High-temperature blowing and deashing technology for deduster

A dust collector and ash cleaning technology, applied in chemical instruments and methods, dispersed particle separation, dispersed particle filtration, etc., can solve the problems of increased equipment cost, difficulty in adapting to medium gas, complex structure, etc., and achieve stable gas temperature and long-term. The effect of effective dust removal and filtration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

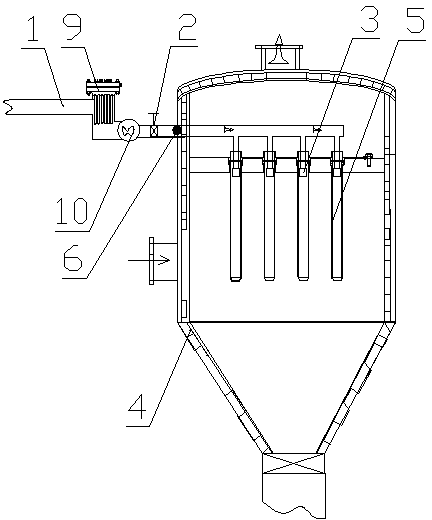

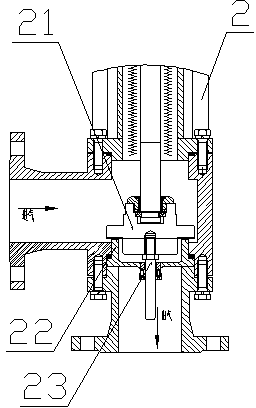

[0024] Such as figure 1 , figure 2 As shown, a high-temperature blowing soot cleaning process for a dust collector involves equipment including a blowing gas delivery pipe 1, a blowing valve 2, and a nozzle 3. The blowing gas delivery pipe 1 communicates with a high-temperature pressurized gas. During the forward filtration process of the filter element 5 of 4, the blowing valve 2 is periodically started to carry out back-blowing and dust-cleaning. A high-pressure expansion zone is formed to quickly remove the accumulated dust attached to the outside of the filter element 5. After the backflushing and dust removal process is completed, the injection valve 2 is closed to resume the forward filtering process of the filter element 5.

[0025] Wherein, the high-temperature pressurized gas source is connected to an external gas supply device, and the gas supply device is an inert gas, such as nitrogen, and a booster device 10 is arranged on the injection gas delivery pipe 1; Th...

Embodiment 2

[0028] A high-temperature blowing soot cleaning process for a dust collector, the difference from Embodiment 1 is that it involves equipment, and the high-temperature pressurized gas source is connected to the air outlet pipe of the clean air chamber of the dust collector 4 .

Embodiment 3

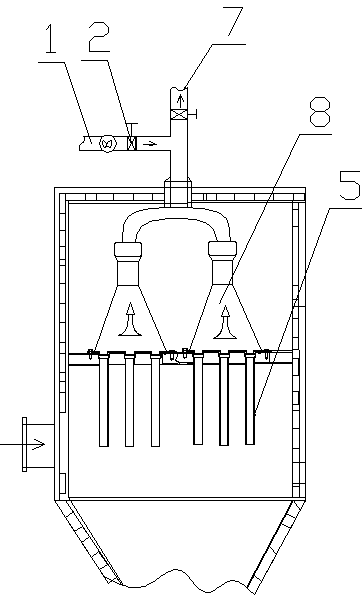

[0030] A high-temperature jet cleaning process for dust collectors, the difference from Embodiment 1 is: as image 3 As shown, which involves in the equipment, the outlet end of the blowing gas delivery pipe 1 is connected to the venturi tube 8 through the blowing valve 2, the venturi tube 8 covers the upper part of the filter element 5, and the upper part of the venturi tube 8 is set There are branch gas paths, which are connected to the blowing gas delivery pipe 1 and the purified gas outlet 7 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com