Regeneration method of cyclohexene hydration catalyst

A cyclohexene hydration and catalyst technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve the effect of regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

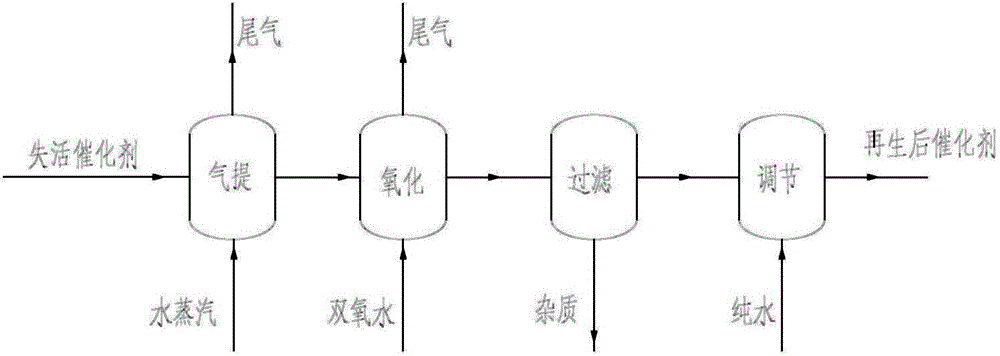

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. However, the drawings and specific embodiments do not limit the present invention.

[0021] Part of the catalyst with reduced activity (about 1% of the total amount of catalyst) from the reaction system enters the stripper, and the entrained cyclohexene and cyclohexanol are removed by steam stripping. The stripping pressure is 10KPaG and the temperature is 102 ℃. The stripping ends when the content of organic matter in the tail gas components is lower than 10ppm. After air stripping, the slurry enters the oxidation tank, and 20% hydrogen peroxide is introduced for oxidation treatment. The amount of hydrogen peroxide is 10% of the catalyst amount, the oxidation pressure is normal pressure, and the temperature is 90°C. The catalyst after oxidation treatment is filtered to remove acid water. After the filtration is completed, add high-purity wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com