Illumination structure

A lighting structure and technology of light-emitting diodes, applied in lighting devices, lighting and heating equipment, lighting device components, etc., can solve problems such as high cost, light decay, and cost can not be effectively controlled, so as to save costs and reduce damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable your review committee members to clearly understand the content of the present invention, only the following descriptions are used together with the drawings, as follows:

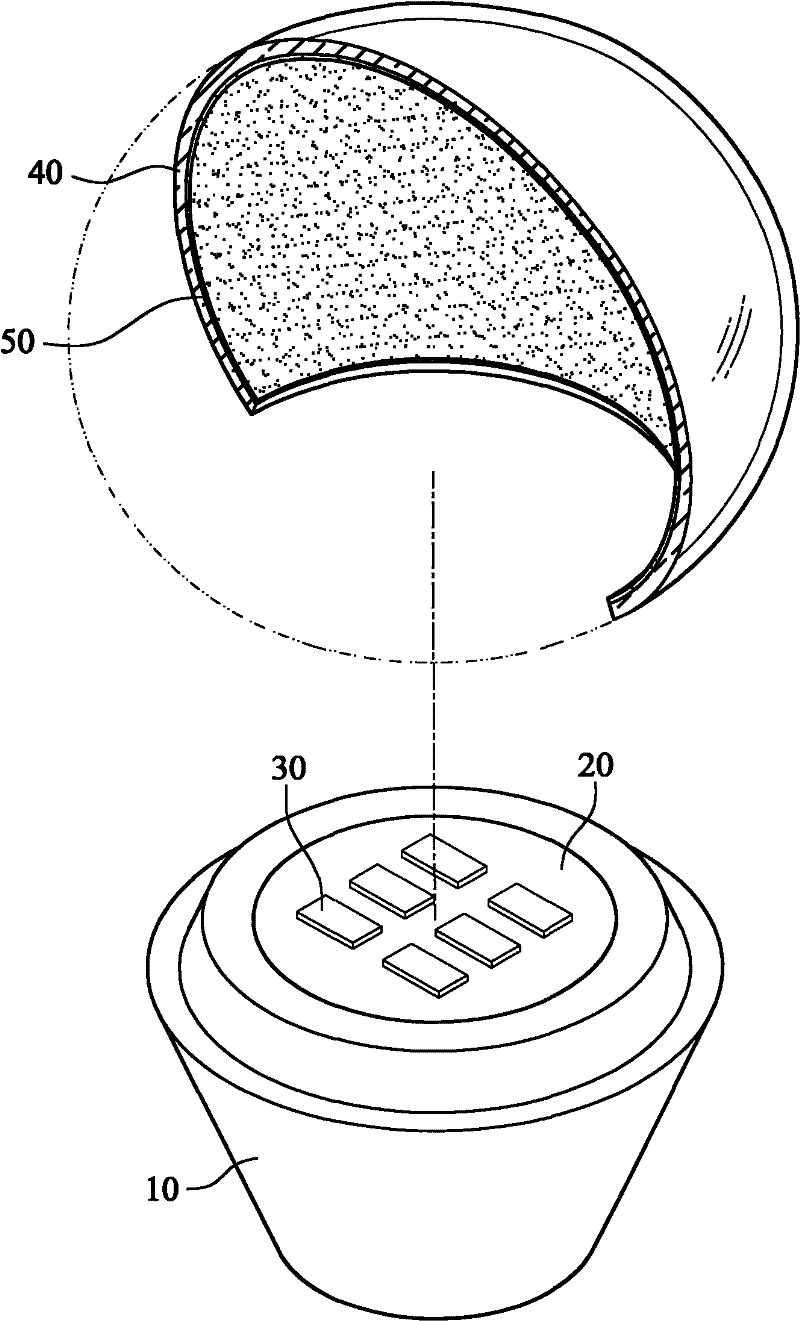

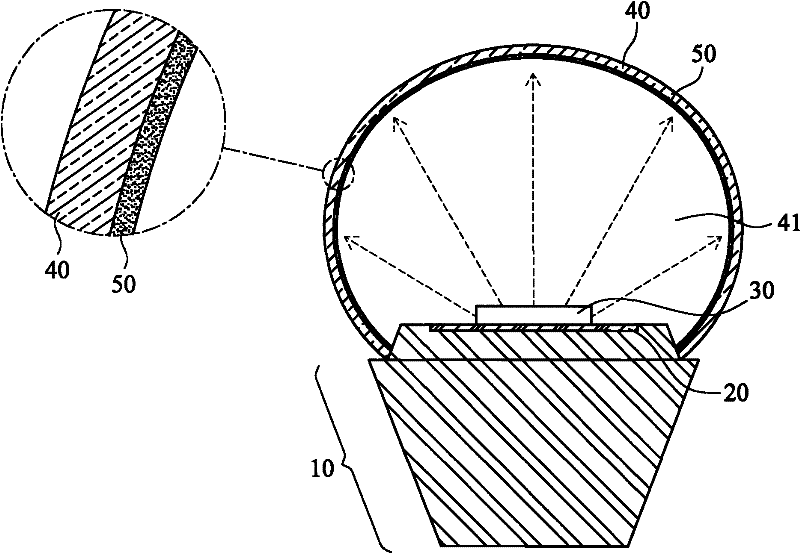

[0025] Please see figure 1 , figure 2 As shown, the present invention at least includes:

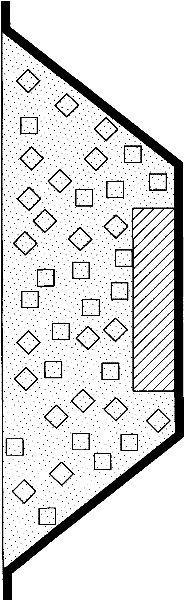

[0026] A lamp holder heat dissipation module 10 is provided with a circuit board 20 at one end, and at least one high-power light-emitting diode chip 30 is provided on the circuit board 20, and the light-emitting diode chip 30 has two implementation modes, the first One is a light-emitting diode (LED) bare chip that simply emits colored light, that is, a bare chip that does not have phosphor powder or protective sealant (Lens), so it can be one of blue light, red light, and green light; A second embodiment of diode die 30 is a bare die capable of emitting high power ultraviolet (UV) light.

[0027] The above-mentioned heat dissipation module 10 of the lamp holder can be integrally formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com