Device for online vacuum drying and regeneration of activated carbon of retention bed of nuclear power unit

A technology for vacuum drying and nuclear power units, which is applied in filter regeneration, nuclear engineering, radioactive purification, etc. It can solve the problems of unable to fundamentally remove the humidity of activated carbon, decrease the ability to absorb inert gas, and decrease the adsorption performance of activated carbon, so as to avoid radioactive solid waste The effect of increasing and reducing the difficulty of equipment manufacturing and shortening the regeneration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below by means of the accompanying drawings and specific embodiments.

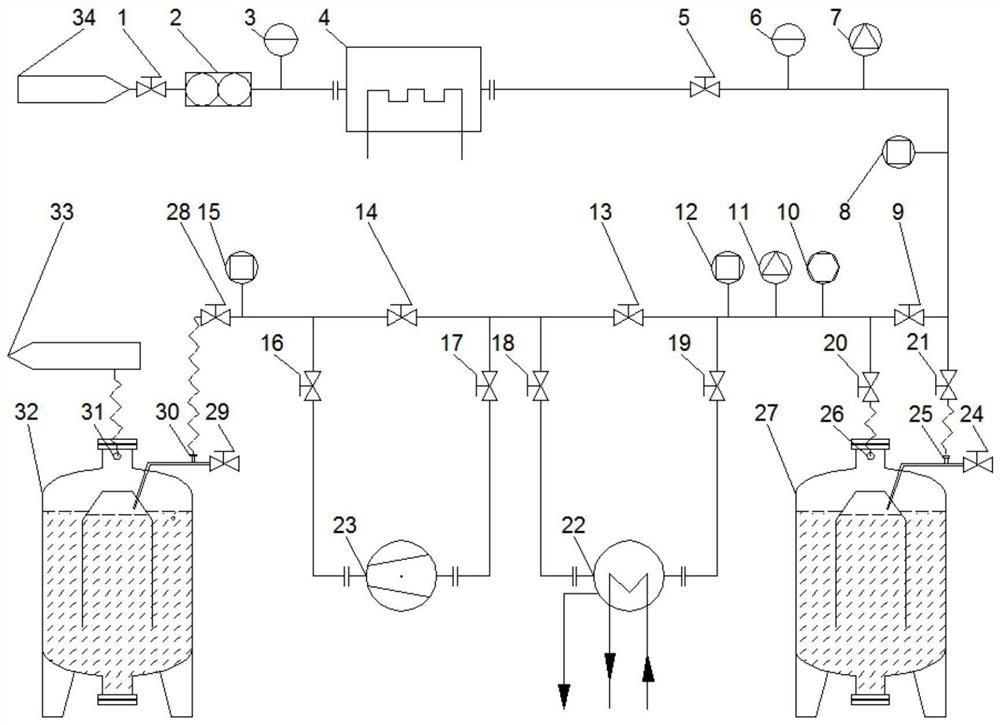

[0034] Such as figure 1 As shown, the regeneration device includes a compressed air source 34 that introduces compressed air, an electric heater 4 that heats the output pipeline of the compressed air source 34, a test retention bed 27 that is connected to the heated output pipeline through a valve, and a refrigerated air dryer 22. , vacuum pump 23 and evacuation of the stagnant bed 32.

[0035] A compressed air supply switch 1, a flow meter 2 and an intake pressure gauge 3 are sequentially installed on the pipeline between the compressed air source 34 and the electric heater 4;

[0036] Install the following valves and instruments in sequence on the heated output pipeline.

[0037] Including heating flow regulating valve 5, heating circuit pressure gauge 6, thermometer I7, hygrometer I8, heating circuit bypass valve 9, radiation monitor 10, thermomet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com