High-precision injection moulding machine for optical-grade transparent product

An injection molding machine, high-precision technology, applied in the field of injection molding machines, can solve the problems of unbalanced, uneven mold heating, and difficult to control the thickness of injection molding, and achieve the effect of enhancing precision and heating accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

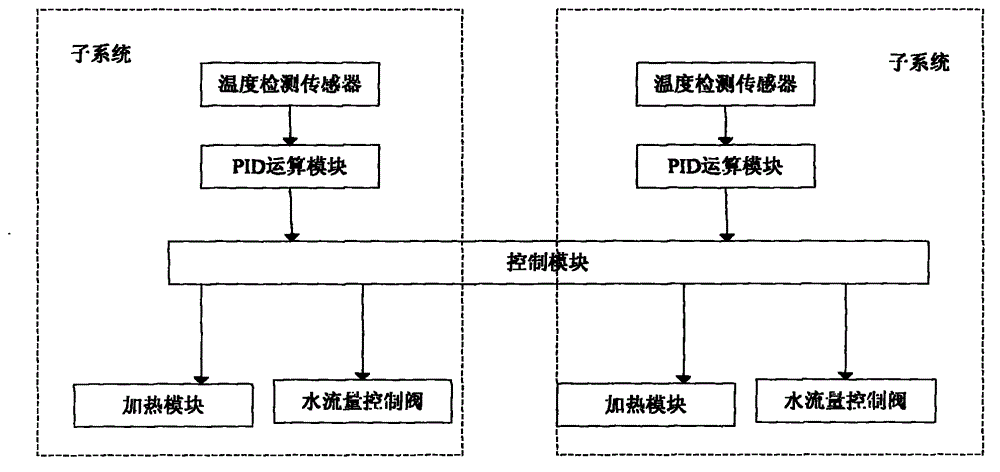

[0017] Please refer to figure 1 , figure 1 It is a circuit principle block diagram of the high-precision injection molding machine temperature control system for optical-grade transparent products of the present invention. The temperature control system includes multiple PID calculation modules, control modules, multiple heating modules, multiple water flow valves and multiple temperature detection sensors. Each group of heating modules includes heating elements, and each group of heating modules corresponds to a temperature detection sensor, a water flow control valve and a PID calculation module.

[0018] In the present invention, multiple sets of heating modules and multiple temperature detection sensors are distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com