Energy saving strong convection sheet glass heating oven

A flat glass and heating furnace technology, applied in glass tempering, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of difficult adjustment and control, large energy loss, uneven heating, etc., to achieve high heating efficiency, reduce heat loss, The effect of high temperature control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

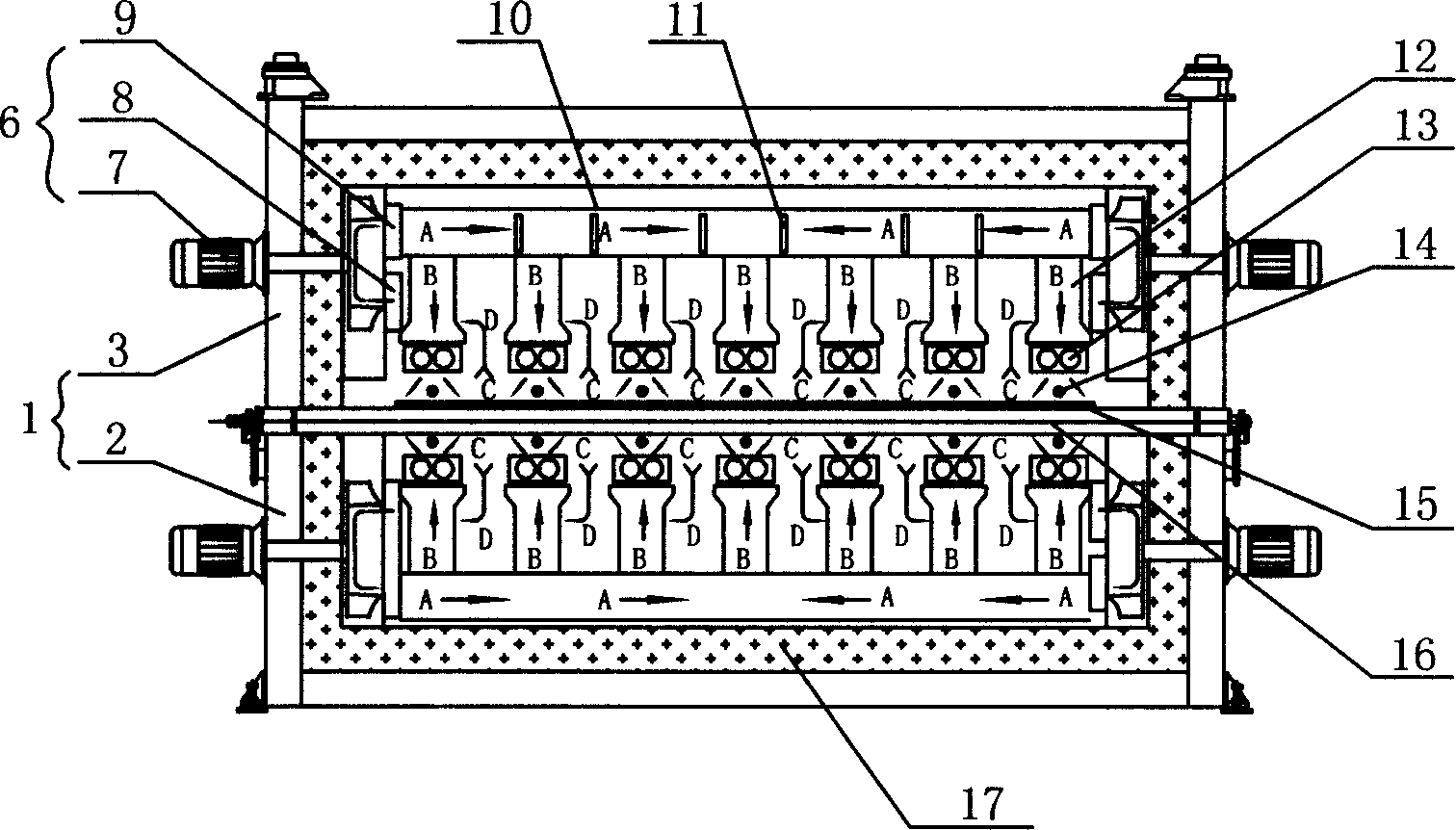

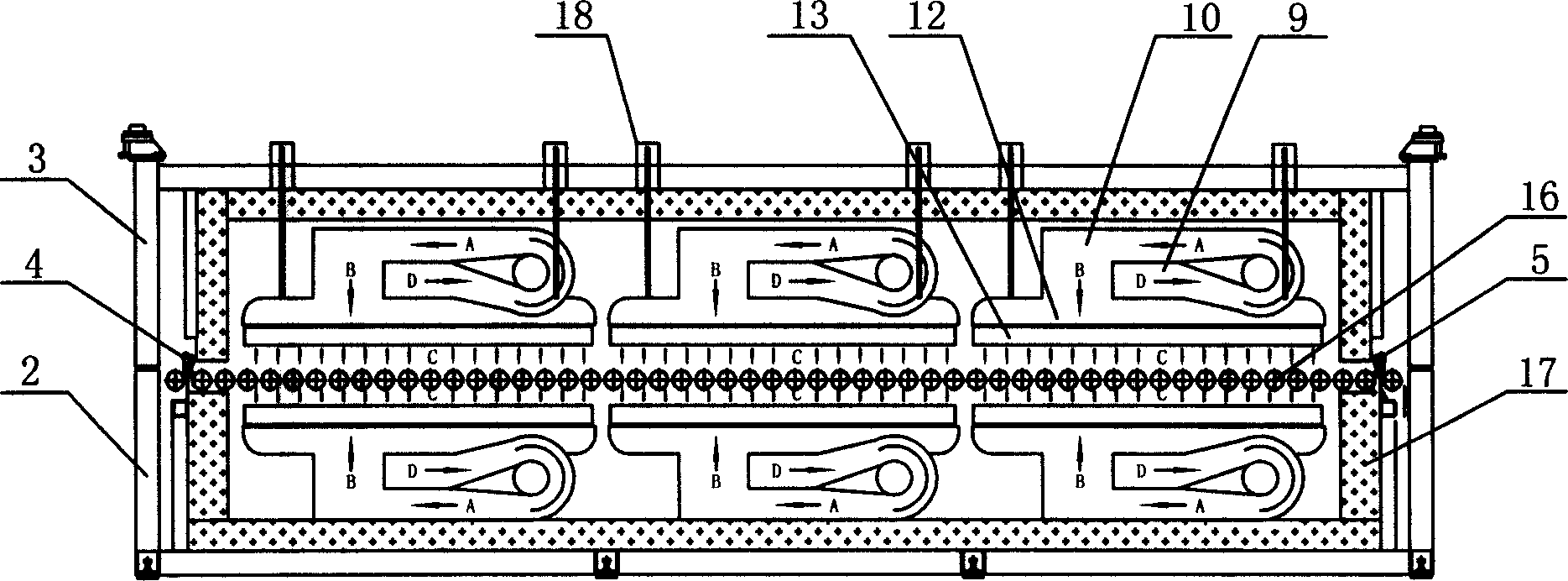

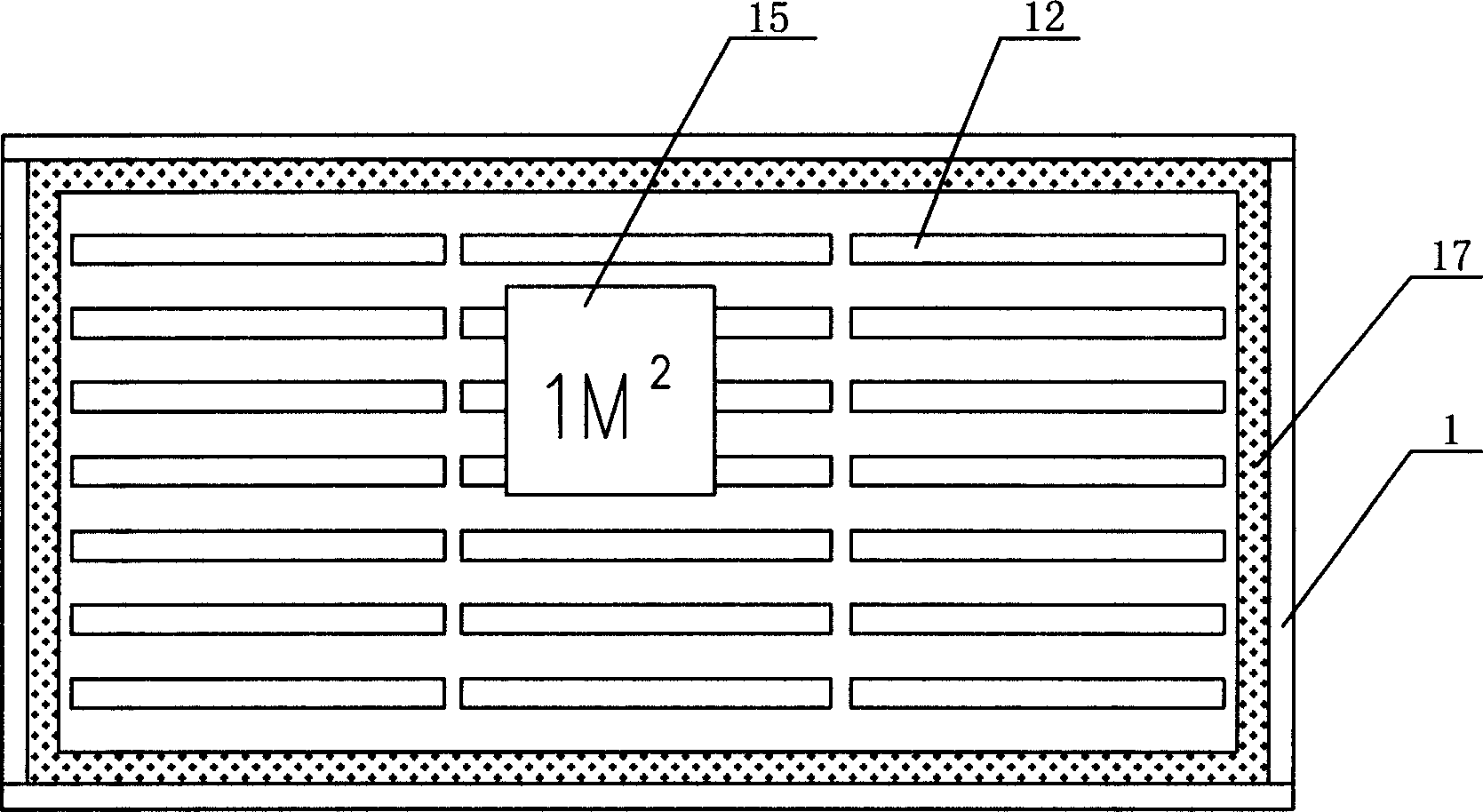

[0026] Such as figure 1 , 2 As shown, an energy-saving strong convection flat glass heating furnace includes a furnace body 1. The furnace body 1 is composed of a liftable upper furnace body 2 and a lower furnace body 3 fixed on the ground. The inner walls of the furnace body 1 are provided with insulation layers. 17. The furnace body 1 is provided with a glass plate inlet furnace door 4 and an outlet furnace door 5. The furnace body 1 is provided with a ceramic roller table 16 for conveying flat glass 15. The furnace body 1 is provided with several groups of temperature-resistant furnaces arranged symmetrically up and down. Windmill 6, the air outlet 9 of each temperature-resistant windmill 6 communicates with the corresponding pipeline. The pipe 10 is connected with several branch air pipes 12 through the flexible suspension mechanism 18. Both the upper and lower air pipes are distributed symmetrically above and below the ceramic roller table 16 facing the ceramic roller ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com