Preparation method of methyl tris-methylethylketoxime silane

A technology of methyltributanone oxime and butanone oxime is applied in chemical instruments and methods, compounds of elements of Group 4/14 of the periodic table, organic chemistry, etc. Many other problems, to achieve the effect of high purity and low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

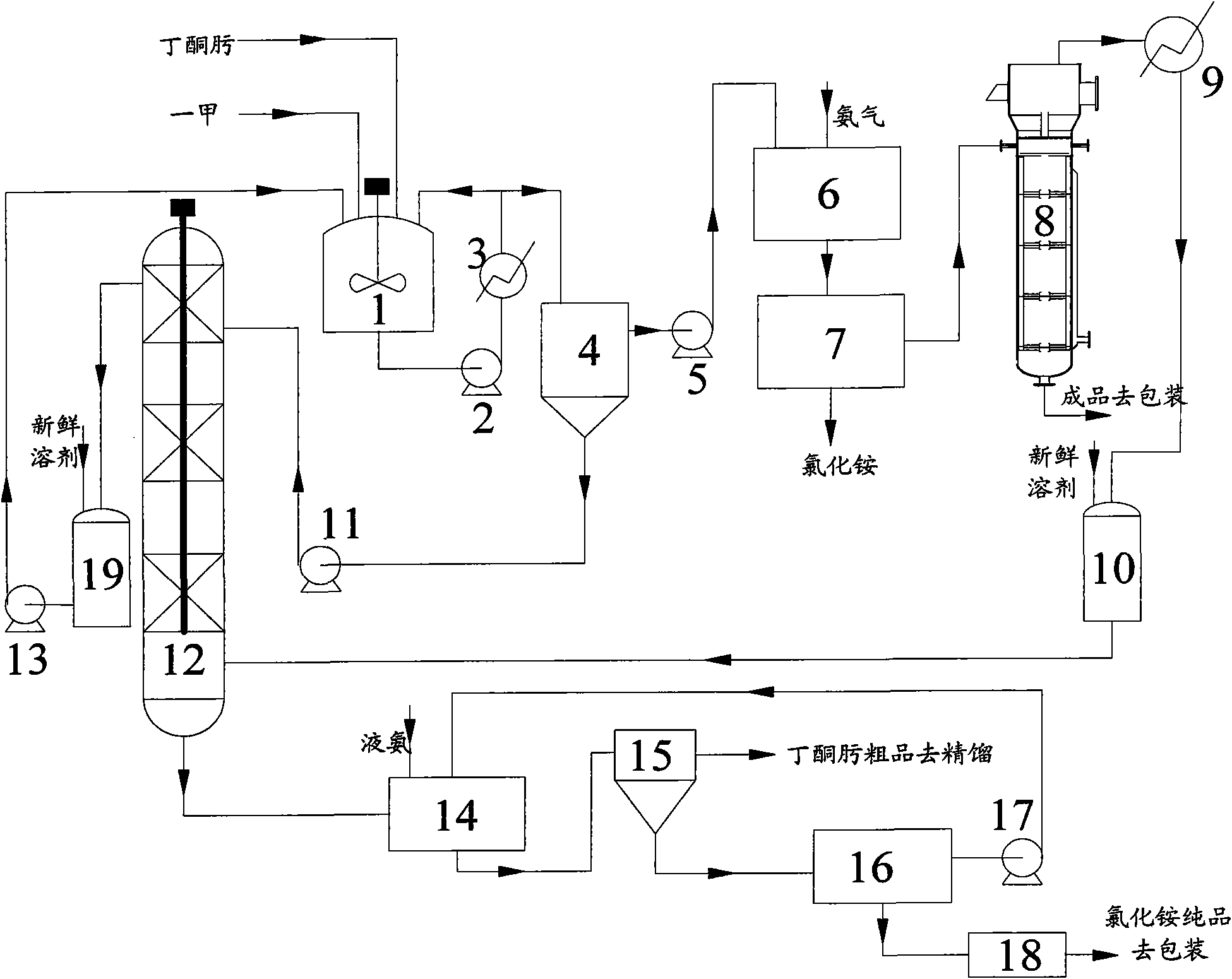

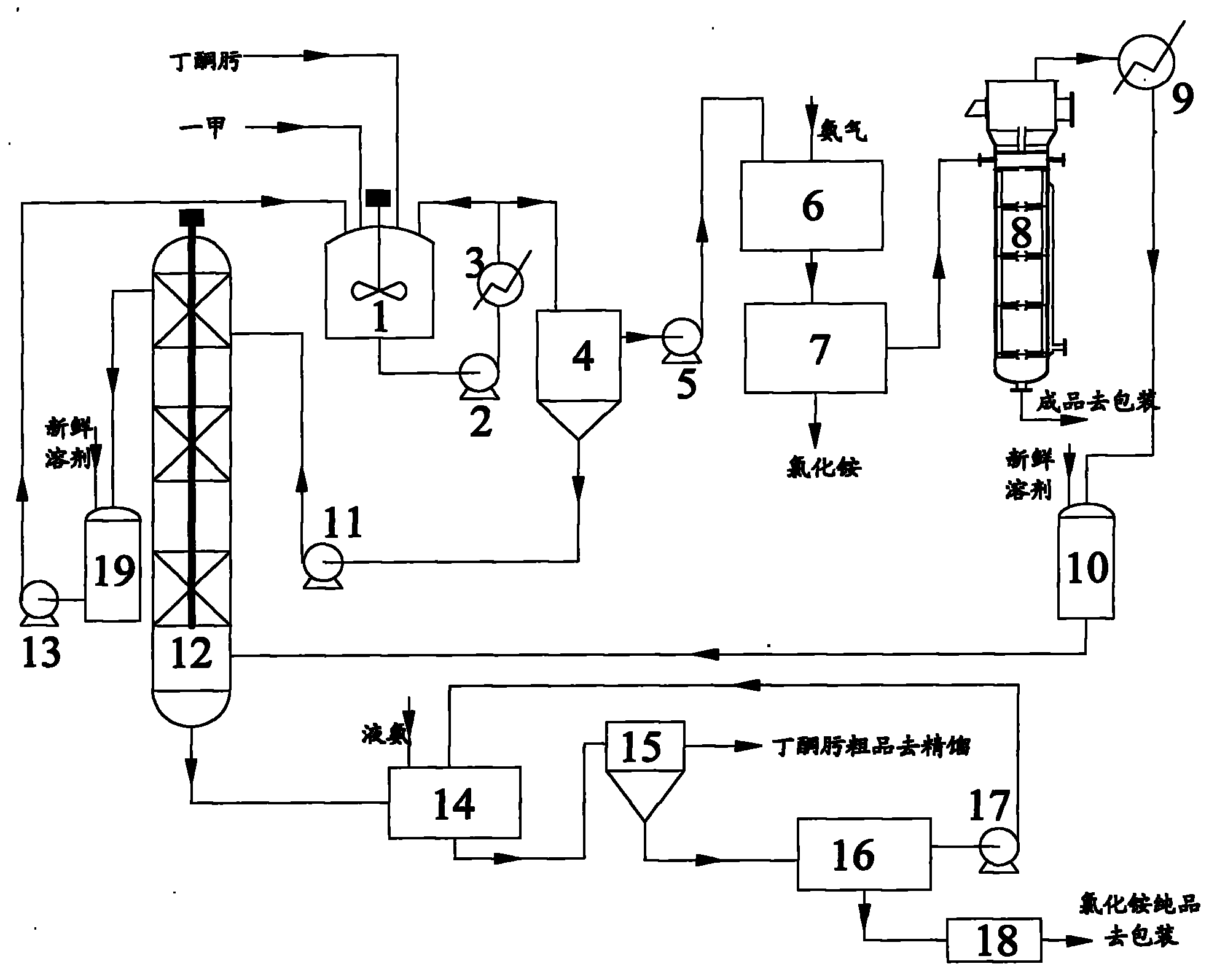

Image

Examples

Embodiment 1

[0024] First, put 1.8t of butanone oxime and 0.5t of 120# solvent gasoline into the reactor, turn on the stirring, start the circulation pump for full reflux, turn on the A feed pump to inject 1t / h into the reactor, turn on the circulation pump and cool down Keep the temperature at 30°C. After reacting for 30 minutes, turn on the butanone oxime feed pump to inject the butanone oxime into the reactor at a flow rate of 3.6t / h, and turn on the solvent feed pump to inject the solvent at a flow rate of 1t / h. into the reaction kettle, and open the extraction valve of the pump at the same time, keep the circulation flow rate of the pump at 20m3 / h, and the output flow rate at 5.6t / h; The feed flow rate of the bottom solvent is controlled at 0.85m3 / h, and the solvent extracted from the product is pumped back to the reactor for recycling. Butanone oxime is recovered, the ammonium chloride solution in the lower layer is crystallized and dried in a crystallizer to obtain pure ammonium chl...

Embodiment 2

[0026] First, put 1.8t of butanone oxime and 0.5t of 120# solvent gasoline into the reactor, turn on the stirring, start the circulation pump for full reflux, turn on the A feed pump to inject 1t / h into the reactor, turn on the circulation pump and cool down Keep the temperature at 40°C. After 30 minutes of reaction, turn on the butanone oxime feed pump to inject the butanone oxime into the reactor at a flow rate of 3.6t / h, and turn on the solvent feed pump to inject the solvent at a flow rate of 1t / h. into the reaction kettle, and open the extraction valve of the pump at the same time, keep the circulation flow rate of the pump at 30m3 / h, and the output flow rate at 5.6t / h; The feed flow rate of the bottom solvent is controlled at 1.25m3 / h. The solvent extracted from the product is pumped back to the reactor for recycling. After the bottom sediment and solvent of the extraction tower are neutralized by the neutralizer, the crude product of butanone oxime in the upper layer is ...

Embodiment 3

[0028]First, put 1.8t of butanone oxime and 0.5t of 120# solvent gasoline into the reactor, turn on the stirring, start the circulation pump for full reflux, turn on the A feed pump to inject 1t / h into the reactor, turn on the circulation pump and cool down Keep the temperature at 35°C. After reacting for 30 minutes, turn on the butanone oxime feed pump to inject the butanone oxime into the reactor at a flow rate of 3.55t / h, and turn on the solvent feed pump to inject the solvent at a flow rate of 1t / h. into the reaction kettle, and open the extraction valve of the pump at the same time, keep the circulation flow rate of the pump at 30m3 / h, and the extraction flow rate at 5.55t / h; The feed flow rate of the bottom solvent is controlled at 1.0m3 / h, and the solvent extracted from the product is pumped back to the reactor for recycling. After the bottom sediment and solvent of the extraction tower are neutralized by the neutralizer, the crude butanone oxime in the upper layer is re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com