Reaction system and method for preparing ethylene through regeneration of super gravity solvent

A technology of high-gravity and high-gravity rectification, which is applied in the direction of catalyst regeneration/reactivation, chemical instruments and methods, hydrogenation and hydrocarbon production, etc. It can solve the problems of low reaction pressure in slurry bed, affecting catalyst activity, difficulty in heat transfer of reaction, etc. problems, to achieve the effect of stable state, large operation flexibility, and reduction of potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

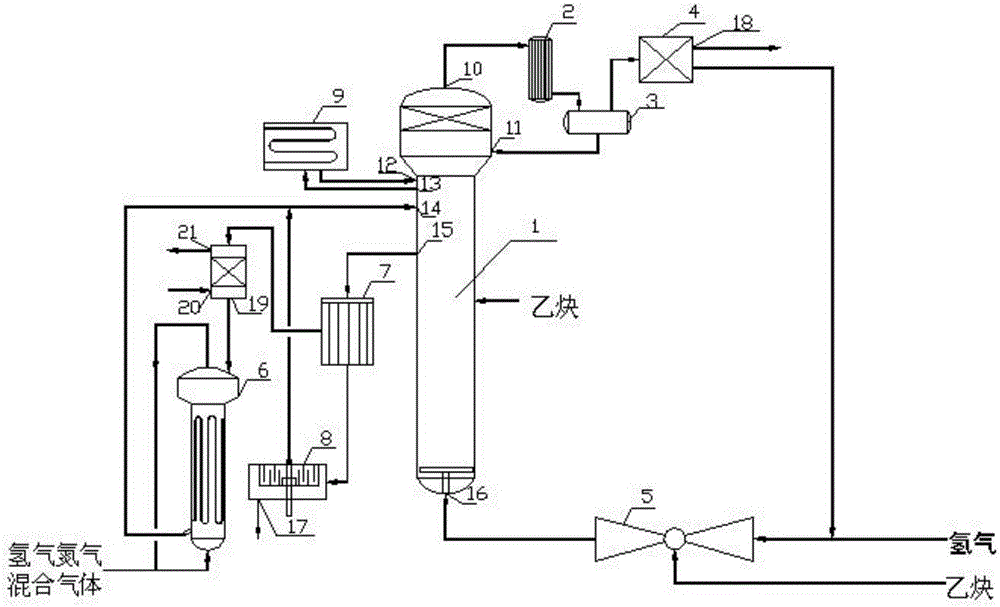

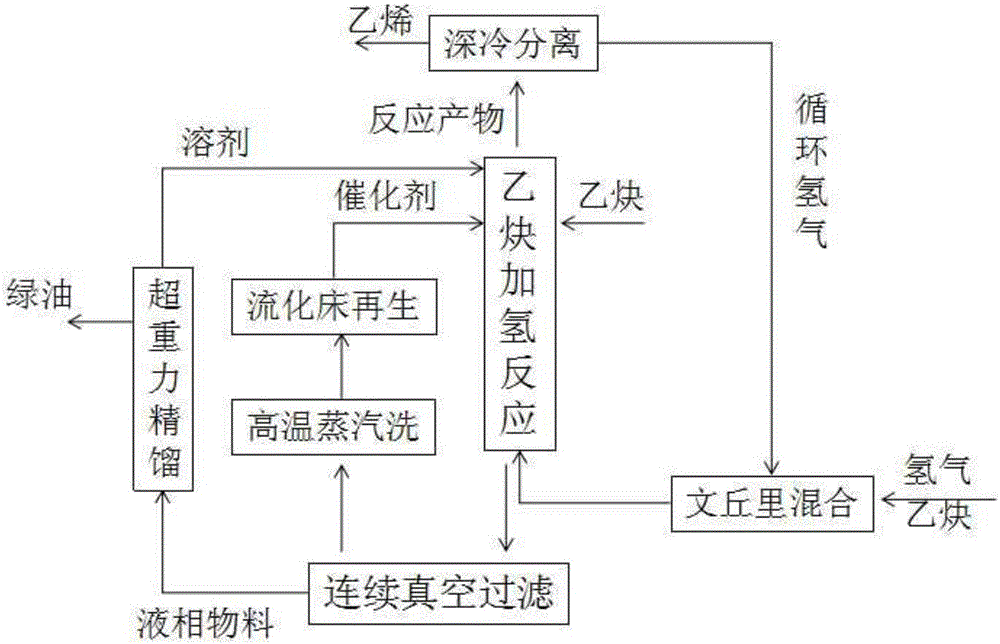

[0054] like figure 2 As shown, a high-gravity solvent regeneration system for producing ethylene is characterized in that the system includes a hydrogen acetylene mixing and equalizing unit 5, a hydrogenation reaction unit, a cryogenic separation unit 4, a vacuum filtration unit 7, high-temperature steam and flow Bed regeneration unit and high gravity rectification unit 8. The high-temperature steam and fluidized bed regeneration unit further includes a fluidized bed 6 and a high-temperature steam eluting device 19 . The high-temperature steam eluting device 19 is provided with a high-temperature steam inlet 20 and a high-temperature steam outlet 21. The high-temperature steam inlet 20 is used to input high-temperature steam, and the high-temperature steam outlet 21 is connected with the steam inlet of the high-pressure soft water temperature control device or the steam temperature control device.

[0055] The hydrogenation reaction unit includes a slurry bed 1, a slurry bed...

Embodiment 2

[0059] Adopt the system of embodiment 1, the technology of the ethylene making of high-gravity solvent regeneration is:

[0060] Mix the catalyst diluent aluminum oxide with a particle size of 50 mesh to 80 mesh and the acetylene hydrogenation catalyst according to the mass ratio of 2:1 to form a solid phase material, and then add it to the inside of the slurry bed and mix it with the solvent N-methyl pyrrolidone to form a slurry. Mix 20KPa, 40°C acetylene with 0.1MPa, 5°C hydrogen at a molar ratio of 1:6 through a Venturi mixer to form a mixed gas. The mixed gas enters the slurry through the internal gas distributor of the slurry bed and reacts at 130°C. After the reaction, the gas phase material is subjected to cryogenic separation to obtain the target product ethylene, and the recovered hydrogen is mixed with the raw material hydrogen. The liquid phase material is passed through the rotary drum vacuum filter to obtain solid phase material and liquid phase material. The so...

Embodiment 3

[0062] Adopt the system of embodiment 1, the technology of the ethylene making of high-gravity solvent regeneration is:

[0063] Mix the catalyst diluent perlite particles with a particle size of 100 mesh to 150 mesh and the acetylene hydrogenation catalyst at a ratio of 10:1 to form a solid phase material, and then add it to the slurry bed and mix it with the solvent N-methyl pyrrolidone to form a slurry. Mix 40KPa, 80°C acetylene with 2.2MPa, 10°C hydrogen at a molar ratio of 1:15 through a Venturi mixer to form a mixed gas. The mixed gas enters the slurry through the internal gas distributor of the slurry bed and reacts at 170°C. After the reaction, the gas phase material is subjected to cryogenic separation to obtain the target product ethylene, and the recovered hydrogen is mixed with the raw material hydrogen. The liquid phase material is passed through a belt vacuum filter to obtain solid phase material and liquid phase material. The solid phase material is first elut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com