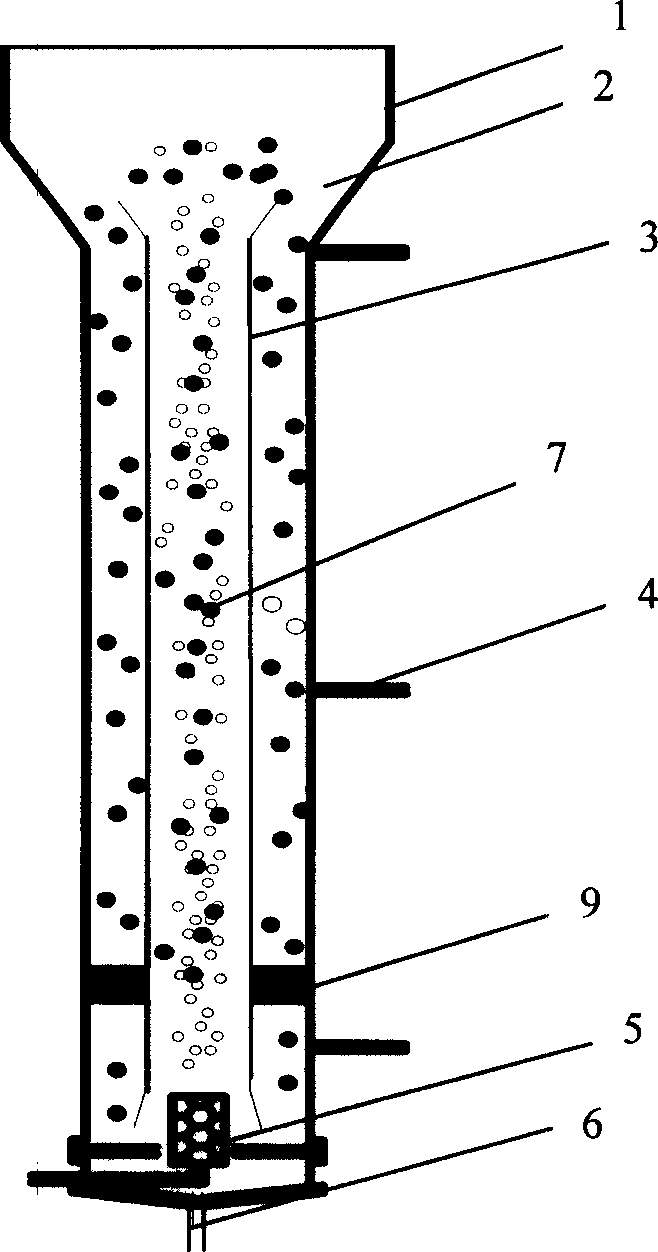

Device for treating organic wastewater by ozone and active carbon and method therefor

A technology of organic wastewater and activated carbon, applied in the field of environmental technology and water treatment, can solve the problems of frequent regeneration and limited adsorption capacity, and achieve the effect of reducing treatment cost, simple method and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The wastewater object is the effluent produced by a fine chemical factory. The water quality is complex. The main organic pollutants are adiponitrile and phenolic compounds after analysis. The COD concentration of the wastewater is 10911mg / L, the initial pH is 4.4, and the ozone inlet flow rate is 60L / h. The gas phase ozone concentration is 41mg / L, the water sample is 500mL for a single treatment, and 30g of activated carbon is added. After 60 minutes of reaction, the COD removal rate is 66.9%. The removal rates of ozone oxidation and activated carbon adsorption are 13.6% and 56.9%, respectively. Activated carbon reacts water COD to a level of 3600mg / L, and the ozone utilization efficiency is 0.58mgCOD / mgO when ozone is oxidized alone 3 Increased to 1.3mg COD / mg O 3 , Ozone utilization efficiency increased by 55%. Under alkaline conditions, the treatment effect is better. Adjust the pH of the wastewater to 10.0 and keep other reaction conditions unchanged. After 60 min...

Embodiment 2

[0017] The treatment object is 1g / L nitrophenol wastewater, the initial reaction pH=4.5, the ozone inlet flow rate is 60L / h, the gas phase ozone concentration is 41mg / L, and the water sample is 500mL for a single treatment, and 10g of activated carbon is added, and the reaction takes 60min. The removal rate of nitrophenol was 93.2%, the removal rate of COD was 85.4%, and the COD of the effluent was reduced from 1780mg / L in the influent to 260mg / L. The test data and results are shown in Table 1.

[0018] Sewage

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com