Release agent for lead storage battery grid casting and preparing method thereof

A technology of lead storage battery and mold release agent, which is applied to casting molding equipment, casting molds, casting mold components, etc. It can solve the problems of poor high temperature tolerance of cork powder, rough surface porosity of grids, shortening battery cycle life, etc., and achieves Good mechanical and electrical properties, increased durability, and the effect of extending time intervals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

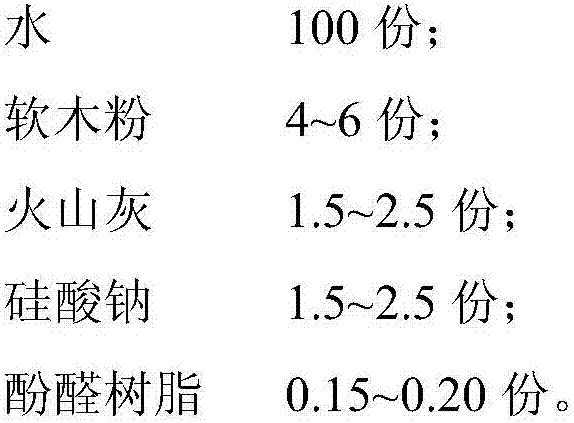

[0030] Prepare the release agent as follows:

[0031] (1) First weighing 50 g of cork powder with a fineness of 500 mesh and 20 g of volcanic ash with a fineness of 800 mesh (produced by U.S. HESS company, the same below), dry stirring the two powders for 2 minutes, and mixing them uniformly;

[0032] (2) Heat distilled water with conductivity ≤10 μS / cm to a temperature of 60°C to 76.7°C, then slowly put the mixture in step (1) into 1000g of heated water, stir continuously for more than 15 minutes to mix evenly, and then let stand for 6 Allow to cool down to room temperature over an hour;

[0033] (3) The sodium silicate that weighed 20g is dropped into and stirred evenly, stirring time 10 minutes;

[0034] (4) Stand still and ripen for 24 hours, waiting for the penetration of cork powder and solvent;

[0035] (5) Add 15g of 12% phenolic resin solution (containing 1.8g of phenolic resin) with a weighed concentration and stir evenly for 10 minutes;

[0036] (6) Stand for 24 ...

Embodiment 2

[0038] Prepare the release agent as follows:

[0039] (1) First weigh 40g of cork powder with a fineness of 500 mesh and 15g of volcanic ash with a fineness of 800 mesh, dry stir the two powders for 2 minutes, and mix well;

[0040] (2) Heat distilled water with conductivity ≤10 μS / cm to a temperature of 60°C to 76.7°C, then slowly put the mixture in step (1) into 1000g of heated water, stir continuously for more than 15 minutes to mix evenly, and then let stand for 6 Allow to cool down to room temperature over an hour;

[0041] (3) The sodium silicate that weighed 25g is put into and stirred evenly, stirring time 10 minutes;

[0042] (4) Stand still and ripen for 24 hours, waiting for the penetration of cork powder and solvent;

[0043] (5) Add 16.7 g of 12% phenolic resin solution (containing 2 g of phenolic resin) with a weighed concentration and stir evenly for 10 minutes;

[0044] (6) Stand for 24 hours to allow the cork powder and solvent to penetrate completely.

Embodiment 3

[0046] Prepare the release agent as follows:

[0047] (1) First weigh 60g of cork powder with a fineness of 500 mesh and 25g of volcanic ash with a fineness of 800 mesh, dry stir the two powders for 2 minutes, and mix well;

[0048] (2) Heat distilled water with conductivity ≤10 μS / cm to a temperature of 60°C to 76.7°C, then slowly put the mixture in step (1) into 1000g of heated water, stir continuously for more than 15 minutes to mix evenly, and then let stand for 6 Allow to cool down to room temperature over an hour;

[0049] (3) The sodium silicate that weighed 15g is dropped into and stirred evenly, stirring time 10 minutes;

[0050] (4) Stand still and ripen for 24 hours, waiting for the penetration of cork powder and solvent;

[0051] (5) Add 10g of phenolic resin solution (containing 1.5g of phenolic resin) with a weighed concentration of 15% and stir evenly for 10 minutes;

[0052] (6) Stand for 24 hours to allow the cork powder and solvent to penetrate completely....

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com