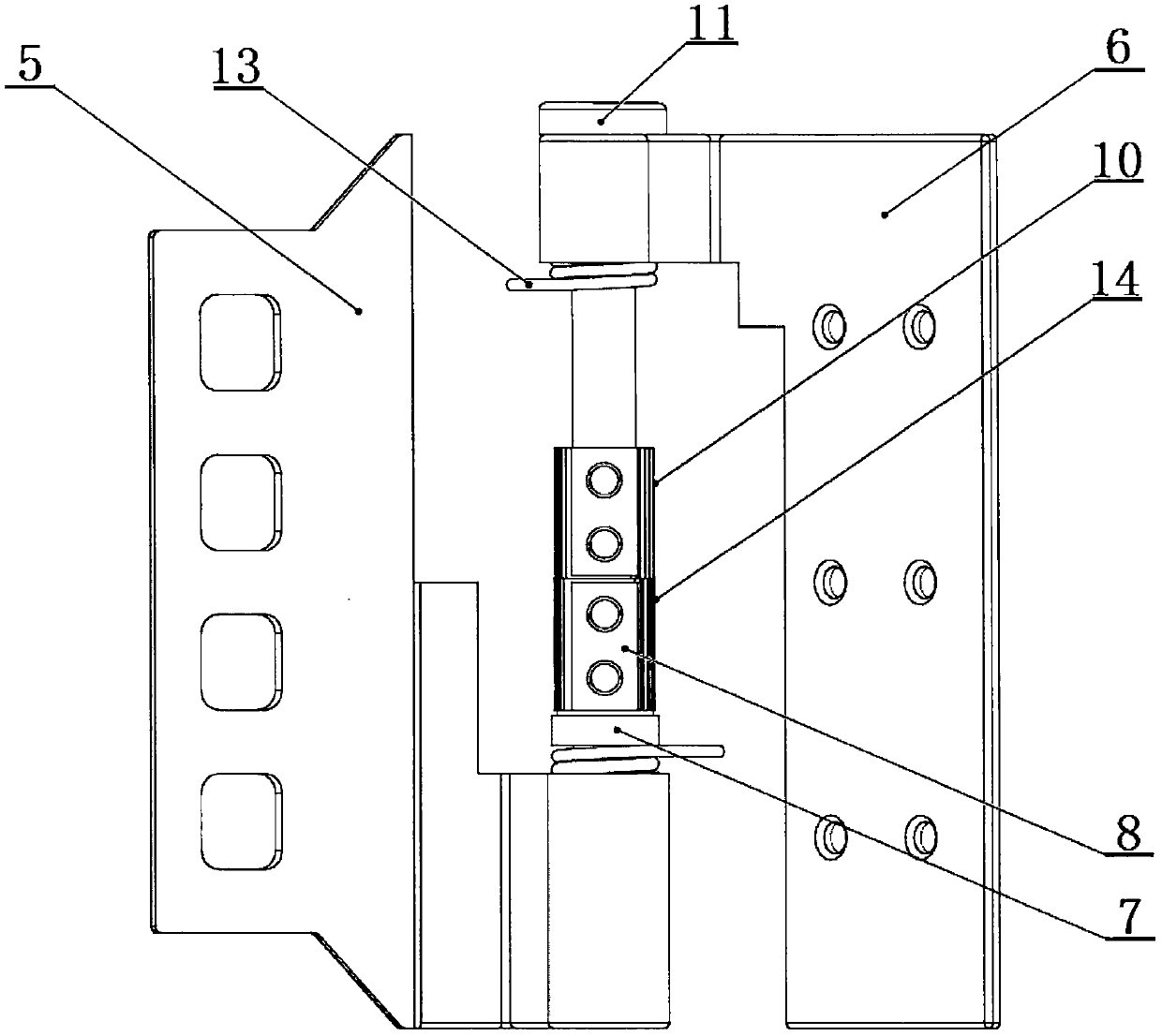

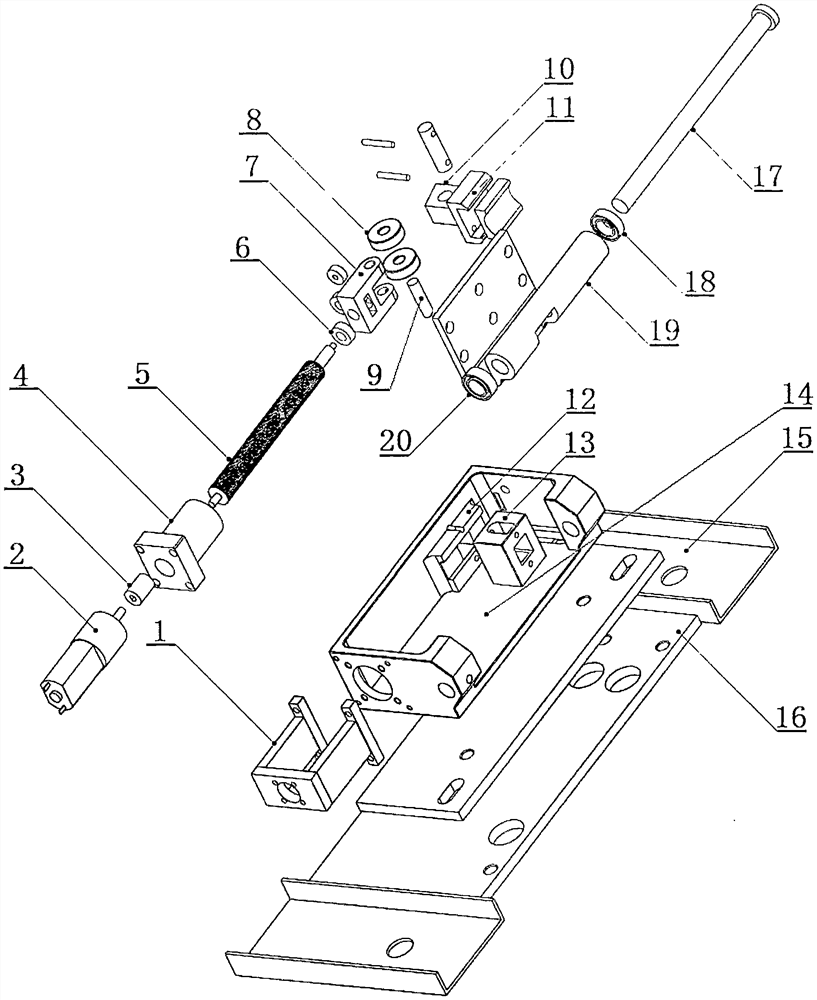

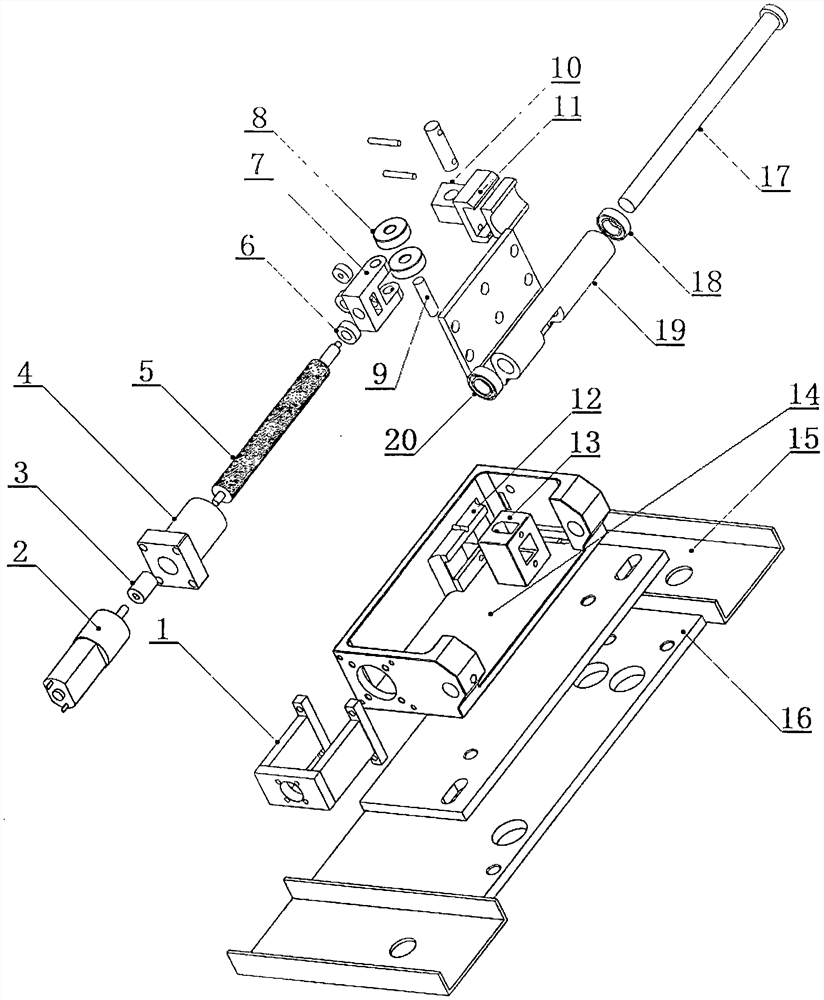

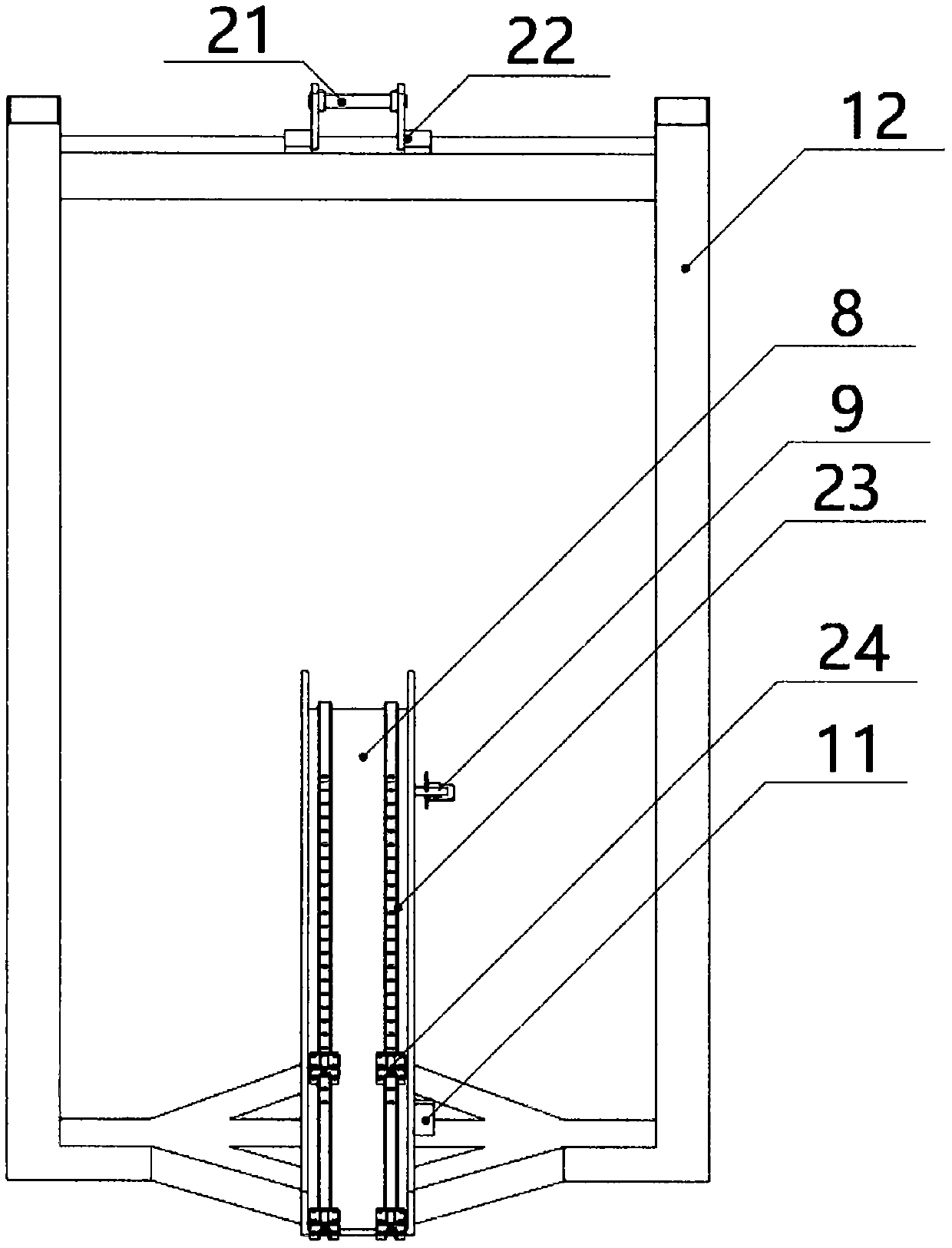

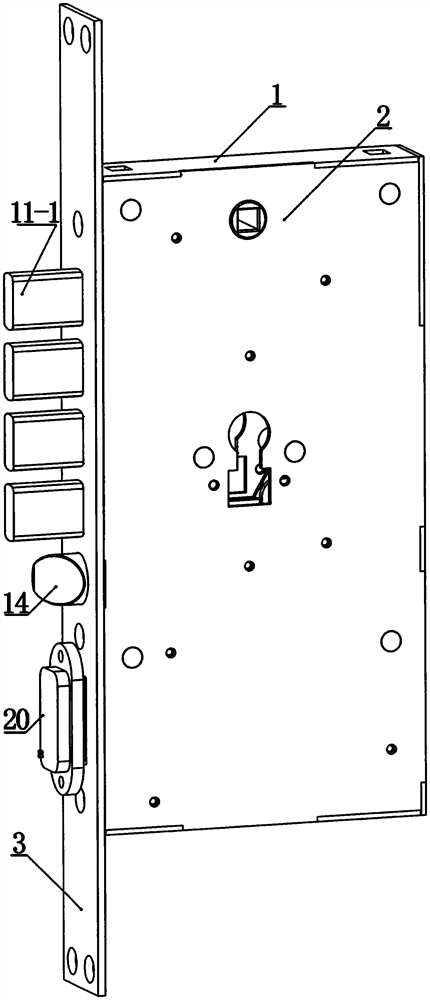

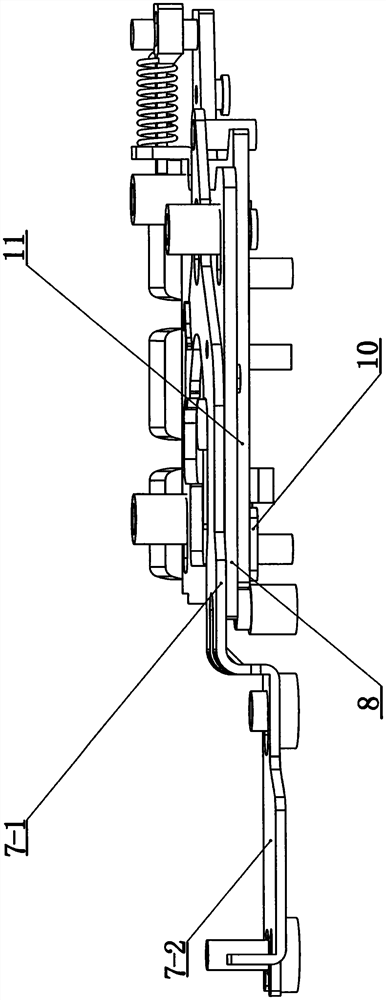

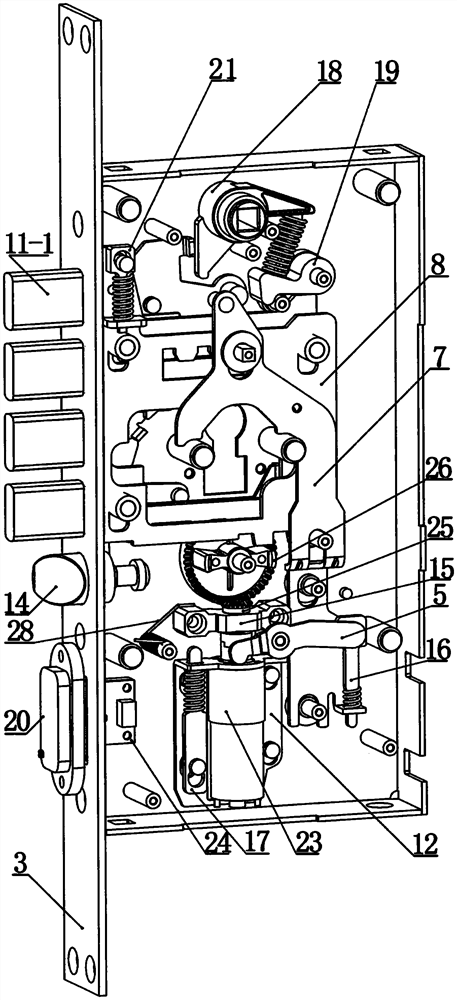

Intelligent lock structure

ActiveCN111173382AAvoid direct connectionExtended service lifeNon-mechanical controlsIndividual entry/exit registersElectric machineGear wheel

The invention relates to the technical field of locks, in particular to an intelligent lock structure. The intelligent lock structure comprises a lock shell, a bottom plate, a side plate, a face plate, a buckle, a pull plate, a fixed plate, a clamping plate, a push plate, a clamping groove plate, a spring bolt plate, a motor fixing piece, a rack plate, a latch bolt, a fixing piece, a fixing pin, amotor buffering pin, a shifting fork, a shifting sleeve, an electromagnet, a clamping plate pin, a circuit board, a motor, an electromagnetic induction piece, a bevel gear, a gear push block, a coilspring and a torsional spring. A cavity can be defined by the lock shell, the bottom plate and the side plate. Four layers of structures are arranged at the upper middle position in the cavity, the position where a ladder is located on the fixed plate is the first layer, the position where the clamping plate is located is the second layer, the position where the spring bolt plate is located is thethird layer, and the position where the clamping groove plate and the rack plate are located is the fourth layer. A door is locked through electromagnetic induction and opened through vena digitalisrecognition, a switch of a motor is controlled through a vena digitalis technology, a spring bolt telescopic mechanism is driven by the motor, the motor is prevented from being directly connected witha door catch, the service life of the lock is prolonged, and the safety of the intelligent lock is improved.

Owner:ZHEJIANG DINGLI IND

Planishing method for tube number soldering opening

InactiveCN101244505ATo achieve the purpose of smooth rollingNice appearanceWind musical instrumentsWeld seamSoldering

The invention relates to a welding seam planishing method of the pipes and the horns, belonging to the musical instrument processing field. The method comprises following steps: firstly, the horn mouth and the horn body, which are welded with each other, are sleeved on the mould which is arranged on the machine tool main shaft, and then the core clamper backs the mould; secondly, a cutter, which is provided with a press roller at the front end, is arranged at the cutter holder of the machine tool; thirdly, the cutter holder moves to the welding seam of the horn mouth and the horn body, which makes the press roller and the welding seam face to face; fourthly, the main shaft of the machine tool drives the mould to rotate, and the feeding cutter holder makes the press roller and the welding seam roll extrusion molding until the welding mouth, the horn mouth and the horn body are consistent horizontally; finally, the cutter holder and the core clamper move back, and the product is a finished product on the mould. The method in the invention has the advantages that: the design is of novelty, practicality, high productivity and good quality; the equipment using the process method is of simple structure, convenient operation and high automation level, which can make the welding seam planishing method of the pipes and the horns widely used and achieves the industrialized production of the pipes and the horns.

Owner:TIANJIN JINBAO MUSICAL INSTR

Field bus adapter with line collecting devices

InactiveCN106299918ASimple structureNovel and practical designNetwork connectorsFlexible lead accommodationEngineeringElectrical and Electronics engineering

The invention discloses a field bus adapter with line collecting devices. The field bus adapter comprises an adapter body, a left line collecting device and a right line collecting device. The adapter body includes an adapter shell and an adapter core circuit board. Each of the left and right line collecting devices comprises a left-wheel line collecting device, a right-wheel line collecting device, and an internally hollowed connection rod. The left-wheel line collecting device is provided with a rotating disc, a rotating shaft connected with the rotating disc, and a micro electrical machine motor. A cylindrical groove is inwardly disposed on the transverse center position of the rotating disc. The rotating shaft is disposed in the connection rod. The micro electrical machine motor is located in a right position below the connection rod and a battery compartment is arranged at a left position below the connection rod. The battery compartment is connected to the micro electrical machine motor via a wire. The field bus adapter has advantages of simple structure, novel and practicable design, and uses the wheel-type line collecting devices, greatly saves space, improves the aesthetical degree of the whole equipment, and makes daily life more convenient and tidy.

Owner:HEFEI AGEDE INFORMATION TECH

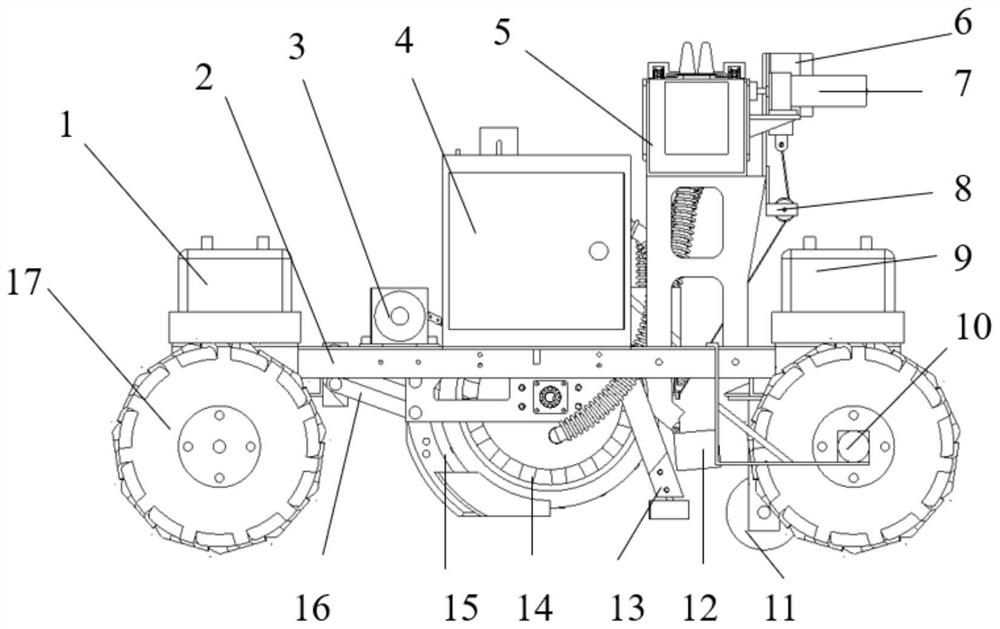

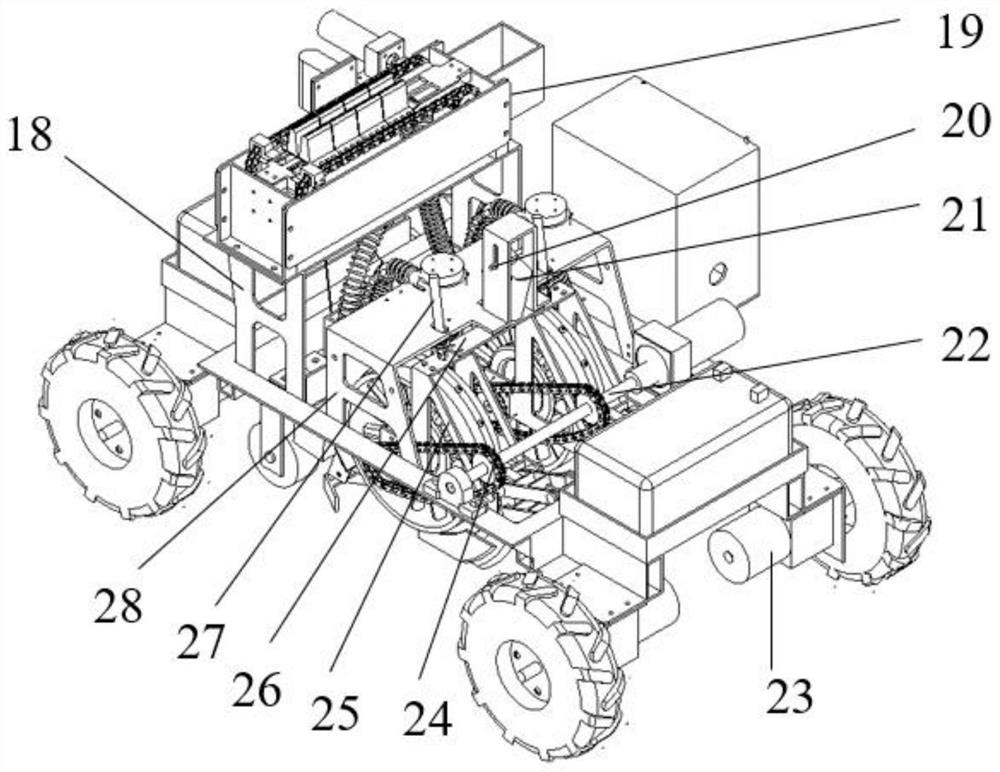

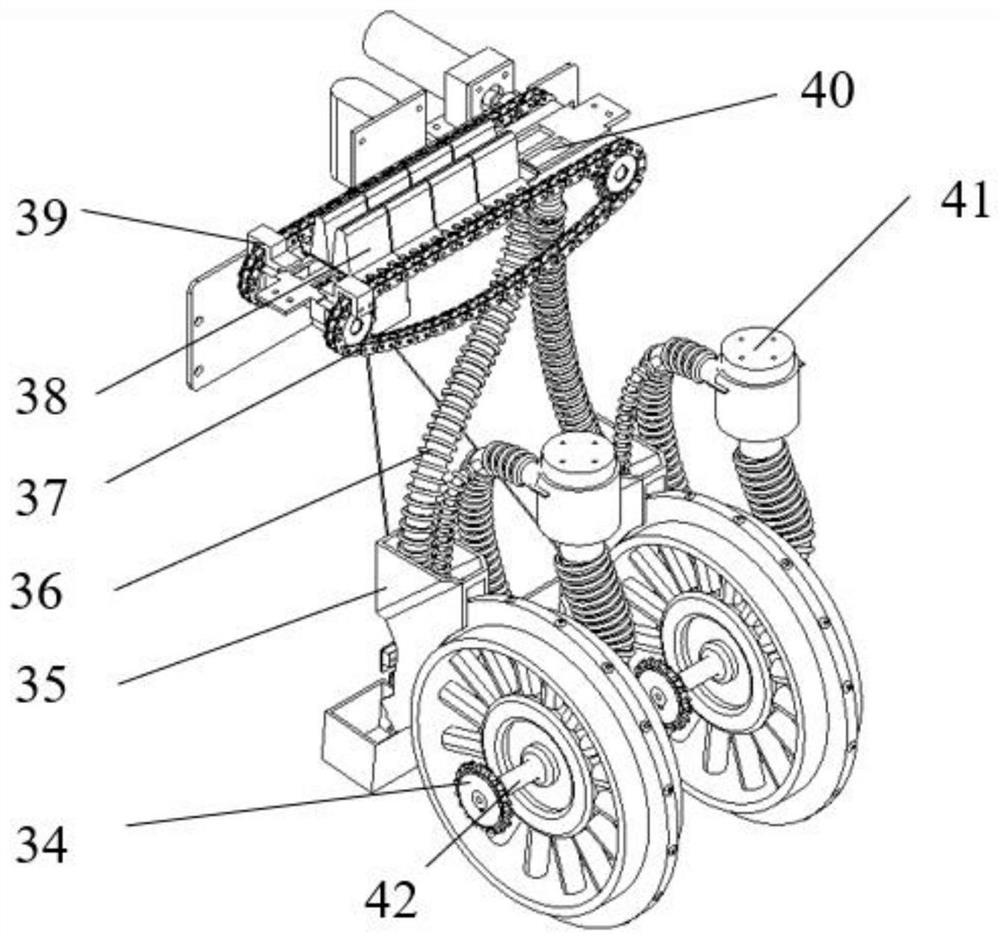

Remote control self-propelled district dibble seeder

PendingCN112930788AImprove field operation efficiency and operation effectSmall turning radiusSeed depositing seeder partsRegular seed deposition machinesElectric machineryAgricultural engineering

The invention provides a remote control self-propelled district dibbler seeder. The remote control self-propelled district dibbler seeder comprises a main machine frame, a walking power battery, a parallel four-bar mechanism, a seeding power motor, a control box, a front supporting frame, a rear supporting frame, a press wheel, an encoder and a seeding power battery are sequentially mounted on the main machine frame from front to back, a single-chip microcomputer plate, a delay control module, an encoder module, a transmission module and a fan controller are arranged in the control box, and the seed supply action is controlled by the single-chip microcomputer plate and the delay control module; the single-chip microcomputer plate realizes four-wheel differential steering of the dibbler seeder by controlling a walking motor connected with a speed reducer, and remote control is realized by the transmission module and the single-chip microcomputer plate; and the seeding power motor is jointly controlled by the encoder and a remote controller to work. According to the remote control self-propelled district dibbler seeder, electromechanical integration, sensing detection and remote control technologies are integrated, remote control operation, field automatic seeding, seed supply and change and waste seed cleaning are realized, the field operation efficiency and the operation effect are improved, and the agricultural intelligent development trend is met.

Owner:CHINA AGRI UNIV

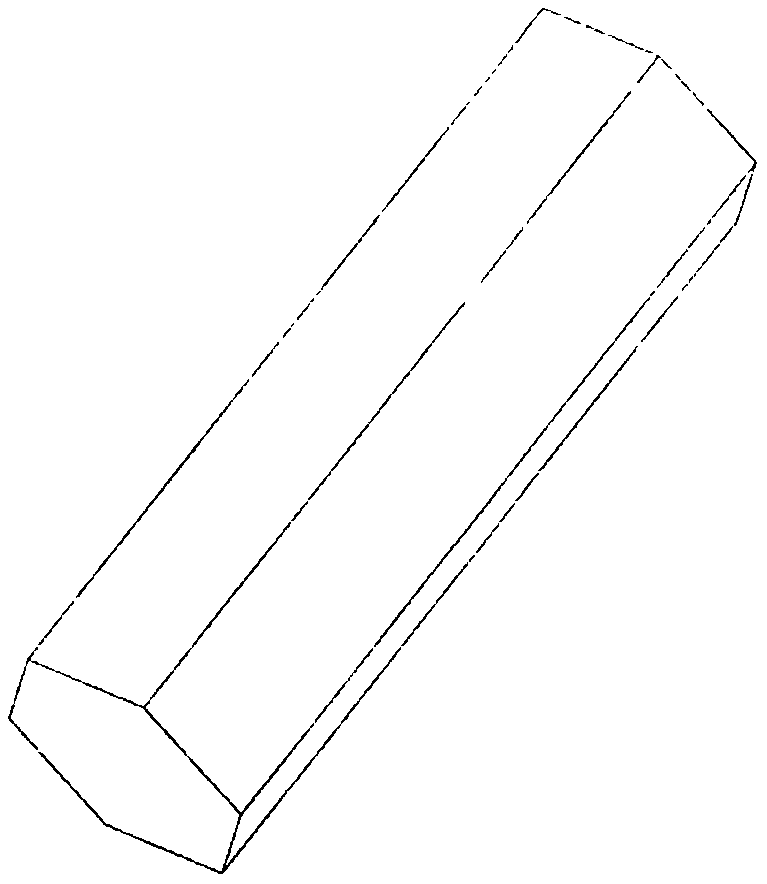

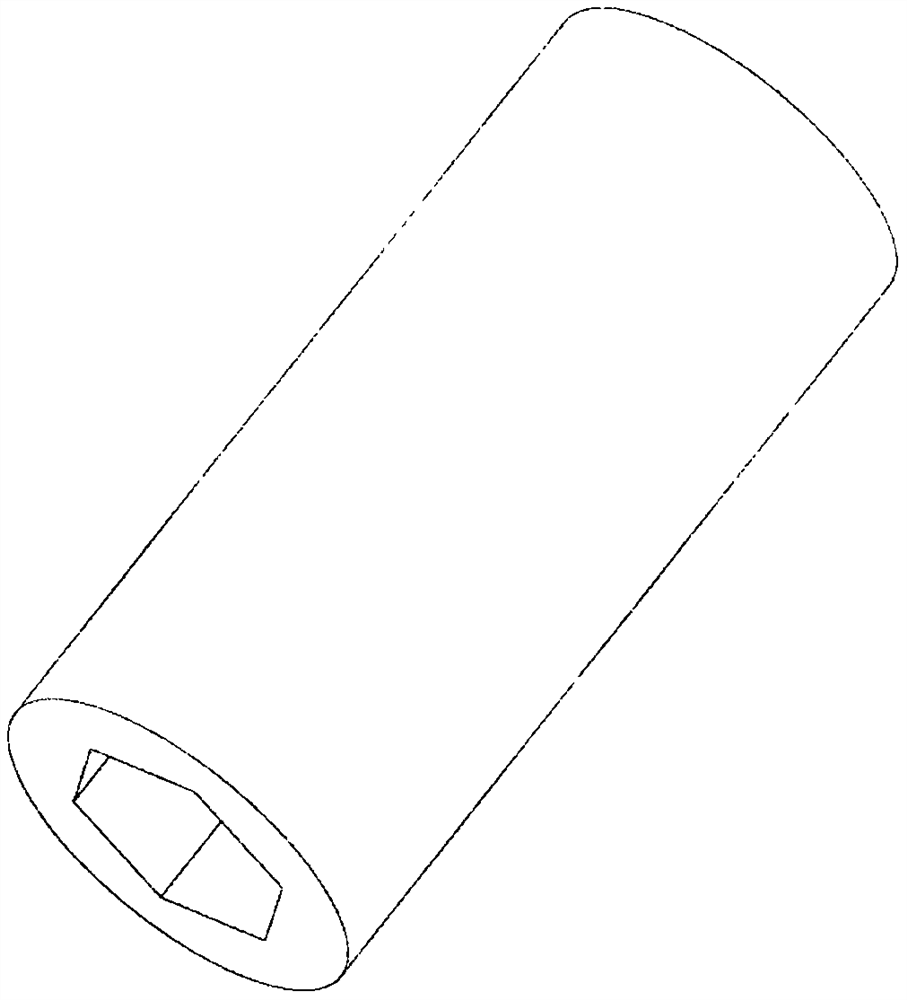

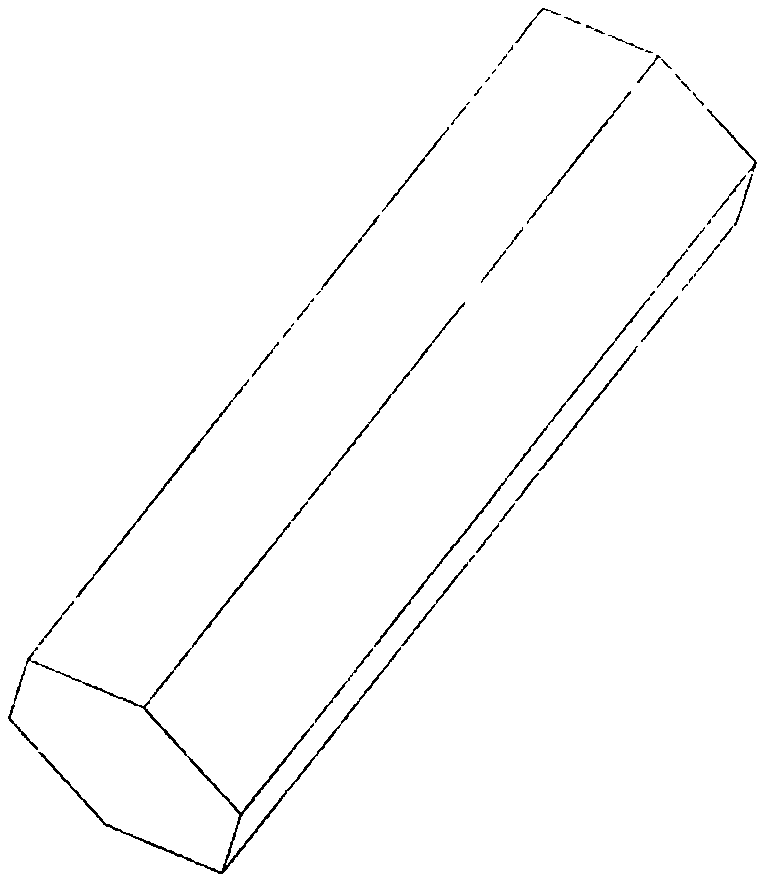

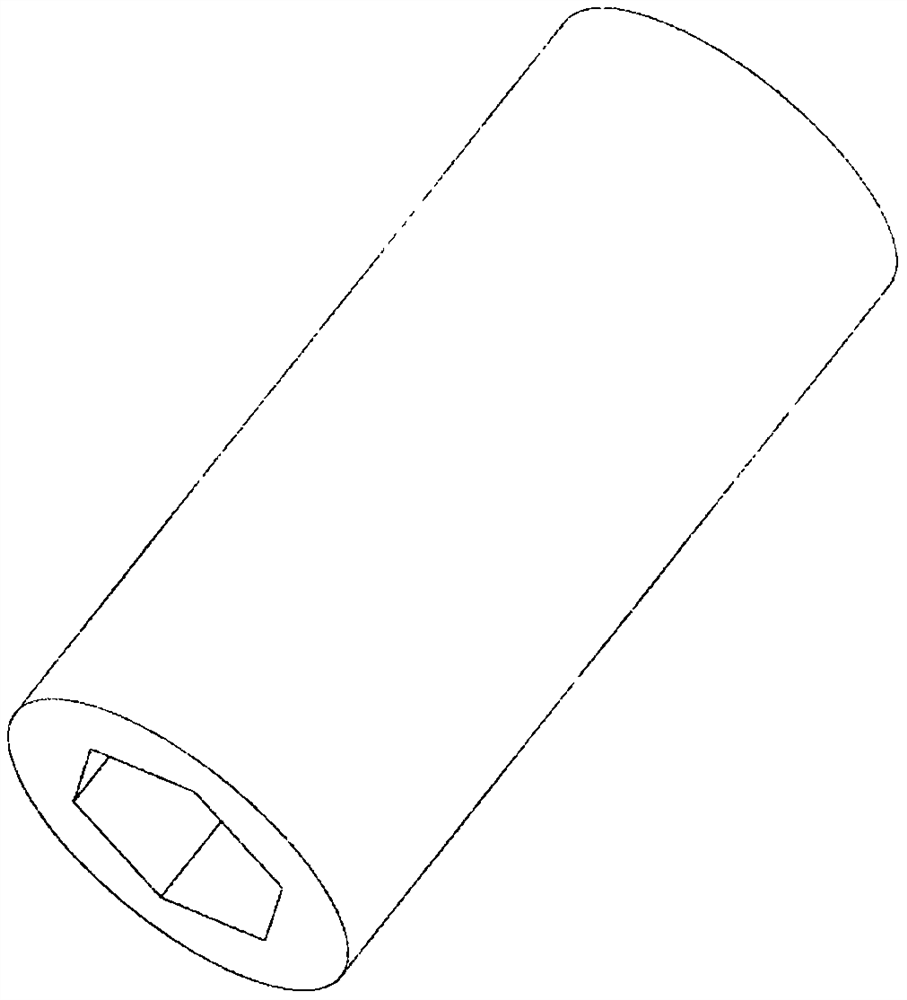

Novel electric parking door hinge

ActiveCN112647788ARealize multi-angle parkingNovel and practical designPower-operated mechanismPin hingesBall screwElectric machine

The invention relates to a door hinge, in particular to a novel electric parking door hinge. The novel electric parking door hinge comprises a power transmission part, a idler wheel mechanism, a parking mechanism and a hinge part; the power transmission part is provided with a motor frame, a motor, a coupler, a ball screw nut and a ball screw rod; the coupler comprises a hexagonal rod and an inner hexagonal cylinder which are in sliding fit with each other, one end of the hexagonal rod is connected with a motor shaft, the other end of the hexagonal rod is inserted into one end of the inner hexagonal cylinder to form sliding connection, and the other end of the inner hexagonal cylinder is connected with the tail end of the ball screw rod; the idler wheel mechanism is provided with an idler wheel connector and an idler wheel, and the other end of the idler wheel connector is connected with the top end of the ball screw rod through a gasket I; the parking mechanism is provided with a trapezoidal sliding block, a brake pad assembly, an idler wheel groove and a sliding block groove which are connected with one another, wherein the trapezoidal sliding block is provided with a springback device; and the hinge part is provided with a hinge main body and a hinge mandrel, and a hinge blade is provided with a mandrel sleeve. When the idler wheel abuts against the inclined face of the trapezoidal sliding block with the springback device from the position between the idler wheel groove and the sliding block groove, a brake pad is driven to tightly hold the mandrel sleeve of the hinge blade, and door parking is achieved.

Owner:ZHEJIANG DINGLI IND

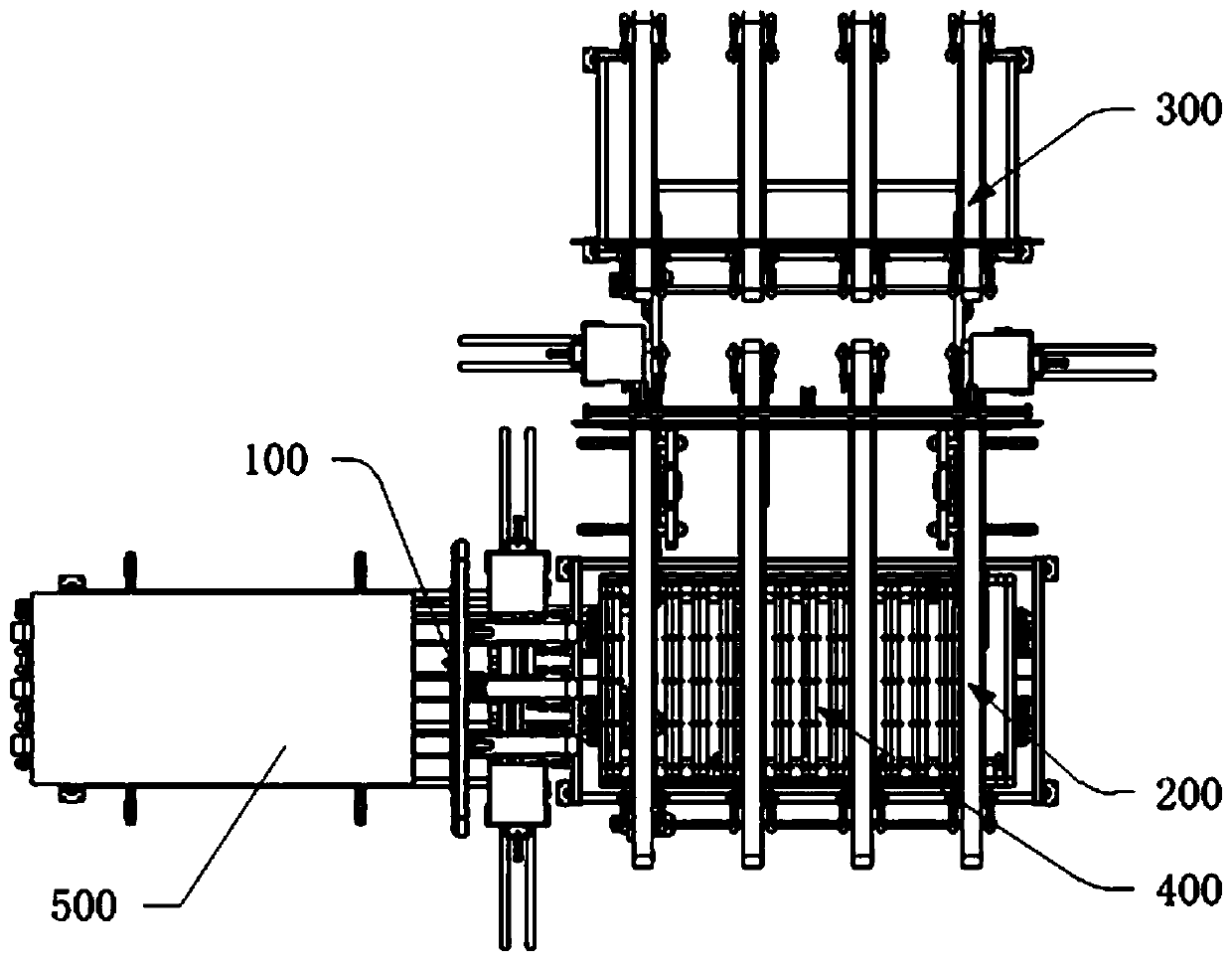

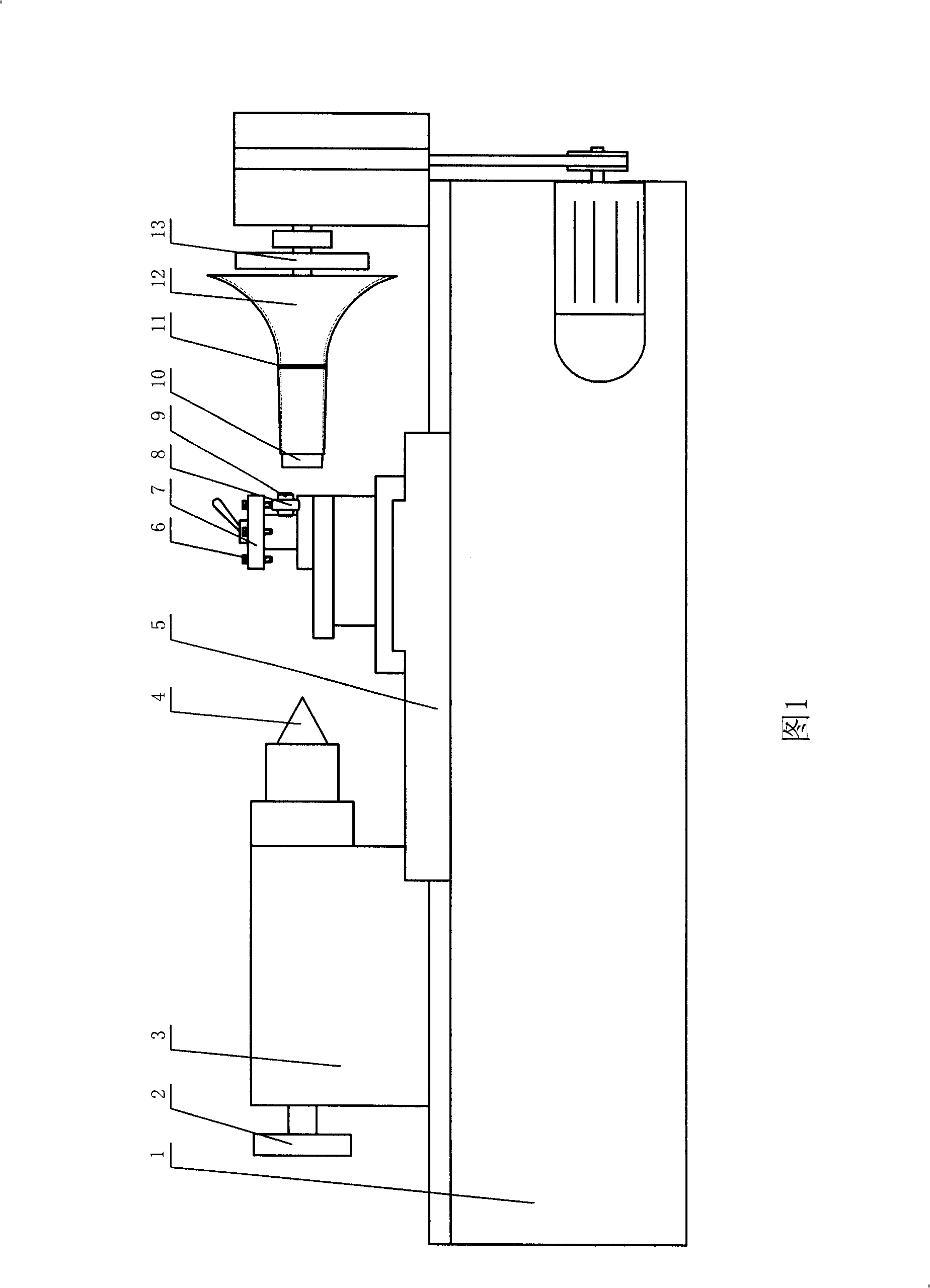

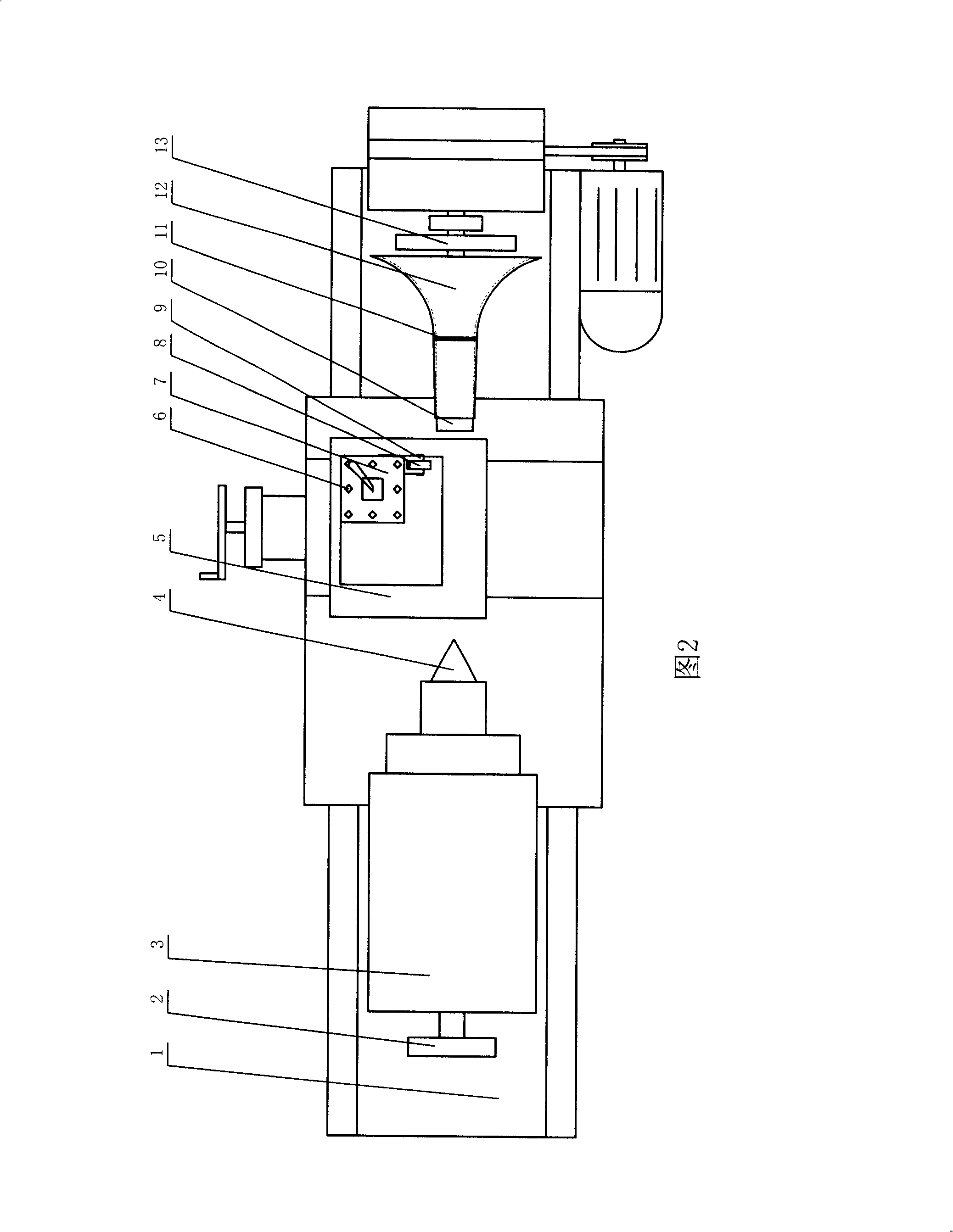

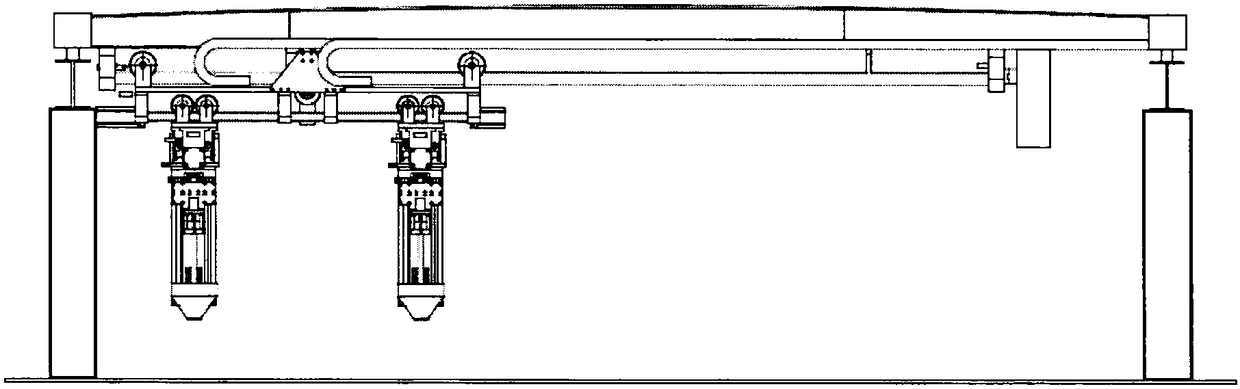

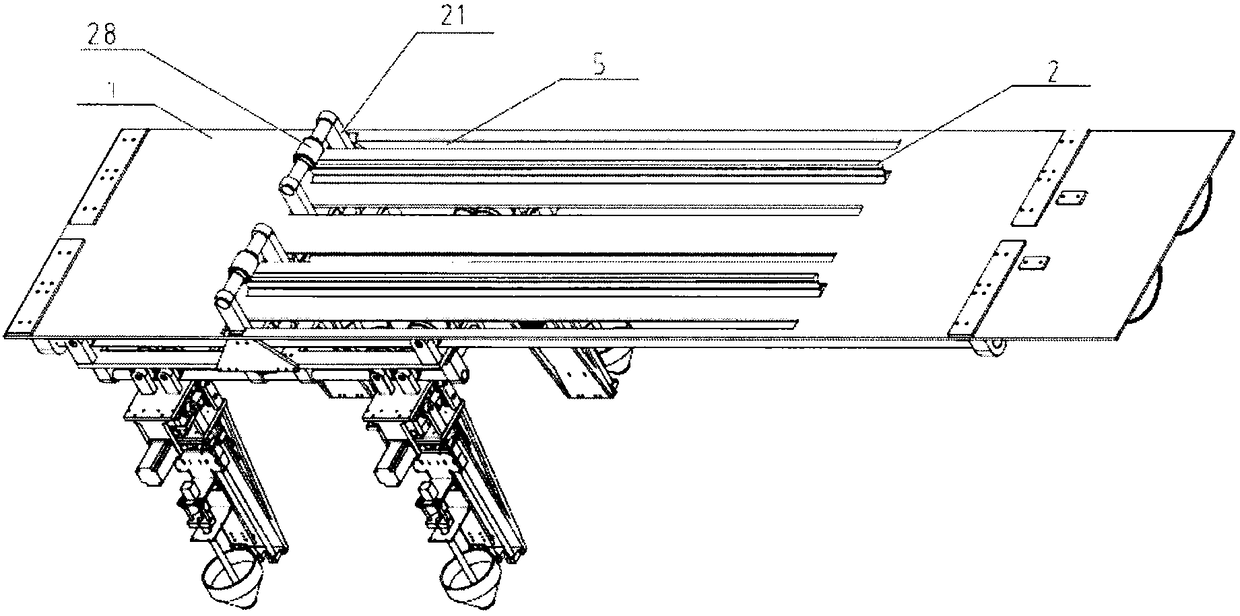

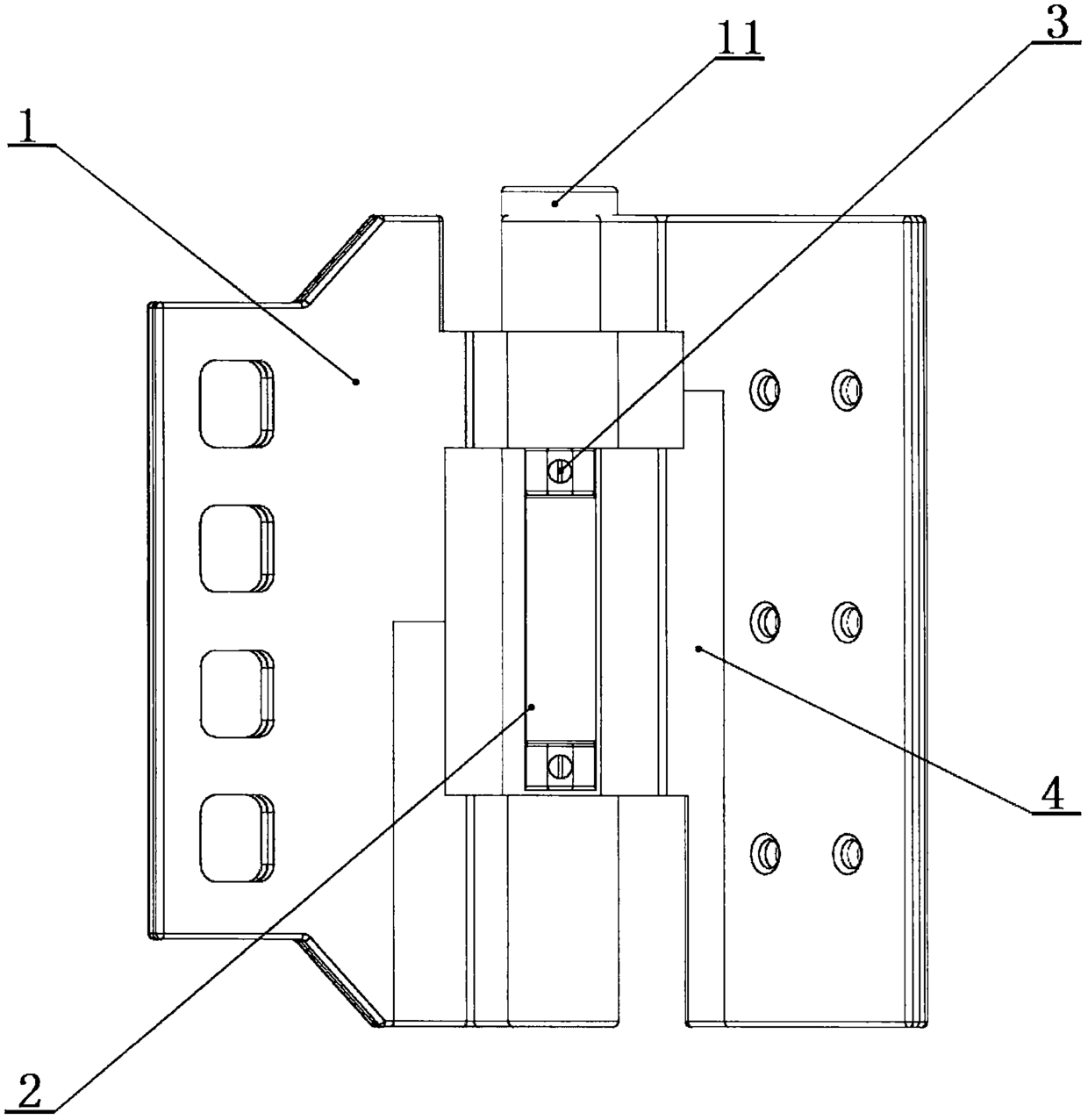

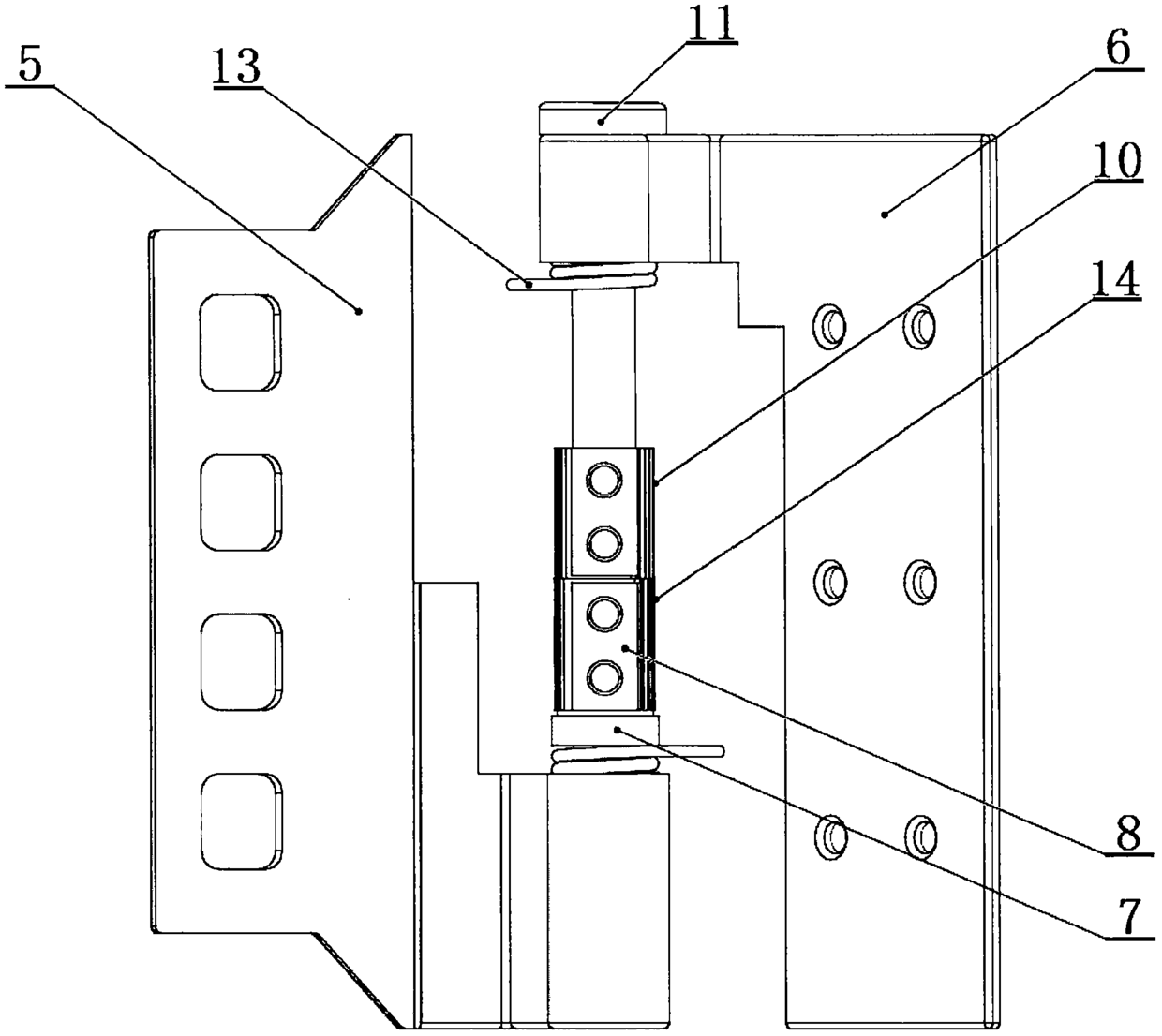

Automatic molten aluminum casting machine

PendingCN108580863ANovel and practical designSmooth castingMelt-holding vesselsMolten metal conveying equipmentsAutomatic controlAluminium

The invention relates to the technical field of aluminum ingot production. An automatic molten aluminum casting machine comprises a walking mechanism, a spindle mechanism, a translation mechanism, a lifting mechanism, a molten metal feeding and discharging mechanism and a control system, wherein the control system comprises a touch screen, a PLC controller and a servo system; the automatic moltenaluminum casting machine is controlled automatically in the whole casting process and stable to cast, the product is stable in quality and low in labor intensity, and safe in production, and the situation that proficient casting workers are in shortage and the manual cost is raised in the production process can be solved, casting products high in quality can be obtained, waste of molten aluminum is avoided, and the safety of the casting process is guaranteed; the labor intensity of workers is alleviated, the casting risk is reduced, and the production efficiency of enterprises is improved. Asthe quantity of workers is reduced, harmful degree on human bodies by aluminum gas can be reduced greatly during casting. Manual labor can be replaced, and various types of aluminum, copper, iron andmolten steel are casted automatically. The automatic molten aluminum casting machine provided by the invention is novel and practical in design and is of creativity.

Owner:ZHEJIANG DINGLI IND

Door hinge with continuous stop and power assist function

ActiveCN109184397AParked to achieveWithout breaking integrityPin hingesWing openersEngineeringTorsion spring

The invention relates to door hinges, in particular to a door hinge with continuous stop and a power assist function. The door hinge mainly comprises a door frame upper half sheet, a pressing cover, mimus screws, a door lower half sheet, a door frame lower half sheet, a door upper half sheet, a shaft sleeve, two wave pressing plates, four springs, a wave pipe I, a pin, a long key, two torsion springs, and a wave pipe II. Key grooves are formed in axis holes of the wave pipe I and the wave pipe II. The wave pipe I and the wave pipe II are connected with the pin by the long key, and are arrangedon the limiting end faces in axis holes of the door lower half sheet in a sleeving mode. Protruding convex wavy strips are arranged on three quarters of the surfaces of the circumferences of the outer lateral faces of the wave pipe I and the wave pipe II. A protruding longitudinal concave wavy strip is arranged on the inner side of the wave pressing plate. The concave wavy strip is engaged with the convex wavy strips. One ends of the springs are fixed into limiting holes outside the wave pressing plate. A limiting pit is formed in the pressing cover. The other ends of the springs are matchedand connected with the limiting holes of the pressing cover. The four springs are assembled in the pressing cover is a limiting mode. The pressing cover is matched with a preformed groove of the doorlower half sheet.

Owner:ZHEJIANG DINGLI IND

Method for casting by utilizing automatic molten aluminum casting machine

ActiveCN109128115AAvoid wastingLess harmfulMelt-holding vesselsMolten metal conveying equipmentsAutomatic controlControl system

The invention relates to the technical field of aluminum ingot production, and discloses a method for casting by utilizing an automatic molten aluminum casting machine. According to the method, a crane mechanism, a main shaft mechanism, a translation mechanism, a lifting mechanism, a water feeding and discharging mechanism and a control system are utilized, wherein the control system comprises a touch screen, a PLC and a servo system, the whole casting process is automatically controlled, casting is stable, the product quality is stable, the labor intensity is low, the production is safe, thesituations that workers skilled in casting are in shortage and the labor cost is increased in the production process can also be avoided, the high-quality casting product can be obtained, waste of themolten aluminum is avoided, and the safety of the casting process is guaranteed; the labor intensity of workers is relieved, the casting risk is reduced, the production efficiency of an enterprise isimproved, due to the fact that the number of used labor is reduced, the harmful degree of the aluminum gas to the human body is greatly reduced in the aspect of quantity in the casting process, the manual work can be replaced, various automatic casting of aluminum, copper, iron and molten steel can be realized, the method is high in efficiency, novel and practical in design and creative.

Owner:ZHEJIANG DINGLI IND

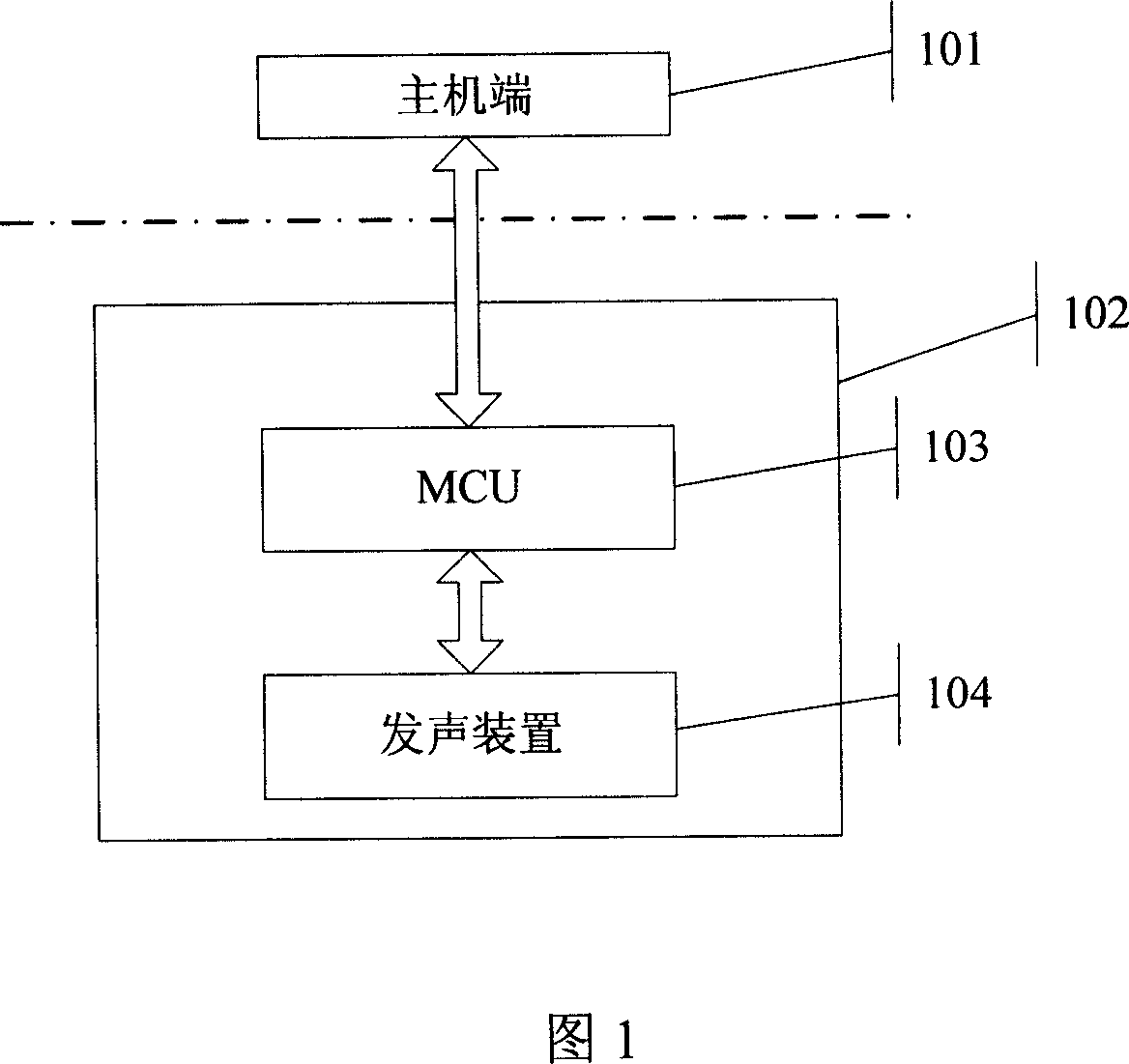

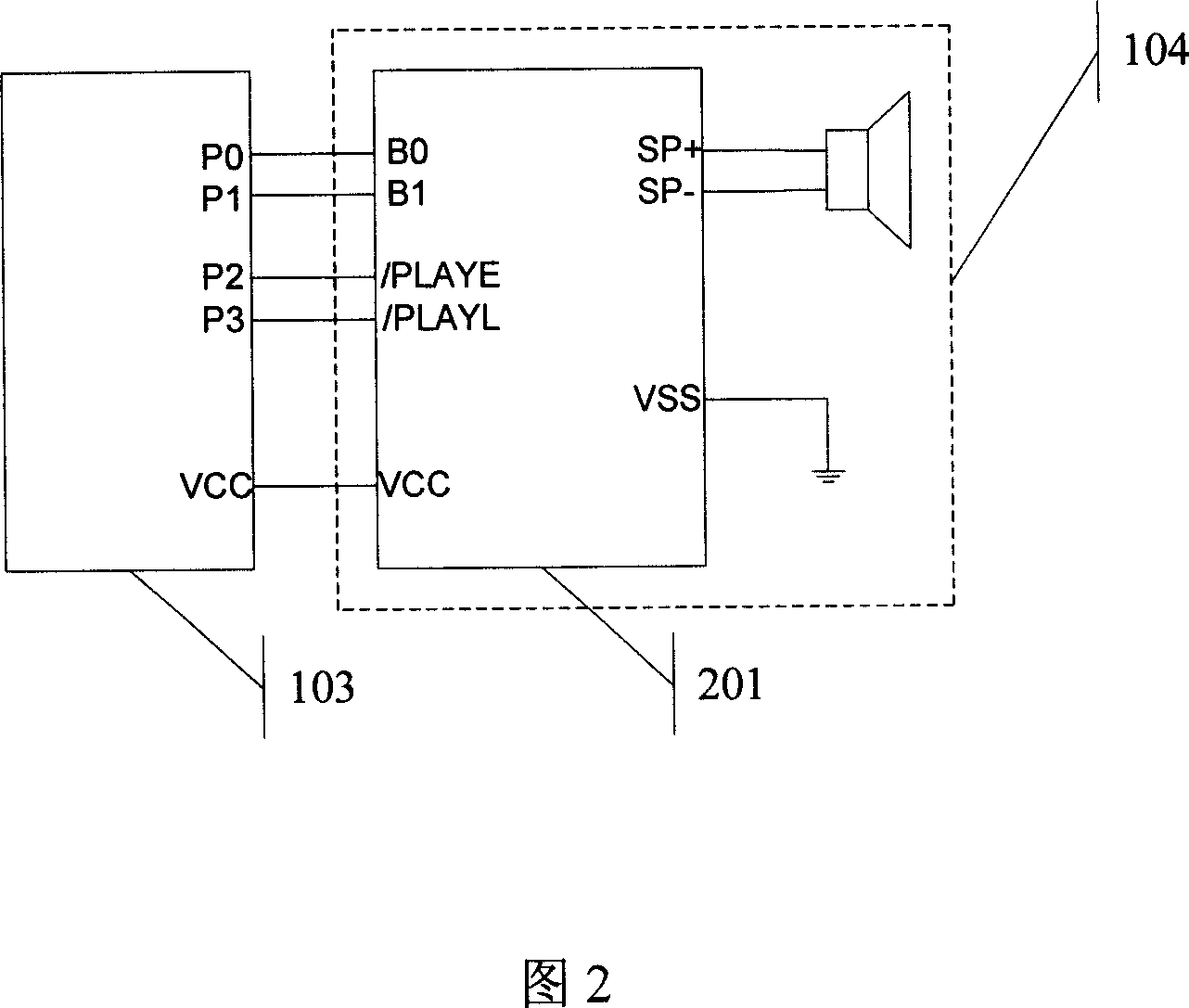

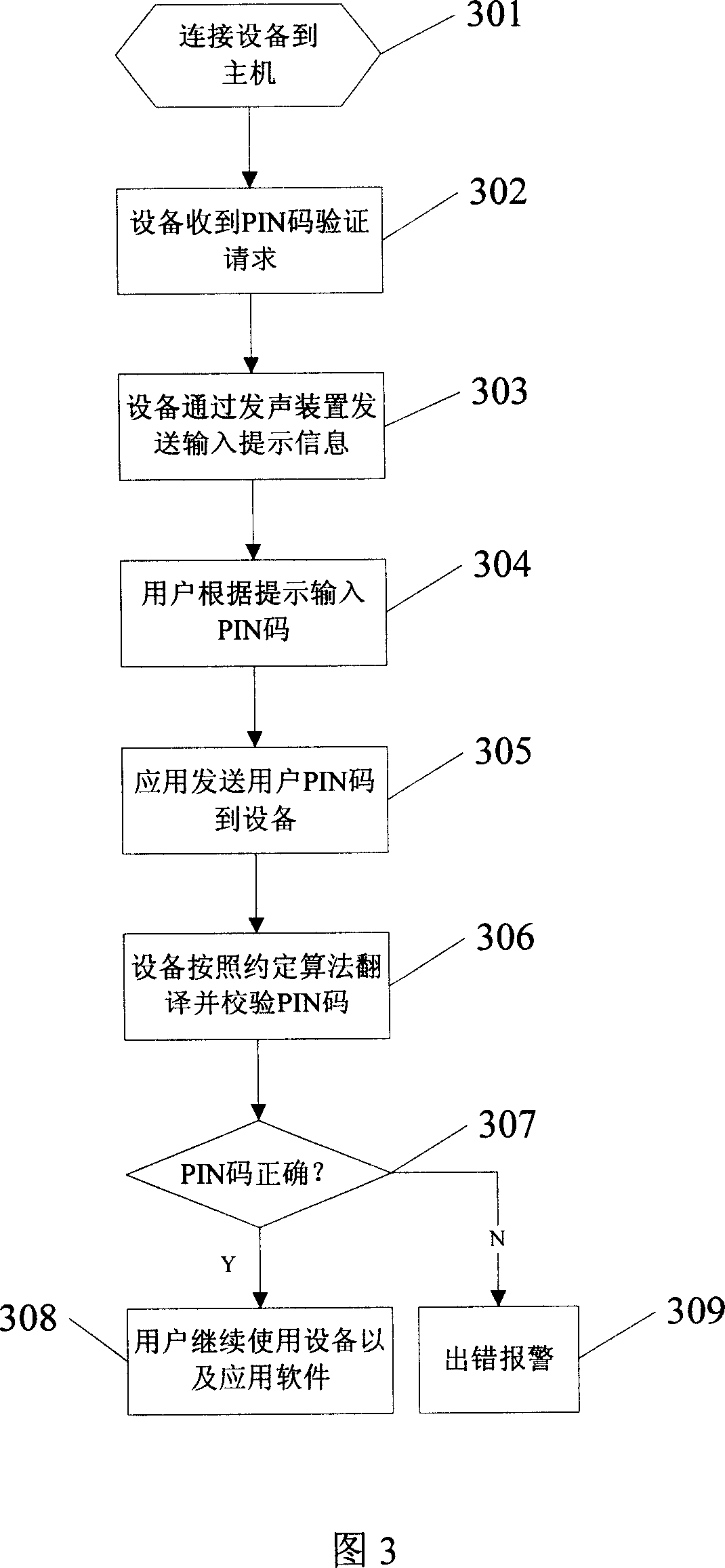

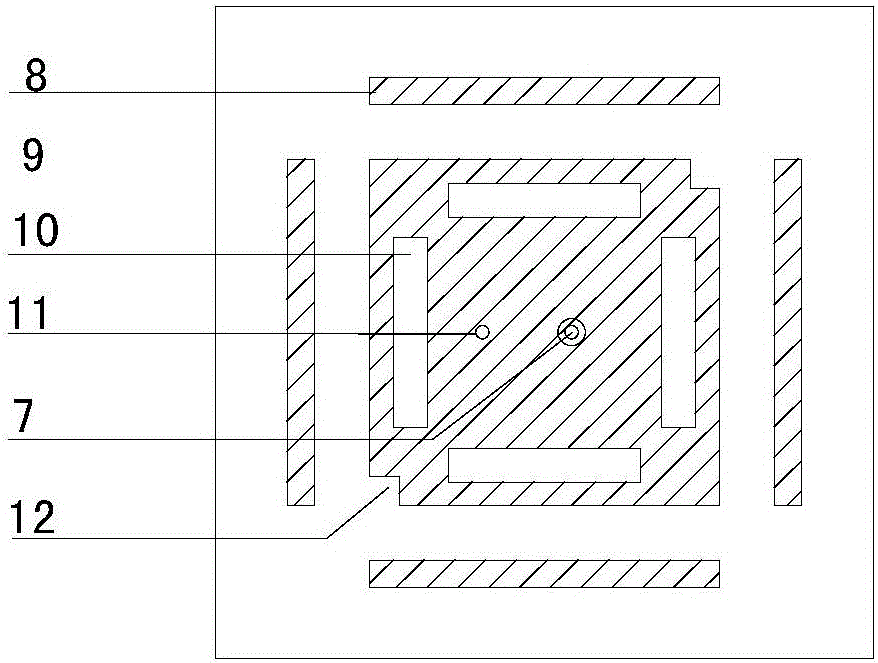

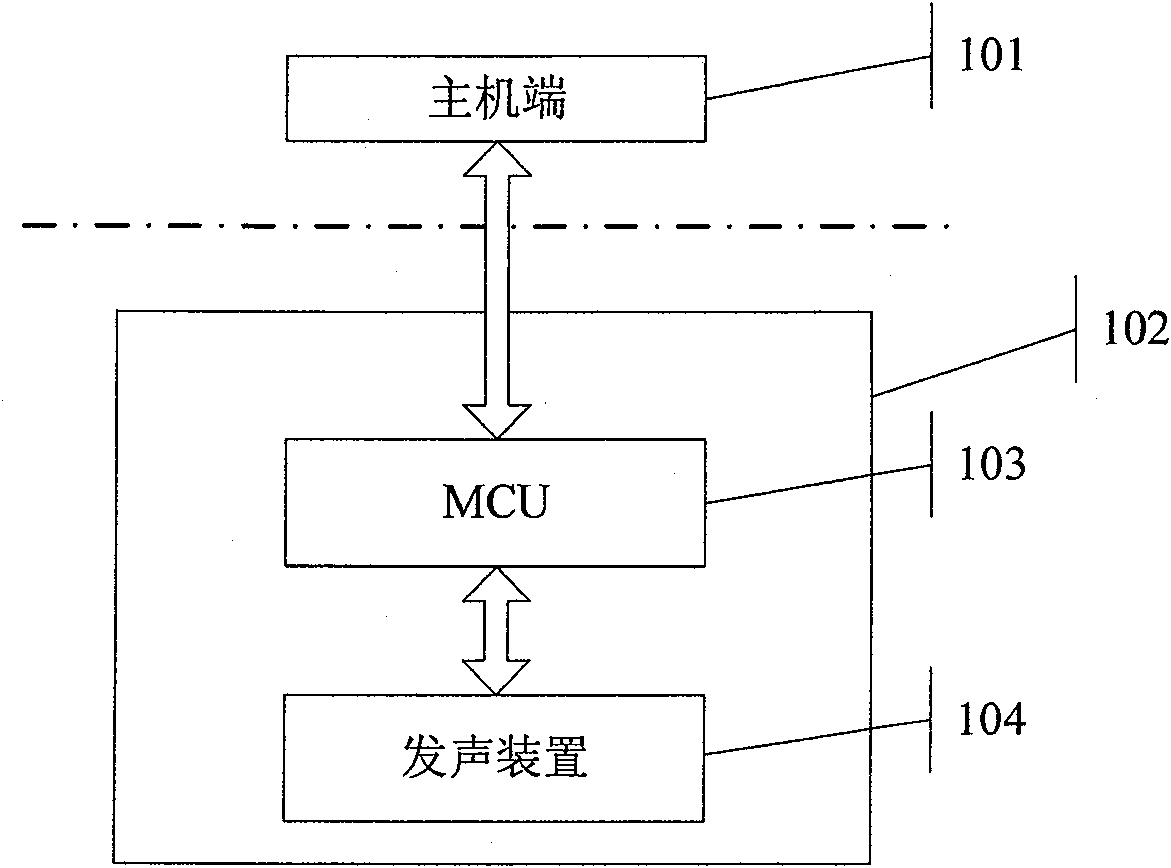

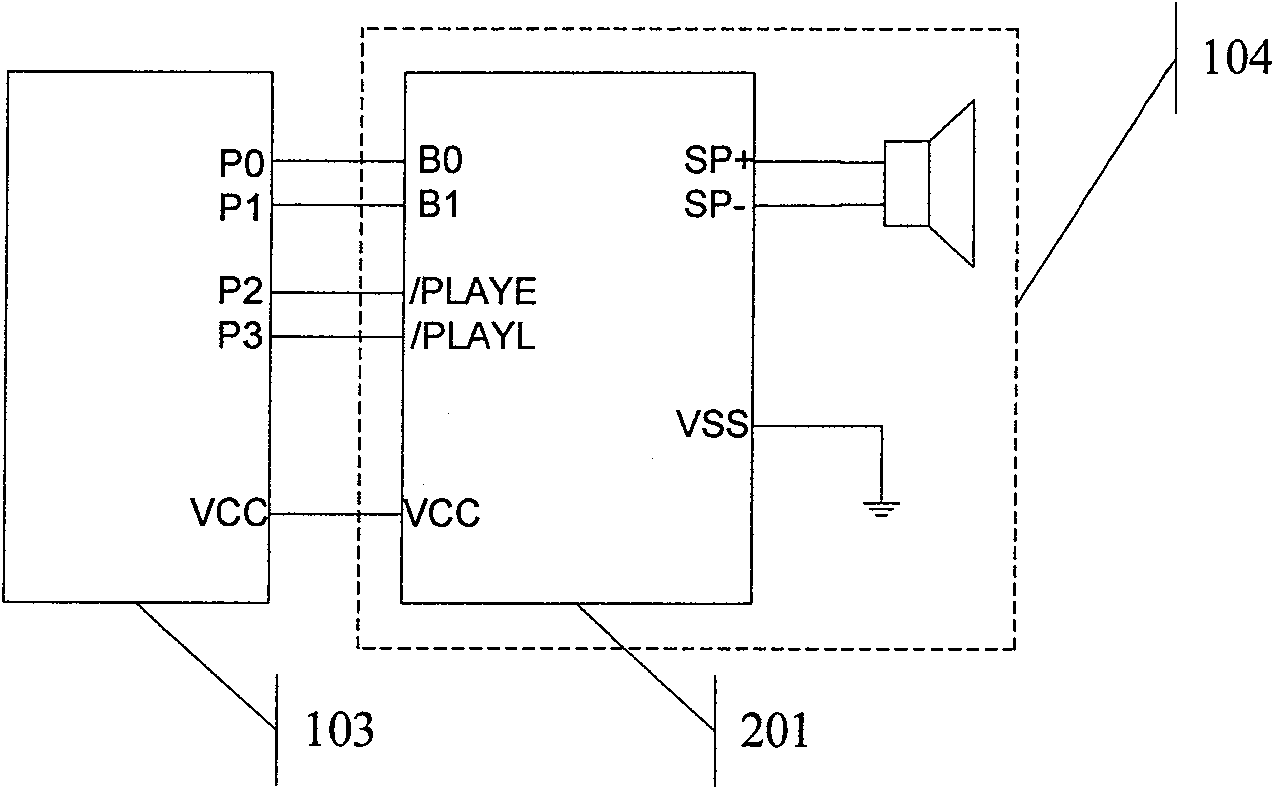

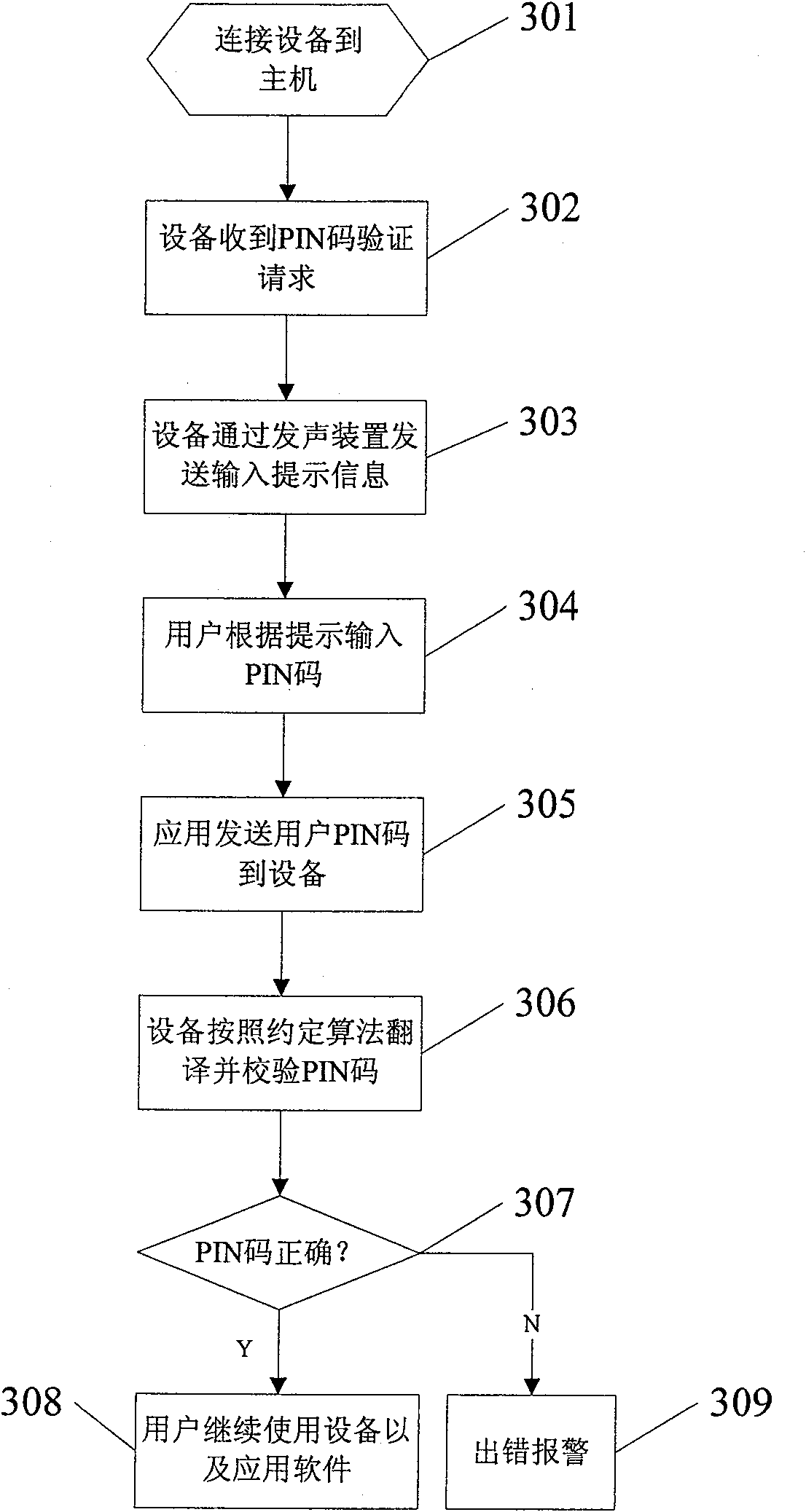

Intelligent key apparatus equipped with sounding device

ActiveCN1921393AImprove usabilityReduced risk of interceptionUser identity/authority verificationCapacitanceSignal amplifier

The invention relates to an intelligent key device with sound device. Wherein, it comprises MCU and sound device; the sound device comprises sound element connected to the MCU directly or via resistance, capacitor, or signal amplifier; the sound element can be loudspeaker or buzzer; the sound element can comprises an A / D converter or sound chip with serial input or parallel input that connected to the MCU bus. The invention based on the need of remote terminal or host uses sound element to generate prompt information, which can be different each time, to prompt input information, to improve the safety. And the sound element can realize safety alarm, read-write prompt, and operation prompt, etc.

Owner:FEITIAN TECHNOLOGIES

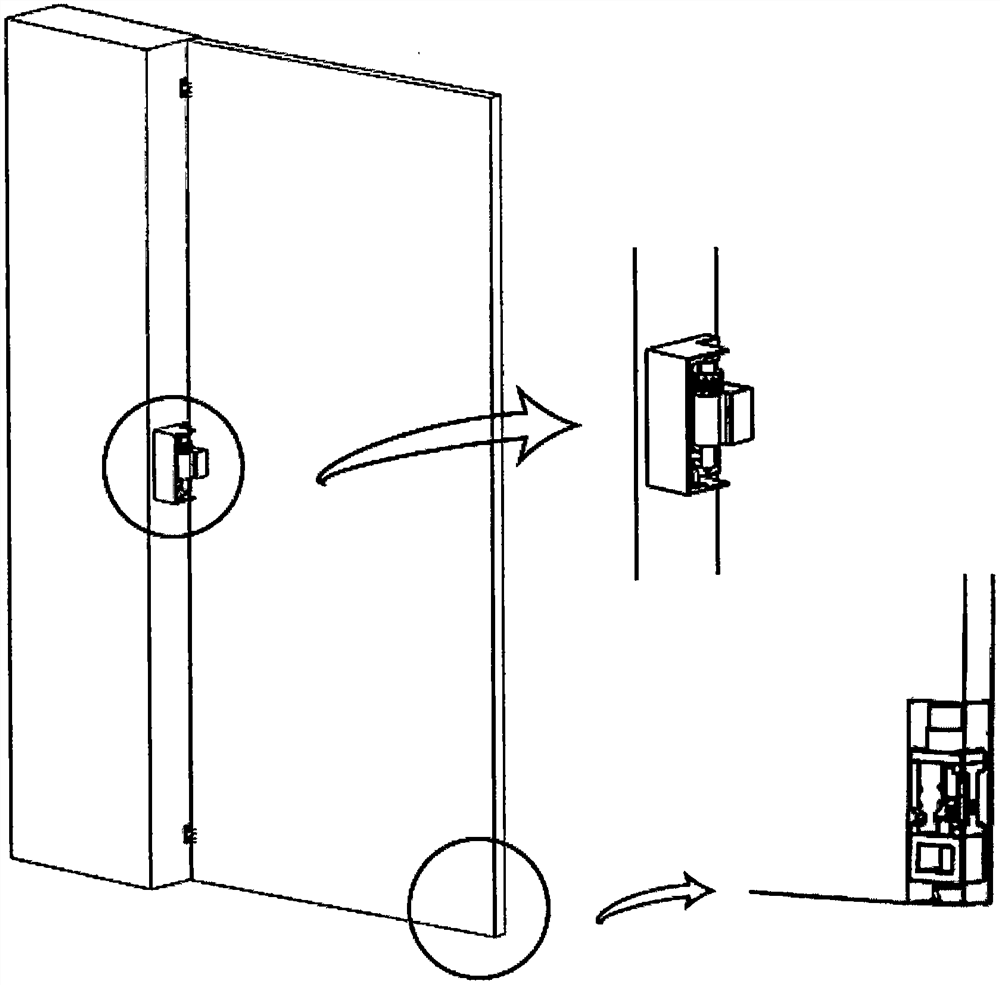

Novel parking door hinge

The invention relates to a door hinge, in particular to a novel parking door hinge which is mainly composed of a magnetic adsorption type gear parking device and a lead screw friction plate parking device, and the magnetic adsorption type gear parking device is installed in the middle of a door frame and mainly composed of a positioning connecting mechanism and a magnetic parking mechanism. The lead screw friction plate parking device is installed at the outward position of the bottom of the door body and mainly composed of a supporting and positioning mechanism and a mechanical transmission mechanism, the positioning and connecting mechanism comprises a base, a connecting piece, a positioning piece, a fan and a plane bearing I. The magnetic parking mechanism comprises an upper magnetic gear, a lower magnetic gear, a linear bearing, a rotary positioning block and a mandrel. The supporting and positioning mechanism comprises a motor positioning block, a left positioning block, a supporting block, a dustproof ring, a right positioning block, a plurality of inner hexagon screws and a ball screw sleeve. The mechanical transmission mechanism comprises a direct current motor, a set screw, an inner hexagon connecting piece, a lead screw, a plane bearing II, a rubber gasket, a conical friction plate, a gasket and a long screw.

Owner:ZHEJIANG DINGLI IND

A door hinge that can be parked continuously and has a power assist function

The invention relates to door hinges, in particular to a door hinge with continuous stop and a power assist function. The door hinge mainly comprises a door frame upper half sheet, a pressing cover, mimus screws, a door lower half sheet, a door frame lower half sheet, a door upper half sheet, a shaft sleeve, two wave pressing plates, four springs, a wave pipe I, a pin, a long key, two torsion springs, and a wave pipe II. Key grooves are formed in axis holes of the wave pipe I and the wave pipe II. The wave pipe I and the wave pipe II are connected with the pin by the long key, and are arrangedon the limiting end faces in axis holes of the door lower half sheet in a sleeving mode. Protruding convex wavy strips are arranged on three quarters of the surfaces of the circumferences of the outer lateral faces of the wave pipe I and the wave pipe II. A protruding longitudinal concave wavy strip is arranged on the inner side of the wave pressing plate. The concave wavy strip is engaged with the convex wavy strips. One ends of the springs are fixed into limiting holes outside the wave pressing plate. A limiting pit is formed in the pressing cover. The other ends of the springs are matchedand connected with the limiting holes of the pressing cover. The four springs are assembled in the pressing cover is a limiting mode. The pressing cover is matched with a preformed groove of the doorlower half sheet.

Owner:ZHEJIANG DINGLI IND

A door hinge that can be parked at any angle by using the thread self-locking function

ActiveCN108756551BRealize infinite parking at any angleAvoid automatic shutdownPin hingesSelf lockingScrew thread

The invention relates to door hinges, in particular to a door hinge capable of achieving parking at random angle through the thread self-locking function. The door hinge mainly comprises a sliding block, an inner hexagon nut I, a connecting rod, a fixed hinge, a guide rail, a center shaft, a blocking piece, a locking fixed screw cap, a left-hand rotating moving screw cap, a pressure spring, aright-hand rotating moving screw cap, a rotating hinge, a shell, an inner hexagon bolt, an inner hexagon nut II, a fixed plate and a hinge fixing shell; a left-hand thread and a right-hand thread are arranged at the two ends of the center shaft correspondingly, the lengths and the screw pitches of the left-hand thread and the right-hand thread are equal, the pressure spring is arranged on the middle segment of the periphery of the center shaft in a sleeving manner, the left-hand moving screw cap and the right-hand moving screw cap are screwed in from the two ends of the center shaft and are in abutjoint with the two ends of the pressure spring tightly, and the pressure spring is pre-tightened; the left-hand moving screw cap and the right-hand moving screw cap are connected with sliding blocksthrough the inner hexagon nuts and the connecting rods, the two sliding blocks are matched with the guide rail, and under the pressure effect of the pressure spring, threads in the left-hand moving screw cap and the right-hand moving screw cap generate enough self locking.

Owner:ZHEJIANG DINGLI IND

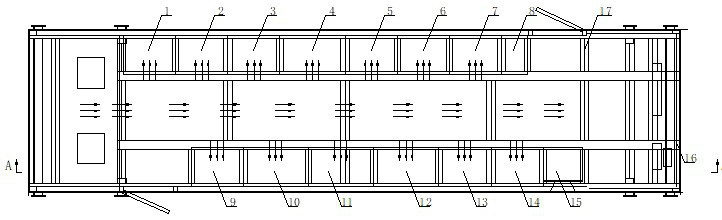

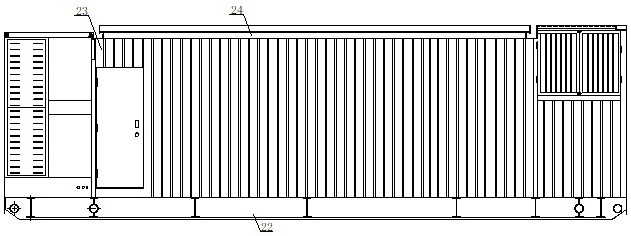

Internal environment temperature intelligent control drilling machine electric control room

PendingCN112577106AHigh strengthNo down pressure problemDucting arrangementsMechanical apparatusCold airAir volume

The invention discloses an internal environment temperature intelligent control drilling machine electric control room. The device comprises an electric control room body, a room body base is arrangedat the bottom of the electric control room body, a base cold air channel is longitudinally arranged inside the room body base, an integrated air conditioner is arranged at one end inside the electriccontrol room body, an air conditioner plenum chamber is installed at the bottom of the integrated air conditioner, an air outlet of the air conditioner plenum chamber is connected with an air inlet of the base cold air channel, a plurality of cabinet bodies are arranged on the two sides of the interior of the electric control room body, control equipment is placed in the cabinet bodies, air holeswith the adjustable air inlet amount are formed between the cabinet bodies and the base cold air channel, an aisle is arranged between the cabinet bodies on the two sides of the electric control roombody, and a top cover is arranged at the top of the electric control room body. The internal environment temperature intelligent control drilling machine electric control room solves the problems that an existing drilling machine electric control room cabinet cannot achieve control over the air inlet amount of different cabinets, hot air circulation short circuit occurs, the air supply amount andthe air return amount of an air conditioner are unequal, the path of cold air entering the cabinet bodies is long, and losses exist.

Owner:TIANSHUI ELECTRIC DRIVE RES INST +1

An electric parking door hinge

ActiveCN112647788BRealize multi-angle parkingNovel and practical designPower-operated mechanismPin hingesBall screwElectric machine

Owner:ZHEJIANG DINGLI IND

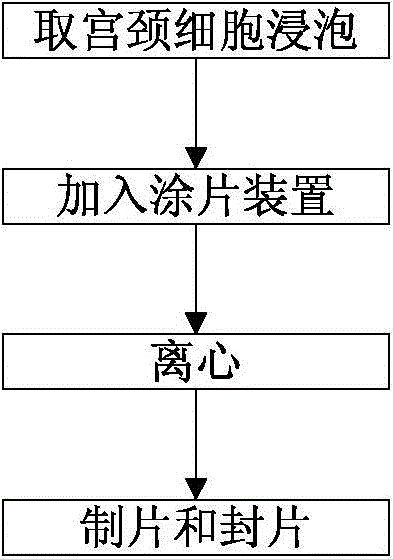

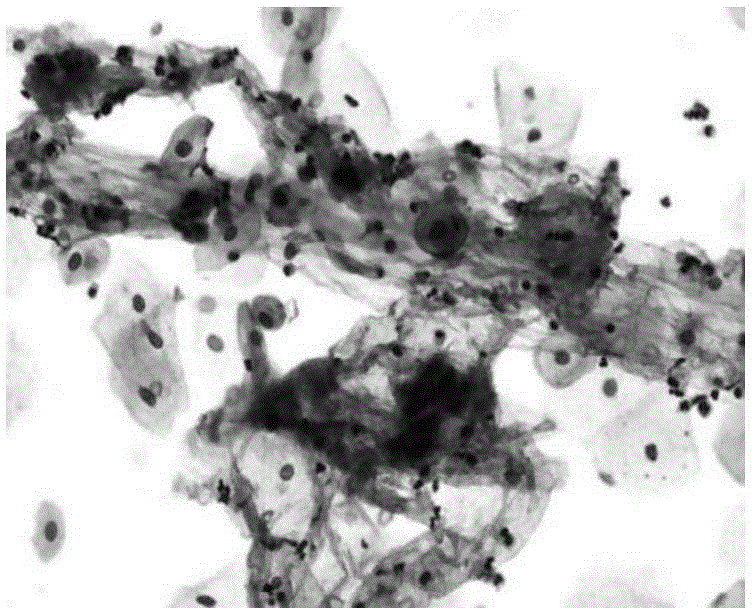

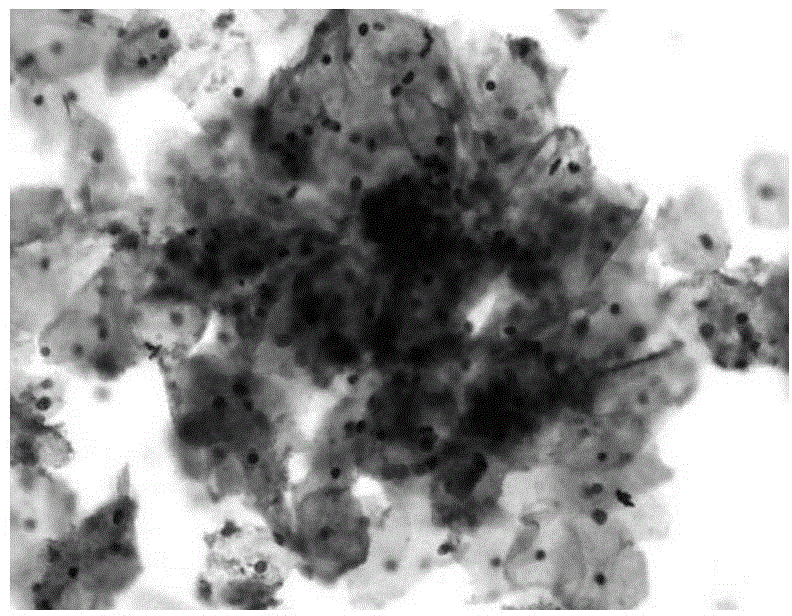

Endocervical cell preserving fluid and method for preparing endocervical cell specimen

InactiveCN103875653BMorphological integrityComplete structurePreparing sample for investigationDead animal preservationChemistryCysteine

The invention discloses endocervical cell preserving fluid and a method for preparing an endocervical cell specimen. The endocervical cell preserving fluid comprises N-acetyl-3-cysteine, anhydrous alcohol, sodium chloride, disodium hydrogen phosphate, sodium dihydrogen phosphate, glacial acetic acid, concentrated hydrochloric acid and distilled water. The method for preparing the endocervical cell specimen comprises the following steps; soaking endocervical cells in a collection tube of the endocervical cell preserving fluid, uniformly oscillating, adding the endocervical cells in a smear device, arranging the smear device in a centrifugal machine for centrifuging, and taking a glass slide with a uniform thin-layer cell smear; and fixing the obtained glass slide with the cell smear by a fixing solution, dyeing, dehydrating, making the glass slide transparent, and finally, mounting to obtain a specimen smear for diagnosis. The endocervical cell preserving fluid and the method for preparing the endocervical cell specimen are reliable and practical, are low in cost, and have useful effects, thus being suitable for large-scale popularization.

Owner:THE MILITARY GENERAL HOSPITAL OF BEIJING PLA

Rod-seam compound directivity dual-frequency double-feed low-elevation-angle high-gain microstrip antenna

InactiveCN103401069BOptimized low elevation gainReduce operating frequencySimultaneous aerial operationsRadiating elements structural formsDual frequencyMicrostrip

Owner:XIAMEN UNIV

Intelligent key apparatus equipped with sounding device

ActiveCN100550736CImprove usabilityReduced risk of interceptionUser identity/authority verificationCapacitanceEngineering

The invention discloses an intelligent key device with a sounding device, which includes an MCU and a sounding device. The sounding device includes a sounding device and is directly connected to the MCU, or connected to the MCU through a resistor, a capacitor or a signal amplifying device. The sounding device can be a speaker or a buzzer, and the sounding device can include a serial input or parallel input or a digital-to-analog conversion module or a voice chip connected to the MCU bus. According to the application requirements of the remote end of the network or the host end of the smart key device, the prompt information sent by the sounding device can be different each time, reminding the user of the information to be input, which increases the security of the device during use, making the present invention more suitable for Use in public. At the same time, the use of the sound device can realize the functions of equipment safety warning, reading and writing prompts, and operation prompts, which improves the usability of the smart key device and makes the smart key device more humanized.

Owner:FEITIAN TECHNOLOGIES

A new control circuit for electric parking door hinge

ActiveCN112647798BSimple structureLow failure rateBatteries circuit arrangementsPower-operated mechanismPush switchCircuit design

The invention relates to a door hinge, a novel control circuit of an electric parking door hinge, a motor current sampling circuit, a current signal amplification module and a microprocessor I are sequentially connected, a power supply interface, a 5V voltage stabilizing circuit, and a 3.3V voltage stabilizing circuit Connect with microprocessor 1 successively, motor interface, DC motor drive circuit and microprocessor 1 are connected successively, wireless signal receiving module, wireless switch signal interface circuit and microprocessor 1 are connected successively, wired switch interface connects microprocessor 1; The wireless signal transmitting module, the microprocessor II, the rechargeable battery, the wireless charging receiving module, the wireless charging transmitting module, the power adapter, the backup charging power supply module and the power interface are connected in sequence, and the button switch is connected to the microprocessor II; the wireless signal transmitting module sends The signal can be received by the wireless signal receiving module; the structure of the control circuit is simple, and the position of the motor can be judged without adding additional sensors; the design of the peripheral circuit is simple, which can reduce the failure rate of the circuit.

Owner:ZHEJIANG DINGLI IND

Manufacturing method of concrete precast pile

ActiveCN102773918BIncrease productivityGuarantee product qualityCeramic shaping plantsPre stressEngineering

Owner:山东三原混凝土桩业有限公司

A device for parking electric vehicles on the lower floor and parking bicycles on the upper floor

The invention relates to the field of parking devices, in particular to a device for parking electric vehicles on a lower layer and parking bicycles on an upper layer. The device mainly comprises a supporting device, a foot treading locking device, a crank mechanism, a sliding device, a vehicle locking device, fast chucks, two V-shaped plates, an upper bottom plate I, an upper bottom plate II, anupper bottom plate III, springs and two gas springs. The two ends of the upper bottom plate II are connected to the bottoms of two V-shaped plates correspondingly; the two ends of the upper bottom plate I and the upper bottom plate III are connected to the left and right upper edges of the two V-shaped plates correspondingly; the lower V-shaped plate can be placed on the ground; the upper bottom plate I, the upper bottom plate II and the upper bottom plate III are all provided with the upper ends and the lower ends and are each in an arc shape in the length direction; the fast chucks are arranged at upper end edge openings of the upper bottom plate I, the upper bottom plate II and the upper bottom plate III correspondingly; the two ends of the springs are connected with the lower portionsof left end plates of the upper bottom plates and an upper cross beam correspondingly; and the two ends of the two gas springs are connected to the upper cross beam and the bottom of the upper end ofthe upper bottom plate II correspondingly. The electric vehicles and the bicycles can be picked up or parked at random without sequence limitation.

Owner:JINHUA VOCATIONAL TECH COLLEGE

A smart lock structure

ActiveCN111173382BAvoid direct connectionExtended service lifeNon-mechanical controlsIndividual entry/exit registersFinger vein recognitionElectric machine

The invention relates to the technical field of locks, and relates to an intelligent lock structure, including a lock case, a bottom plate, a side plate, a panel, a buckle, a pull plate, a fixed plate, a clamp plate, a push plate, a slot plate, a bolt plate, and a motor fixing piece , rack plate, oblique tongue, fixed piece, fixed pin, motor buffer pin, shift fork, dial sleeve, electromagnetic block, clamp pin, circuit board, motor, electromagnetic induction part, helical gear, gear push block, coil spring and The torsion spring, the lock case, the bottom plate and the side plate can form a cavity, which has a four-layer structure at the upper middle of the cavity. On the second floor, the position of the deadbolt plate is the third floor, and the position of the card slot plate and the rack plate is the fourth floor. The door is locked by electromagnetic induction, the door is opened by the finger vein recognition head, and the switch of the motor is controlled by the finger vein technology. , The motor drives the lock bolt telescopic mechanism, avoiding the direct connection between the motor and the door bolt, prolonging the service life of the lock and improving the security of the smart lock.

Owner:ZHEJIANG DINGLI IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com