Waste-gas denitration device and method

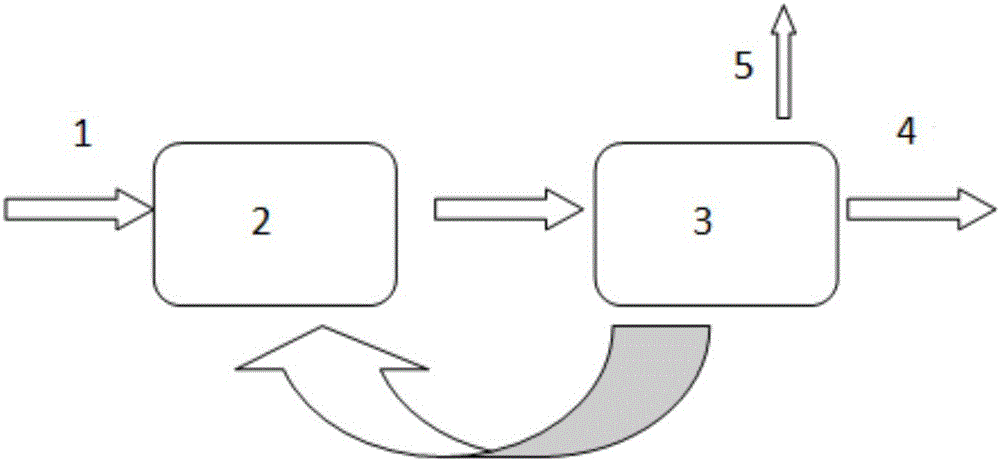

A technology for waste gas and denitration, which is applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of inability to regenerate catalysts, reduce storage volume, and high temperature requirements, and achieve convenient operation and maintenance, high removal effect, and equipment. less demanding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

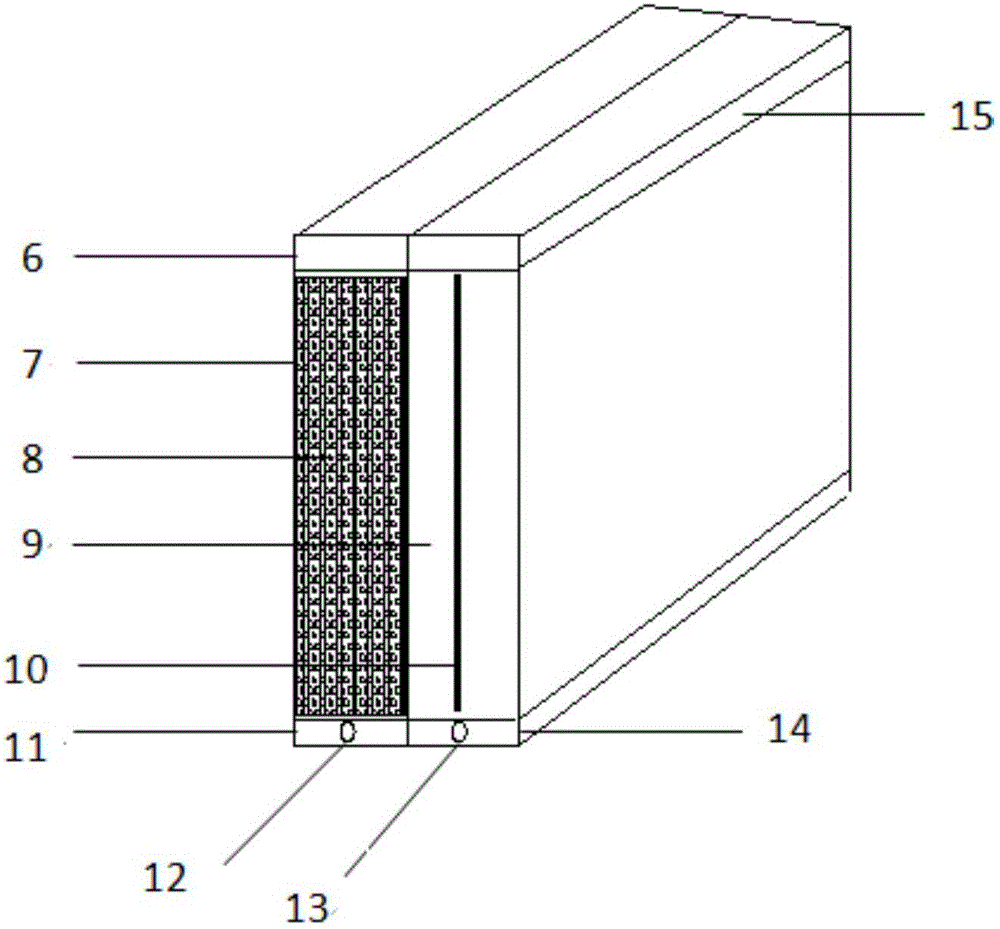

Embodiment 1

[0027] An exhaust gas denitrification device, including an exhaust gas absorption device and an exhaust gas removal device, wherein the exhaust gas removal device is an electrochemical device with an integrated structure, and the shape of the exhaust gas removal device is set in a square shape, including a cathode, an anode, and a reaction channel, and the cathode is set It is a cathode three-dimensional electrode composed of granular conductive materials. The cathode and anode are arranged in parallel in an interspersed structure. Titanium plate, metal oxide coating can play the effect of preventing and controlling oxidation; Described negative electrode is set as the metal plate with excellent conductivity, and one or more of graphite carbon felt, graphene, activated carbon are filled around the metal plate or net. The characteristics of many dense pores greatly increase the cathode reaction area. The electrolysis device includes a cathode cavity and an anode cavity, and the...

Embodiment 2

[0029] An exhaust gas denitrification device, including an exhaust gas absorption device and an exhaust gas removal device, wherein the exhaust gas removal device is an electrochemical device with an integrated structure, and the shape of the exhaust gas removal device is cylindrical, including a cathode, an anode, and a reaction channel, The cathode is set as a cathode three-dimensional electrode composed of shaped conductive materials, the cathode and anode are arranged in a scroll shape, the water inlet and outlet channels of the cathode and anode are set to one or more, and the anode is set to titanium with metal oxide coating The metal oxide coating can prevent oxidation; the cathode is set as a metal mesh with excellent conductivity, and one or more of graphite carbon felt, graphene, and activated carbon are filled around the metal plate or mesh , and its many dense pores greatly increase the cathode reaction area. The electrolysis device includes a cathode cavity and an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com