Online regeneration system of denitrification catalyst

A denitrification catalyst and regeneration system technology, applied in the field of flue gas treatment, can solve problems such as unsatisfactory regeneration effect, shutdown and disassembly, etc., and achieve the effect of prolonging the life of the catalyst and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

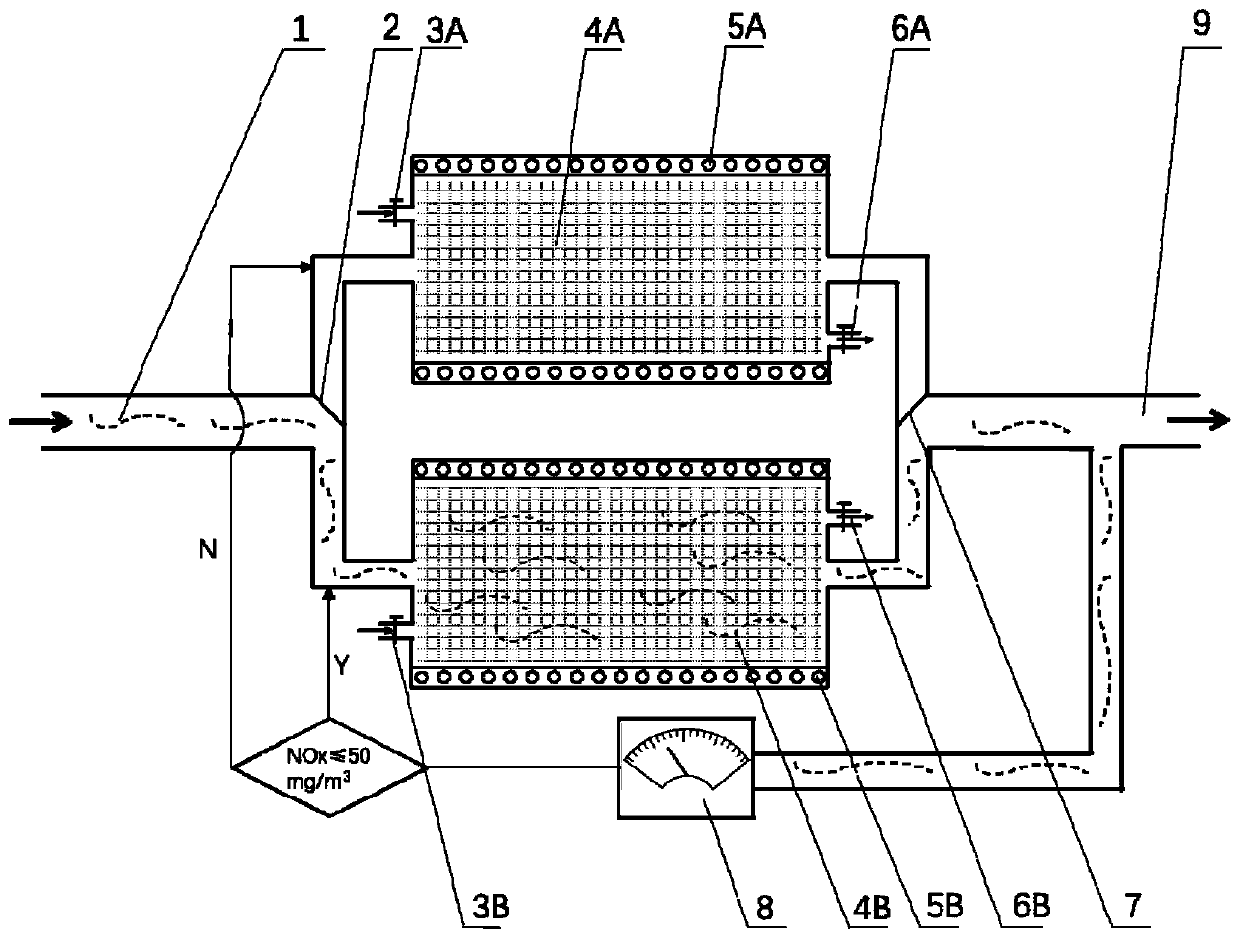

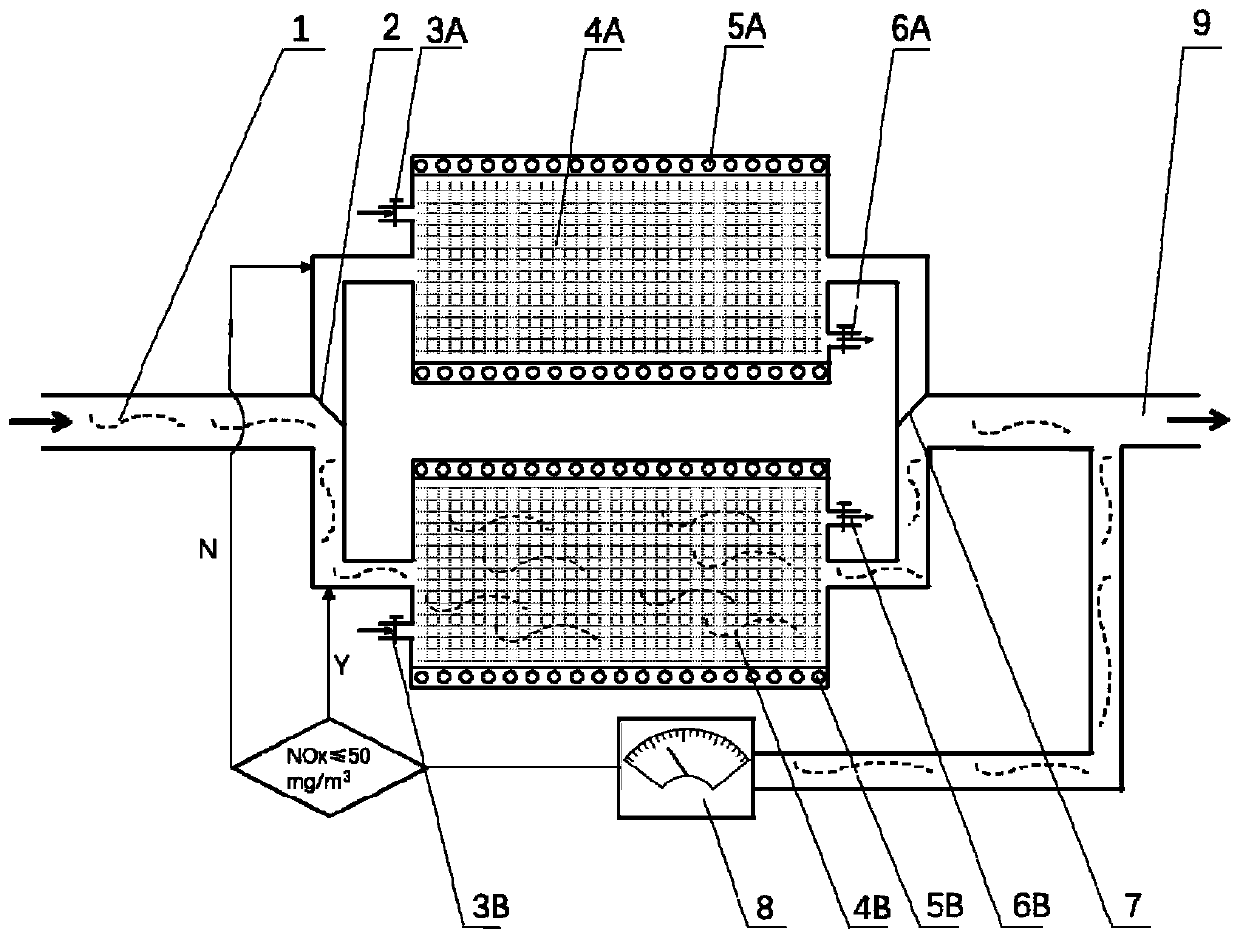

[0046] An online regeneration method for a denitration catalyst, comprising:

[0047] The denitrification catalytic unit of Group A is performing catalytic denitrification reaction, and the denitrification catalytic unit of Group B is in standby state. When the flue gas denitrated by the denitrification catalytic unit of Group A is monitored by the flue gas analyzer 8, NO x Concentration greater than 50mg / m 3 At the same time, the flue gas inlet three-way valve 2 and the flue gas outlet three-way valve 7 are switched at the same time, the denitrification catalytic unit of group B is started for denitrification, and then the denitrification catalytic unit of group A is cleaned and regenerated online.

[0048] The method for online cleaning and regeneration of the denitrification catalytic unit of Group A is as follows:

[0049] The cleaning liquid is injected into the denitrification catalytic unit of group A from the cleaning liquid and the activating liquid inlet 3A, the pre...

Embodiment 2

[0052] An online regeneration method for a denitration catalyst, comprising:

[0053] The denitrification catalytic unit of Group A is performing catalytic denitrification reaction, and the denitrification catalytic unit of Group B is in standby state. When the flue gas denitrated by the denitrification catalytic unit of Group A is monitored by the flue gas analyzer 8, NO x Concentration greater than 50mg / m 3 At the same time, the flue gas inlet three-way valve 2 and the flue gas outlet three-way valve 7 are switched at the same time, the denitrification catalytic unit of group B is started for denitrification, and then the denitrification catalytic unit of group A is cleaned and regenerated online.

[0054] The method for online cleaning and regeneration of the denitrification catalytic unit of Group A is as follows:

[0055] The cleaning liquid is injected into the denitrification catalytic unit of Group A from the cleaning liquid and the activating liquid inlet 3A, the pre...

Embodiment 3

[0058] An online regeneration method for a denitration catalyst, comprising:

[0059] The denitrification catalytic unit of Group A is performing catalytic denitrification reaction, and the denitrification catalytic unit of Group B is in standby state. When the flue gas denitrated by the denitrification catalytic unit of Group A is monitored by the flue gas analyzer 8, NO x Concentration greater than 50mg / m 3 At the same time, the flue gas inlet three-way valve 2 and the flue gas outlet three-way valve 7 are switched at the same time, the denitrification catalytic unit of group B is started for denitrification, and then the denitrification catalytic unit of group A is cleaned and regenerated online.

[0060] The method for online cleaning and regeneration of the denitrification catalytic unit of Group A is as follows:

[0061] The cleaning liquid is injected into the denitrification catalytic unit of group A from the cleaning liquid and the activating liquid inlet 3A, the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com