Planishing method for tube number soldering opening

A technology of welding joints and pipe numbers, which is applied in the field of musical instrument processing, can solve problems such as inability to realize industrialized production of products, inconsistent product specifications, and large human influence factors, and achieve novel and practical design, uniform and standardized shapes, and shorten processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

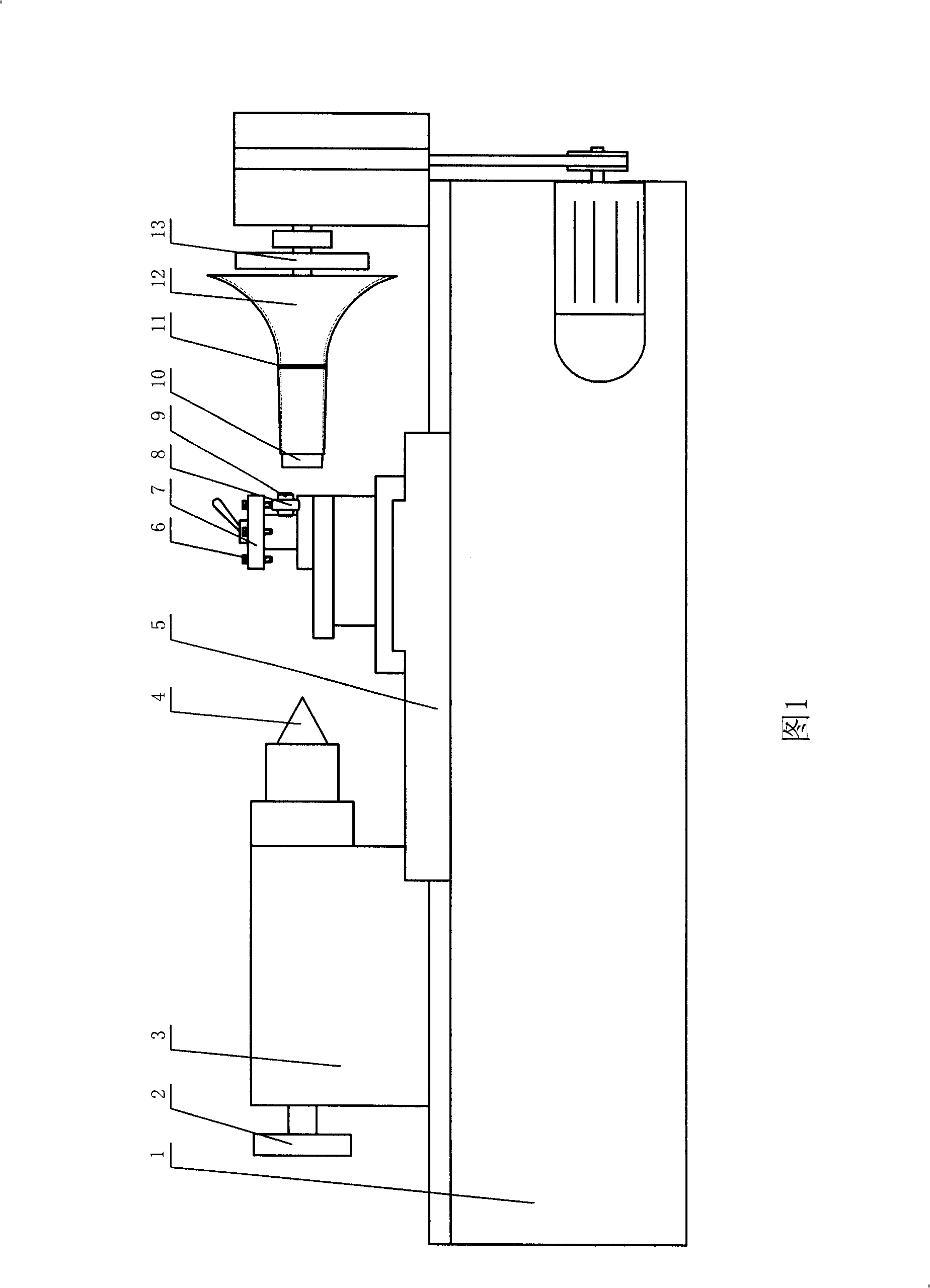

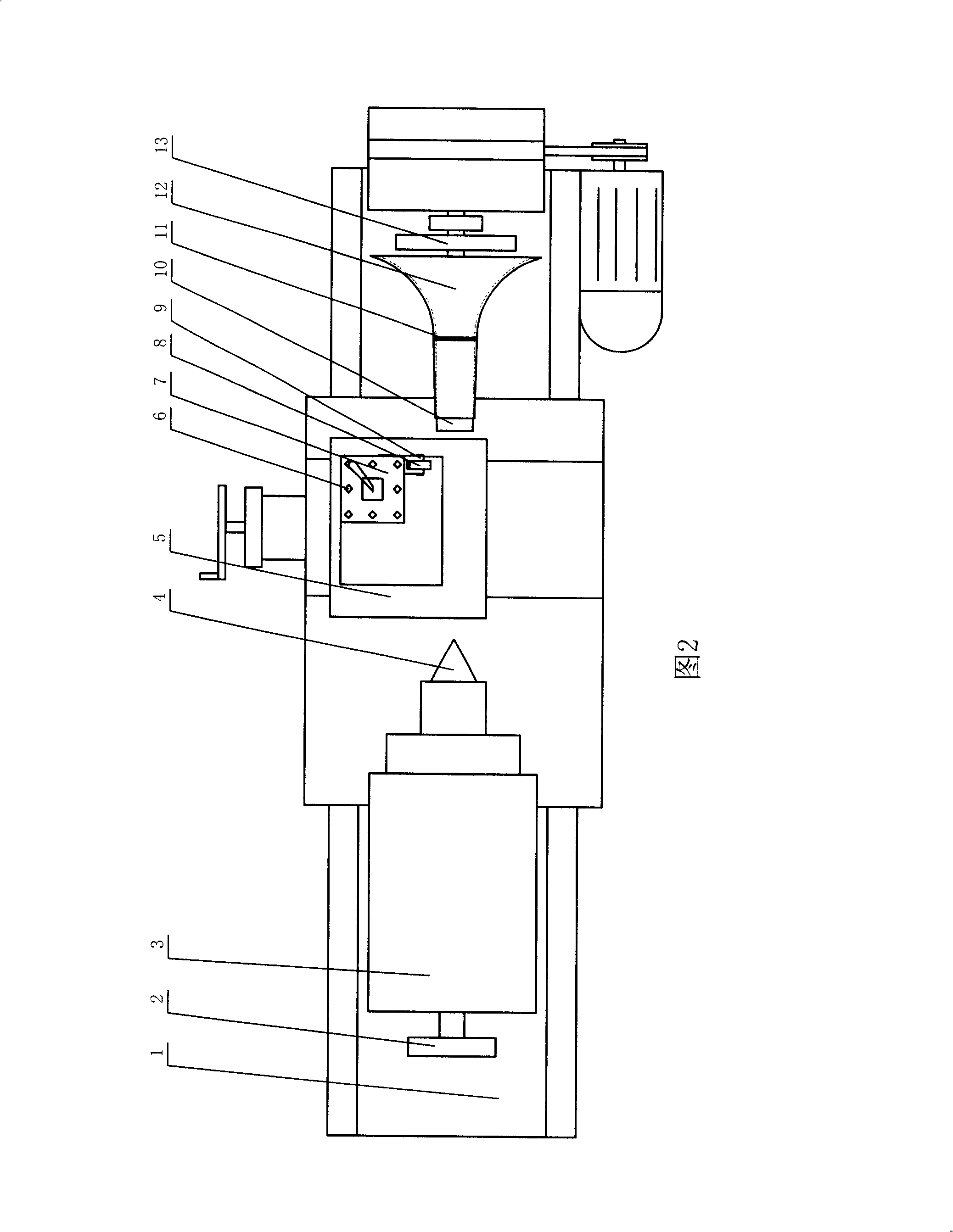

[0021] In order to describe the flattening method of the pipe number welded joint of the present invention more clearly, the machine tool used to realize the above-mentioned pipe number welded joint flattened method is firstly described with reference to the accompanying drawings.

[0022] The machine tool that the present invention adopts is the common lathe that is made of bed 1, tailstock 3, tool rest 5 and chuck 13. The tailstock is fixed on the bed, and a top 4 is installed on the side of the tailstock near the chuck. The top can be stretched and retracted by the rotation of the handle 2, and adjusted to an appropriate position. A model 10 that can rotate with the chuck is clamped on the chuck installed on the main shaft. This model is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com