Ethyl acetate synthetic process and apparatus thereof

A technology for ethyl acetate and acetic acid, which is applied to the synthesis process of ethyl acetate and the field of devices thereof, can solve the problems of high energy consumption and equipment investment, low thermodynamic efficiency, unfavorable economic benefits and the like, and achieves reduction of energy consumption and equipment investment cost. , the effect of improving the reaction conversion rate and simplifying the distillation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

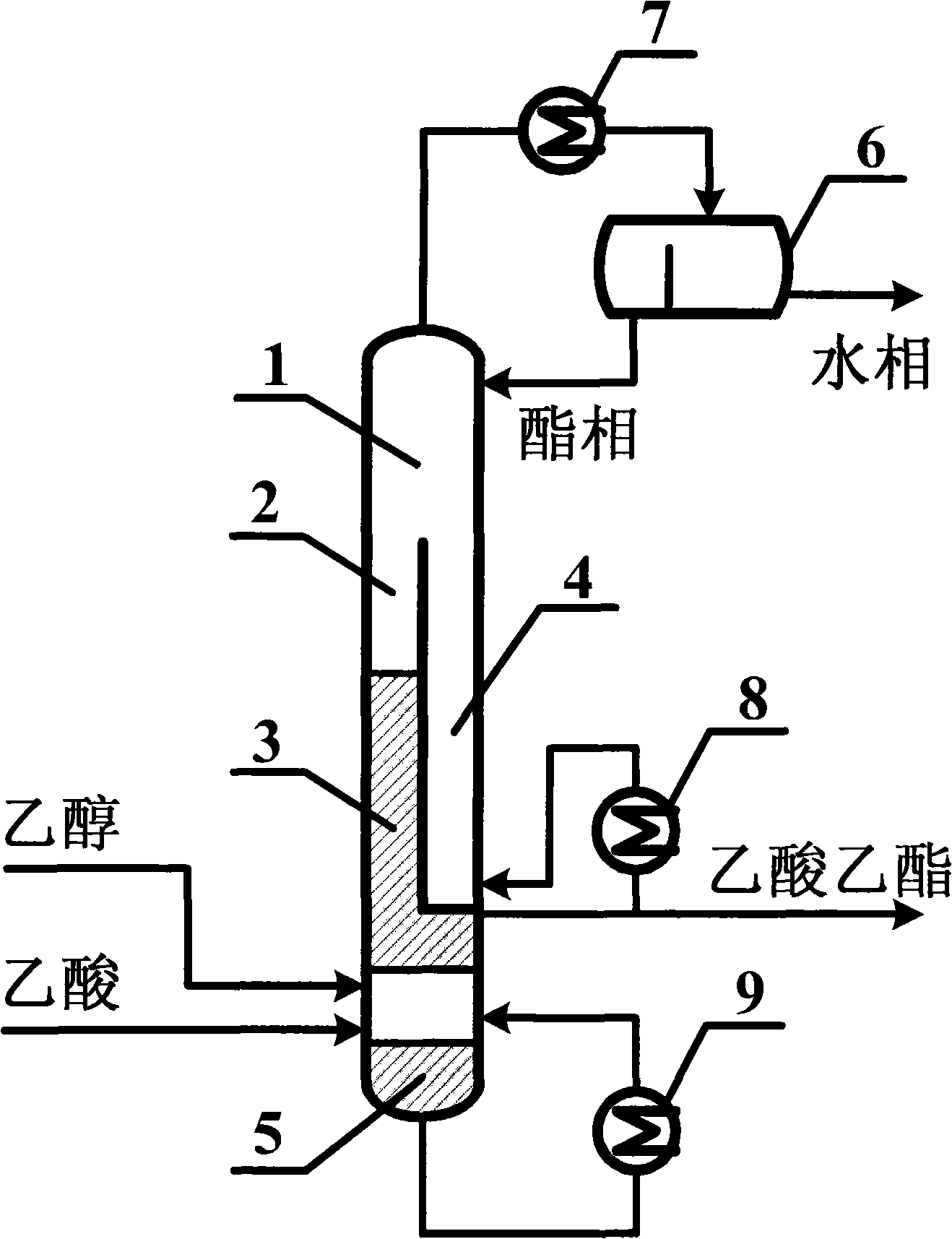

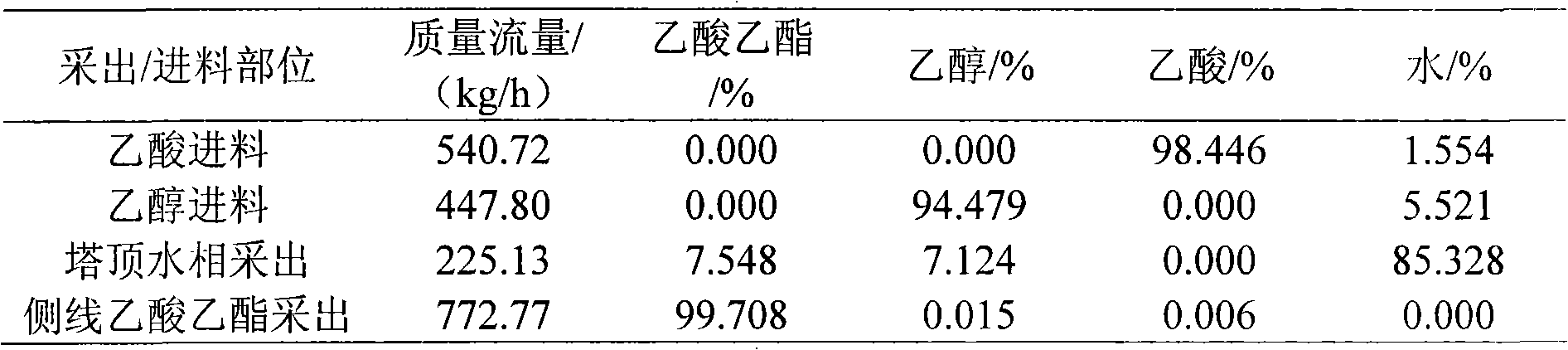

[0018] Example 1: The reactive distillation dividing wall tower is a packed tower with a tower diameter of 1600mm and a height of 18000mm. The packing heights of areas (1) to (4) are 2500m, 2500m, 5500m, and 3500m respectively. The rectifying section (2) and the side stripping Section (4) has a cross-sectional area ratio of 3.4:1. The operating pressure is 1 atm, and the operating temperature of the overhead condenser and phase separator is 40°C. The reaction section (3) and the lower part of the tower kettle (5) are equipped with a catalyst, the catalyst is Purolite CT179 acidic cation exchange resin, and the temperature of the catalyst bed is 105-115°C. The volumetric space velocity of the acetic acid feed is 0.77h -1 , the molar ratio of ethanol feed to acetic acid feed was 1.04:1. The ratio of the mass flow rate of the liquid phase flowing into the rectifying section (2) from the top of the bulkhead to the mass flow rate of the liquid phase flowing into the side strippin...

example 2

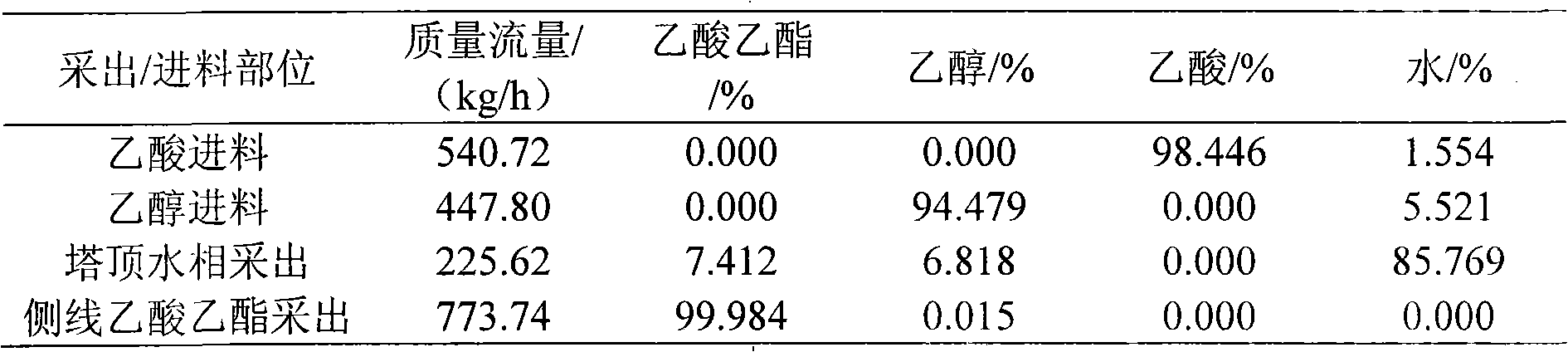

[0021] Example 2: in the device described in example 1, each parameter is the same as example 1, but the cross-sectional area ratio of the rectifying section (2) and the side strip stripping section (4) is 2.3: 1, and flows into the rectifying section by the partition top The ratio of the mass flow rate of the liquid phase of (2) to the mass flow rate of the liquid phase flowing into the side stripping section (4) is 3:2, and the catalyst is Amberlyst 15 acidic cation exchange resin, and the temperature of the catalyst bed is 105-115°C. The flow rate and composition of each stream are shown in Table 2. The resulting acetic acid conversion was 99.99%.

[0022] Table 2 Example 2 Each logistics flow rate and composition

[0023]

example 3

[0024] Example 3: The reactive distillation dividing wall tower is a tray tower with a tower diameter of 1600 mm and a height of 24000 mm. The number of plates in the area (1) to area 4 is 10, 10, 22, and 14 respectively. The rectifying section (2) and the side stripping section (4) The cross-sectional area ratio is 1.5:1. The operating pressure is 1 atm, and the operating temperature of the overhead condenser and phase separator is 40°C. The reaction section (3) and the lower part of the tower kettle (5) are equipped with a catalyst, the catalyst is Purolite CT179 acidic cation exchange resin, and the temperature of the catalyst bed is 105-115°C. The volumetric space velocity of the acetic acid feed is 0.86h -1 , the molar ratio of ethanol feed to acetic acid feed was 1.04:1. The ratio of the mass flow rate of the liquid phase flowing into the rectifying section (2) from the top of the partition wall to the mass flow rate of the liquid phase flowing into the side stripping ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com