Microalgae high-pressure continuous tower-type liquefying process

A microalgae, high-pressure technology, applied in the petroleum industry, preparation of liquid hydrocarbon mixtures, etc., can solve problems such as difficulty in realizing large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

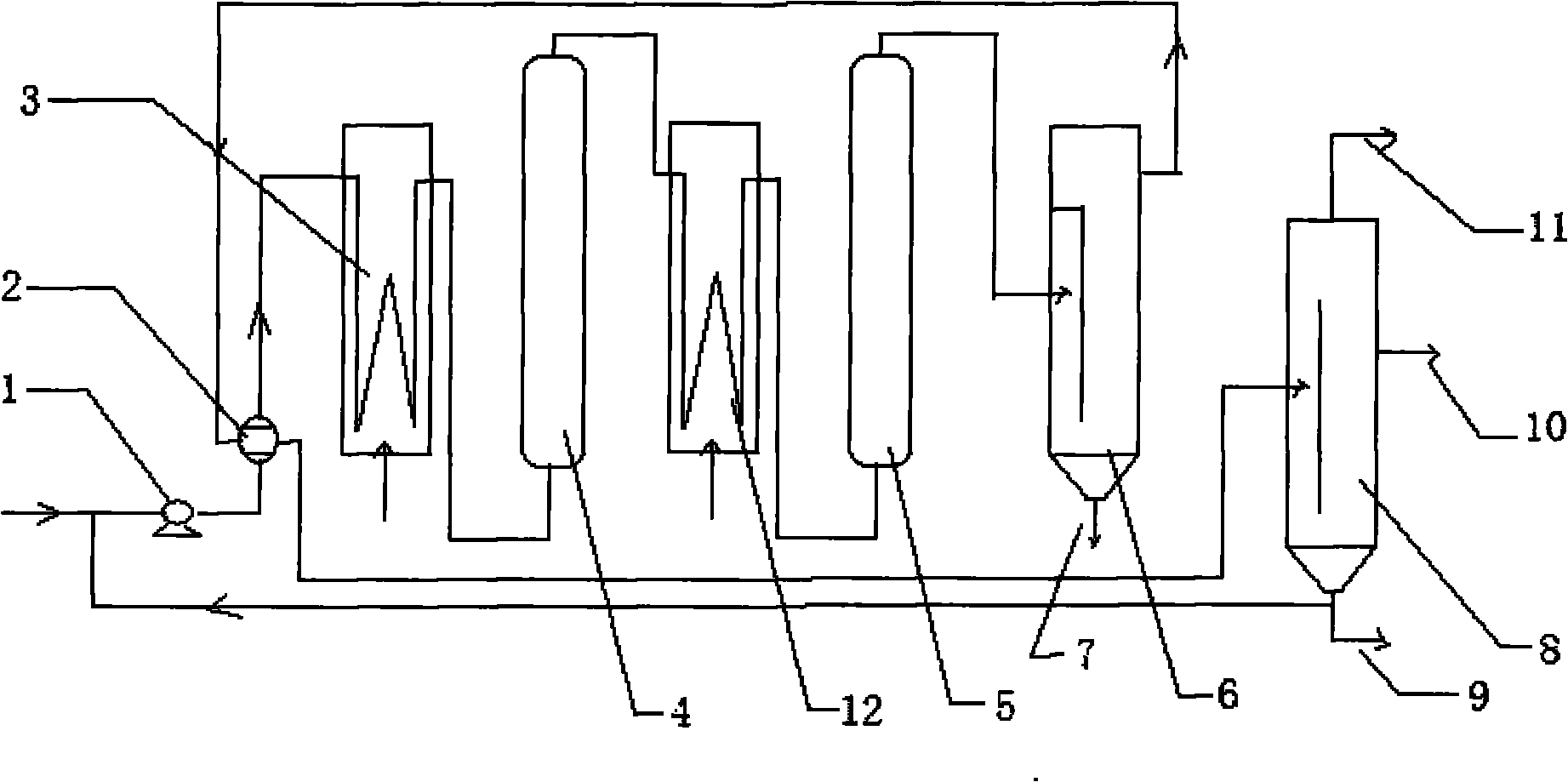

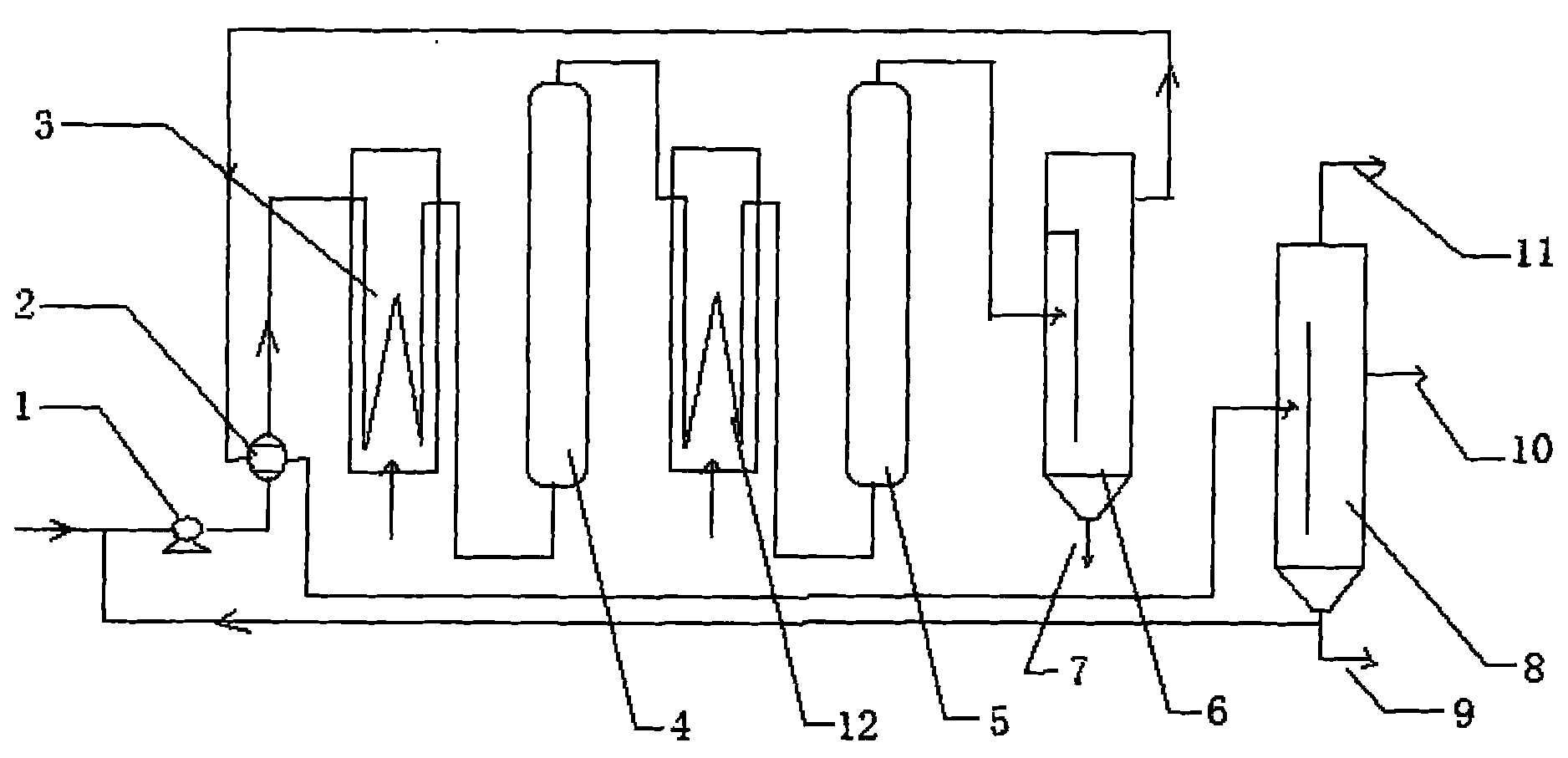

[0011] Example 1, after the suspension containing microalgae is pressurized by the high-pressure pump (1), it flows through the heat exchanger (2) to exchange heat with the liquefied liquid first, and then the heating furnace (3) heats up to 180- 250°C, and then keep it warm for a certain period of time in the gelatinization tower (4) to make the solid biomass into a flowable slurry; the gelatinized liquid is rapidly heated to 270-350°C at a certain heating rate through the secondary heating furnace (12). ℃, enter the liquefaction tower (5) for hydrothermal liquefaction to produce liquid fuel; the hydrothermal liquefaction product is separated from the char slurry by the high-pressure settling tank (6) and discharged from the char slurry outlet (7), and the liquefied gas and liquid are passed by the high-pressure settling tank (6 ) top flows into the three-phase separator (8) after exchanging heat with the microalgae suspension through the heat exchanger (2); the liquefied gas-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com