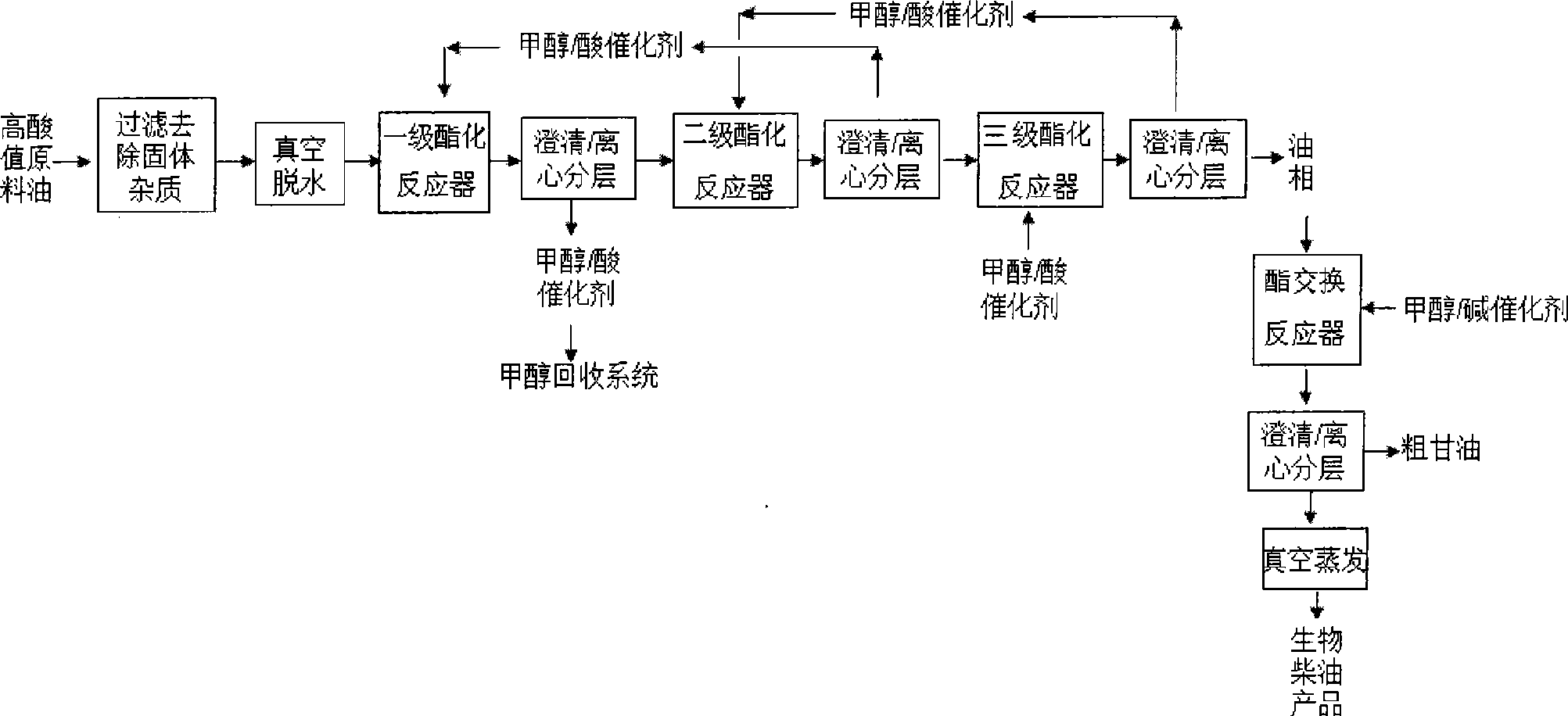

Method for preparing biodiesel by utilizing stratified and graded esterified deacidification of high acid value oil

A high acid value oil and biodiesel technology, applied in the production of biological raw materials, biofuels, bulk chemicals, etc., can solve the problems of difficult dehydration in esterification reaction, low esterification rate, etc., and achieve light color and high conversion rate. , the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

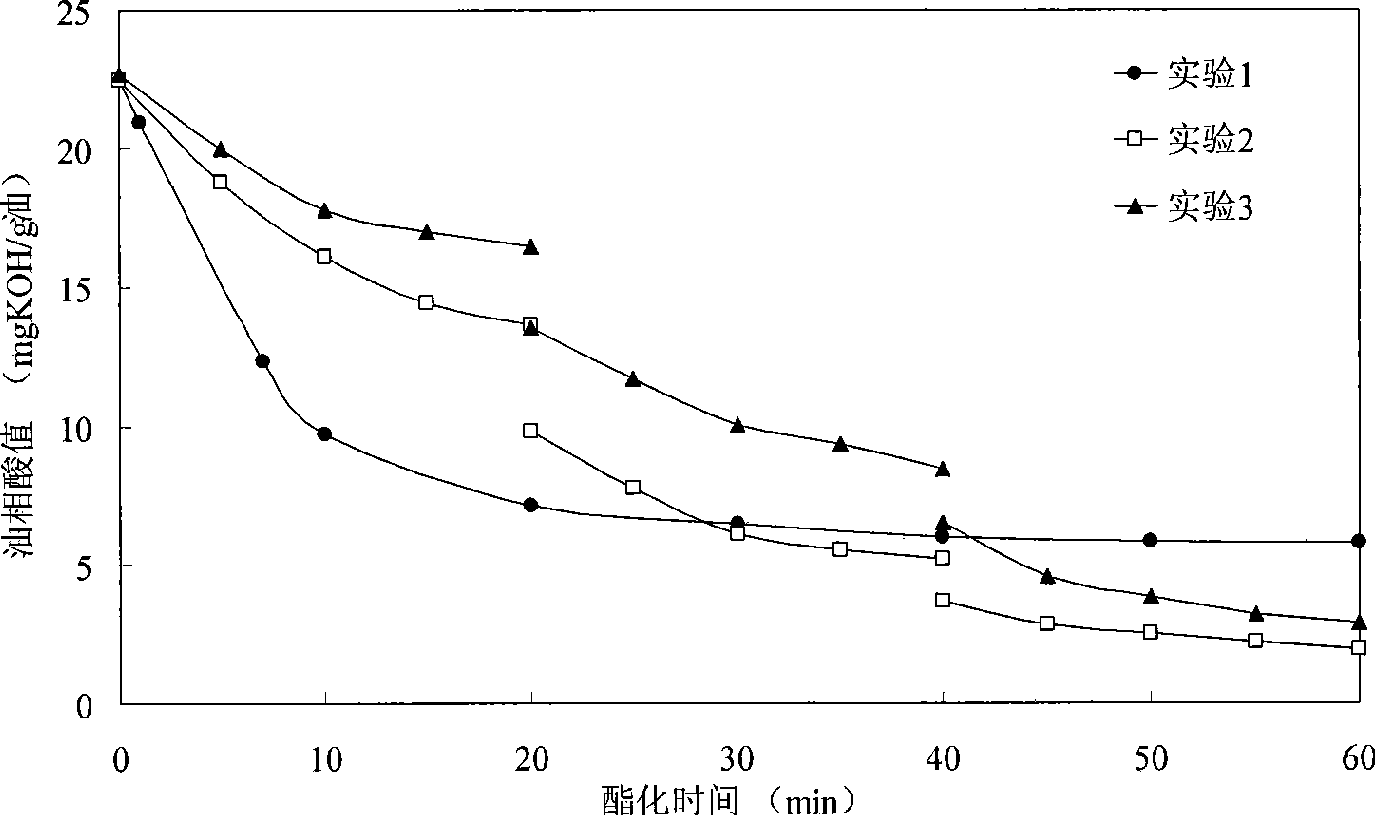

Embodiment 1

[0030] Primary esterification and layering:

[0031] Add 1500 grams of tallow bark oil (acid value 30mgKOH / g oil) through filtration and dehydration into a jacketed storage tank, and preheat to 60°C, then add 75 grams of methanol solution that is dissolved with 7.5 grams of 98% concentrated sulfuric acid , transported into the hydraulic cavitation esterification reactor with a pump, reacted at 60°C for 20min, the reaction liquid entered the clarification tank, stayed in the clarification tank for 1 hour, and removed the methanol / water / catalyst phase by layering to obtain 1501 grams of the oil phase, according to The national standard GB / T5530-85 measures the acid value of the oil phase to be 13.68mgKOH / g oil, and the moisture content of the oil phase measured by the Karl Fischer moisture analyzer is 3.0ug / uL.

[0032] Secondary esterification and stratification:

[0033] Put 1501 grams of the oil phase obtained after primary esterification and layering into a storage tank wit...

Embodiment 2

[0039] Primary esterification and layering:

[0040] 1500 grams of tallow bark oil (acid value 30mgKOH / g oil) after filtering and dehydration add in the storage tank with jacket, and preheat to 60 ℃, then add 85 grams of methanol / catalyst layer (#1, embodiment 1 (obtained after the second stage esterification reaction in the medium), pumped into the hydraulic cavitation esterification reactor, reacted at 60°C for 20 minutes, the reaction liquid entered the clarification tank, stayed in the clarification tank for 1 hour, and removed methanol / water / For the catalyst phase, 1502 grams of the oil phase was obtained. The acid value of the oil phase was measured according to the national standard GB / T5530-85 to be 16.47 mgKOH / g oil, and the moisture content of the oil phase was measured by a Karl Fischer moisture analyzer to be 3.0 ug / ul. Secondary esterification and stratification:

[0041] 1502 grams of the oil phase obtained after primary esterification and layering are added in...

Embodiment 3

[0048] Primary esterification and layering:

[0049] Add 1500 grams of acidified oil (acid value 170 mgKOH / g oil, gum content about 10%) into a jacketed storage tank, and preheat to 60 ° C, then add 900 grams of methanol solution dissolved in 30 grams of concentrated sulfuric acid, and use a pump Transported into the hydraulic cavitation reactor, reacted at 60°C for 30min, the reaction solution was centrifuged at 3000rpm, and the methanol / water / catalyst layer was removed to obtain 1647g of the oil phase, and the oil phase acid was measured according to the national standard GB / T5530-85 The value is 50.1mgKOH / g oil, and the water content of the oil phase measured by the Karl Fischer moisture meter is 3.5ug / uL.

[0050] Secondary esterification and stratification:

[0051] Add 1647 grams of the oil phase after primary stratification and graded esterification into a jacketed storage tank, and preheat it to 60°C, then add 900 grams of methanol solution dissolved in 30 grams of co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com