Plasma-melting electrode electric arc dynamic composite welding device and welding method thereof

A melting electrode welding and composite welding technology, which is applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of complex parameter adjustment, large arc electromagnetic interference, and electrode burnout, and achieve high weld seam quality and welding defects. Less, the effect of increasing welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

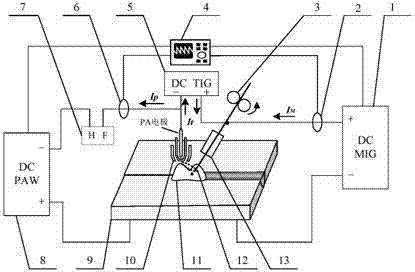

[0034] Fig. 1 is a schematic diagram of plasma-melting electrode dynamic arc hybrid welding method and device implementation, the welding device is mainly composed of melting electrode pulse arc welding power supply 1, DC plasma pulse arc welding power supply 8, TIG arc welding power supply 5, and wire feeding mechanism 3 , current signal detection devices 2 and 6, pulse coordination controller 4, plasma torch 10 and melting electrode torch 13 and so on. During welding, the plasma arc welding torch 10 and the melting electrode welding torch 13 are combined to form a composite welding torch, and the angle α between the axes of the two welding torches is 0-90°. Connecting the workpiece 9 constitutes a plasma welding current circuit; while the positive pole of the melting pole arc welding power supply 1 is connected to the current signal detection device 2 and connected to the welding wire contact tip of the melting pole welding torch 13, and the negative pole is connected to the ...

specific Embodiment approach 2

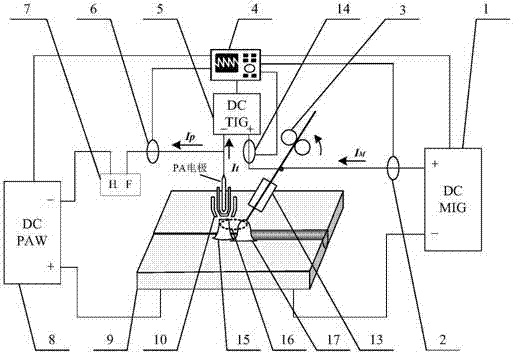

[0041] Fig. 2 is a schematic diagram of plasma arc welding / plasma-melting electrode indirect arc welding / melting electrode arc dynamic composite welding method and device implementation, the welding device is mainly composed of pulse melting electrode arc welding power supply 1, DC pulse plasma arc welding power supply 8, TIG arc welding power supply 5, wire feeding mechanism 3, current pulse signal detection devices 2, 6 and 14, pulse coordination controller 4, plasma arc welding torch 10 and melting electrode welding torch 13 and so on. During welding, the plasma arc welding torch 10 and the melting electrode welding torch 13 are combined to form a composite welding torch, the angle α between the axes of the two welding torches is 0-90°, and the positive pole of the melting electrode arc welding power supply 1 is connected to the current signal detection device 2 and the melting welding torch 13 welding wire contact tips, the negative electrode is connected to the workpiece 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com