Wood plastic composite foaming material and forming process and equipment thereof

A technology of wood-plastic composite and foaming materials, which is applied in the field of foaming materials and its molding process and equipment, can solve the problems of long time, high energy consumption of equipment, material deformation, etc., and achieve low production cost, wide application and low density Effect

Inactive Publication Date: 2011-01-12

佛山市科昌塑料制品有限公司

View PDF14 Cites 45 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

CN101545300A discloses a wood-plastic board filled with foam material and its preparation method. It uses the wood-plastic board whose inner space is sealed as the shell, and pours general-purpose foam material into it to form a new foam structure. This material is not easy to process. Convenient, foaming is unreliable, the force generated by foaming can easily deform the material as a whole, and the dimensional stability is difficult to control, and it is difficult to realize fully automated high-speed production. At the same time, the material cannot fully biodegradable

This method improves the product quality of wood-plastic composites to a certain extent, but the wood fibers are mixed when the plastic is still solid, and the flow of wood fibers in the melt is limited by the initial state during the further melting of the plastic. , it is difficult to fully disperse, and at the same time, the wood fiber feed is unreliable, the time of wood fiber in the extrusion process is too long, the temperature is too high, it is easy to carbonize and degrade, the product does not foam, and the product cannot be fully biodegraded

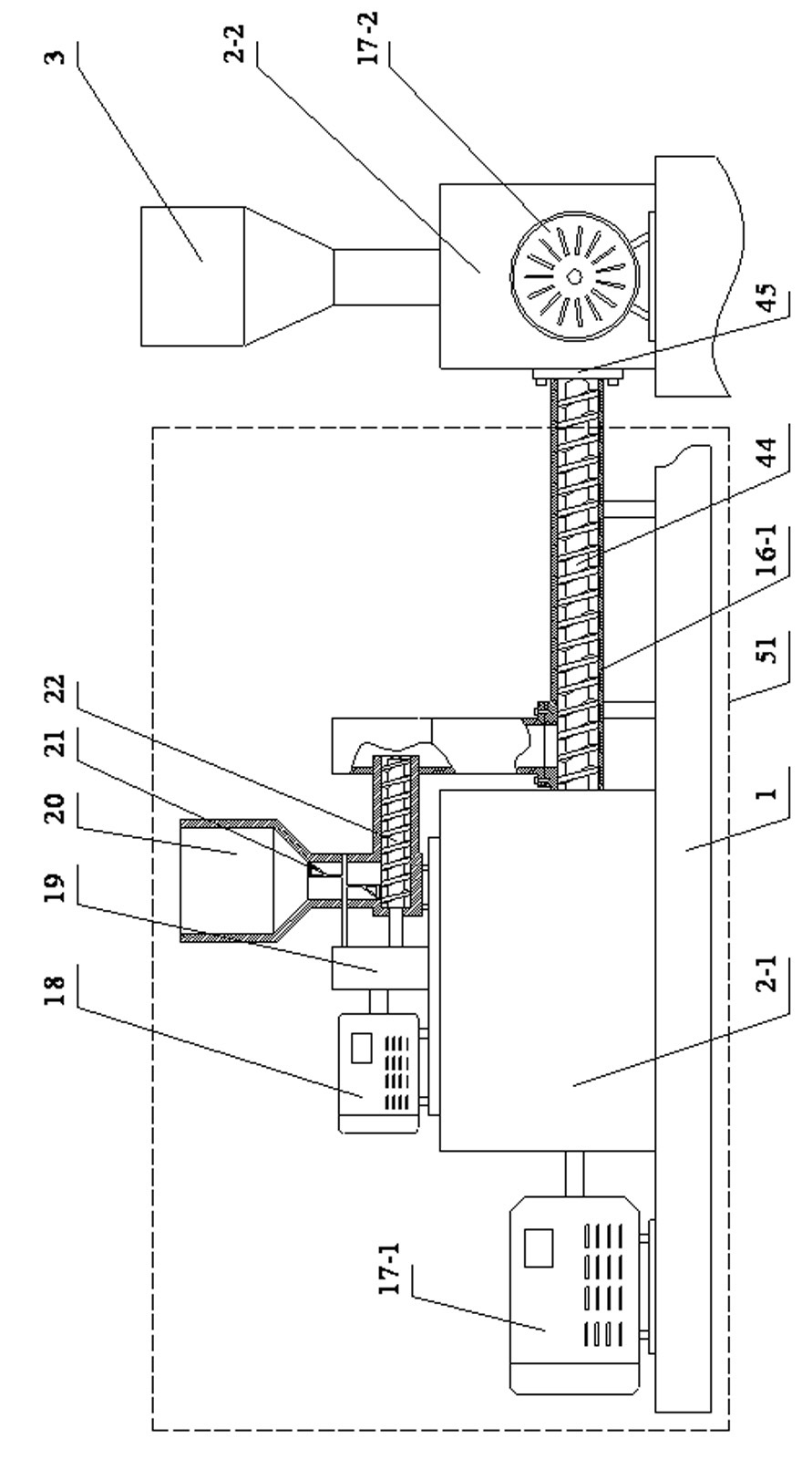

CN100563999C discloses a special conical twin-screw extruder for wood-plastic composite materials. The conical twin-screw used in it has a mixing section, and the length-to-diameter ratio of the barrel and the screw is greater than 30, and only A vent hole, the device makes the molten plastic wrap the heated wood flour and mix evenly before the vent port, but the device only loads a vertically downward screw at the position of the feeding bin, and does not improve the difficulty of fiber At the same time, the extruder cannot guarantee the uniform dispersion of fibers in the melt. The wood fiber stays in the equipment for too long, the temperature is too high, and it is easy to carbonize. The product has no foaming and is not environmentally friendly. The equipment can High consumption, complex operation

CN2650971Y discloses a wood-plastic extruder, which adopts two horizontal and vertical screws, and the horizontal screw plays a plasticizing role. However, the problem of stable blending ratio between wood fiber feeding and plastic-wood composite system has not been fundamentally solved, the fiber feeding is difficult, the fiber stays in the equipment for too long, it is easy to carbonize, and the fiber dispersion effect is poor. Equipment without foaming unit

It can be seen from the drawings in the description that it does not take into account the connection position between the horizontal and vertical extruders, but for the blending of wood fiber and thermoplastics, the influence of the molten state of the polymer on its blending timing Very large, also does not solve the problem of fiber feeding difficulties and easy carbonization of fibers, the equipment has no foaming unit, and the product cannot be fully biodegraded

CN2925844Y discloses a twin-screw extruder of fiber-reinforced thermoplastics, which sets the feeding position of the fiber in the first half of the plasticizing section of the twin-screw to optimize the mixing effect of the fiber and the plastic matrix, but because there is no feeding of the fiber way, making it difficult to determine how well it optimizes

Because in the plasticizing section of the plastic, the internal pressure of the polymer material is quite large, it is difficult for the fiber material to enter the plastic melt, the blending effect of the fiber and the plastic is poor, the fiber is easy to carbonize, and the equipment has no foaming unit

During the feeding process of plant fibers and thermoplastics, if they are added from the hopper and then extruded by the screw, the fibers will often disperse and form coils due to strong mechanical action during the mixing process, which will cause uneven mixing of raw materials and affect the product. Quality; at the same time, this feeding method is also easy to cause blockage or even jamming of the feeding system, affecting the entire process of product processing

CN201419503 discloses a hopper device of an extruder device, which is loaded with a variable-diameter spiral agitator in the hopper, and the main function of the variable-diameter spiral agitator is to carry out screw conveying for bulky materials that are difficult to discharge , its disadvantage is that it is difficult for such materials (mainly fibers) to be fed under the action of gravity at the feeding port

CN201049512 discloses a short glass fiber feeding device, which adds periodic vibration during the feeding process of the silo to achieve uniform feeding, but for plant fibers with low density, this feeding method still cannot solve the problem of uniform feeding

CN1064059C discloses a fiber-reinforced thermoplastic structure, manufacturing method and production equipment thereof. Fibers mainly adopt glass fibers, carbon fibers and mixtures thereof. one or more platens installed at least in the form of a network and partially wedge-shaped in cross-section between the front end of the screw and the die to control the degree of combing of the reinforcing fibers in the thermoplastic resin masterbatch, the fiber length and the helical flow of the mixed melt, This method of controlling the fiber size and the uniformity of fiber and thermoplastic resin mixing has too high technical requirements, especially the processing of the surface structure of the barrel and screw, and the equipment processing cost is too high. foam unit

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Login to View More

Abstract

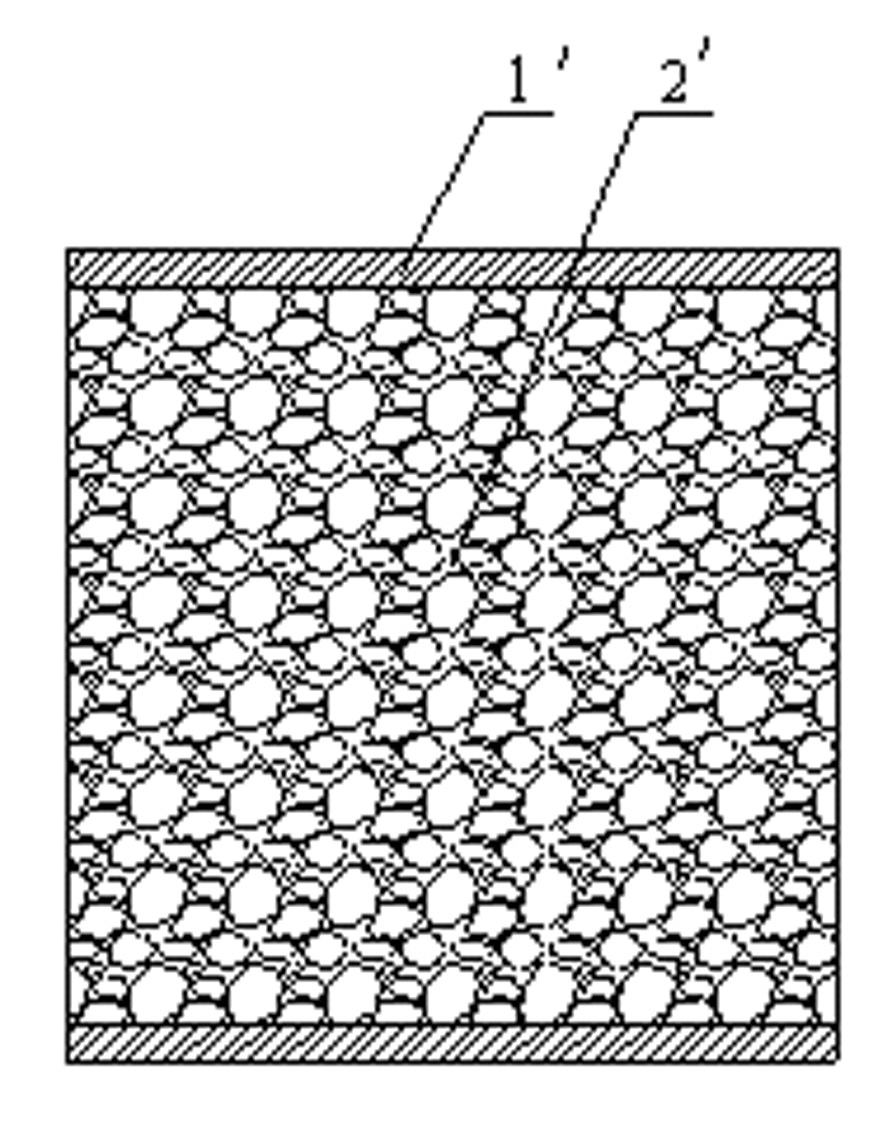

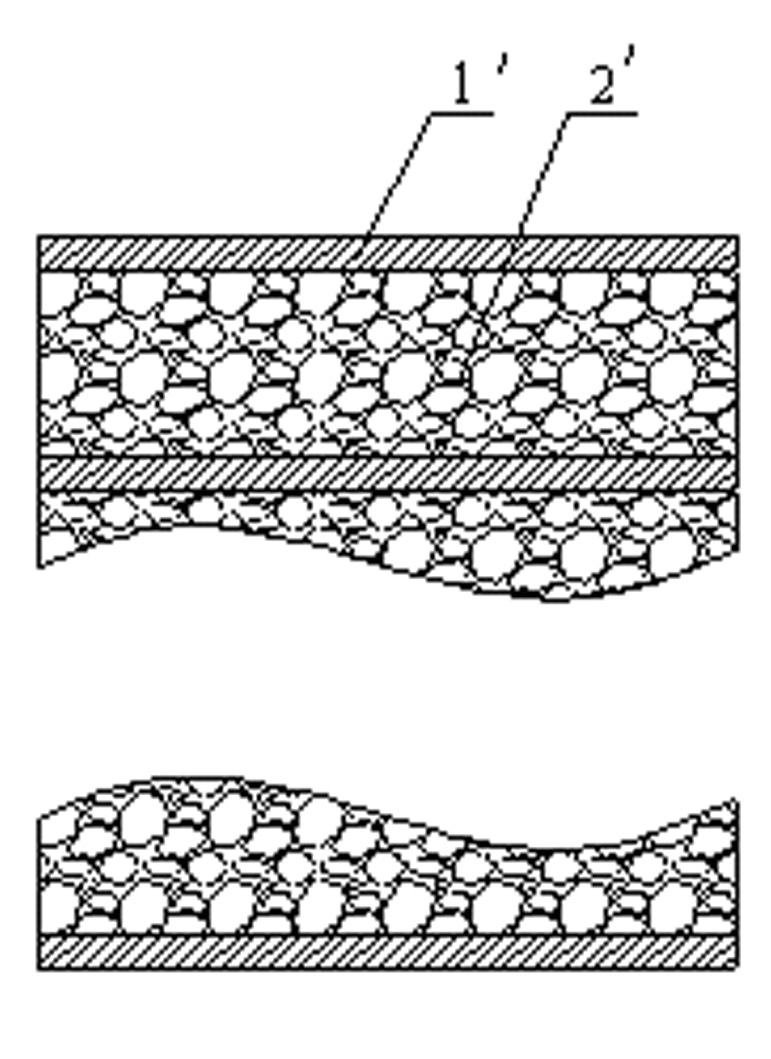

The invention relates to a wood plastic composite foaming material and a forming process and forming equipment thereof. The diameters of foam holes of the wood plastic composite foaming material are 0.01 to 5 millimeters; and the main component of the material is a mixture of thermoplastic plastic and plant fiber powder, or a mixture of thermoplastic plastic, starch and plant fiber powder, or a mixture of thermoplastic plastic, rubber powder and plant fiber powder. The invention also relates to the forming process and the forming equipment for the wood plastic composite foaming material. The wood plastic composite foaming material has the advantages of low density, high strength and low production cost, is suitable to be used as a packing material for various commodities, a buffering member for various devices, an elastic member of a product such as a sofa, a mattress, a sole and the like and a structural component of a household electric appliance, and is used for replacing wood for manufacturing floors, handrails, doors and windows, resting chairs used in gardens and the like.

Description

Technical field The invention relates to a foam material and its molding process and equipment, in particular to a wood-plastic composite foam material and its molding process and equipment. Background technique Wood-plastic composite foaming materials are a new generation of green and environmentally friendly materials that have developed very rapidly in the world recently. Their raw materials are mainly natural plant fibers, thermoplastics (including various recycled plastics, plastic raw materials, etc.) or starch, and related modifications. agents and processing aids. It is a lightweight, highly cushioned and elastic material. Compared with pure plastic, this material has a higher natural degradation ratio, lower material costs, and enhanced many properties. It has become a widely watched new material that can replace wood and plastic, and has been widely used internationally. In the extrusion molding technology of wood-plastic composite foam materials, according to t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L23/06C08L23/12C08L25/06C08L27/06C08L55/02C08L69/00C08L77/00C08L53/02C08L97/02C08L3/02C08L21/00C08J9/04B29C67/20

Inventor 曾广胜刘跃军

Owner 佛山市科昌塑料制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com