Upper end glue adding device of automatic edge sealing machine

An edge banding machine, automatic technology, applied in the direction of adhesive application device, wood processing equipment, manufacturing tools, etc., can solve the problems of long hot melt glue time, impact on edge banding quality and efficiency, insufficient glue supply, etc., to achieve heating and Precise control, high gluing height, and improved competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

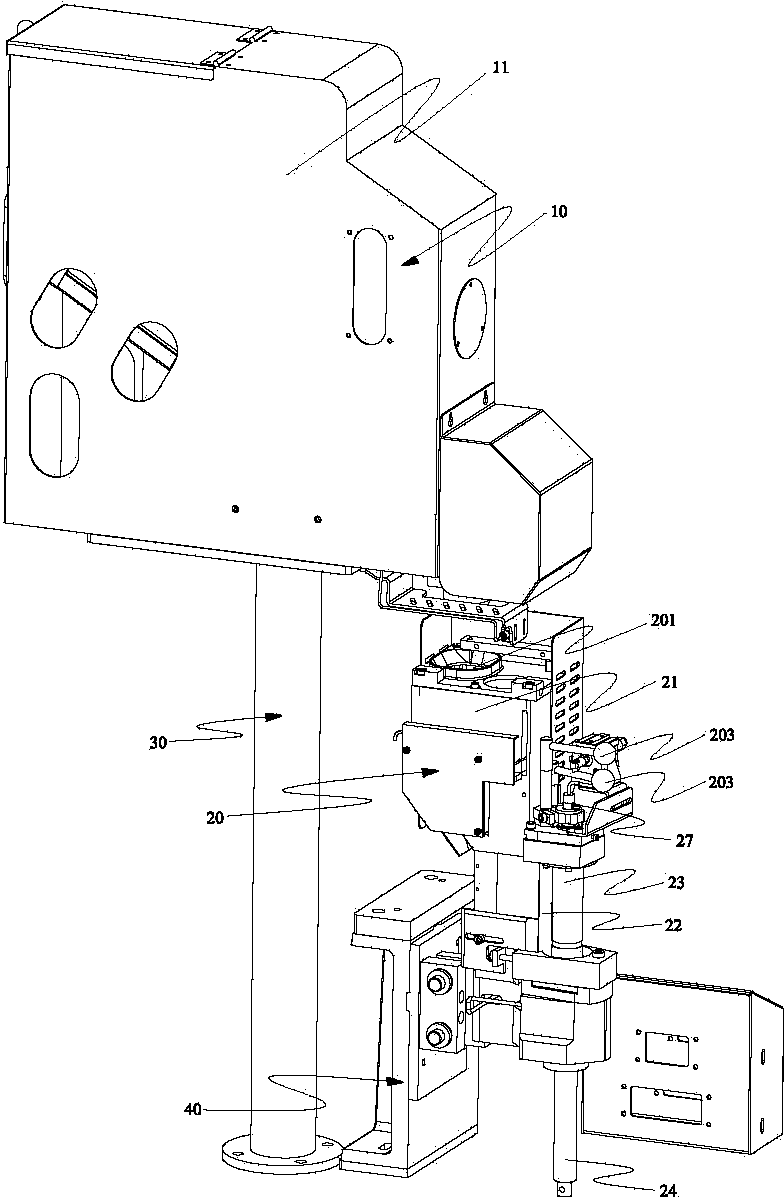

[0044] Please refer to Figure 1 to Figure 5 As shown, it shows the specific structure of the preferred embodiment of the present invention, including the glue-melting glue module 10 and the glue-coating module 20 installed under the glue-melting glue module 10 .

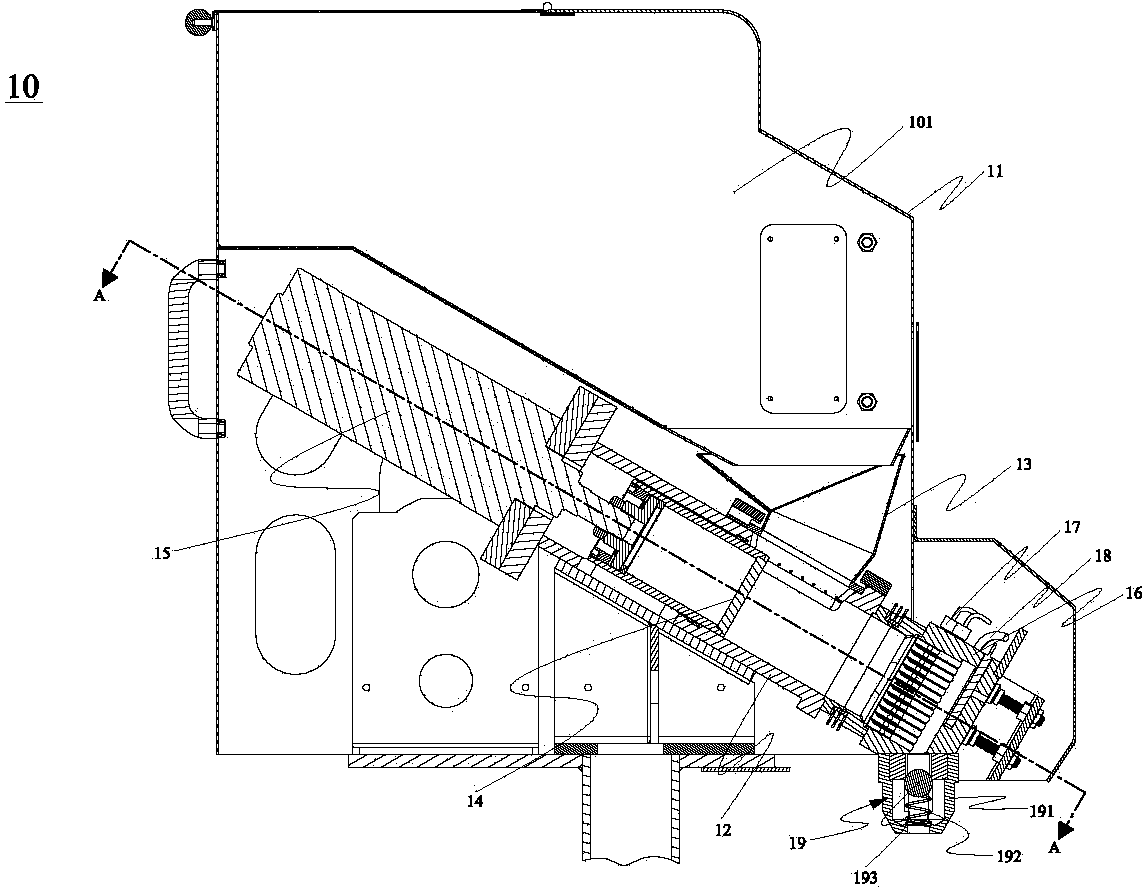

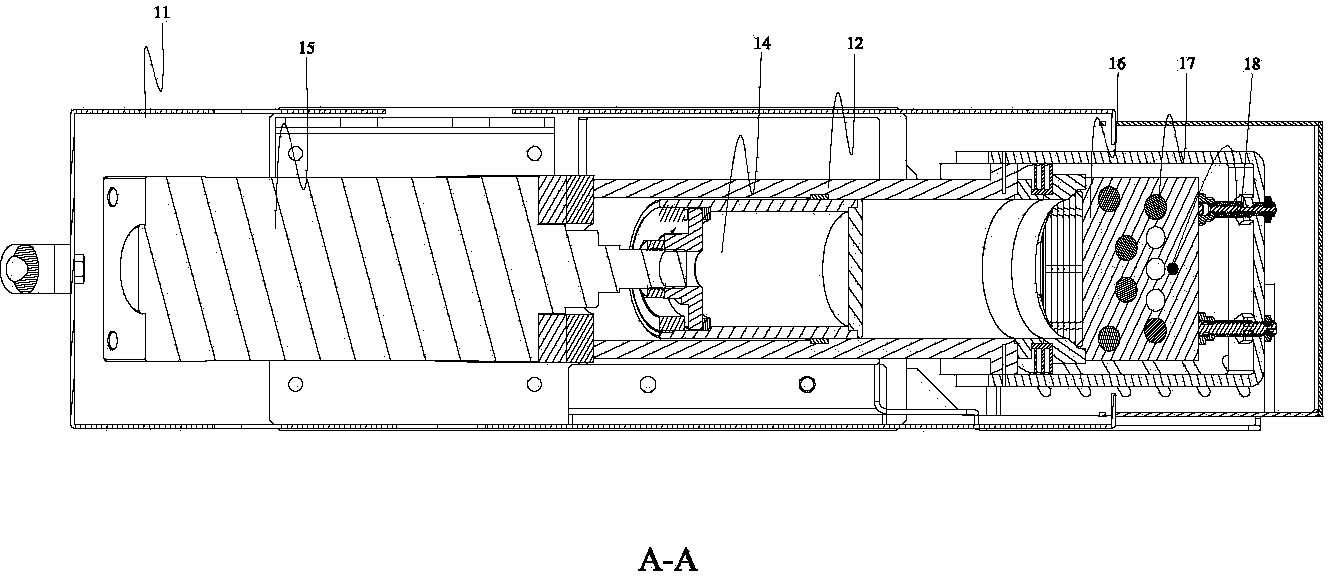

[0045] The glue-melting glue module 10 is installed on the edge banding machine through the column 30, such as figure 2 and image 3As shown, the glue melting module 10 includes a casing 11, a piston frame 12, a hopper 13 and a piston 14; the casing 11 has a silo 101, the piston frame 12 is inclined, and the hopper 13 communicates with the bottom of the hopper 101 And between the entrance of piston frame 12, this piston 14 is arranged in the piston frame 12 and matches with piston frame 12, and piston 14 is driven by a pusher cylinder 15, and, the output end of piston frame 12 is provided with heating block 16. The inside of the heating block 16 communicates with the inside of the piston frame 12. The heating blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com