Rolling shear type straw briquetting machine

A forming machine and shearing technology, which is applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve the problems of easy carbonization and crash of equipment, and achieve the effects of not easy to crash, less friction, and ingenious technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

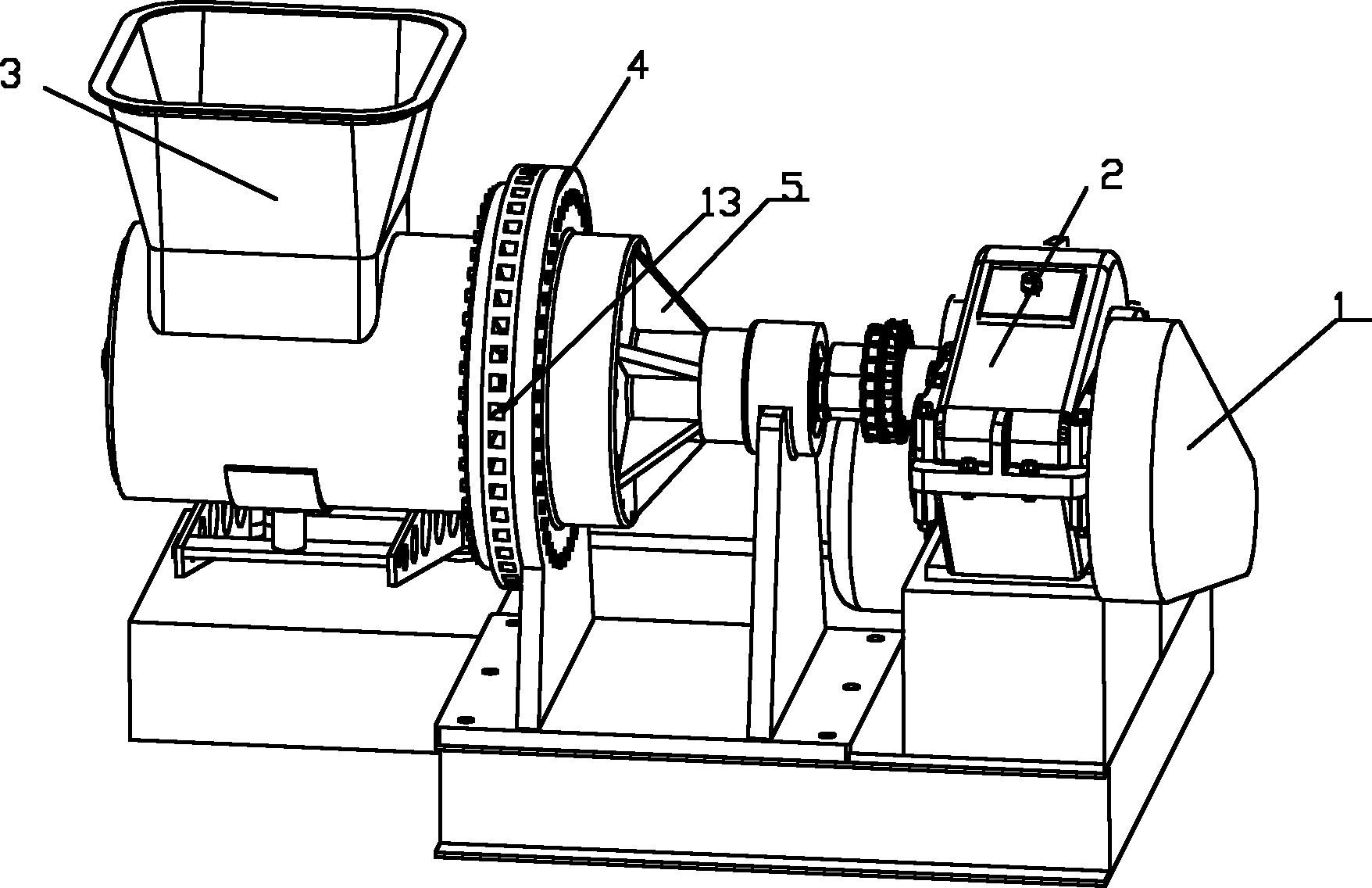

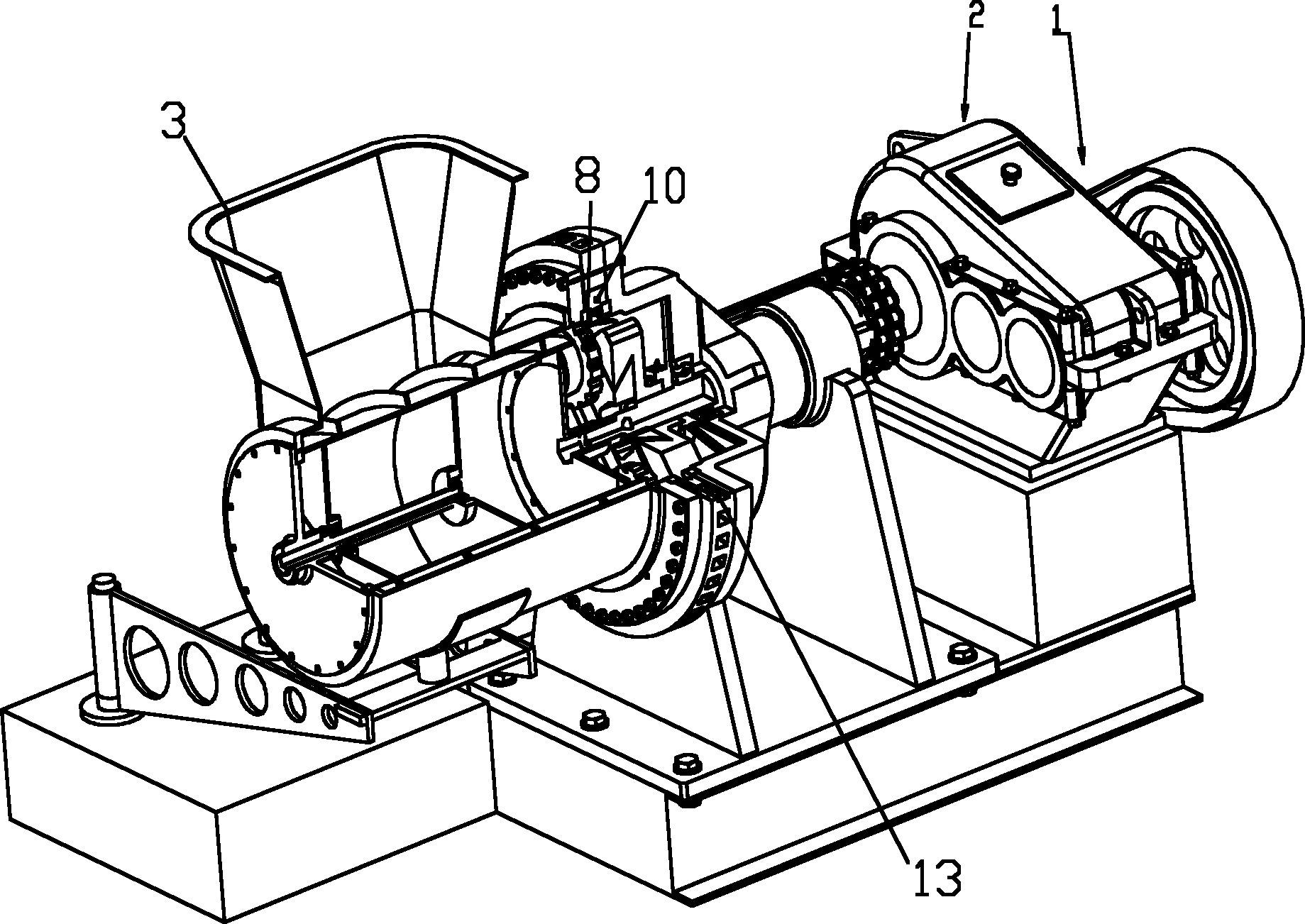

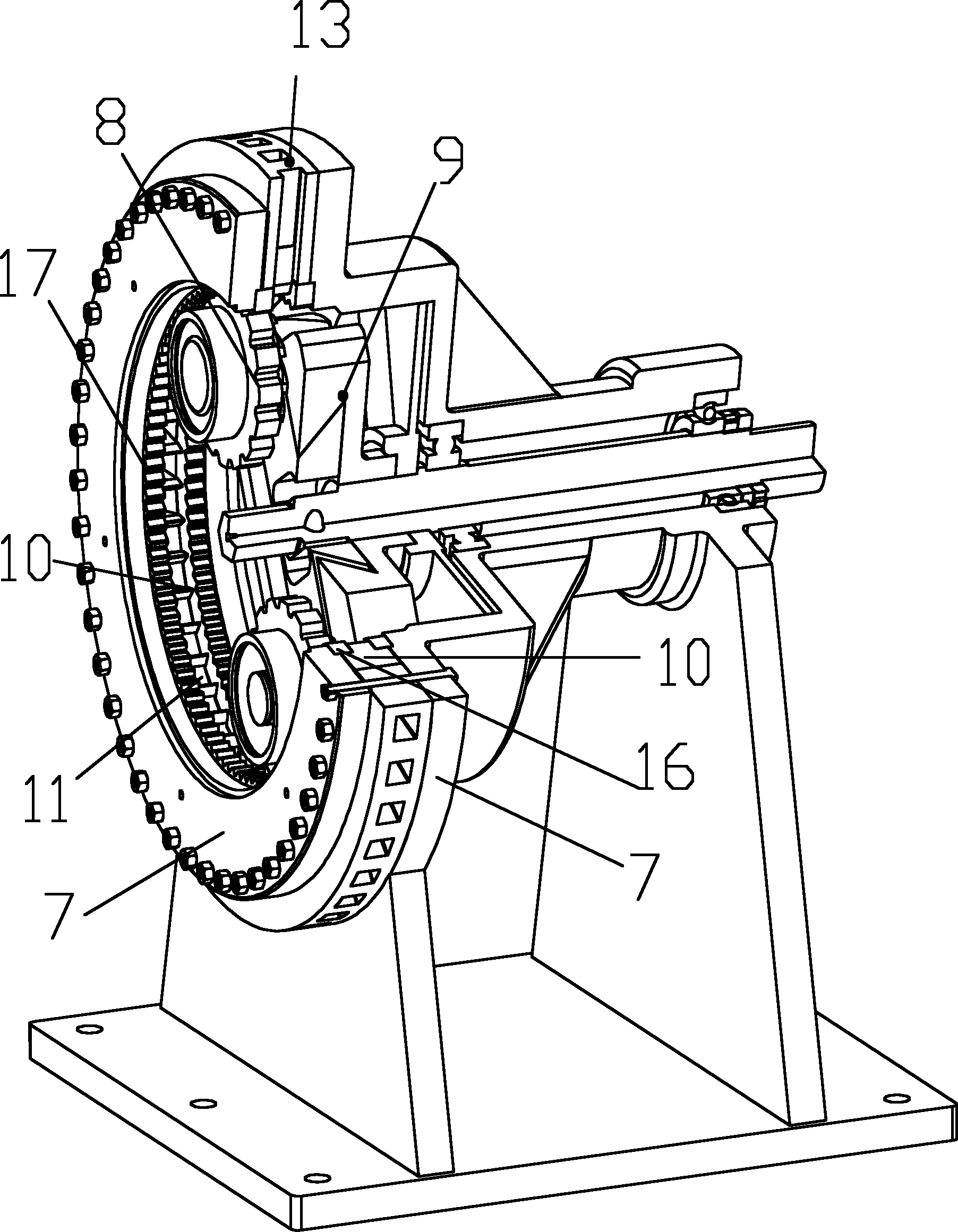

[0022] Below in conjunction with accompanying drawing, the present invention is described in further detail. As shown in the figure, the figure includes: power device 1, transmission device 2, feeding device 3, straw briquette forming device 4, frame 5, knife body 6, round blade 7, toothed hob 8, adjustable hob Knife holder 9, wire cutting trapezoidal sharp knife 10, trumpet-shaped feed port 11, annular knife groove 12, discharge cavity 13, knife holder 14 of the knife body, cutter teeth 15 of the circular blade, rake face and center surface of the cutter teeth The included angle A, the included angle B between the cutter flank and the center plane.

[0023] figure 1 It is an overall schematic diagram of the rolling shear type straw briquetting machine of the present invention. It can be seen that the power unit 1 is connected with the straw briquette forming device 4 through the transmission device 2 , and the straw briquette forming device 4 is connected with the feeding d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com