A block hole type pressureless sintered silicon carbide heat exchange module and process

A technology of sintered silicon carbide and heat exchange modules, applied in indirect heat exchangers, heat exchanger types, heat exchange equipment, etc., can solve the problems of unstable O-ring sealing method, increased production cost, broken pipe leakage, etc. , to achieve the effect of reliable sealing, improving performance and avoiding breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

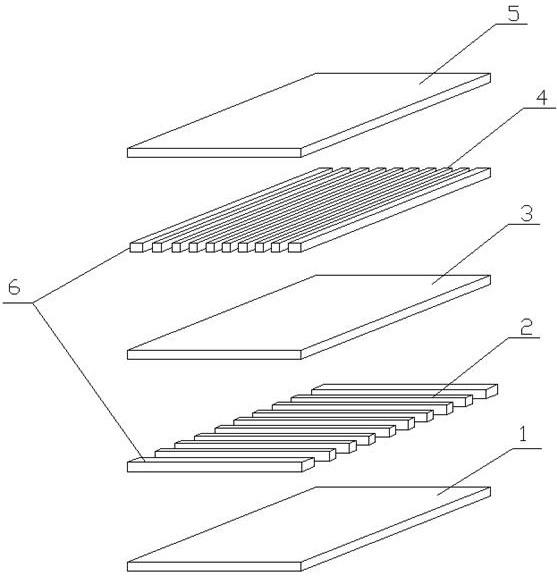

[0018] Such as figure 1 As shown, it is a block-hole type pressureless sintered silicon carbide heat exchange module, which includes a sintering unit, and the sintering unit is a lower plate 1, a horizontal grid 2, a middle plate 3, and a vertical grid 4 from bottom to top. , Upper board 5. The horizontal grid bars 2 and the vertical grid bars 4 are all provided with several and arranged at a certain distance, and the borders of the horizontal grid bars 2 and the vertical grid bars 4 are all provided with side bars 6 . In this embodiment, the width of the side bars 6 is greater than the widths of the horizontal grid bars 2 and the vertical grid bars 4 .

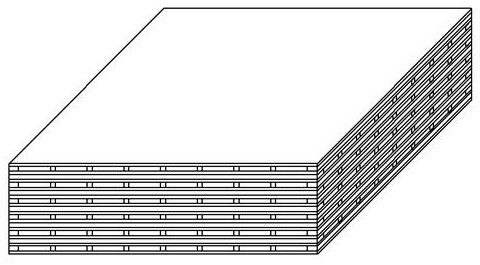

[0019] Adhesives are arranged on the upper and lower surfaces of the above-mentioned horizontal lattice strips 2, vertical lattice strips 4, and side strips 6 to facilitate bonding and sintering. Such as figure 2 As shown, a plurality of sintered units are combined to form a block-hole pressureless sintered silicon carbid...

Embodiment 2

[0021] The preparation process for the block hole type pressureless sintered silicon carbide heat exchange module in Example 1 includes the following steps: (1) Manufacturing the pressureless sintered silicon carbide green body, the lower plate, the horizontal grid, the middle plate, the vertical grid The blanks of strips and upper plates are manufactured separately;

[0022] (2) Manually coat the bonding material on the upper and lower sides of the horizontal grid, side strips, and vertical grids, with a coating thickness of 0.3-0.6 mm, and apply the , the upper plate and the side strips are assembled;

[0023] (3) Place the assembled block-hole silicon carbide green body into a vacuum furnace for sintering, the sintering atmosphere is argon, the sintering temperature is 2000-2200°C, and the holding time is 0.5-3h;

[0024] (4) After the sintering is completed, continue to place it in a vacuum furnace for annealing treatment. The annealing atmosphere is nitrogen, the tempera...

Embodiment 3

[0027] It is a small-hole heat exchanger of 1 square meter, and the cross-sectional area of the hole channel is 4*28.7=118mm 2

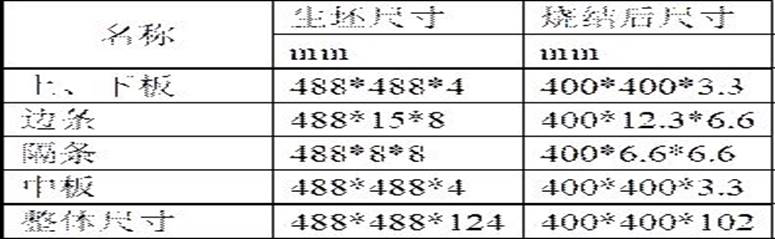

[0028]

[0029] The above is a statistical table of the sintered size and the sintered size data of an embodiment according to the process of embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com