Method for improving temperature resistance of cigarette paper

A cigarette paper and temperature-resistant technology, which is applied in the directions of wrapping paper, wrapping paper, flexible covering, etc., can solve the problems of complicated coating preparation, high gram weight of cigarette paper, increased use cost of cigarette paper, etc., and achieves high temperature resistance performance. , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

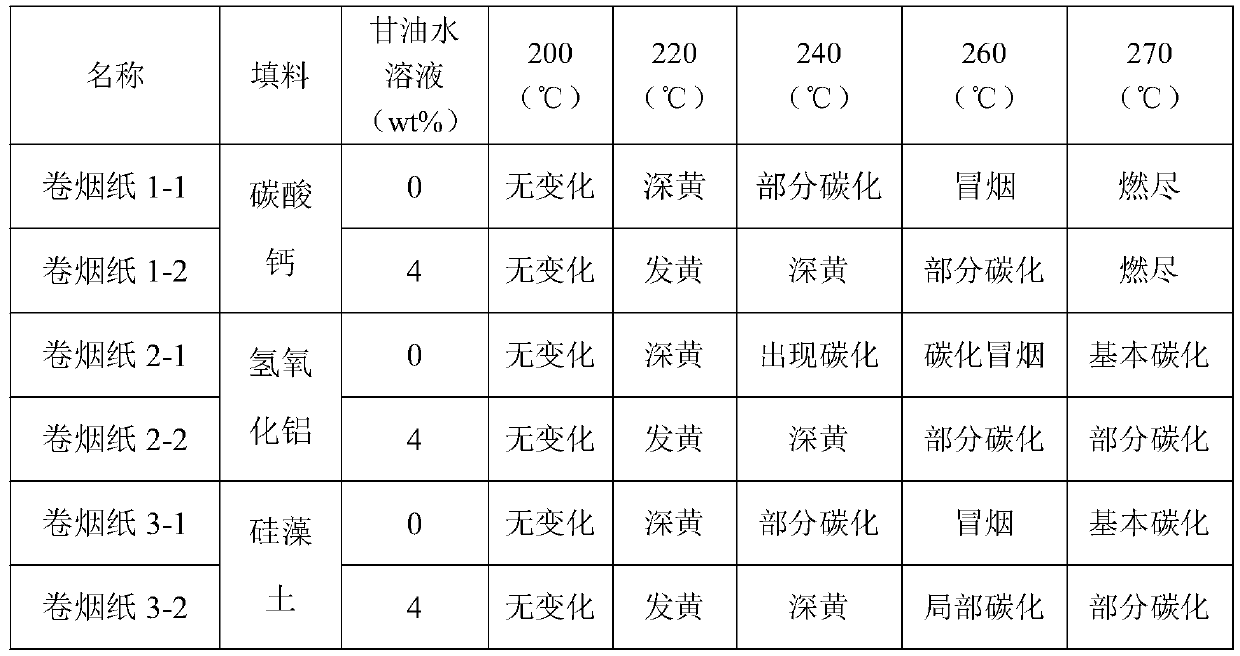

Embodiment 1

[0018] Cigarette paper is manufactured according to the conventional cigarette paper production process, wherein the difference is that calcium carbonate, calcium hydroxide, and diatomaceous earth are used as fillers respectively, and glycerin aqueous solution with a concentration of 4wt% is used as a sizing agent for sizing, and the grammage produced is 32±0.5g / m 2 The different types of cigarette papers are named as cigarette paper 1-2, cigarette paper 2-2, and cigarette paper 3-2.

[0019] Cigarette paper is manufactured according to the conventional cigarette paper production process, using calcium carbonate, calcium hydroxide, and diatomaceous earth as fillers respectively, without sizing, and the produced grammage is 32±0.5g / m 2 The different types of cigarette papers are named as cigarette paper 1-1, cigarette paper 2-1, and cigarette paper 3-1.

[0020] Use cigarette paper 1-1, cigarette paper 2-1, cigarette paper 3-1 and cigarette paper 1-2, cigarette paper 2-2, ciga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com