Air protecting and heating type braze welding furnace

A gas shielding and brazing furnace technology, used in metal processing, welding equipment, metal processing equipment and other directions, can solve problems such as inability to meet requirements, and achieve the effects of uniform shielding gas atmosphere, uniform temperature, and high welding quality of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

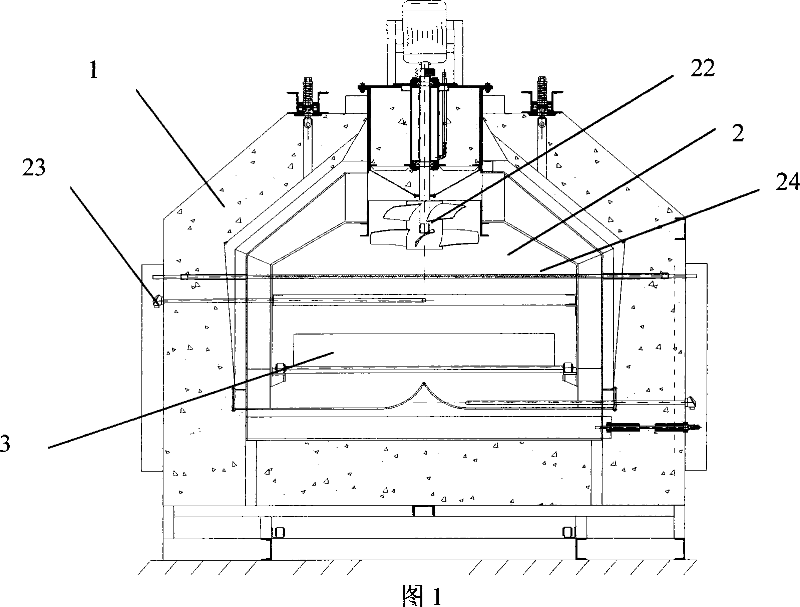

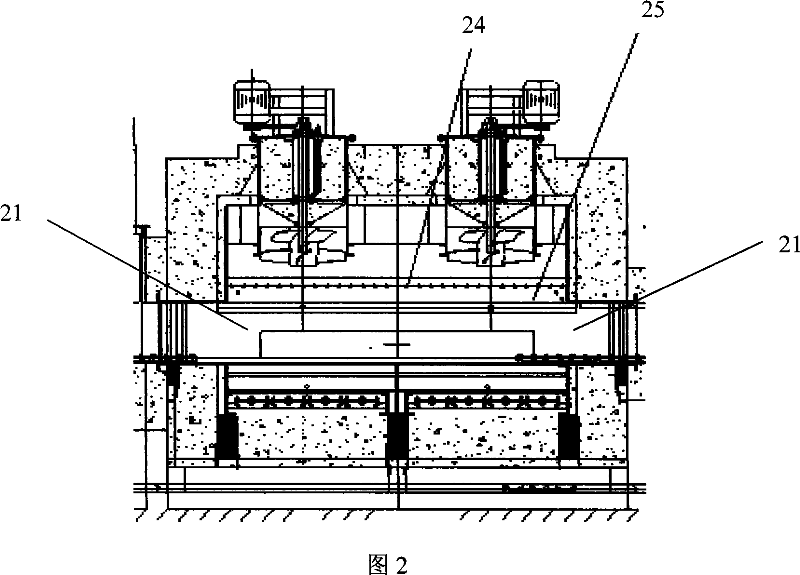

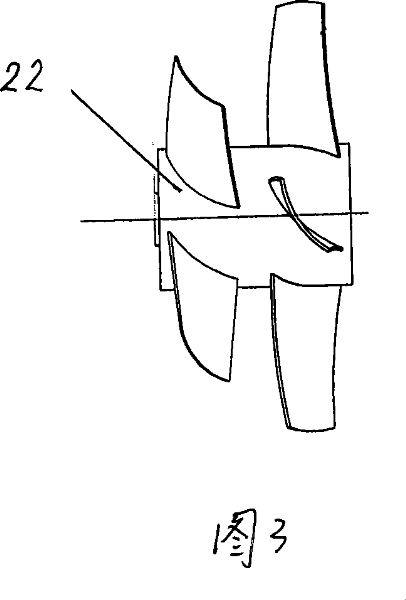

[0016] A gas shielded heating brazing furnace according to the present invention comprises a body of furnace 1 and a welding chamber 2 formed by a hearth, and the welding chamber 2 is divided into a group of different temperature control zones 21 from the inlet to the outlet; Each temperature control zone 21 is equipped with an internal heat circulation fan 22, a temperature sensor 23, a tubular electric heater 24, and a temperature controller; the preheated protective gas communicates with the wind cavity of the internal heat circulation fan 22 through a pipeline; the entire welding The internal heat circulation fan 22 with a uniform temperature and protective gas atmosphere in the room 2 is set above the welding room 2, and the tubular electric heater 24 is evenly and symmetrically arranged above and below the workpiece 3; Compared with the specified parameters, the tubular electric heaters 24 in each temperature control zone 21 are controlled.

[0017] In order to further i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com