Preparation method of micro-emulsified cutting fluid for aero-engine aluminum alloy processing

An aero-engine and aluminum alloy technology, applied in the petroleum industry, lubricating compositions, etc., can solve problems such as poor cooling performance, shortened tool life, carbonization failure, etc., to improve lubricity and cooling performance, improve cooling performance, and The effect of lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

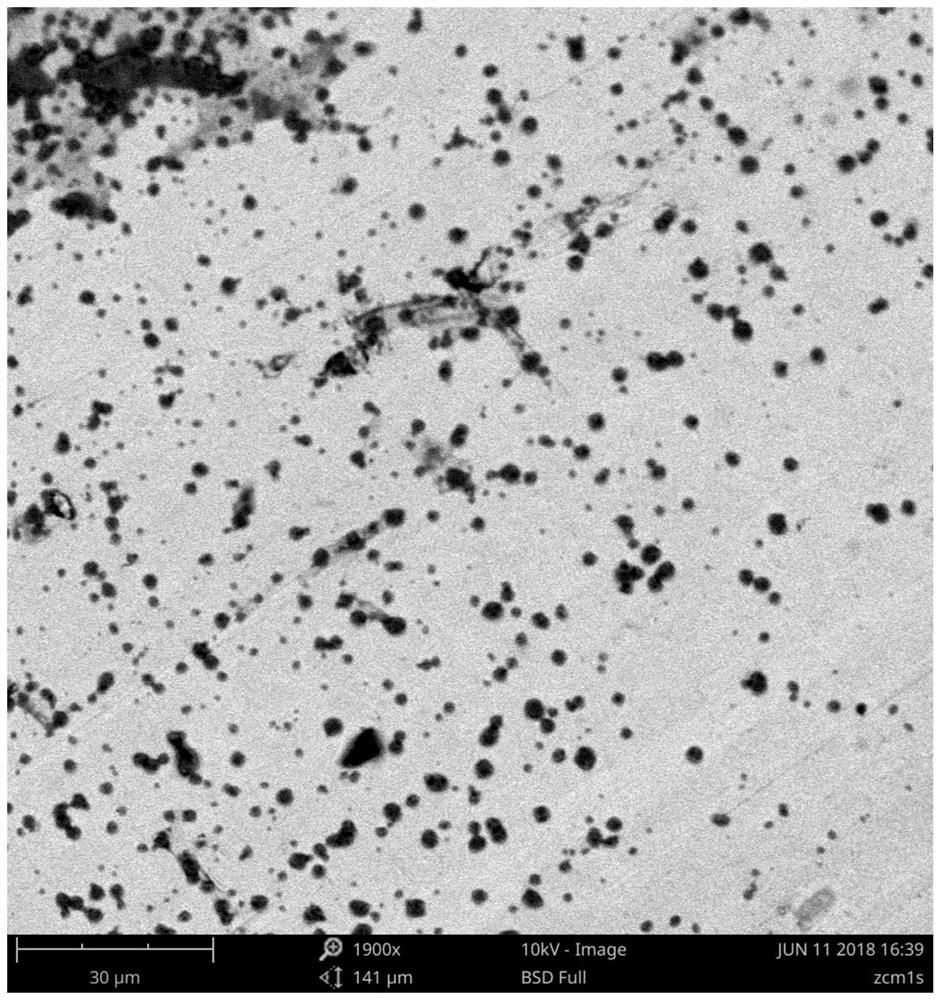

Image

Examples

Embodiment 1

[0023] 1) Preparation of sulfonated graphene: (1) pre-reduced graphene oxide: take 750mg graphene oxide and dissolve it in deionized water, and ultrasonically disperse it for 2h to form a brown dispersion solution; adjust its pH value to 9 with sodium carbonate solution, and Slowly add sodium borohydride to it at 60°C and stir for 1 hour; then partially reduce graphene oxide and redisperse it in deionized water, centrifuge and wash with deionized water for 5 times to make the pH value neutral 7; (2) sulfonation 1.38g ammonium sulfonate and 0.54g lithium nitrate were dissolved in hydrochloric acid solution, and the mixture was slowly added into the dispersion solution with pH 7 in step (1), and magnetically stirred for 6h under ice-bath conditions; the product was again dispersed in deionized Disperse in water, then centrifuge and wash with deionized water three times; (3) Hydrazine hydrate reduces the remaining oxygen functional groups: add hydrazine hydrate to the dispersion i...

Embodiment 2

[0030] 1) Preparation of sulfonated graphene: (1) pre-reduced graphene oxide: take 750mg graphene oxide and dissolve it in deionized water, and ultrasonically disperse it for 3h to form a brown dispersion solution; adjust its pH value to 9.4 with sodium carbonate solution, and Slowly add sodium borohydride to it at 80°C and stir for 2 hours; then partially reduce graphene oxide and redisperse it in deionized water, centrifuge and wash with deionized water three times to make the pH value neutral 7; (2) sulfonation : 0.69g ammonium sulfonate and 0.27g potassium nitrate are dissolved in the hydrochloric acid solution, and the mixture is slowly added into the dispersion solution with a pH of 7 in step (1), and magnetically stirred for 5h under ice-bath conditions; the product is again dispersed in a deionized Disperse in water, then centrifuge and wash with deionized water three times; (3) Hydrazine hydrate reduces the remaining oxygen functional groups: add hydrazine hydrate to t...

Embodiment 3

[0037] 1) Preparation of sulfonated graphene: (1) pre-reduced graphene oxide: take 750mg graphene oxide and dissolve it in deionized water, and ultrasonically disperse it for 3h to form a brown dispersion solution; adjust its pH value to 9 with lithium carbonate solution, and Slowly add sodium borohydride to it at 80°C and stir for 1 hour; then partially reduce graphene oxide and redisperse it in deionized water, centrifuge and wash with deionized water three times to make the pH value neutral 7; (2) sulfonation : 2.76g ammonium sulfonate and 1.08g lithium nitrate are dissolved in the hydrochloric acid solution, and the mixture is slowly added into the dispersion solution with a pH of 7 in step (1), and magnetically stirred for 5h under ice-bath conditions; the product is again dispersed in a deionized Disperse in water, then centrifuge and wash with deionized water three times; (3) Hydrazine hydrate reduces the remaining oxygen functional groups: add hydrazine hydrate to the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com