Steel rail induction butt welding and heat treatment device

A heat treatment device and butt welding technology, applied in heat treatment furnaces, heat treatment equipment, rails, etc., can solve problems such as unstable quality of rail welded joints, low efficiency of rail construction organization, and increased requirements for construction sites, so as to reduce the influence of human factors, The effect of improving the efficiency of construction organization and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

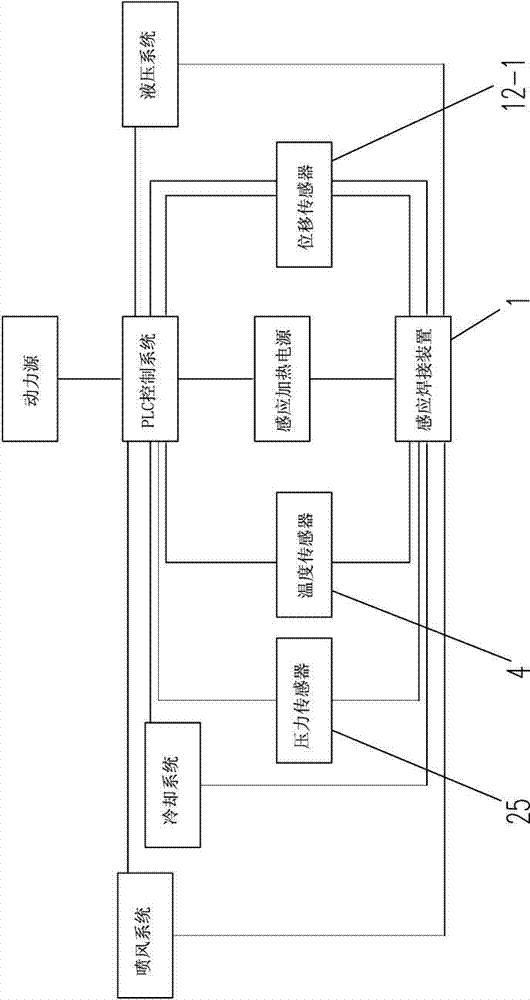

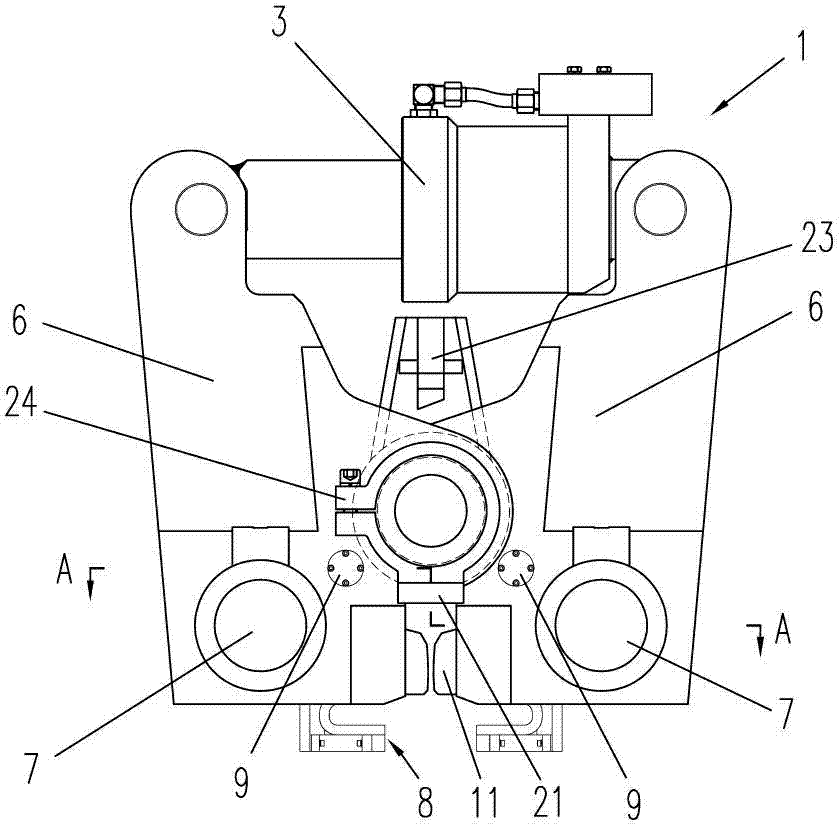

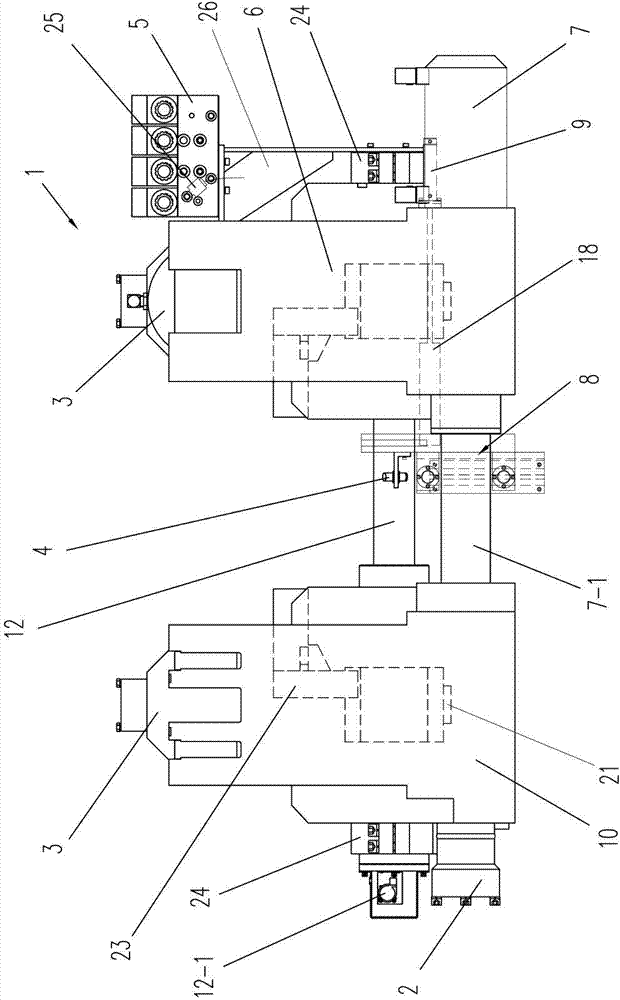

[0034] Such as figure 1 , 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, and 13, the rail induction butt welding and heat treatment device of the present invention includes an induction welding device 1, a PLC control system, a hydraulic system, a cooling system, an induction heating power supply and a blast system, the induction welding device 1 includes a first set of clamp body 10, a second set of clamp body 6, a central shaft 12, a clamping cylinder 3, an upsetting cylinder 7, a pushing device 2 and Jaws 11, wherein the first group of clamp bodies 10 and the second group of clamp bodies 6 are all hinged on a common central axis 12 to form two pairs of pincer-shaped clamping devices, and the clamp bodies of each pair of pincer-shaped clamping devices Clamping oil cylinders 3 are installed between them to drive the first group of clamp bodies 10 and the second group of clamp bodies 6 to rotate around the central axis 12 respectively, and the first group of clamp bodies 10 and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com