Automatic molten aluminum casting machine

A technology of casting machine and molten aluminum, which is applied in casting equipment, casting molten material containers, and equipment for sending molten metal into molds, etc. It can solve problems such as easy splashing of molten aluminum on the human body, difficulty in breathing, and quality accidents , to achieve the effect of reducing casting risk, low labor intensity and reducing harmfulness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

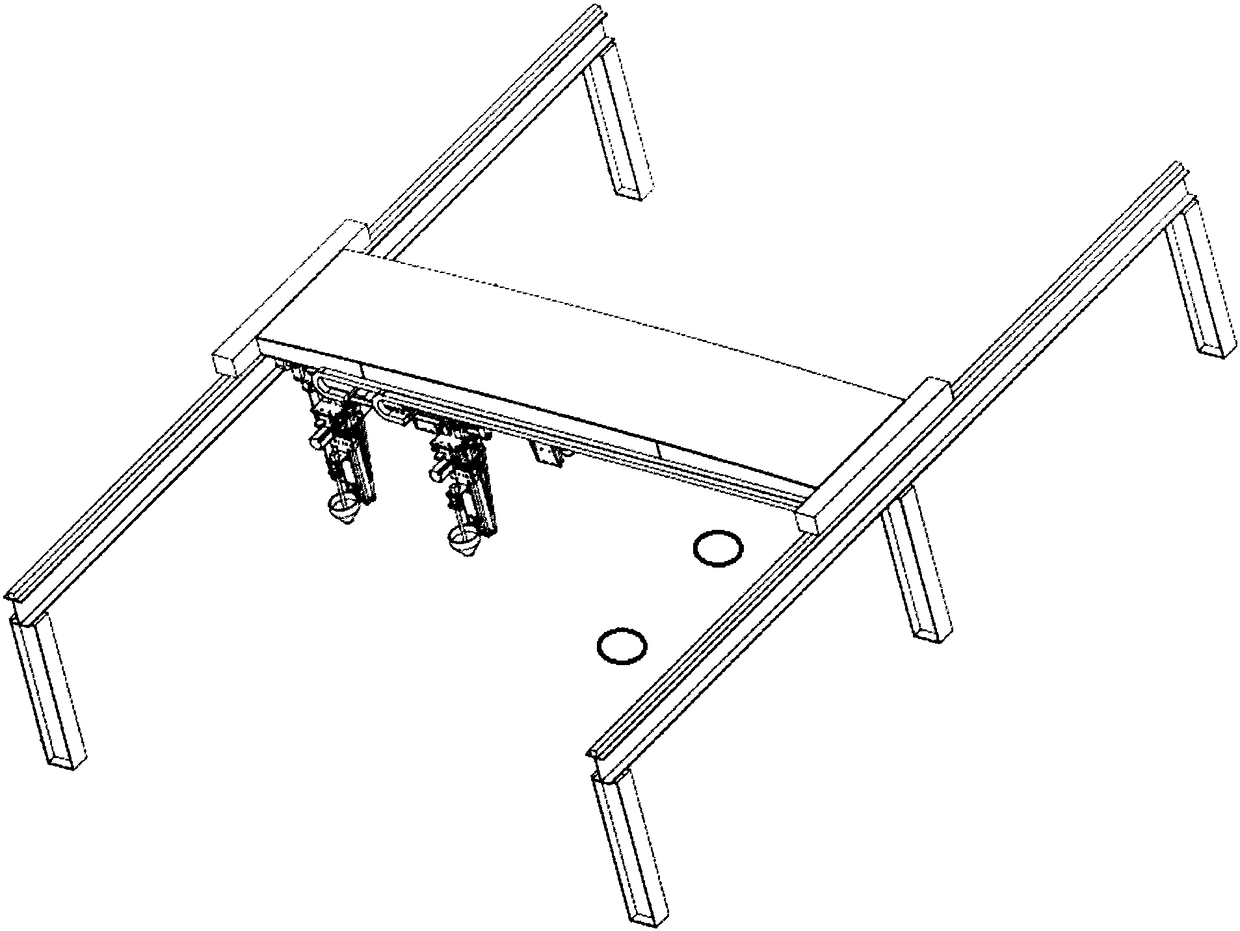

[0045] Such as figure 1 It is an overall perspective view of the present invention, including a driving mechanism, a main shaft mechanism, a translation mechanism, a lifting mechanism, a water inlet and discharge mechanism, and a control system. The control system includes a touch screen, a PLC controller, and a servo system. The driving mechanism and the main shaft mechanism are reflected in the figure. The driving mechanism has There are two upper rails, and there are two aluminum water holding furnaces and four molding sandboxes arranged vertically on the ground between the two upper rails. The main shaft mechanism can run above the upper rail of the driving mechanism.

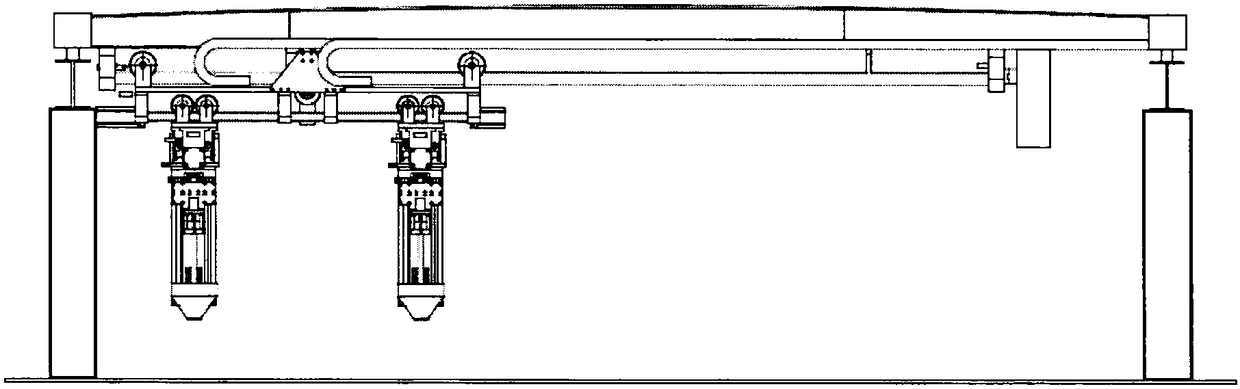

[0046] Such as figure 2 It is the front view of the present invention, reflecting the main shaft mechanism and the translation mechanism, lifting mechanism and water inlet and discharge mechanism located below the main shaft mechanism, and the main shaft mechanism has an outer cover.

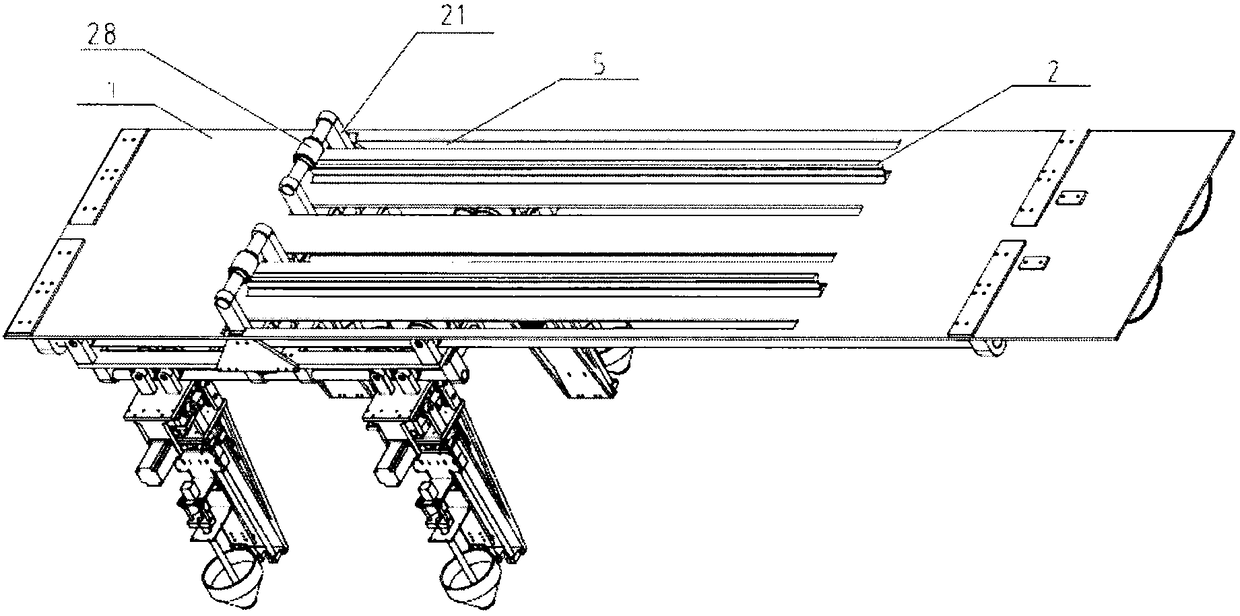

[0047] Such as im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com