Online-renewable biogas dry-process desulfurizing device and method

A dry desulfurization and biogas technology, applied in separation methods, chemical instruments and methods, gas fuels, etc., can solve problems such as high cost and complex process, achieve low cost, prolong service life, and realize the effect of automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

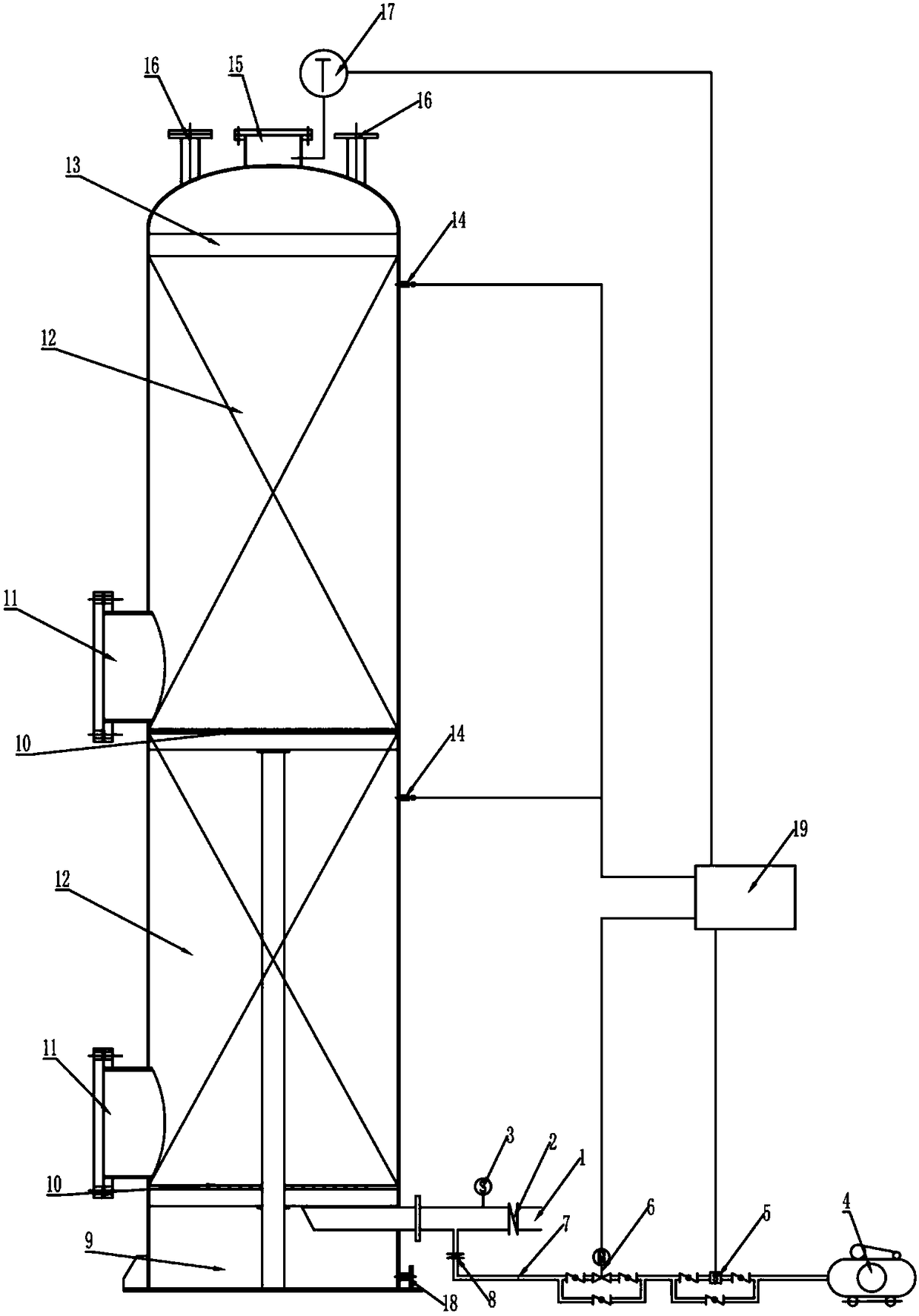

[0027]An on-line regenerable biogas dry desulfurization device, comprising a dry desulfurization tower main body 13, an online regeneration device and a PLC controller 19, the inside of the dry desulfurization tower main body 13 is provided with several layers of desulfurizer supporting partitions, desulfurization The agent supporting partition 10 divides the main body 13 of the dry desulfurization tower into several desulfurizing agent filling areas 12, the desulfurizing agent filling area 12 is filled with iron oxide desulfurizing agent, and the bottom of the dry desulfurizing tower main body 13 is provided with biogas Intake pipe, biogas check valve 2 and biogas flow meter 3 are arranged in turn on the biogas inlet pipe, biogas outlet 15 and exhaust port 16 are arranged on the top of the dry desulfurization tower main body 13, and the biogas outlet 15 is provided with a gas detector 17; the online regeneration device includes an air intake pipe connected with the biogas inta...

Embodiment 2

[0035] An on-line renewable biogas dry desulfurization method adopts the biogas dry desulfurization device of embodiment 1, comprising the following steps:

[0036] (1) The biogas enters the main body 13 of the dry desulfurization tower through the biogas inlet pipe 1. After the biogas enters the main tower, it passes through the desulfurizer supporting partition 10 and the desulfurizer loading area 12 in turn, and then is discharged through the biogas outlet 15. The gas detector 17 Measure the outlet hydrogen sulfide concentration and oxygen concentration. When the outlet hydrogen sulfide content is higher than 100ppm for 1 hour, the desulfurizer is basically saturated, and online regeneration is started;

[0037] (2) Air is injected through the air compressor 4 through the air intake pipe 7, and the oxygen in the air is used to regenerate the reacted desulfurizer. The air flow meter 5 is used to measure the intake air volume, and the electric control valve 6 is used to adjust...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com