Copper and aluminum connection structure with flame retardant insulation bush

A technology of insulating sleeve and connection structure, which is applied in the field of wire and cable, and can solve problems such as reducing strength, failing to ensure good contact of wires, and losing insulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

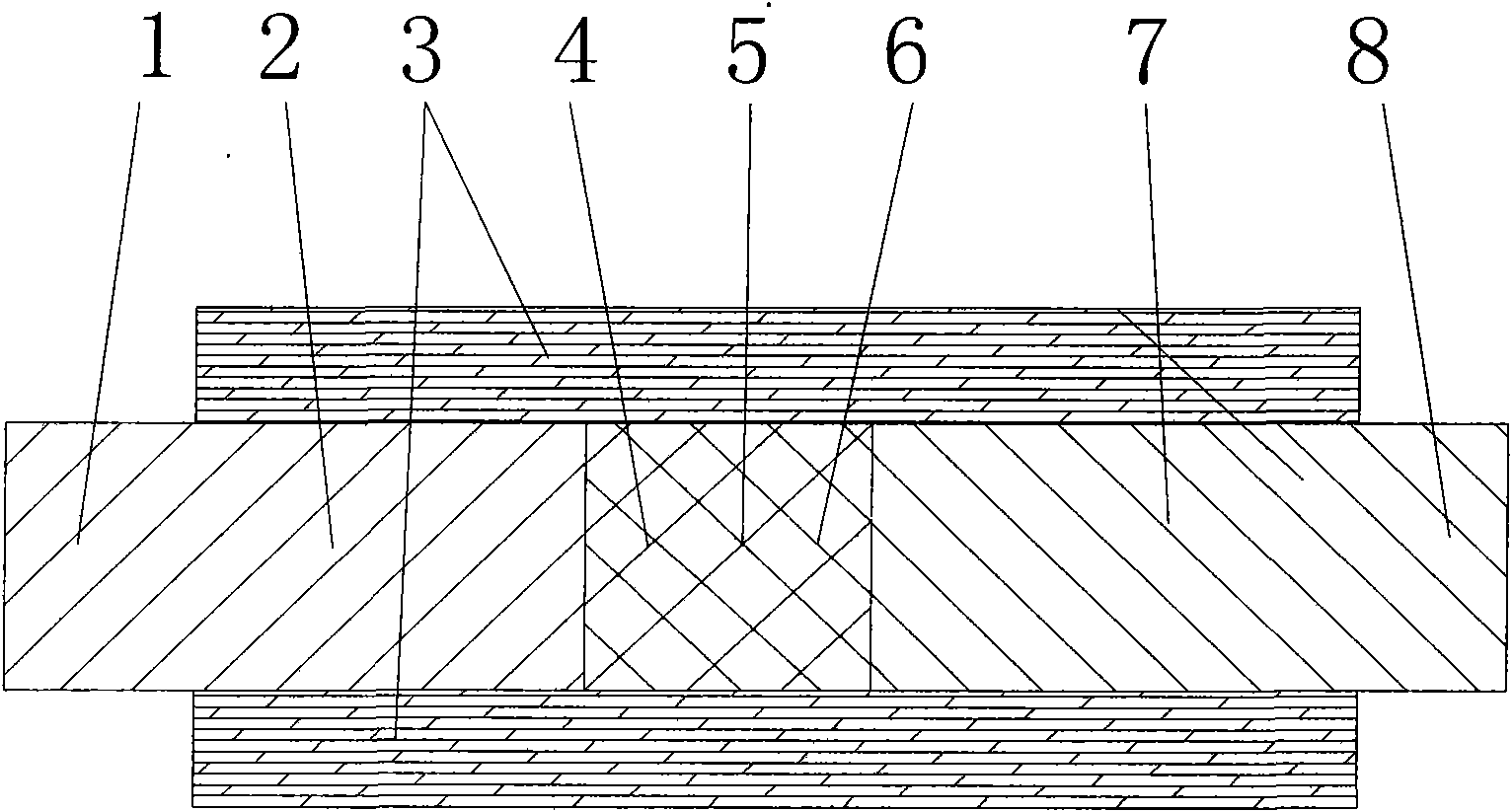

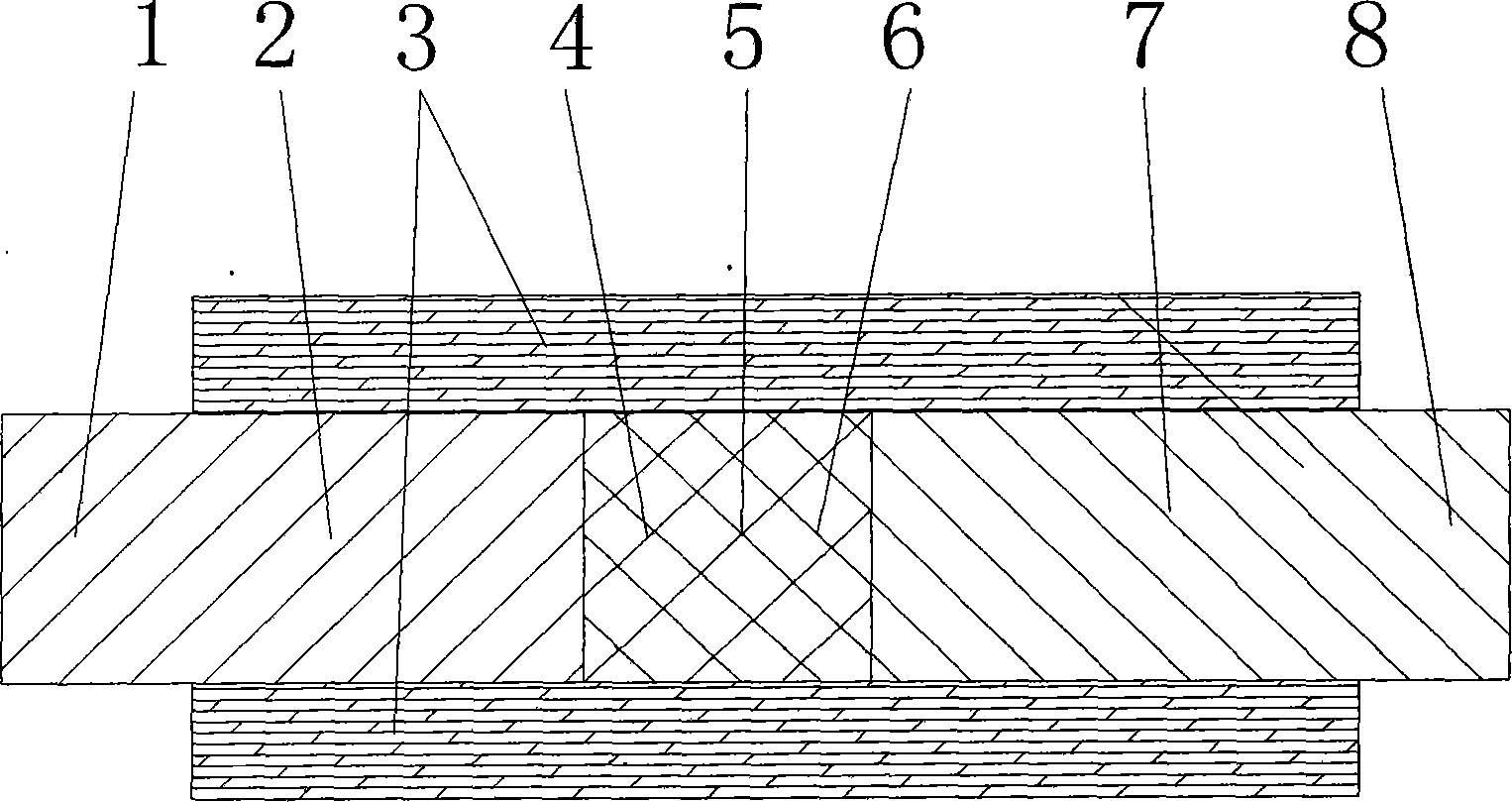

[0012] Such as figure 1 The illustrated embodiment is as follows: a copper-aluminum connection structure with a flame-retardant insulating sleeve. The copper wire joint section 2 of the copper wire 1 and the aluminum wire joint section 7 of the aluminum wire 8 are fixedly connected into the copper-aluminum wire joint section 5 by means of cold welding and crimping at the same time. A heat-shrinkable insulating sleeve 3 with good flame-retardant performance is coated on the periphery of the copper-aluminum wire joint section 5 and the copper wire joint 4 and the aluminum wire joint 6 adjacent to the copper-aluminum wire joint section.

[0013] The tensile strength of the copper-aluminum wire joint section 5 should not be lower than 200N.

[0014] The copper conductor 1 adopts TR type soft round copper wire, and the aluminum conductor 8 adopts LY9 type hard round aluminum wire.

[0015] The insulating sleeve 3 is first heated by a hot air blower to soften and tightly cover the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com